An intra-house staircase is not only an engineering structure that provides convenient movement between different levels, but also a striking element of interior design. Its design requires an individual approach, especially if the frame is made of concrete or metal - materials that need additional finishing. In this case, the facing of stairs and steps should correspond to the general style of the house.

In this article, we will tell you how to tile a staircase and what materials to use for this.

Finishing materials

The choice of materials for facing steps and other parts of the staircase is primarily influenced by its design and shape..

For example, metal ladder frame They are “covered” mainly with wood, and natural or artificial stone, floor tiles, wood and synthetic coatings are perfectly placed on concrete. The choice between them is made based on the requirements for design, safety, convenience. The cladding price also plays a significant role.

Advice. The most affordable and economical option finishing concrete stairs - painting.

Moreover, it is not necessarily considered temporary.

In a minimalistic interior, complemented by metal and glass, this finish looks very appropriate.

And visually lightening the structure can be painted by the risers in a light color, and the treads in a dark color.

These materials differ not only in appearance, but also in their properties - the ability to retain heat, extinguish sounds, etc. Let's talk about each in more detail.

Wood

For many, facing the stairs with wood is the only option.

And not because of the lower cost than stone or porcelain stoneware, but due to the special performance properties of this material.

- The wood is warm to the touch. It is pleasant to walk on it with bare feet, the surface remains warm even with insufficiently comfortable air temperature;

- This is a relatively soft and therefore less traumatic material, unlike other types of cladding;

- Wooden steps are distinguished by good sound absorption;

- Finally, wood can be easily processed and finished, which is important for those who want to do their own cladding.

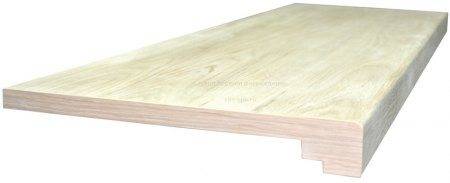

Solid wood or glued timber from deciduous trees can be used for this purpose. Preference is given to hard rocks with high wear resistance. These include beech, oak, maple, ash, as well as many exotic species. In this case, the wood must be well dried, without cracks and knots.

Attention!

Lining the stairs with laminate or parquet boards is not recommended, especially if it has high traffic.

If the budget is limited, the risers and baseboards of the stairs can be made from cheaper coniferous wood - spruce or pine.

Stone

This material is chosen when it is necessary to emphasize the richness, solidity and luxury of the interior. It does not have the advantages of wood, since it has high thermal conductivity and poor sound insulation qualities, but it is able to give the interior a truly inimitable style.

The steps are best faced with hard sandstone, granite, basalt, calcite marble - that is, abrasion-resistant rocks. Porous rocks are poorly suited for these purposes, since the pores are quickly clogged with dirt and lose their attractive appearance.

Various types of artificial stone are becoming more and more popular.

For finishing stairs, acrylic stone can be considered the most preferable, which has the following important advantages:

- Compared to natural, the surface of acrylic stone is warm, which is important for comfortable use;

- Durability and abrasion resistance is not inferior to natural counterparts, and even surpasses them;

- A huge variety of patterns and colors, the ability to choose them.

The disadvantage of this finish is the high cost and the inability to carry it out on your own, since all the details - every step, baluster, handrail - are manufactured in production according to preliminary measurements. This requires special equipment.

Tile

Cladding stairs tiles Is a fairly economical finishing option that you can handle on your own with some experience and tools. But the choice of tiles must be approached responsibly - not every one has the necessary characteristics: resistance to abrasion, preservation of its original appearance, the ability to withstand serious loads.

It is best to use porcelain stoneware or techno tiles. These materials as well clinker and paving slabs can also be used to decorate the steps of street stairs.

Advice. Steps finished with tiles or stone are rather slippery, therefore, for safety reasons, it is recommended to install embossed metal or rubber strips on them or to make a special spraying that gives the surface a roughness.

The disadvantage of tiling is the presence of seams and the need to cut it to size. However, this can be avoided if you purchase ready-made kits in advance, consisting of treads, risers, baseboards and corners, and design a staircase for their size.

Roll coatings

Elastic roll materials and carpets are not often used as staircase finishes due to the difficulties in maintaining cleanliness and wet cleaning. Although with the advent of modern washing vacuum cleaners and steam cleaners, this is no longer a problem.

This coverage can be permanent or temporary if there are young children, the elderly, or family members with disabilities in the home who find it difficult to climb stairs. The warm, soft and non-slip surface makes the process less difficult and safer.

It is not recommended to cover stair treads with woolen, acrylic or felt coatings of low strength, as well as materials with a long pile. Polyamide and polypropylene roll coatings are considered more suitable.

Wood cladding technology

Wood is not only the most popular, but also the most affordable material, most often used for the construction and decoration of inter-house interfloor stairs. The second most affordable is tile, but it is rarely used for residential premises. More often - for finishing street or structures leading to the basement.

Facing a concrete staircase with tiles does not differ much from the device of a floor covering made of this material, the only difference is that it has to be cut and adjusted more.

Finishing concrete stairs

In a nutshell, the step finishing process consists of the following steps:

- Leveling the surface. All cracks, holes and dents on the concrete surface are leveled with mortar or "self-leveling floor".

- Fastening to the steps of moisture resistant plywood. The plywood must be at least 10 mm thick. It is fastened with dowel-nails, and in order to avoid the appearance of a squeak under it, a thin layer of polyurethane foam is applied to the concrete surface.

- Installation of steps and risers. It is carried out using glue "liquid nails". You can additionally use screws, followed by sealing the attachment points with putty.

Attention. If facing of concrete stairs includes the installation of risers, then they are first attached to the steps, and then the whole structure is glued to the base.

- Framing. If the side surface of the stairs is not sheathed with wood, then it becomes necessary to close the ends of the plywood under the wooden step. For this, wooden planks are used.

Although you can apply another method of mounting the steps in order to avoid the need to mask the plywood visible from under them. To do this, each tread is made a little more. concrete stepso that protrusions form in front and on the side, and on the seamy side, a notch is made in it according to the size and thickness of the plywood. In this case, the wooden part is put on the prepared base tightly and without gaps.

Finishing metal stairs

The metal frame of the stairs can be sheathed with wood in different ways. The easiest option is to install wooden steps or steps with risers without cladding the rest of the structure. They can be simply painted after the appropriate treatment.

But some people prefer to completely hide the metal, giving the staircase the appearance of an exclusively wooden structure and providing it with wooden handrails and balusters. In this case, the back of the marches is also closed, for which lining, drywall, plywood or other sheet materials are used.

Instructions for finishing metal stairs:

- Measure each step carefully and cut out the parts from the wood, numbered in order. Before installation, they must be sanded to give the surface smoothness. On the underside of the steps, make grooves for the risers.

- Drill holes in the metal frame and first fix the first tread with the riser glued into the groove on it.

Advice. For fastening, you can use self-tapping screws for corrugated board or metal tiles.

- Assemble the second step by lubricating the top end of the riser with glue or silicone and inserting it into the groove in the tread. Then glue the back end of the tread with glue and install it in place, pressing it against the upper riser and screwing it down with self-tapping screws.

- Continue from top to bottom until you are done with all the steps.

<oltart=»5″>

- Before revetting the metal staircase from the side, fix the balusters on the steps and install the railing.

- Sew the visible wireframe. If you decide to use sheet materials for this, you will first need to make an exact pattern in the shape of the finished steps.

Conclusion

The stairs in the house must be safe and comfortable. But it is very important that it is also beautiful, that it forms a single ensemble with other interior details. Not everyone can make it this way, many will prefer to entrust this work to real professionals.

But if you nevertheless decide to finish the stairs yourself, in the video presented in this article you will find additional information on this topic.