Entrance groups of private houses are made of various materials. One of the most common is concrete: structures made of it are distinguished by a variety of shapes, sufficient strength and durability. Making a concrete porch for your own cottage is easy to do with your own hands. It is enough to strictly follow the sequence of actions outlined below.

Project development

Before you make a concrete porch yourself, you need to prepare a sketch of it. In particular, it is important to find the correct dimensions for the entrance lobby. Otherwise, using the stairs will not only be inconvenient, but also unsafe.

The optimal parameters for the porches are enshrined in industry regulations - SNiP.

This instruction provides:

- The minimum width of the flight of stairs must be 80 cm... However, in order for several people to use the ladder comfortably, the distance between the railings must be increased to 130 cm.

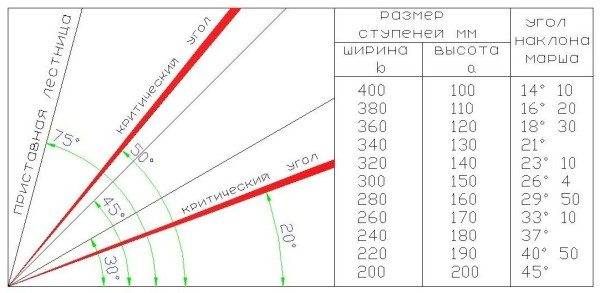

- The maximum angle of inclination of the stairs is 45 degrees... But for external entrance groups, a value of 30 degrees is considered safe. It is recommended to stick to this value.

- The number of steps in a flight of stairs must be odd.

- Tread depth - 25 cm... For the convenience of ascent and descent, it is recommended to increase this parameter by at least 5 cm.

- If you will make overhanging steps, the tread should not protrude more than 3 cm above the riser.

- The upper platform should be located 3-5 cm below the entrance... This will allow the door to swing open regardless of the presence of snow and debris in front of it.

Advice!

At the design stage, you need to think about how to decorate the porch with concrete.

In this case, the main selection criteria should be not only an attractive appearance and an affordable price, but also the safety of the materials used.

Porch construction

Stage 1. Making the foundation

The construction process begins with the construction of the base. First of all, you should clean the area in front of the entrance from debris and vegetation, and then remove the fertile soil layer. Naturally, if there is an old and worn-out entrance group in front of the entrance, it should be dismantled.

Subsequent work takes place according to the following scheme:

- A pit is dug, after which a cushion of gravel mixed with sand is set up at the bottom. This layer should be carefully tamped down to avoid further shrinkage and destruction of the concrete monolith.

- Fittings are installed. You can use metal rods with a diameter of 10 cm or other metal products suitable in shape and size. The frame is cooked from individual parts. The distance between adjacent elements is 10-20 cm.

Advice!

The reinforcement rods must be positioned so that after pouring the mortar, they are completely immersed in it.

Otherwise, the iron will react with air and water, rust and quickly deteriorate.

- Formwork is being installed. It is better to use steel sheets for this. Plywood or boards will also work, but they will need to be additionally protected with polyethylene so that the process of concrete dehydration occurs correctly.

- The solution is being poured. You can buy a ready-made one and deliver it to the object by special transport or mix the required amount using a concrete mixer.

- In the process, take care of high-quality compaction of the solution and leveling the surfaces.

- To avoid too rapid evaporation of water, it is better to cover the structure with plastic wrap for several days. It will prevent the water from evaporating too quickly, which can lead to improper strength gain.

Stage 2. Construction of steps

Making a staircase and an upper platform is not much different from the process of pouring a foundation. The main point is the correct installation of the formwork.

It must meet the following requirements:

- in the upper part, teeth should be cut out (like in a kosour), located at an angle of 90 degrees - they will serve as a guide for arranging risers and treads;

- the thickness of the boards or plywood used must be sufficient to withstand the weight of the poured concrete (it is advisable to additionally fill the formwork with bars that will play the role of stiffeners);

- the treads can be made not horizontal, but slightly inclined to the side of the porch - this will allow more efficient removal of the water entering the entrance group;

- the formwork must be protected from water - roofing material can be used, which will later serve as a waterproofing agent.

Once this step is completed, the reinforcement cage can be mounted. Here, massive rods are not needed, it is enough to place a steel wire mesh inside the formwork, bending it at the required angles.

Then concrete is poured. Thoroughly compact the mortar with a vibrating machine and level the surfaces. Subsequently, it will be easier to glue ceramic tiles or porcelain stoneware on them.

Note!

Many novice craftsmen are interested in how to make a round concrete porch.

In this case, the work is carried out in a similar way.

It is only necessary to arrange the formwork in a special way, bending steel sheets or plywood under a certain radius.

Stage 3. Decoration

The final stage of the work is finishing the concrete porch. The easiest way to give a structure an attractive look is to paint it. But it is better to spend more money and buy a special ceramic tile, which is used to cover the upper landing, stairs and sidewalls of the entrance group.

Choose a material with a rough surface. This will ensure the safety of using the stairs in winter. In extreme cases, a special anti-slip rubber tape should be glued to the ends.

And don't forget the railings. Any entrance group consisting of more than three steps definitely needs comfortable and durable handrails.

Output

By taking on the independent manufacture of the entrance group, you can save a considerable amount of money, which, otherwise, would have been used to pay for the services of a hired team of builders. A staircase in the house can be made in a similar way. For more details, see the video in this article.