The porch is an indispensable attribute of the facade of almost any cottage. Not only the appearance of the house, but also the durability of the structure itself largely depends on how correctly it is laid. The question of how to build a concrete porch with their own hands is asked by many of our compatriots, so a sensible instruction will definitely come in handy, even if you decide to hire people, because it will be easier to control the work using it.

Preparing a project

Before making a concrete porch with your own hands, you should carefully calculate everything, prepare the tool and material. In the course of construction, there will be no time to think out and finish, so you should clearly understand the specifics of the construction from the very beginning.

Let's start by calculating the basic parameters:

- It is believed that the greater the width of the flight of stairs, the better. This is partly true, but we will focus on the minimum sizes.... In particular, a minimum of 800 mm is required for the comfortable movement of 1 person. In order for two to pass relatively freely on it, at least 1 meter is required.

- Railings are often installed only on high flights of stairs.... Low structures are equipped with handrails only as a decorative element, there is no great practical benefit from them. At the same time, the comfortable height of the handrails is made from 800 mm to 1 meter.

- Also, during operation, the angle of inclination of the staircase plays an important role.... According to SNiP standards, the maximum slope should not be more than 45º, the minimum angle can be made at your discretion, but experts advise not to plan less than 26º.

- Subconsciously, it is comfortable for any of us to step on the first and last steps with one foot.... Therefore, the number of steps must be odd. That is, 1, 3, 5, 7, and so on.

Important: so that your guests do not stumble over the steps, they are made of the same height, the allowable difference is 5 mm.

In this case, the height is selected individually, but it should be within 120 - 200 mm.

- It has been experimentally tested and calculated for a long time that the width of the step should lie within the aisles of 250 - 300 mm... Otherwise, if you deviate in any direction, it will be inconvenient to walk on such a march.

- Sometimes the edge of the step is made with an overlap., so, the size of such a visor should be no more than 30 mm.

- The top step or door plate must be 50 mm below the edge of the door itself... If you do less, the door can cling. And if you raise the door higher, you will constantly stumble over the threshold.

- Do-it-yourself concrete porch for a house is made wider than the doorway by 150 - 200 mm... These are the minimum allowable parameters, more is possible, less is not recommended.

Construction procedure

The whole process is conventionally divided into stages. First of all, this is the preparation of the tool and the purchase of material. After that, we are arranging the foundation pit and laying the foundation. The most important stage is the installation of the formwork, the installation of the reinforcing frame and the filling of the structure with concrete, but first things first.

Important: when building cottages, such a convenient material as aerated concrete is often used.

So experts do not advise building a porch from aerated concrete with your own hands.

This material is generally of little use for the porch, but if you still use it, then you need powerful waterproofing, since the material is very hygroscopic.

A few words about the tool and materials

It is impractical to buy a ready-mixed concrete mixer right away, since do-it-yourself concrete staircase the porch is poured in stages.This is especially true if the structure is high and the volumes are large enough. The best solution would be to get a concrete mixer.

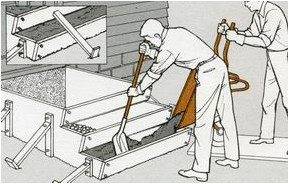

For even distribution, the concrete will need to be tamped, if you have the opportunity to take an electric vibrator, this will be ideal. Otherwise, it will have to be tamped manually. And of course you will need a traditional woodworking tool, shovels, trowel, crowbar, hammer, hacksaw or grinder.

We concrete the porch with our own hands with cement grade 400, with a strength class of B15 and frost resistance F150, its price is quite acceptable. Naturally, you will need sand and crushed stone or gravel. A standard solution is prepared in a proportion of 1 measure of cement, 3 measures of sand and the same amount of crushed stone. But keep in mind the fact that you will need sand and rubble in order to lay a pillow under the foundation.

Roofing material and bitumen mastic are used for waterproofing. For the reinforcing frame, reinforcement with a cross section of 8 to 16 mm is taken. Plus, don't forget to bring some knitting wire to it. It is not recommended to use welding, structures can lead and then your threshold will crack.

Preparing the foundation

Under the middle porch, up to 5 steps in height, a pit 600 mm deep is enough. After the pit has been dug, a pillow of 200 mm of crushed stone and 100 mm of sand is laid and well rammed. In the process of falling asleep and tamping, the pillow must be watered with water. A layer of roofing material is laid on top of the pillow, a layer of reinforcing mesh is knitted and concrete is poured.

Formwork installation and pouring

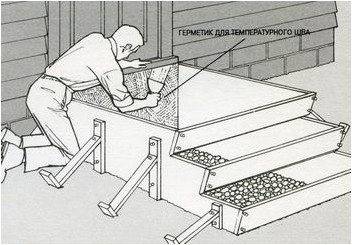

As a formwork, you can use special metal shields, but most often thick plywood or planed boards with a thickness of 20 mm or more are taken. Note that what the inner surface of the formwork is, this will be the appearance of your porch when you remove the formwork.

When installing side panels, especially if plywood is used, stiffeners must be stuffed on them, since they can be spread with concrete. From the outside, the boards are additionally supported by wooden struts. On the inside, you need to clearly mark the steps.

Next, we proceed to the installation of the reinforcing frame under the flight of stairs. On average, the width, depth and height of the cells are made about 100 mm, but this is an approximate size that can be changed for a specific structure. The corners and turns of the reinforcing frame should not be knitted end-to-end; it is better to lay the rod bent at the desired angle.

When the reinforcement skeleton is tied, vertical stops can be placed on the risers. They are attached to the side panels of the formwork in accordance with the markings. Next, the solution is poured in stages. Concrete is set within 3 - 5 days, but the final solidification occurs in 28 days.

Advice: when the concrete has set slightly, but is still wet, it must be sprinkled with dry cement on top.

This procedure is called ironing and gives a harder surface.

The video in this article shows the intricacies of installing a porch.

Output

The surface with iron can stand indefinitely, but, as a rule, a month after pouring, the porch is covered with porcelain stoneware or clinker tiles. As a result, you get a high-quality and practical concrete porch for the house + erected by your own hands, which is doubly pleasant and profitable.