In most cases, a small structure at the entrance is included in the project documentation, but very often it requires restoration. Therefore, it will not hurt an individual developer to know how the stairs for the porch are arranged with their own hands.

Immediately before manufacturing, it is necessary to make a choice in favor of the most effective and affordable material.

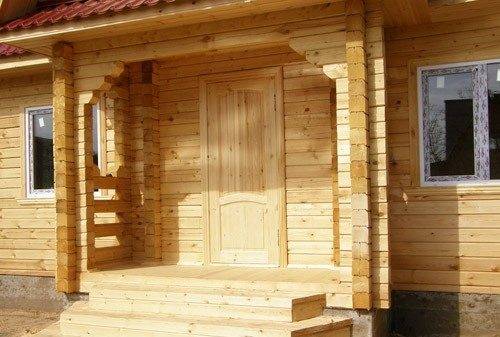

Construction from wood

Similar designs are performed most often if a log, frame or log house with a small extension is already on the site. In this case, the object is obtained in a single style solution, although sometimes the combination is only beneficial. Spruce or pine is mainly used to create wooden stairs.

Important advantages

In fact, the advantages of this material can be enumerated almost endlessly, but at the same time it is possible to note really significant ones that can influence the choice of an individual developer.

They relate to the aesthetic and practical side of the issue.

- Decorative and natural beauty allows you to create delightful designs yourself.

- The ability to use the material in the construction of intricate architectural solutions.

- The ecological purity of wood creates a pleasant environment that has a beneficial effect on the body.

- Sufficient strength for the construction of reliable and quite durable structures.

Addition!

Recently, modern designs have become more and more complex, so simplicity and ease of processing plays an important role, while allowing you to make luxurious stairs.

Self-execution

The simplest option involves the manufacture of a stepped box that is fixed on a concrete base.

In this case, the lower part must be treated with a composition that protects against all kinds of environmental influences.

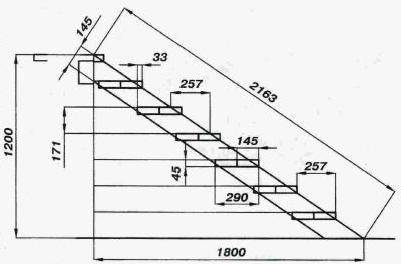

- Work begins with the construction of stringers and a bowstring of the staircase, which can have embedded steps or ready-made ledges. In the latter case, the dimensions of the recesses must correspond to the horizontal part.

- After calculating the height and width of the lift, the markings are carried out. After that, a wooden profile is cut out.

- After the manufacture of the elements of the stairs and their installation in place, the evenness is checked by the level. If necessary, remove extra centimeters.

- A board with special grooves is fixed to the platform strip, where the spikes of the created profiles will be inserted. For added strength, metal staples and strips are recommended.

- At the last stage, the steps of the stairs are arranged. Fastening using screws and nails, as a rule, is complemented by a groove connection.

Attention!

Antiseptic treatment of wood components is carried out using drying oil or a composition of copper sulfate.

Other protective solutions can also be purchased, especially since their price is relatively low.

Concrete structure

These types of structures are considered the most durable and reliable, of course, if they were made correctly. The material is not subject to destruction from moisture, and the internal reinforcement is reliably hidden in the concrete mass. Detailed instructions will help you understand the creation process.

Step by step laying

- In place of the concrete staircase, a pit is being dug into which waste bricks, aerated concrete and other stone materials are laid in layers.

- The upper part is covered with sand, while leveling and careful compaction is carried out.

- The surface of the finished pit is covered with roofing material, and one layer is enough.

- A grid of metal rods with cells of 100 × 100 mm is installed on an organized bedding. The same waste is used as linings.

- A wooden formwork for the steps is being formed. For this, stakes are driven in, and boards are attached to them.

- The upper levels are arranged in much the same way. In the process of work, a screwdriver is used. If necessary, short struts are installed.

- The resulting structure is filled with concrete. To reduce costs, metal or stone waste can be incorporated into the slab array.

- A reinforcing mesh is placed in the upper layer, after which the entire formwork is gradually poured.

- After the composition has set, the upper part is smoothed. The components of the internal filling must not protrude from the solution.

Note!

After the final hardening of the concrete composition, the created structure is covered with plastic wrap to protect the surface from rapid drying.

Metal creation

A staircase for a porch made of metal can also be made independently, if you have at least simple welding skills. However, this process can be entrusted to professionals, having prepared all the necessary details beforehand. The cost of the construction will still be reduced significantly.

Phased assembly

Before you start directly with the installation, you need to evaluate your knowledge in the field of welding, since this business has some peculiarities.

Without knowing the basic provisions, it is easy enough to ruin the metal frame or not notice damage that will lead to the destruction of the structure in the future.

- For an external staircase made of a steel channel, two bowstrings are made, the lower edges of which are cut at an angle to ensure adherence to the plane of the base.

- The upper ends are fixed to the front porch beam using garage hinges, which are welded directly to the channel. On the other side is a thick steel plate.

- A special template is made from wooden scraps, which allows you to determine the location of the steps. On metal elements, the markings are best done with a traditional marker.

- After finding the optimal pitch, metal corners with ready-made holes are welded to the side posts to fix the horizontal elements.

- Using the same stencil, the angle for the staircase rails is marked. The verticality of the extreme parts of the parapet is measured by level or plumb line.

- On properly prepared beams, steps are mounted, which in fact can be made of any material.

Attention!

To protect the metal elements, it is advisable to treat them with weather-resistant enamel, then you do not need to worry about the durability of the stairs, created without outside help.

Finally

For more detailed information, it is recommended that you watch the video in this article, thanks to which you will be able to understand the difficult points. It is better to make a choice in favor of some option, starting from a more accessible installation technology.