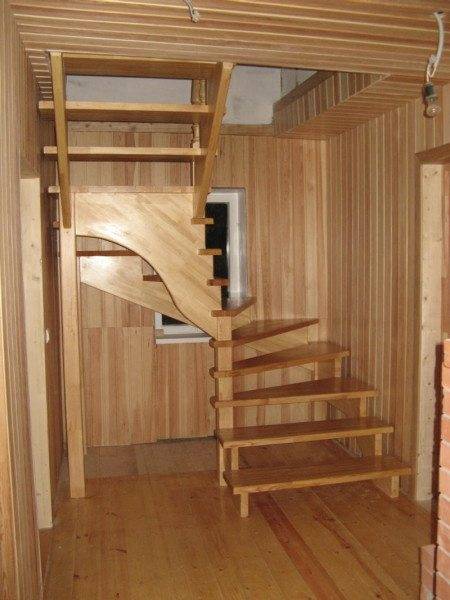

Natural wood is still the most valuable modern material in construction, especially in the construction of reliable, comfortable and light stairs, both for prestigious houses and country-style summer cottages. By the way, larch steps for stairs are the safest, because they do not slip.

The durability and comfort of a larch staircase is a unique combination of elegance and performance, in harmony with existing finishing materials. An inexpensive but very effective staircase is an organic element of the interior. And in houses with high humidity, it is simply irreplaceable.

Material features

Staircase steps can be finished with fashionable carvings, art firing and many other types of woodworking art. And it is more economical to make only steps and railings from expensive wood - the most noticeable part of the staircase.

Advantages

According to statistics, most often home owners order steps for larch stairs for very good reasons:

- the resin of this tree has excellent bactericidal properties;

- this material does not shrink and does not deform from weather and time;

- larch does not rot, as it contains tannins;

- it is a fire resistant tree, which also increases its rating;

- larch steps for stairs will become even stronger over time - this is because they are 30% denser than pine;

- the absence of knotty simplifies processing, while carefully preserving the structure of the fibers.

Device recommendations

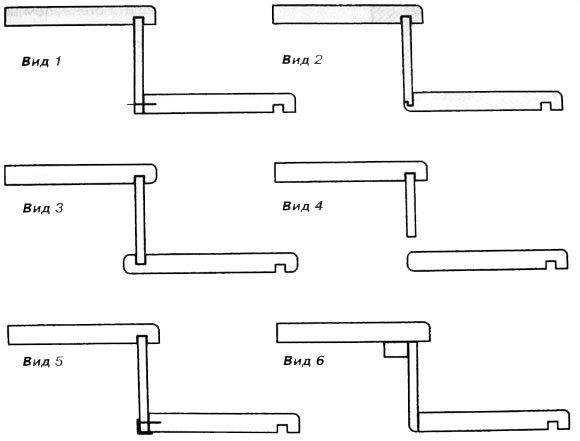

For those wishing to make such a structure, you need to remember the rules for its construction and concretize the type:

- wooden;

- combined staircase (made of metal and wood).

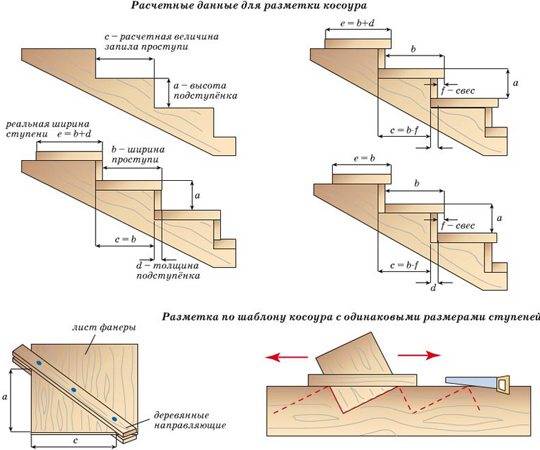

We calculate the sizes

Recall that the exact dimensions will eliminate waste of materials, speed up and facilitate assembly. Larch is not a cheap material, and each spoiled and discarded extra piece of it increases the cost of the product.

- Professional instruction will remind us of the Pythagorean theorem, familiar from school: height is a perpendicular (we have a plumb line lowered from the top of the opening to the floor). So we get the first of the legs - A.

- In terms of height, we calculate the number of steps with a height of 200 mm and divide the result by these 200 mm. With a fractional number, slightly adjust the step height to get an integer as a result.

- Then we determine the width of the step - proceed. This is up to 300 mm.

- We multiply it by the number of steps and get a horizontal projection of the stairs to the floor - the second leg B.

- According to the formula C2 = A2 + B2, we find out the length of the hypotenuse C, which is the length of the flight of our stairs.

Choosing a material

Choosing wood meticulously. Larch must be:

- no deformations, cracks, chips;

- without rusty and gray spots, green bloom, traces of bark beetle;

- the same thickness throughout the length;

- length, exactly dividing by the numbers of our calculations, then the price of the stairs will be minimal, since there is no overspending of the boards.

Advice! If there are no thick boards for the steps, we connect 2 thinner boards with dowels and wood glue, and powerful glue "liquid nails" will strengthen the steps.

We make the necessary details of the stairs

Nagel - a wooden pin that we insert into the ends of the boards to be joined.

- We drill holes in half the length of the dowel - up to 5 cm in 15 cm increments.

- Drive in the pins with a hammer.

- We smear the pins with paint and put them on the second board - we got accurate marks for drilling.

- We drill and join the boards, additionally greasing the ends with glue.

- We will process the step with a grinder.

The width of the stairs is about 1 meter.

A wider or narrower design is impractical due to discomfort, wasteful use of space and high cost.

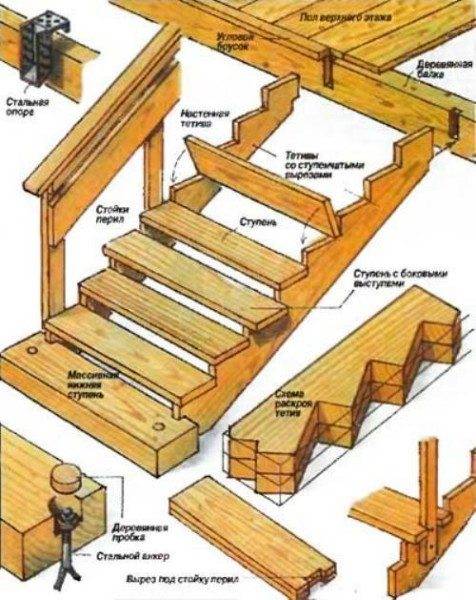

- Similarly, we make risers (from a board 25 mm thick - after all, the load is only on its end).

- We cut the stringers at the ends with an electric saw at the desired angles, when the plane of the upper such cut corresponds to the plane of the given wall, and the lower cut corresponds to the floor. After all, the wall and floor are the main supporting planes for the structure.

- We will process all the details with a plane.

- Before assembling the surfaces, except for the end ones, we will cover with a stain, then varnish. A good choice of stain will add the luxury of a valuable or exotic wood. But the wrong option will spoil the noble drawing of natural material.

Advice! To prevent the varnish from flowing onto the ends, we can glue them with tape.

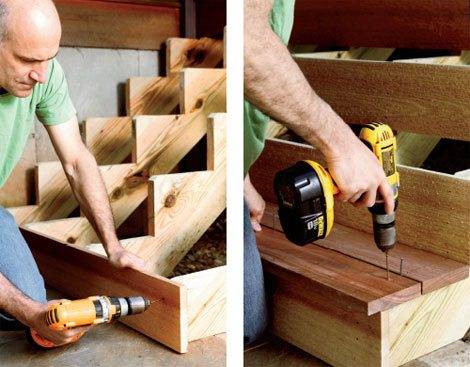

Assembling the staircase

- After the varnish has dried, start assembling.

- First, we install the stringers in parallel, while using temporary clamps - simple slats.

- Then we will mark all the sections of fastening of risers, steps.

- We will install the risers, securing them with self-tapping screws (stainless steel!). In the places of their installation, we drill recesses for the screw head. Then we will close them with decorative caps, overlays or corks.

- Then we also attach the steps.

- First, thinly coat all end connections with glue.

Output

Now the larch steps are connected with glue. In such a glued "sandwich" there are 2 to 5 layers. The popularity of such an innovation is in increasing strength and reducing wear, since the density of the entire tread increases from gluing.

The unique noble texture, colorful color scheme of the larch staircase is more advantageous in comparison with pine. Only by our own efforts will we make special decorative details, rivets, wood carvings or mosaics, bent, broken elements for risers, railings, and the video in this article will help us understand this topic (also find out what a stacked staircase is).

quite a good choice of stairs for a private house. a good plus is that the feet do not slip on such steps. also, in terms of costs, it is not so expensive.And it remains at high humidity. the absence of knots due to the type of wood is also important.

I agree with Oleg. I really like the foliage. In Siberia, we mainly have birch, pine, aspen, larch. Of all the options for strength and durability, I chose larch. For the staircase itself.