A mounting stand is essential everywhere - at home and at work.

To safely have access to the upper shelves of shelves, bookcases, upper floors of shelves in stores, they use platform stairs.

Choosing a staircase

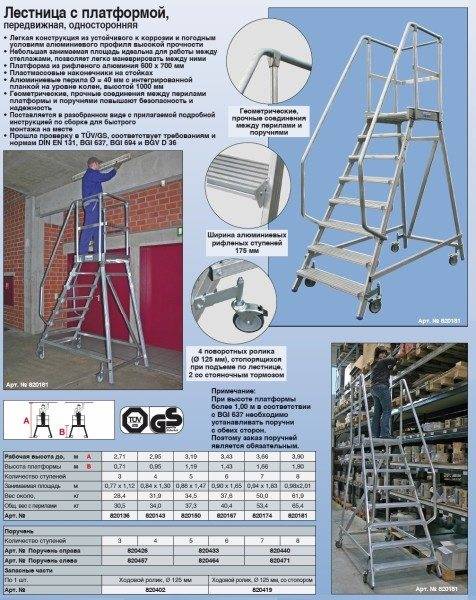

When choosing stairs with a platform, you need to pay attention to their following parameters, which may be different depending on the model:

- Overall height and platform height.

- Weight without ballast.

- Weight and the presence of ballast, which allows you to work safely at high heights, while taking up little space for an emphasis.

- The number and material of the steps of the stairs.

- Pay attention to safety of use: in models with more than 3 feet, handrails and knee restraints, safety chains can be installed.

- Possibility of height adjustment.

- Withstand load. Usually it is about 150 kg. But there are also more durable models. For example, more and more semitones are used when testing Krause stairs.

- Working height.

Advice!

To determine the optimal working height for you, you need to subtract the height of the person from the height to which access is required and another 30 centimeters so as not to touch the ceiling when working.

Types of stairs with a platform

Relatively speaking, the platform ladder can be of several types:

- Regular - with simple legs.

- Bilateral - differs from the usual one in that the steps are located on both sides. This is convenient when working together.

- Transition bridge - similar to a two-way ladder, but with a long platform and handrail on one or both sides. Allows you to work by moving the platform along obstacles.

- Mobile - with one or two pairs of wheels.

- Attached - has only two legs on one edge, and the other edge allows you to put it on the shelf of the rack.

- Foldable - can be quickly assembled into a compact form using a special mechanism.

- Transformer - a universal version of the ladder, it can be an ordinary attached ladder, with a platform, retractable, double-sided or simple step-ladder.

- With ledge - the platform is fixed with a ledge.

Additional elements

Separately, for such stairs, you can find accessories for sale:

- Security bars;

- Removable fences;

- Anti-slip handrails;

- Chain fences;

- Protective strips under the steps;

- Hinged tool shelf.

Peculiarities

- Unlike stationary household ladders, portable options have a much higher angle of rise: it can be in the range from 45 to 75 degrees.

- The standard step width is usually 60-80-100 cm, and other dimensions are made to order.

- The width of the steps, as a rule, depends on the angle of inclination of the stairs. For example, at 45 degrees, the treads are 22.5 cm wide, and at 60 ° - 17.5 cm to save space.

- The most popular material for portable platform ladders is aluminum. The steps are made of corrugated or perforated aluminum, or aluminum grating. This material allows you to achieve the required strength, while providing a low weight, which is always important for mobile work.

- The standard platform length is 60-70 cm, but sometimes other sizes are made.

Prices and manufacturers

Platform ladders are mainly used in production, so their price does not allow them to be widely used in the household.

The products of the German company Krause are most widely represented on the market. This company has been operating since 1900, and over the years has proven its leadership in this segment.Also, stairs with a platform are made by another German company Zarges, founded in 1933.

The cost of the simplest Krause platform ladder starts from 30-36 thousand rubles. Products from Zarges will be cheaper: their cost starts from 22 thousand rubles.

Ladder installation

Note!

Ballast weights may be required depending on site height.

They are needed to increase resilience.

They are installed in the connecting beams.

Since the mobile ladder with platform is supplied unassembled, you will need to assemble it yourself. Let's describe the assembly process using the example of a staircase from Krause. To install it, you need a pair of 13 wrenches, as well as two corner hexagons: 5 and 4.

The instruction is shown in the video in this article.

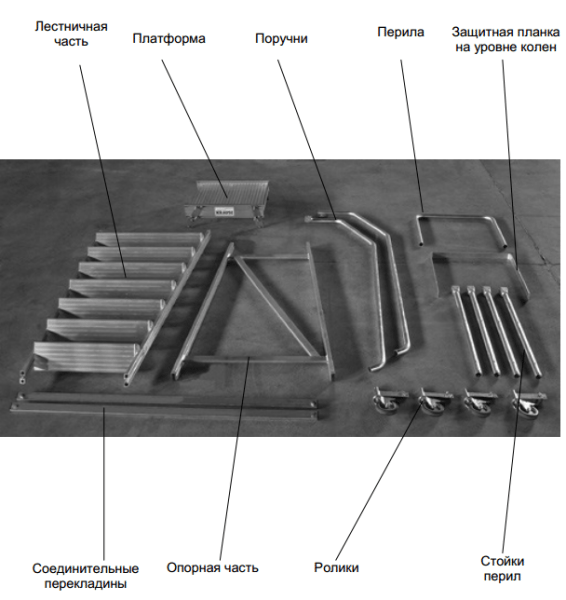

The photo shows the designation of parts:

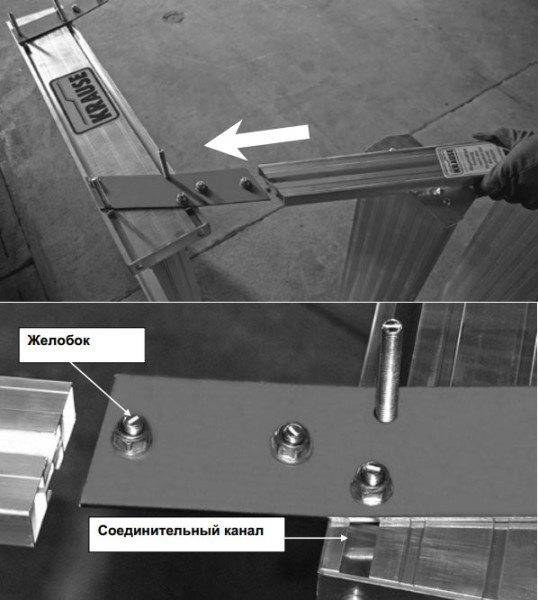

Place the platform on the edge and insert the ladder section into the special strip. Tighten the nuts by hand and note that the groove on the bolt is perpendicular to the platform connecting channel.

Then secure the second ladder or support legs in the same way, depending on the model.

Flip the ladder over. It cannot be used yet. Fasten the connecting bars to the marked spots on the lower outer part.

Align the ladder and make sure the foot and ladder fit snugly against the platform before finally tightening the nuts. After that, you can tighten the nut connections to the end with a wrench.

After that, you need to install 4 railing posts and hand tighten all the nuts.

Then the knee restraint is attached. To do this, insert the railing into the special holes on the back and tighten the connections.

If handrails are used, the handrails are inserted only halfway into the holes, as shown in the photo. For low stairs less than 1 meter, handrails are not required, so the handrails can be inserted all the way.

To fasten the handrails, insert it from above into the connecting element and tighten it. From below, fastening occurs by screwing the fastening in the form of a plate to the staircase.

If the wheels for travel were not installed by the manufacturer, or they need to be adjusted, install the ladder at a height of 0.8 cm. Then screw the roller to the supports. Please note that their fastening must be done strictly according to the marking, do not confuse!

In order for the rollers to roll well on the floor, you need to align them well horizontally and vertically. In accordance with BGI 637, a distance of 6-10 mm must be made between the floor and the foot. If the ladder will be used by people with little weight, it may be a problem that the rollers will not push through when working on the platform. In this case, you need to adjust them deeper so that the legs barely reach the floor.

Conclusion

The presence of a ladder with a platform will greatly simplify the work in high warehouses or workshops. However, if possible, to increase safety, you need to look for more stable sites, and use mobile options as little as possible. When working on an unstable surface, it is important to comply with all safety requirements specified by the manufacturer.