Today the marble staircase is not a luxury item.

This is one of the most proven solutions for combining sophistication and reliability in interior design.

The constituents

The main components of a classic marble staircase are:

- steps;

- risers;

- pillars,

- galoshes,

- railings;

- balusters.

Steps

The steps for stairs made of marble represent a horizontal plane that a person steps on when going up or down. The standard step has a tread (width) of 300 mm, as for all stairs. The length of a marble step is usually from 800 to 1200 mm, and its thickness is from 30 to 40 mm.

Riser

A riser for a marble staircase is a strip of marble in the form of a vertical or slightly beveled element that covers the distance between the planes of two successive steps.

Backsplash

The wall skirting board, or, as it is called, the galoshes, can be made in three types:

- solid;

- typesetting, with an applied figured profile;

- direct typesetting.

Usually the price of a type-setting skirting board is lower than that of a solid shoe rack. This option is considered budgetary.

Important. You should know that if the plinth is solid, then the plinth is first attached, and the steps with risers move towards it.

With a type-setting plinth, we do the opposite.

First of all, the steps and risers are attached, and only then the galoshes.

Balusters and handrails

An important element is the structure fencing. Handrails, balls and marble balusters will give the stairs a special expressiveness and complete the classic design.

Why marble

The interior decoration of premises, especially museums, banks, various government agencies, benefits greatly when it is decorated with a marble staircase. Any buildings where such stairs are installed have a special appeal, charm and a very presentable view.

Stairways located on the street must withstand very heavy loads, both from the external environment and from the stream of people walking along them. This is especially true for public buildings. (see also Single-flight ladder: a simple solution)

Advantages

Marble is one of the most durable building materials used for staircase construction. Perhaps only granite can compete with it. The high strength inherent in these natural materials has led to their use in construction for several centuries..

Stairs made of granite and marble can withstand any temperature fluctuations, they are quite durable and beautiful. Only modern high-strength concrete can argue with them. (see also Do-it-yourself concrete stairs: tips and tricks) But marble is considered more favorable in terms of environmental properties.

Classic marble staircases have a number of advantages that have been verified over the centuries.

These include:

- durability;

- wear resistance (marble stairs will last for decades without repair);

- practicality (marble structures require simple maintenance, without unnecessary difficulties);

- environmental friendliness (marble is considered absolutely safe for human health);

- resistance to a sharp temperature drop;

- resistance to moisture;

- a wide range of colors (hundreds of shades from boiling white natural marble to bluish black).

Problems

Sometimes you can hear that marble crumbles heavily, often cracks and cannot serve as a reliable material for construction. This opinion is erroneous. It is clear that marble is not granite, its structure is slightly softer. But this does not mean that he is very fragile.

For example, many stations of the Moscow metro are finished with marble, some of these stations are already 70 years old, and they look great.

But all the same it is necessary to take into account that, in comparison with granite, marble is a softer material. It is not advisable to make steps from it in shopping centers or other buildings with very high operating loads.

There is one more problem that was relevant until recently. Marble stair treads can be slippery, which affects their safety. But they learned to deal with this problem.

Today, all such steps are impregnated with compounds specially created for this. After proper processing, the appearance of the steps does not change, they are still glossy and shiny, but they become rough to the touch and are completely non-slippery.

Important. Sometimes yellow spots appear on the surface of white marble, which cannot be removed.

The appearance of such stains can be avoided by not using raw metal for reinforcement or fasteners.

All metal parts of the fastener must be made of stainless steel.

Types of processing

Marble is one of the oldest natural materials that was actively used in the construction of palaces and temples. It underwent special processing many centuries ago, when masters created real works of architectural art, which delight us today.

Over the years, a whole school of stone processing has developed, studying various methods of working with it.

There are several standard types of marble processing, which are subdivided depending on the given properties of the surface of the material.

The surface after such processing gets one of the following names:

- bush hammered, texture with a relief difference of up to 5 mm, gives the effect of solid massiveness;

- polished, smooth and matte, with a distinctly natural stone pattern;

- sawn, with traces of exposure to metal shot, rough, height difference up to 5 mm;

- polished, revealing completely the beauty of the natural color and pattern of the stone, with a mirror shine;

- heat-treated, with traces of the action of a gas jet with a high temperature, with traces of peeling and a clearly visible structure of the stone itself;

- polished, with traces of processing with abrasive tools, slightly rough;

- the "rock" texture, rough, is obtained by chipping off rather large pieces of marble, the relief difference is up to 200 mm.

Care

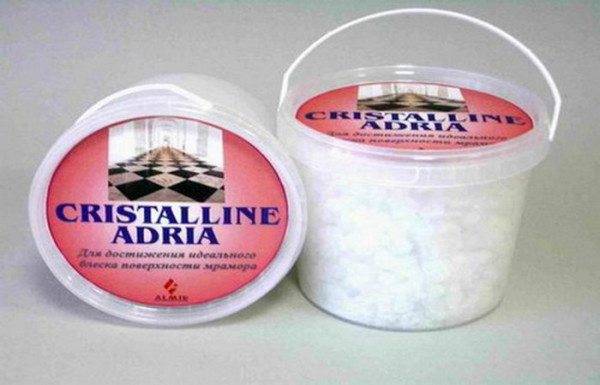

After laying the steps or floors, the so-called primary polishing is performed, but if it is necessary to perform it during operation to make the surface shine, then it is called secondary.

Marble processed in different ways needs different types of care. In this regard, it is very important to know whether marble staircases in your home or office were made of polished or unpolished marble.

To care for polished marble with your own hands, you can use service polishes, which are produced on the basis of wax components and have anti-slip properties.

These pastes are very easy to use, they will help to preserve the shine and novelty of the product, both in a public place and in a private home.

If the steps were not polished in advance or received minor damage, it is necessary to grind them, and only then polish.

This process is quite laborious, but it is quite within the power of persistent and skillful ones.

You need to prepare:

- sandpaper of varying grain size;

- sand;

- paraffin;

- soft tissue;

- special pastes for the care of marble;

- grinder (grinder);

- flexible diamond discs of all numbers from 50 to 800.

Step-by-step instructions for polishing marble at home:

- rinse the steps well with detergents;

- moisten the step surface with fine-grain sandpaper;

- we carry out the process of rough grinding using the coarse-grained of the discs, you can add fine sand;

- we wash the surface;

- the normal grinding process is carried out with a disc with a finer grain;

- we wash the surface;

- finishing process, we carry it out with discs with the finest grain;

- we thoroughly clean the surface;

- we rub with paraffin and special compounds.

Important. The recommended sanding process thickness for normal quality is three millimeters.

Summary

A staircase made of marble is not only a very important architectural element that requires a high degree of reliability. The appearance of such a staircase often becomes the very final touch that gives zest to the overall design.

In the video presented in this article, you will find additional information on this topic.

I wanted to make myself a marble staircase at my dacha, but then changed my mind when I saw the price of materials and the work of builders. Everything together is very expensive. so I made it myself, it turned out well, there are of course small joints, but if you don't know where they are, then you won't notice.