Multi-level apartments and private country houses of several floors are no longer exotic. To move between tiers, they use stairs of a wide variety of layouts. These are classic designs with straight and rotary flights, and screw designs and a number of others.

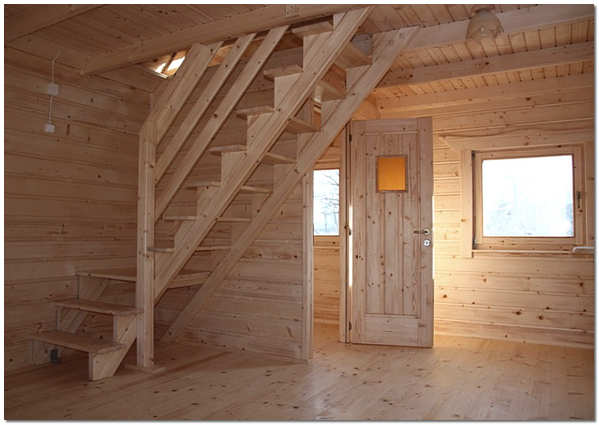

A staircase supported on a kosour is one of such original and interesting technical solutions. Its appearance differs from other schemes by its airiness and lightness.

The design and manufacture of such a staircase is a complex process that requires knowledge and experience. It is not easy to form your own opinion about it from the descriptions. The video in this article will clearly demonstrate all the stages of this process. This will help to form an accurate understanding of the order of actions of workers, and following a sequence of individual operations will provide the necessary skills.

Detailed instructions for the video materials allow you to understand all the nuances and make this design with your own hands. Even an inexperienced craftsman with minimal metalworking or woodworking skills can embody such a scheme in the material with his own hands. The whole process can be conditionally divided into several stages and should begin with a study of the installation site of the stairs.

Settlement and design work

If you strictly adhere to the order established in the construction industry, then you should start with drawing up a technical task. The calculation of stairs on kosoura is carried out in accordance with the requirements of SNiP IV-14-84, GOST 23120-78 and GOST 8717.0-84, as well as other guidance documents. The terms of reference define the initial conditions for calculations and design.

In practice, when constructing buildings, such a document is naturally not drawn up according to all the rules. However, the most necessary data for calculations are determined with a sufficiently high accuracy.

We are talking about such information as:

- stair material: metal, wood (rock), reinforced concrete or their combinations;

- total staircase height;

- the relative position of the upper and lower platforms;

- the total width of the structure;

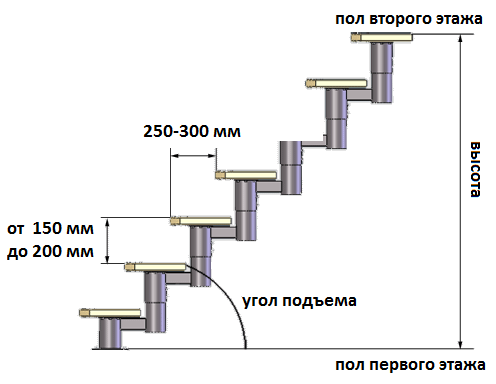

- the angle of inclination of the kosour and the height of the riser;

- the bearing capacity of the material at the points of attachment of the load-bearing structures and the like.

Experience shows that such data is quite sufficient for calculations on the geometry and strength characteristics of a structure.

Additionally, the calculation of the ladder stringer for instability and stability is performed. The mathematical apparatus of such operations is rather complicated and requires a large number of reference coefficients. Such calculations can be performed both manually and using special software. Professional applications are difficult for an inexperienced user, but you can also find simple software on the net.

At this stage, the cost of manufacturing and installing the stairs is also estimated. The calculation is made taking into account the cost of the necessary materials and the remuneration of the involved specialists. Additional costs may arise when purchasing or renting an instrument. The final cost of the structure can be reduced if all or at least most of the work is done in-house.

The choice of material for structural elements

Material is of great importance in the manufacture of building structures. Wood is one of the most technologically advanced and easy to process. It has a low specific gravity, high mechanical strength and a very interesting texture.The wooden staircase on the kosoura has a decent look and is able to decorate an apartment or house with author's design in the classic English style.

This material lends itself well to grinding and polishing. The use of modern primers and varnishes makes it impervious to moisture. Wooden stairs on kosoura can be made independently in a home workshop.

No specialized tools are required for sawing and roughing workpieces. Finishing of parts is carried out with grinders and sandpaper of different grain sizes.

Helpful advice!

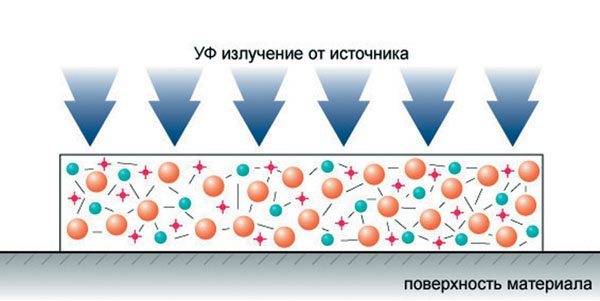

To give a staircase made of wood an unusual look, the latest technology of ultraviolet polymerization of a protective decorative coating can be used.

Its essence lies in the fact that a special oil is applied to the prepared surface.

It is exposed to short-term radiation, as a result of which a strong and beautiful film is formed.

This coating is highly durable and is immediately ready for intended use.

How to make a ladder yourself

When the material for building structures is selected, you can proceed to the main part of the technological process.

Making a ladder on kosoura with your own hands begins with the preparation and production of all the necessary parts and assemblies:

- Kosour is a load-bearing beam, the ends of which are attached to the lower and upper platform. On top of it there are braces for steps; when looking at this structure from the side, it resembles a ridge;

- Stair steps - processed boards fixed on the stringer and intended for people to move along them;

- The balustrade or railing on such stairs is attached to the steps and protects a person from falling from a height.

Depending on the geometric dimensions and some other specific parameters, this structure may have features. Depending on the number of load-bearing beams, there are stairs on a mono-frame and with two load-bearing elements. The first option in private houses and apartments is most widespread.

Carrying Beam Manufacturing Options

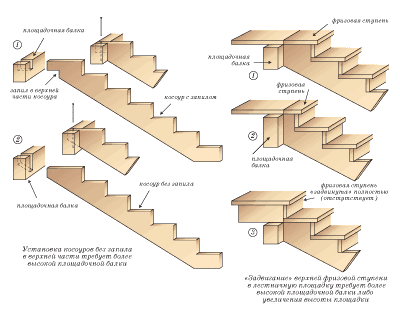

A ladder on a monokosour is based on a power section made of a solid wooden bar or a composite one. In the first version, the teeth on the beam are cut using an electric circular saw.

For a composite beam, the triangles are cut separately and secured to the beam using dowels and glue. Such a connection, if necessary, can be disassembled for repair.

A ladder on one stringer made of a solid bar has a higher manufacturing cost. It requires a workpiece with a thickness of at least 50 mm and a width of at least 300 mm. Such a bar can only be cut from a very large tree. Therefore, the use of a solid beam is a rather rare phenomenon.

Composite construction is easier to manufacture: each triangle is cut and processed separately.

Important!

In the production of kosour, it is necessary to achieve the most accurate fit of all elements.

Particular attention is paid to fixing elements to the base.

Support platforms for steps must be strictly parallel to each other.

Then, with the correct installation of the ladder, they will ensure the horizontal plane of each step.

Steps and balustrade are important components of the design

Ladders on stringer have open transgressions without risers, this feature of their design gives them lightness and grace. For the production of steps, a board with a thickness of 50 mm and more is used, a width of 250-300 mm, as for the length, it can be different. This indicator depends on the size of the opening and should ensure the free movement of a person.

The stairs on the center stringer have only one point for fastening the steps, and this is located in the middle of the part.This connection must be sufficiently reliable and tough. In this case, the step itself must have a sufficient section and strength so that when a load is applied to any of its edges, it does not deform and deflect. Each element is carefully ground and polished after finishing.

The manufacture of enclosing structures: balustrades or railings is a complex and responsible operation. The dimensions of these elements of the staircase are determined by the design documentation, and the shape must correspond to the style of the interior design. The material for them is also wood, and for the manufacture you will need a lathe. The workpieces are finished and ground.

Installation of the load-bearing beam and assembly of the ladder

Before installing the stringer, you must make sure that both support pads are strong enough. If necessary, they are reinforced with metal structures.

The staircase on the central stringer is mounted in the following sequence:

- The power beam is installed and fixed; anchors or bolted connections are used as fasteners. Additional elements can be used to ensure sufficient joint strength;

- Installation of steps is carried out using dowels and wood glue, this operation requires high accuracy;

- Installation of balustrades and handrails can be done both by glue method and using detachable screw connections. In the first case, removing parts for repair without destroying them is impossible;

- After complete assembly and testing, its final grinding and varnishing is carried out.

The manufacturing and installation process of this type of staircase can be considered complete. The stringer structure does not need the operation process or any specific maintenance. Periodically, it will be necessary to update the lacquer coating on the steps. It is subject to the most intense wear and tear.

Conclusion

Do-it-yourself wooden stairs on kosoura are made within a few weeks. In the process of work, you will have to master several methods of woodworking. DIY parts manufacturing and assembly means cost savings. The building itself will invariably attract attention with its grace and lightness of forms.