One of the most important organizational tasks during construction work is to ensure labor protection of all participants in the process.

Naturally, the implementation of this task is not complete without the registration of a significant number of documents, and one of the most important among them is the logbook for registering and testing stairs and ladders.

Lifting device testing

Inspection and Testing Approaches

Ladders and stepladders, which are registered with the construction site, must be registered and checked without fail. Only if the visual and instrumental control has been successfully passed, the structures can be allowed to work.

The accounting and verification process is regulated by the following standards:

- POT RO 14000 - 005 - 98 - "Regulations on the organization and performance of work with increased danger."

- POT RM 012 - 2000 - "Interindustry rules for high-altitude work."

- GOST 26887 - 86 - "Ladders and platforms used in construction and installation work."

According to these documents, the following are subject to verification and accounting:

- Three-knee extension and sliding devices made of wood or metal.

- Suspended and attached single-knee structures.

- Stepladders and devices based on them.

The frequency of testing is as follows:

- At least once a year - for metal structures.

- At least once every 6 months - for wooden ladders, as well as for models with flexible elements (rope, cable, etc.).

The results of control measures are compulsorily recorded in the ladder and step ladder test log.

Note!

An extraordinary check should be carried out immediately after a major overhaul.

Also, structures made by hand directly at the facility are subject to control.

Preparation for control

Before starting measures for instrumental verification of the operational characteristics of structures, a visual assessment of their condition is mandatory. The results of this check can be recorded in a separate log of inspection of stairs and stepladders, or can be recorded in a single consolidated document..

During the inspection, it is necessary to assess:

- The tightness of parts to each other, as well as the presence of gaps. This primarily concerns the wooden base and metal fittings.

Note!

Sealing the gaps with sealants or similar materials is not allowed, since it does not provide the required strength of the joint.

- The quality of the impregnation of wooden parts with natural drying oil and the state of the varnish coating.

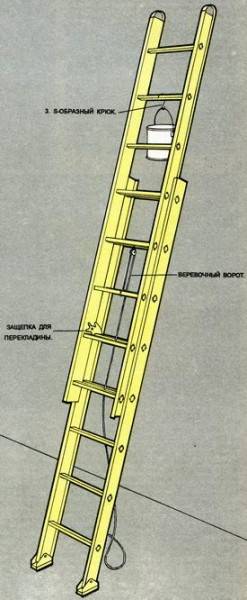

- The condition and reliability of the fastening of metal or plastic shoes on the lower support parts, as well as the strength of the installation of the hook hooks on the upper edge.

- The presence or absence of cracks, chips, delamination and other defects that can lead to a decrease in performance.

- The presence and condition of the tie bolts responsible for fixing the bowstrings (the bolt diameter must be at least 8 mm, and the installation pitch must be no more than 2 meters).

In this case, it is very important to pay attention to the very design of the connection unit: the steps must be cut into the bowstring. The use of structures with overhead steps nailed to vertical supports on site is not allowed.

For stepladders, it is also important to check the serviceability of the locking mechanisms, which prevent independent movement and disclosure of the segments.

Only after successfully passing the visual inspection, the object is admitted for instrumental inspection.

Implementation of instrumental control

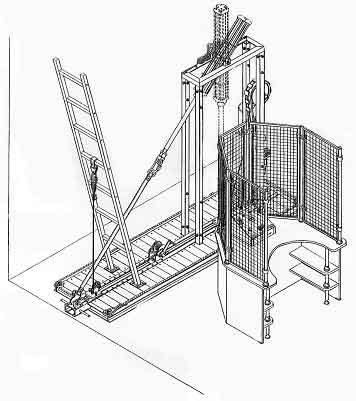

Tests of lifting structures are carried out by authorized persons of the enterprise, who are appointed by a separate order for the structural unit (site, workshop, etc.). It is possible to involve third-party organizations in testing, but the price of their services is quite high, therefore, in most cases, everyone cope on their own.

The inspection instructions contain the following recommendations:

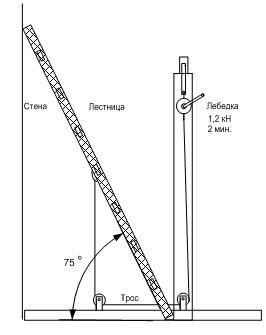

- The ladder must be placed on a solid base. The angle of inclination of the stairs should be 750.

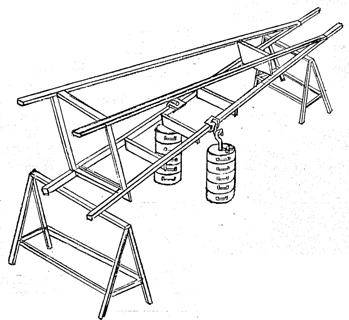

- The stepladder is checked by placing it in the working position. It is also possible to carry out checks when laying horizontally.

- The strength test consists of suspending a fixed mass from the strings and rungs. Each test must last at least 2 minutes.

- The steps of sliding structures are checked under a load of 2 kN (200 kgf), and bowstrings - 1 kN (100 kgf). To control the performance of the ladder, a load of 1.2 kN is used.

- After removing the load, there should be no damage to the parts. The complete absence of any deformations not provided for by the design is also evidence of the successful passing of the control.

Note!

Discovered deficiencies should be eliminated as soon as possible.

After completing the repair, the check is repeated.

Logging

The logbook for accounting and testing of ladders and ladders already mentioned in the previous sections is a single document in which all the lifting structures that are in the responsibility of the structural unit are registered.

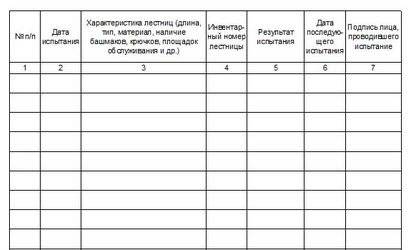

A typical journal contains the following columns:

- Serial number.

- Date of inspection or testing of the lifting structure.

- Inventory number of the structure.

- Ladder type (attached / folding / sliding, dimensions, availability of additional devices, etc.).

- Inventory number of the item (must be marked on one of the bowstrings).

- Control result.

- Scheduled date for the next test.

Each column must be signed by an authorized person.

This organization of logging makes it possible not only to ensure that all stairs and stepladders used at the site are recorded, but also to ensure timely identification of problems. Despite the relative laboriousness of the testing process, this approach significantly increases the safety of all production processes.

Output

A correctly filled staircase and ladder inspection log is by no means useless bureaucracy. Monitoring the condition of devices for work at height is very important from the point of view of effective labor protection, and therefore it is worthwhile to devote sufficient time and resources to it. In the video presented in this article, you will find additional information on this topic.