In this article, we will look at how to build a concrete porch. Of course, you can always hire a construction team to complete this task, but this will require additional financial costs. If you are ready to devote a certain amount of your time to the implementation of your plan in order to save the family budget, then all the work can be done independently.

General Provisions

Why should a porch be made of concrete? Let's take a look at the characteristic features of a structure made of such a material:

Dignity

- Very high strength characteristics... A monolithic concrete structure is capable of withstanding very high mechanical loads.

- Resistance to aggressive environmental influences... Effectively resists precipitation, wind, winter frost and summer heat.

- Attractive appearance... Almost any decorative finish can be easily applied to concrete, which allows you to decorate your porch in accordance with your even the most unusual preferences.

- Availability of do-it-yourself installation work... Pouring cement mortar is, although a rather time-consuming task, but it does not require special skills of a bricklayer, as is necessary in the case of using bricks, or a joiner, as is necessary in the case of using wood.

- Affordable price... Despite all of the above advantages, this option has a relatively low cost.

Installation work

Making a porch from concrete begins with its design:

Stage number 1: drawing up a project

This, of course, is not a house or even a gazebo, so nothing complicated is foreseen, but it is still necessary to take into account some of the nuances.

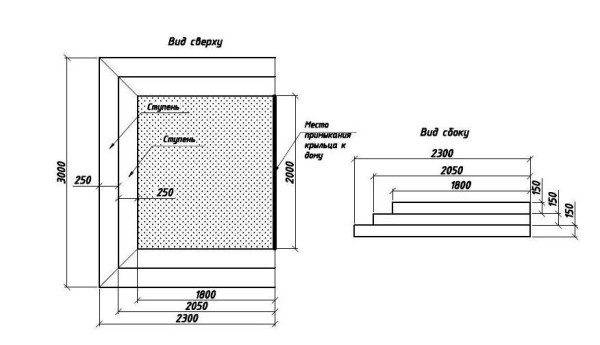

The device of a concrete porch must comply with the following parameters:

| Parameter | Meaning |

| Width | 80-120 cm, adhere to the rule that two people should be able to separate on the steps |

| Railing height | 80-100 cm, although if the design itself is low, then you can do without them at all |

| Step height | 12-20 cm |

| Step depth | 25 cm |

| Porch height | 5 cm below the doorway so that the door can open and close freely |

| Platform width | 15 cm wider than door width |

Advice: it is recommended to use an odd number of steps, since it is more comfortable for a person to start and end an ascent on the same leg.

Having decided on the dimensions, draw up a drawing in compliance with the scale, it will help you not to make mistakes when placing the formwork.

Stage number 2: tools and materials

To accomplish this task, you will need equipment:

| Name | Appointment |

| Water, gravel, cement and sand | Concrete mortar ingredients |

| Boards at least 2 cm wide | Formwork elements |

| Nails and hammer | Fastening the formwork |

| Shovel | Excavation works |

| Putty knife | Screed correction |

| Roulette | Taking measurements |

| Steel rods with a diameter of 12 mm | Reinforcement |

| Soft wire | Rebar tightening |

| Roofing material | Waterproofing |

Tip: It is recommended to use a concrete mixer to mix the mortar. It will not only simplify and speed up the entire process, but also improve the quality of the concrete itself.

Which corner for a porch made of concrete does not really matter when adjusting right angles, it can be either wood or metal.

Also at this stage it is necessary to decide on the question of how to overlay the porch? In the most economical version, you can do without finishing work at all. We will consider how ceramic tiles are used for this purpose.

Stage 3: earthwork and formwork

This is the most creative part of the whole process.

Its instructions look like this:

- We apply markings on the ground in accordance with the drawn up drawing.

- We dig a pit 50-70 cm deep.

- We fill up a pillow 20 cm thick from sand and crushed stone, after which we carefully ram it.

- A layer of roofing felt on top of the pillow. Waterproofing a concrete porch is necessary in order to increase its service life.

- We lay out the formwork, guided by the drawn up project, supporting the boards with vertically stuck steel rods or wooden planks. For reliability, we fasten all structural elements together with nails or self-tapping screws.

Advice: it is recommended to cover the inside of the formwork with a plastic foil.

This will facilitate later removal of the boards from the cement.

- We install the reinforcement in all directions with a step of 20 cm and fasten it with wire.

- At the same time, we also mount the railing posts, if they are provided for in the project.

Stage 4: concreting

- We mix a solution of cement, sand and gravel in a ratio of 1: 3: 5. We add water in such a way that the resulting substance has a mushy state.

- Pour the resulting mixture into the prepared structure.

- With a metal pin, we punch a layer of cement in different places to exclude the possibility of air pockets formation.

- We trim the upper part of the future steps with a spatula.

- We cover the structure with a film and periodically pour it with water during the solidification process.

- We remove the formwork.

In the future, the question may arise, how to repair a porch made of concrete? In case of any damage, mix a mortar of cement and sand in a ratio of 1: 2 and seal the crack or chip with a spatula.

Stage 5: decorative finishing

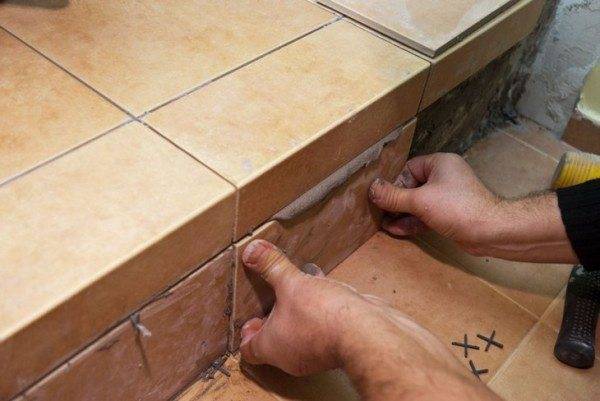

How to lay concrete porch tiles with your own hands? As well as on the wall and bathroom floor.

The process is no different:

- Apply tile adhesive to the tiles with a notched trowel and apply it to the desired place.

- We control the evenness of the finish with a spirit level.

- We put special mounting crosses on the corners, which will allow you to keep the same distance between the products.

Advice: if you doubt your abilities, then it is better to invite a qualified specialist to carry out decorative finishing, since this is not an easy task, and a mistake can ruin the appearance of the entire porch.

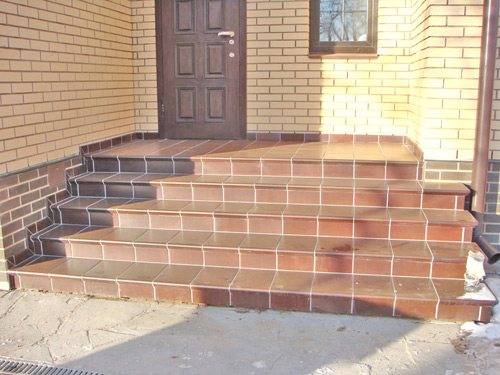

Output

The staircase to the porch made of concrete is a reliable and beautiful structure. At the same time, it is quite possible to complete all installation work on your own.

The video in this article will introduce you to additional materials. Follow these guidelines and you will succeed.