The staircase located in the house can become both an interior decoration and vice versa, spoil the impression of it with its unpresentable appearance. Moreover, the result depends not on the design itself, but on its finish. The easiest way to add visual appeal and grace to the stairs is with wood trim.

This natural material looks spectacular in combination with any design and fits perfectly into any interior. In addition, finishing the stairs with wood will hide many defects that may arise during the manufacturing of the structure.

Most often, the cladding is thought of at the design stage, but sometimes finished products are also trimmed, which were not originally designed for this. Both iron and concrete stairs can be sheathed.

Next, we will take a closer look at how to finish metal, reinforced concrete and wooden stairs with our own hands.

Material selection

It is the cladding material that will determine the final result. It depends on him whether you get a very modest and cozy staircase or a respectable and graceful design. However, regardless of the type of wood, its moisture content is an important parameter.

Excessive moisture can significantly reduce the strength of the material. Therefore, all wooden elements for the staircase must be dried until the moisture level reaches the permissible limits. Otherwise, during operation, you may encounter swelling of wooden elements.

The moisture level of freshly cut wood is 35-100%. It is possible to start facing work only if this figure drops to 12%.

In addition, when choosing wood, it is necessary to pay attention so that the following defects are not absent:

- cracks;

- various pigmentation;

- holes.

- knots.

The most popular types of wood for facing work are:

- Pine;

- Beech;

- Oak;

- Red tree;

- Ash;

- Exotic woods, etc.

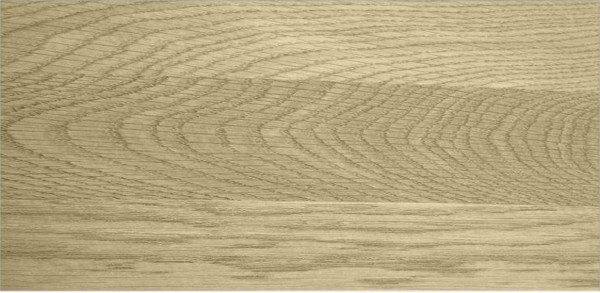

Oak

Of course, oak wood is especially attractive, as it has increased durability and strength. In addition, oak has a rich color range - from light yellow shades to dark, reddish-brown tones.

Note!

When decorating a staircase with oak, one feature of this material must be taken into account - the oak massif darkens over time and acquires a noble deep color.

Ash

Ash is no less attractive wood for stairs than oak, which is not inferior to it in strength. It has a beautiful, pronounced texture and a noble grayish tint.

In addition, ash has the ability to bend without losing strength. Therefore, it can be used for sheathing stairs with complex shapes.

Beech

Beech symbolizes sophisticated style and elegance. This wood has an attractive appearance, a uniform texture and at the same time is not inferior to oak in durability. Beech is great for imitating mahogany.

Pine

Pine is also characterized by good performance properties. In addition, it is easy to process due to its low density. At the same time, the cost of facing the stairs with this material will be much lower than all the previous ones.

It must also be said that experts recommend using pine for the walls. Although, spruce or fir can serve as an alternative.

Exotic varieties

The use of exotic woods will give a great effect.These include teak, wenge, merbau, etc. These breeds have an incredible color palette, ranging from lemon-yellow tones to deep purple and even black! Of course, the price for this material is much higher than for the traditional wood in our area.

Facing metal stairs with wood

Decorating a metal staircase with wood is a creative process that, in addition to skill and knowledge, also requires a good artistic taste. The most widespread and demanded way of sheathing is fastening wooden steps to a metal frame.

If the design project involves the complete sheathing of the metal frame with wood, then you will have to complete a set of works in the following order:

- First of all, you need to decide on the type of wood;

- Then you need to prepare the trim parts. To do this, fit the array to the dimensions of the metal frame, excluding the occurrence of cracks. After taking careful measurements and marking the array, it is necessary to cut out the wooden parts.

- When the trim elements are ready, they need to be secured with a screwdriver. After installing the steps, you need to rest as tightly as possible against the riser frame and also fix them.

- When the steps and risers are mounted, the balusters should be evenly installed. You can use studs for this. Then a railing must be installed on them.

- Then you should completely sew up the side of the stairs with a panel with grooves cut out under the steps.

- After completing all the work, the wooden surfaces must be varnished or painted.

Advice!

In order not to confuse the parts, after cutting them out, they need to be numbered and a simple drawing with part numbers should be made.

Facing of reinforced concrete stairs

Finishing a monolithic staircase with wood will visually remove the bulkiness of the structure and give it elegance. In addition, the use of soft rocks will reduce the noise level of a concrete staircase to a minimum or even eliminate it altogether.

The instructions for finishing concrete stairs are as follows:

- As in the case of metal staircase sheathing, the first step is to decide on the type of wood.

- Then you need to prepare the structure for sheathing, namely, to align it. To do this, you can use a screed or logs. The polymer mixture will dry for two weeks. If the leveling is carried out with concrete, then before facing, you should wait two months so that moisture completely comes out of it.

Tip: The best option would be lags, which will help both save time and make the structure not so heavy.

- On top of the logs, plywood is installed, which has moisture-repellent properties. Sheets must be cut to size and secured with dowels, nails, as shown in the video in this article.

- Then the steps are attached to the plywood with glue and screws.

- Installation of the skirting board must be carried out strictly according to the markings. After installation, you can mount handrails and other parts of the fence.

Wooden structure finishing

Despite the fact that a wooden staircase does not need cladding, sometimes it still needs to be refined. Finishing wooden stairs, as a rule, comes down to sheathing the sidewalls, installing fences and applying paint and varnish on its surface.

Wood staircase finishes can also include wood carvings and other types of ornamentation. But, in any case, no matter what type of finish you are going to produce, you need to think about it even at the stage of material selection.

If, for example, a staircase is made of conifers, then it will be difficult to paint it, since there can be a lot of resin in the wood. If the staircase is made of beech or oak, then it is advisable to choose such varnishes that can emphasize the texture of the wood.

As other types of finishing of wooden stairs do not differ from working with structures made of other materials, we will focus on paint and varnish coatings. Today there are two types of coatings - transparent and opaque. Other materials are selected according to its type, such as primer, mastic, putty, etc.

Experienced builders recommend covering the wooden surfaces of stairs with varnish, which, when dried, forms a transparent, dense protective film. There are two types of such varnishes - nitrocellulose and alcohol.

Nitrocellulose varnishes are based on varnish colloxylin, plasticizers, resins and volatile organic solvents. Almost all types of wood products can be coated with such varnishes. They are resistant to weathering and, moreover, dry quickly.

Alcohol varnishes are made on the basis of volatile solvents and resins. This type of varnish lends itself well to varnishing and also dries quickly. However, its disadvantage is low frost and moisture resistance.

Note!

When choosing paintwork, one should take into account the fact that wood may contain chemical compounds that can react with the paintwork, which can lead to the most unexpected results.

Of the opaque coatings, oil paints are the most popular. They should be applied in several layers. In addition, enamels are sometimes used, which are most often sold in cans, which is very convenient. If you decide to apply cellulose paint, it should be borne in mind that it is not suitable for coating external stairs.

Acrylic coatings are gaining popularity in recent years. They perfectly resist light and moisture, dry quickly and are absolutely harmless to health. As a rule, paintwork is applied at home with a brush.

Output

Finishing is fundamental to the visual appeal of a staircase. In addition, it also affects the durability of the structure. Therefore, this procedure must be approached no less responsibly than the very manufacture of the stairs.