From the moment when the height of houses began to exceed three floors, and cars appeared in the fire brigade, the history of such rescue equipment as fire ladders began.

Today it is simply a vital technique for carrying out rescue operations and extinguishing fires on the upper floors of buildings.

General information

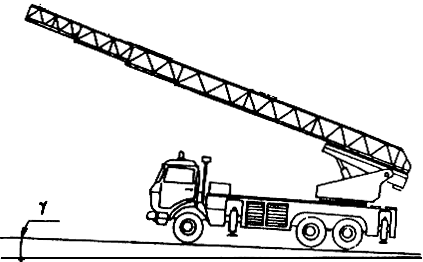

What is a fire ladder

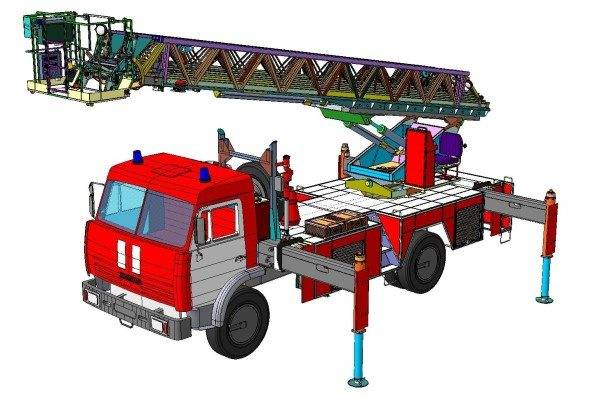

A fire ladder is a specific type of fire and rescue equipment, which is a sliding swing ladder with a hydraulic lifting drive. These ladders are based on the chassis of commercial vehicles.

Purpose and operating conditions

Ladders are used primarily for extinguishing fires, as well as for all kinds of emergency recovery, rescue operations. They are designed to provide access for the rescue team. They also help deliver the necessary weapons and technical equipment to the required height..

Often, with the help of ladders, victims are evacuated from the upper floors of the building and material values with the help of a rescue sleeve.

This technique can be operated in different climates at temperatures from -35 to +35 degrees Celsius. And subject to certain rules, such ladders can be used at lower temperatures.

Types of fire ladders

Firefighters are classified according to:

- The number of knees;

- Length;

- Drive type.

There are three types of knee lengths:

- Lightweight - if the length is up to 20 meters;

- Medium - if the length is more than 20 meters, but less than 30 meters;

- Heavy - if the length exceeds 30 meters.

According to the number of knees, the stairs are divided into:

- Three-knee;

- Four-knee;

- Six-knee.

As the length of the ladder increases, the number of knees increases, which is a difficult engineering task. This is due to the fact that with an increase in the mass of the ladder, the possibility of overturning arises, as well as moments of stress in the details, vibration and deflections appear.

As for the types of drives, ladders are available with hydraulic, mechanical and combined transmission. The most widely used devices are with hydraulic transmission, as they are easy to use and very reliable.

The marking of fire ladders is carried out in letters and numbers, for example, fire ladder AL 50 (131) L21 is deciphered as follows:

- A-car;

- L-ladder;

- The number after the letters denotes the total length of the staircase, which is calculated in meters;

- The chassis brand is indicated in brackets;

- The model numbers, which are manufactured by the manufacturing plant, are written in brackets.

Note!

The "L" after the brackets means that a cradle is attached to the top of the ladder.

Thus, we have a ladder with a length of 50 m, located on the basis of the ZIL131 car, model L21.

Ladder device

Main nodes

Examples for considering the device of the mechanism will serve as a fire ladder AL 30, since in our country it is the most common fire fighting equipment.

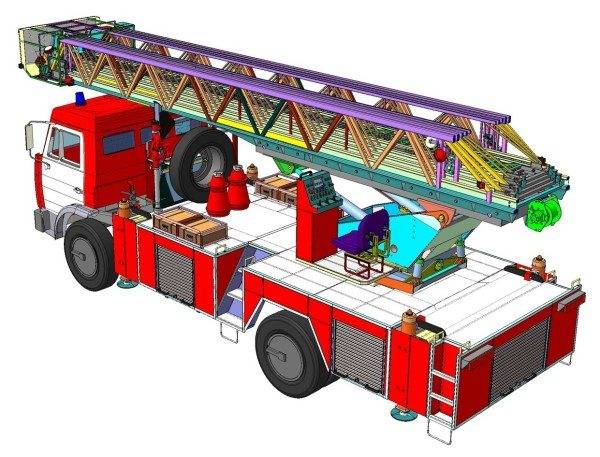

The machine includes the following components:

- base chassis with front support frame and platform;

- Knee set;

- Lifting and turning device;

- Supporting device;

- Tower of hydromechanisms;

- Hydraulic pump transmission;

- Automatic blocking devices;

- Remote Control;

- Intercom and additional electrical equipment.

The vehicle chassis with platform, cab and front support frame is the basis for all other ladder assemblies.The main power unit for the hydraulic pump drive is the chassis engine.

Ladder platform

The platform of the ladder is a metal, box-shaped structure welded from metal corners and solid steel sheathing. The metal frame is bolted to the frame side members.

The platform consists of four parts:

- Front;

- Back;

- Two side platforms with wings.

On the back, under the platform, there is a closed box that allows you to place fire-fighting accessories and removable equipment in it. Access to the gas tank and batteries is carried out using special doors. The platform has steps on the sides.

Front support frame

Behind the driver's cab, at the front of the platform, there is a front support frame. With its lower part, it is attached to the side members of the car, and by its upper part, to the platform of the ladder. This frame is sometimes used for the front of the knees in the stowed position.

In the upper part of the frame there are guides that fix the set of knees in the transverse direction. The knees are kept from vertical movement by spring latches, which are installed on the rails.

Arbitrary extension of the knees during the movement of the technique prevents the locking hook. When the ladder is lifted off the frame, the hook is lowered by its own weight, thereby releasing the knee.

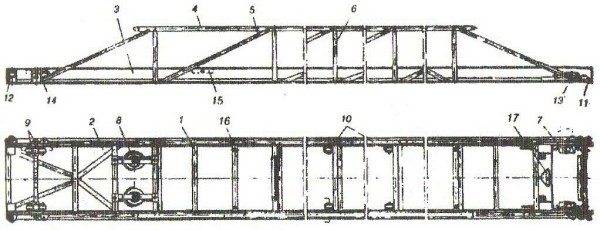

Knee set

This knot includes four bends connected together in a telescopic way. They are made of low-alloy steel grade - 10ХСНД.

This material has the following properties:

- High strength;

- Plastic;

- Corrosion resistance and weldability.

Thus, each elbow is a light steel structure, which consists of two trusses, rigidly fastened to each other by spacers and steps.

The ladder knee kit consists of the following elements:

- Stair bowstring;

- Step;

- Support roller;

- Rack;

- Upper belt;

- Guide roller.

The bowstring is made of a special profile, which provides good rigidity and at the same time has a low mass. Steps are made of rectangular pipes, and the posts, upper chord and braces are made of circular pipes.

The device of all the knees is the same, they differ from each other only in weight and size. The bowstring thickness of the first leg is 2 mm, and the fourth leg is 3.2 mm. The distance between the steps is 300 mm.

To make it easier to move along the stairs, the outer surfaces of the steps of the stairs in the middle part are covered with rubber corrugated pads, which are fixed with metal clips. It is customary to number the knees from top to bottom, i.e. the first is the upper knee.

The carrier is the lower, last knee. It rests on the guides of the lifting frame with the rollers of the rear and front support units and is secured with a pivot. At the rear, the support bend and the mast are connected to each other by a side-leveling hydraulic cylinder.

The movement of the knees relative to each other is carried out using textolite rollers and support guides. The front and rear rollers are paired because they take the main load.

The lower knee is equipped with a plumb-line goniometer, which allows you to measure the angle of inclination of the ladder, the permissible extension length of the structure at a certain angle and the load on the top of the ladder. The extension of the knees is carried out using steel ropes.

When winding the steel cable onto the winch drum, the second, third and first bends are extended simultaneously. All knees, however, move at the same speed relative to each other.

Fixation of the knees is carried out using automatic locks, which are installed at the same level.When transporting, a set of knees is positioned along the chassis above the cab.

In addition to the main four knees of the same type, one additional lightweight knee is mounted on the top of the first knee. It can be pulled out by hand to a length of up to 2.5 m. This additional section is used in exceptional cases. Such a knee cannot serve as a support, so the ladder must rest on the top of the first knee.

Support device

This unit is designed to ensure the stability of the ladder during operation.

It includes:

- Support frame;

- Four retractable supports;

- The control mechanism of the spools, which are located on the platform and blocking the springs.

The support frame is a metal welded structure. It is mounted on the side members of the vehicle at the rear.

The frame consists of:

- Two side cheeks;

- Two crossbars;

- A support ring on which the turntable of the lifting-slewing device is installed.

The side cheeks are brought to the working or stowed position using hydraulic cylinders. The locking mechanism of the rear springs allows to increase the rigidity of the carrier base and thereby increase the stability of the ladder during operation.

Note!

Before starting the movement of the set of knees, it is necessary to bring the support system to the working position.

Hydromechanisms

The operation of the tower systems of hydraulic mechanisms is provided by the hydraulic system. The working pressure in it is 10 MPa. MG oil is used as a hydraulic fluid in summer. In winter, the system is filled with AU spindle oil.

The working fluid is supplied to the units by a hydraulic-motor-axial-piston pump. The hydraulic system tank provides compensation for losses, and also with its help, the working fluid is cooled, air and vapors are released, sludge, etc.

The hydraulic system provides the following movements:

- Rise;

- Extension;

- Turn left or right;

- Maneuver in three directions simultaneously.

The mechanism for sliding the extension of the knees of the stairs contains a worm gear, a drum and an axial piston motor.

Note!

In case of failure of the main pump, a hand pump is fixed to the frame, which ensures the reliability of the ladder.

These are the main nodes that power the ladder.

Operating rules

The instruction manual for the fire ladder consists of the following points:

- To ensure the operability of the fire ladder, it must be stored in a heated garage, at a temperature not lower than 5 degrees Celsius. The machine must always be in full combat readiness: equipped with accessories and equipment, filled with fuel, etc.

- After each training exercise or going to a fire, the structure should be cleaned, wiped down, and then lubricated in accordance with the lubrication chart. Particular attention must be paid to the serviceability of the contactors.

- If more than one wire is found on the cables in a section of 100 mm, they must be replaced.

- The approach of the ladder to the object should be carried out on the basis of the convenience of installation and operation of the ladder. The higher you need to raise the ladder, the closer it should be to the serviced object.

- It is not allowed to work on a ladder if its platform has an angle of inclination to the horizon by more than 6 degrees. In this case, it is necessary to ensure that the rear wheels of the car are not on the cover of mines, fire wells, trenches or on soft soil.

- Before preparing for work, it is necessary to apply the handbrake of the car and lower the support cheeks. The ladder is controlled by handles and handwheels on the console.

- The first maneuver of the ladder is to lift it, since in the transport position all other movements are blocked.

- The most important movement of the structure is the extension of the knees to the required height.The approach of the top of the first knee to the boundary of the field of motion must be performed at low speed. After the top of the ladder reaches the maximum height, the knees must be put on the contactors, and the engine must be turned off.

- When extending and cleaning the ladder, make sure that it does not touch electrical or radio transmission lines.

- The descent and ascent of firefighters along a leaning motor ladder is prohibited at intervals of less than 3m.

Advice! The rise of the ladder must first be carried out at low speed, then, having reached an angle of 30-40 degrees, it should be transferred to a high speed.

The video in this article will allow you to visually look at the work of a fire ladder.

Output

Ladders are an absolutely indispensable form of equipment for ensuring the safety of urban residents, as they allow not only getting to the place of fire and rescue operations in a timely manner, but also saving lives.

Sometimes an auto fire escape is the only escape route. Given this responsibility and the complexity of the structure, it must be operated strictly in accordance with the established rules.

Like any other type of special equipment, ladders are very expensive, the price for them can reach several million rubles.