When it comes to home overhaul or construction, the most demanded are staircases on metal kosoura, and very often they are made by hand. The assembly technique here is not too complicated, since most often this is done using electric welding, sometimes using bolt connections for balusters and handrails.

But design features will always be critical to comfort and safety, which is why they will be discussed below, as well as a video in this article will be provided to your attention.

Structural features of metal stairs on kosoura

Probably, first of all, you should understand for yourself what a kosour is and the architectural dictionary defines it as an inclined beam between platforms, on which stair steps are attached. Such a beam can be with a comb in the size of the steps, but also the treads can be located not on top, but between inclined beams, and in this case they are usually called bowstring.

Nevertheless, the purpose in both cases is the same, since regardless of the name they perform the same function, and if you call the bowstring a kosour, then there will be no big mistake in this.

Slopes and steps

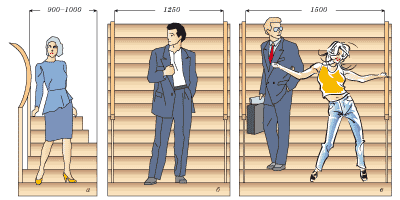

According to the schematic drawing located above, you can determine the calculation of the metal stringer of the stairs, on which not only the slope and convenience of descent and ascent will depend, but also the width of the flights. Pay attention to what angle is appropriate for different situations, and also take into account the physical abilities of the people living in the house. You should take into account that quite popular slope 40⁰-45⁰ it is completely acceptable only for a person of a sports type - the others on such an ascent can be trapped by shortness of breath, and for the elderly it often turns out to be an insurmountable barrier at all.

Nevertheless, due to the saving of free space or its lack, one has to make such sacrifices and even make the slope even steeper. But in any case, you need to ensure the most acceptable height and width of the steps, and for this, the step length of a person is taken as a basis. from 160 to 180 cmwhich officially amounts to 60-64 cm.

In order for a person to feel confident, his foot should be about 70% is on a solid foundation, and this is on average 25-30 cm, therefore, this size is the most optimal for the width of the tread. But this size must be combined with the height of the riser, so that two such heights, in total with the width, correspond to the length of the middle step. To do this, we make a simple arithmetic calculation using the formula dtread+ 2Lriser≈60≈64 cm, for example, 23 + 20 * 2 = 63 cm, which is quite acceptable for low steep stairs in the house.

But what to do in cases where, due to the steepness of the slope, it is impossible to reach the width of the tread even up to 20 cm? For such situations, there is such a concept as winders, this is when the upper tread crosses the riser and hangs over the lower step. The overhanging sector should not be enlarged more than 5 cmso that it does not interfere with the descent and the toe does not cling to it during the ascent.

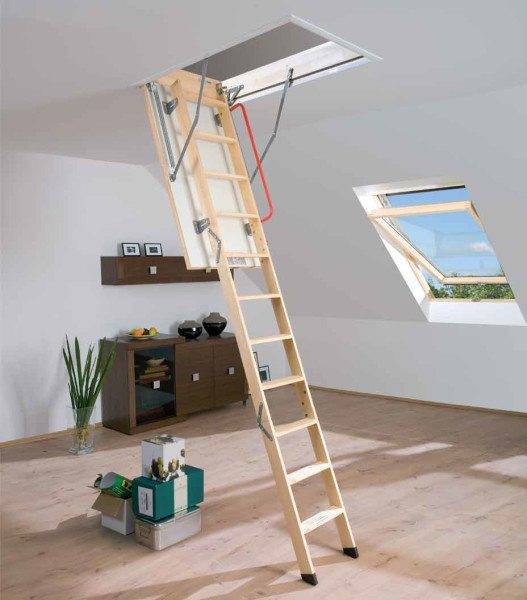

Advice. Where it is impossible to use metal stairs on kosoura due to an elementary lack of space, they use applied and folding structures, but if you do it yourself, then again you have to take care of the optimal distance between the horizontal beams (chutes).If for ordinary structures the length of the average step of a person is required, then here half of this value is quite enough - 30-35 cmto provide a comfortable descent and ascent.

The width of the stairs along the metal stringers can vary, because the beam can be singular or double, so the width of the span can be adjusted, of course, if the size of the room allows it. So, the minimum span width can be from 60 to 80 cm and such designs are most often used for little-used messages such as attics, but they can also be equipped with a lack of space in the room. The most commonly used and recommended widths may fluctuate from 90 to 110 cm, and you are constantly faced with such parameters in the entrances of houses, but for luxury apartments, a march is more suitable in 125-150 cm.

Arrangement of stringers and steps

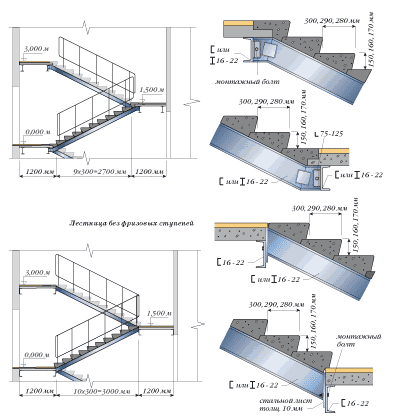

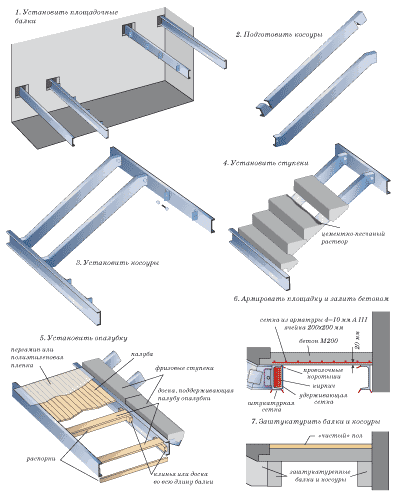

In the upper picture, you can see the preparation methods and types of materials for ladder bowstrings and stringers. As you can see, a metal ladder on one stringer and on bowstrings can be assembled with your own hands. Concrete flights of stairs are usually located on two beams due to the difficulty of fastening.

There are two types of arrangement of a concrete staircase on metal kosoura - with a frieze step and without it. The difference is that the frieze step cuts into the staircase, being its continuation, and without the frieze you have to join them so that the platform looks like the letter G, but this method makes the stairs longer, which is not always convenient. If such a step is cut into the platform, then the last one must be done according to the height of the riser, and this, at least, 14-17 cm - which means that the weight and price of the product increases.

Kosoura for this type of stairs are made exclusively of an I-beam or channel, and brackets or supports made of steel sheet are welded to the places of bends. Beams for platforms are made from a similar profile, they are installed at the design height, joining with the stringers, while short ones are welded from the corner in which holes for the bolts are drilled in advance. Staircases are mounted with niches on beams and aligned according to the design marks so that they do not have the opportunity to slide on their side, but the monolithing is not done immediately, but only after the final assembly of the staircase.

Metal stringers for stairs are mounted with a crane or manually, if two pairs of working hands are enough for this and the installation starts from the bottom. That is, the lower part of the inclined beam is screwed onto a bolt, to the platform horizontal beam, and then the upper end is wound up and attached in the same way, while the sub-platform profiles can be adjusted horizontally or vertically. Embedding is carried out only after a thorough check of all dimensions and connections in accordance with the project documentation.

Fastening of stringers with bolts is temporary and serves only for accurate setting of all dimensions when connecting, and the final fixation is carried out using electric welding. An option is also possible without the use of bolts at all - simply "tacks" are made by welding, which are easily knocked off if necessary, but the structure must be fixed all the time with crane slings, which are removed only after the final installation. The final welding of the stringer is carried out both along the end seam and along the perimeter of the mounting angle, which adds mechanical strength to the ladder.

As a rule, for such structures, standard reinforced concrete steps with dimensions 310 × 140, 300 × 150, 290 × 160, 280 × 170 mm, length 1100, 1200, 1400 mmand for “Elite” class stairs they can be made of natural stone. Despite the weight from 60 to 80kg the laying of such steps is easily handled by two workers, installing them from the bottom up. Where the elements are held by the grooves and their own weight.

During installation, a cement-sand mortar is sprinkled on the edge of the lower step with a trowel and the next part is immediately installed and so on to the top, but in addition, at the bottom of each step there is a metal insert, which is welded to the stringer. If the steps are subsequently tiled with any kind of tiles, then in such situations it is necessary to take into account the thickness of the tread when pouring the site.

The sites themselves can be prepared in advance, that is, reinforced concrete slabs of the required size are purchased, or such blocks are poured directly at the construction site. Pouring is carried out only on the reinforcing cage, which is made from a 10 mm rod with a mesh spacing (cell) of 200 mm, while the lower layer of concrete to protect the metal from corrosion should be not less than 20 mm.

When arranging stairs with frieze steps, the side enclosure of the formwork, as a rule, is not necessary, since this function is performed by the walls of the staircase. For this, the length of the frieze steps must be greater than that of the privates, which allows them to close together to form a flat platform, like an extension of the staircase.

Conclusion

In fact, any reinforced concrete, wooden or metal staircase on kosoura is built according to the finished frame, on which its final configuration depends. Therefore, the installation of such a base will in any case be a decisive and decisive factor, both for appearance and mechanical strength and the resulting safety of the entire product (also learn about the advantages of attached wooden ladders).