The main requirements for staircase structures are strength, reliability and attractive appearance. Therefore, not every material is suitable for making steps. Laminate finishing of stairs is very widely practiced these days, since this material has all the properties that are necessary for a high-quality surface coating.

In this article, we will talk about how to sheathe a staircase with laminate, having considered the advantages and features of working with this material.

Laminate as a finishing material

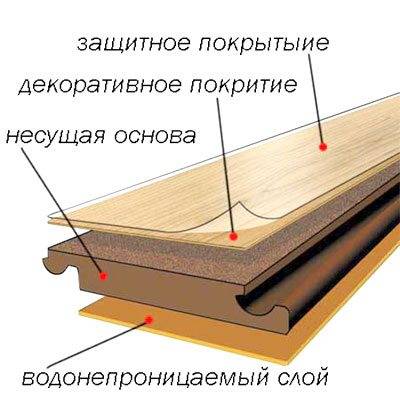

Laminate is a fiberboard-based floor covering. Rigid laminate boards have a fairly high strength, perfectly withstanding various loads, which is achieved due to the layered structure.

Such a board consists of four layers:

- The function of the bottom layer is to protect the board from various deformations.... It is a stabilizing layer designed to increase rigidity. In some types of material, a sound insulator is glued to this layer, which allows the floor covering to perfectly “dampen” extraneous noise.

- Carrier layer serving as the basis of the structure... It is made from high density fiberboard.

It is this layer that is most important in the design, since it performs several functions:

- Firstly, a lock is cut in this layer, by means of which the boards are fastened together.

- Secondly, this layer performs the main soundproofing functions.

- Thirdly, the moisture resistance of the boards directly depends on this layer, which is impregnated with special protective compounds.

- Decorative layer... It is he who performs the function of decoration. It is represented by a sheet of paper on which a pattern of wood, tile, stone or any other texture is applied.

- Top, protective layer... This is an acrylic or melamine resin coating that protects the board from abrasion and impact. The wear resistance class of the material directly depends on this layer, but recently it has also acquired a decorative function. A texture is applied to its surface to better imitate natural wood.

Coating Benefits

Decorating the stairs with a do-it-yourself laminate is the best solution for several reasons:

- Various textures and colors, so this staircase will easily fit into any interior.

- The coating is very easy to repair.

- Low price.

Laminate for stairs must meet the following requirements:

- Abrasion resistance to maintain the attractiveness of the staircase for a long time.

- Durability, since the coating will experience significant loads during operation.

- Anti-slip coating that will ensure the safety of movement on the stairs.

Advice!

To cover the steps, it is necessary to choose a product whose strength will be at least 31 class.

Recommendations for work

- The first ladder rung most often differs from other rungs, since it protrudes strongly from the ladder bowstring from the side. Therefore, it is best to make a cardboard template according to which the plates will be accurately cut, in order to avoid waste of material.

- If you do not encounter any difficulties when cutting out the steps of the marching staircase, then when starting to cut out parts for a screw structure, you definitely need to create templates. In this case, the measurement will most often have to be done from each step, after which the form should be transferred to cardboard.

Otherwise, you will reject a large amount of material by cutting the slabs incorrectly. - A durable coating can be obtained only if the staircase is completely covered with laminate sheets, since the sheathing performs not only a decorative function, but also a protective one.

Preparatory stage

Advice!

If you decide to lay laminated panels on the stairs, then you should firmly remember that they are not able to strengthen loose steps and themselves need a solid and reliable foundation.

- Even if the steps are strong enough, but have a backlash, the panels will move apart. At the same time, you cannot glue them either, since they can crack. The thickness of the panels is 6-12 mm, so this material can become a durable coating, but not a base.

- Providing laminated steps for stairs, you must first of all reliably fix the risers and treads by means of self-tapping screws, eliminating any backlash.

- Before starting work, all weak structural elements should be replaced.

- If any paintwork was carried out before finishing the stairs from the laminate, then the coating should dry well before starting installation.

Advice!

After the self-tapping screw is screwed into the tree, a small depression remains above its head.

In order for the cap not to rust when exposed to moisture, it should be closed with a wooden chopik or repaired with wood putty.

Carrying out work on laying laminate

Now let's look at how to finish the stairs with laminate.

The instruction provides for the following stages of work:

- Before you start finishing, you should consider that you can achieve the best quality if one step is covered with a single laminated panel that does not have interlocks. That is, one panel goes to the tread and one to the riser.

- Today it is possible to find laminated panels according to the tread width without any problems.

In the event that the staircase structure is multi-march, then on the sites you should lay the laminate lock in the lock. (see also the article Two-flight staircase, construction and materials used)

Advice!

In order to calculate the required amount of material, you do not need to measure the staircase at all - it is enough to know how much material should be used for one tread and riser, multiplying this number by the number of steps.

- Any package of laminate flooring contains instructions, which say that immediately before laying under the material, it is necessary to underlay the substrate. This measure allows not only to insulate the floor, but also to reduce noise. A 2 mm polyethylene backing can be used as a sound insulator.

This material has two advantages: price and excellent sound damping.

The joints between polyethylene sheets can be glued with tape.

- To adjust the panels to the steps, you can use an electric jigsaw equipped with a file for wood. However, if you want to cut a curly piece, for example, under a baluster, then you should use a narrow and durable metal file.

Also, the panels are easily cut using ordinary hacksaws for metal or wood, a hand-held circular saw or a grinder with an edging disc.

- After the sound absorber has been installed, laminated panels can be attached to the steps. Placing a staircase with a laminate itself is a simple procedure that requires only carefulness from you. For this, screws can be used, which it is advisable to choose from non-ferrous metals in order to avoid rust.

It will be quite sufficient to screw one self-tapping screw from each edge of the tread, since the panel will also be pressed against by means of a metal corner.

The risers are mounted in the same way. That is, from both edges, the panel is screwed to the base using self-tapping screws. - Since the main load on the covering falls on the edge of the panel, a laminate ladder profile is used to protect it. If such a profile is not installed, then very soon you may need a new laminate finishing of the steps of the stairs, since the old coating will become unusable.

The metal corner will also protect the material from uneven abrasion, and, accordingly, preserve its attractive appearance.

Conclusion

Facing the steps of the stairs with laminated panels is an excellent way out of the situation when the old coating has fallen into disrepair, and the base is strong and reliable. Laminate will provide excellent protection to the substrate due to its strength and durability.

At the same time, you will receive a completely new staircase at an affordable price and in a short time. In the video presented in this article, you will find additional information on this topic.