A very effective technique for decorating stairs is a combination of wood and metal. Aesthetics, reliability, durability, various color and design solutions, as well as respectability have determined the popularity of such designs.

Advantages of combined structures

- Stairs on a metal frame have excellent performance.

- They are distinguished by an increased service life compared to solid wood structures.

- The mass of structures, thanks to wood cladding, is significantly less than that of pure metal or concrete stairs.

- Iron or steel give structures an increased level of strength, as well as wear resistance. Wooden steps - comfort and safety of movement.

- Strong but light grades of metal with increased corrosion resistance are taken as a base material.

- Based on the project and your preferences, the timber frame cladding can be partial or complete.

Structural cladding

The most important characteristic when choosing timber is their moisture content. Its level directly affects the performance of wood.

Note! Excessive moisture content significantly reduces the strength of the skin. Based on this, before work, the wood must be dried to the standard level. The moisture content of freshly felled trees is 35/100 percent... To start facing work, this indicator must be 12%.

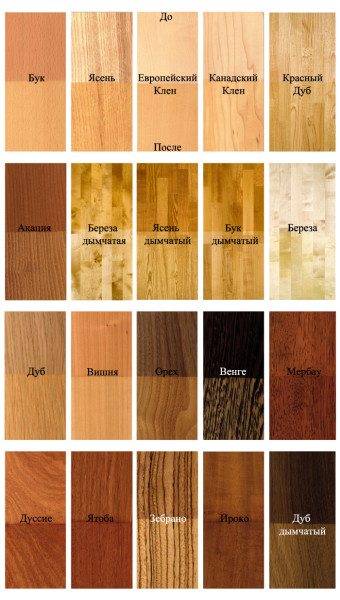

Which wood to choose

Before sheathing a staircase on a metal frame, you need to choose a type of wood. The most demanded for finishing works are oak, walnut, beech, cherry, pear, ash and mahogany.

- Oak has increased durability and strength, a wide color palette - from delicate yellow tones to red-brown shades. This wood has an interesting feature of darkening after a while, acquiring a deep color. It gives nobility to the cladding. Oak staircases - standard quality constructions.

- Ash has the same strength as oak wood. The material has a bright and pronounced texture and a beautiful grayish tone.

- Beech elegant and sophisticated. Its wood has a uniform texture and durability. Perfect to imitate mahogany.

- An excellent effect is obtained if you use exotic woods - teak, wenge, abash, merbau... They have very beautiful colors: yellow-lemon, deep purple, deep red, black, brown. From these materials, incredibly beautiful stairs are obtained.

- For facing the risers, you can use conifers - spruce, pine, fir... Pine has good performance. Due to its low density, it is easy to process. The price of elements that are trimmed with conifers is significantly less than deciduous counterparts.

Sheathing cover

When the staircase is faced with wooden elements, you can tint them in any of the colors. Before that, soak them with an antiseptic, which will prevent the material from rotting. Another coating method is to preserve and emphasize the natural texture, color, and relief of the wood. To do this, you can use a sander with a steel brush attachment.

Comb through hard and soft fibers of the material. As a result of the work, the soft fibers will be removed by the brush, while the hard ones will create a beautiful embossed pattern. Then, with the help of varnish, give the steps the necessary tone. Then grind the surface. After that, the varnish will remain only in the recesses.

Work technology

Now how is it done metal frame staircase do it yourself. This work includes several stages:

- Decide on the design of the building and the method of cladding. Will you only sheathe the treads, or will you also coat the risers. Select the type of railings and balusters.

- Choose the type of wood.

- Prepare the cladding elements. To this end, adjust the material to the dimensions of the frame, making sure that no cracks form. After making measurements, cut out the details of the steps, numbering them.

- The fence of the stairs, in addition to the protection properties, is also a decorative element of the structure. Since railings can have a carved section, choose the most comfortable shape for your palms.

Note! To make the ascents and descents along the structure as safe as possible, you need to determine the correct placement of the balusters. As a rule, the step between them is 9, 13 or 22 cm.

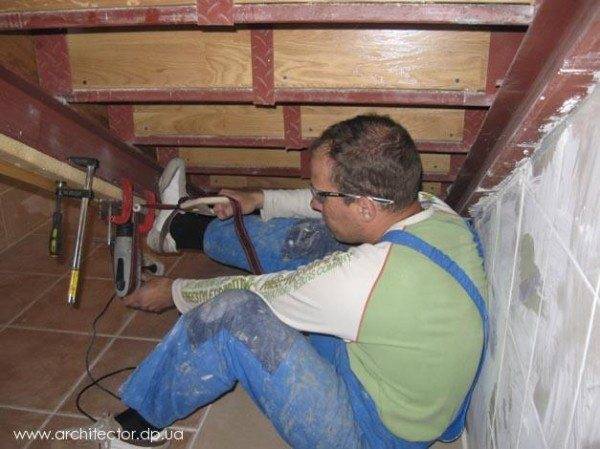

- Fix wood parts. Using a screwdriver, secure the steps at the top. Then press the risers firmly into the frame and fix it. Thus, fix all the trim elements.

- Steps with wooden details that protrude slightly beyond the metal base look great. The instruction says that only hard woods should be chosen for linings. To avoid chips on the skin, chamfer around the perimeter of the panel and round their corners.

- Next, place the balusters along the edges of the steps. After checking the correctness of verticality, then secure the posts with special studs and attach the railing to them.

- Sheathe the metal frame completely. Line the side of the stairs with a wood panel that fits the shape of the steps. After the risers and treads have been sheathed, begin decorating the marches on the back of the structure. For this purpose, drywall sheets can be used.

- When you finish these work, proceed to coating the cladding with paint or varnish.

Output

The manufacture of stairs on a metal frame with a wooden cladding is attractive in that these materials can be widely varied. You only need to choose the option that you like the most. At the same time, it should be aesthetic, practical, functional and, if possible, not very expensive.

In the video presented in this article, you will find additional information on this topic.