Construction in the private sector sometimes surpasses all conceivable technologies, since it is not bound by the State Standards, or rather, by numerous commissions to check the rules and regulations. On the one hand, this is certainly good, but the old masters say that safety precautions are written in blood, and this is not a joke, but the prose of everyday life.

Below we will talk about the requirements that are very important to comply with when installing concrete pouring stairs, and also, as a supplement, watch the video in this article.

Calculation and installation

In any case, concrete stairs to the second floor are not just poured into the formwork prepared in advance, but you will first have to calculate its slope, the number and height of steps, and also select the grade of concrete. Its convenience, attractiveness and reliability will depend on this.

Ladder dimensions

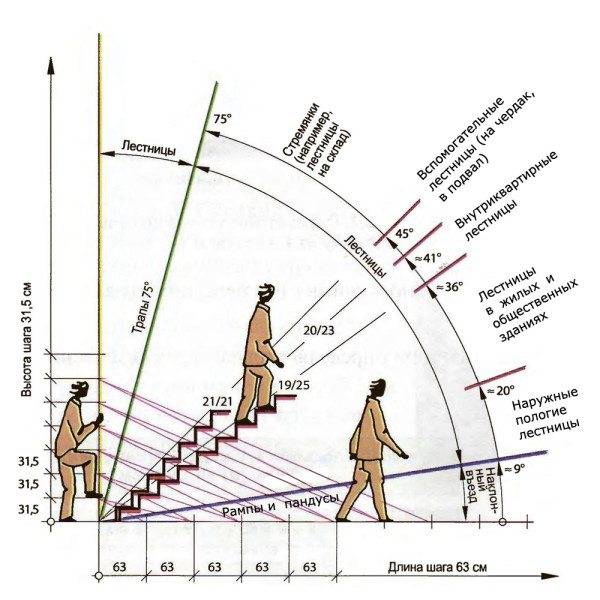

- Since we're talking about reinforced concrete stairs, then we will immediately determine the angle of inclination, which in our case makes sense from 30⁰ to 45⁰ - other options do not make sense (for residential premises) and we simply will not consider them. But one should not forget that this range has distinctive features for its perception by certain people. The most convenient is the slope from 30⁰ to 35⁰, but the long march 40⁰-45⁰ is quite tiring for children and the elderly.

- Nevertheless, sometimes it is necessary to somehow solve the problem with a large slope and most often in such cases they resort to L-shaped and U-shaped stairs - with a platform or run-in steps. Of course, screw structures are a good way out to solve the problem with a large slope and a small free area, but this is a completely separate topic.

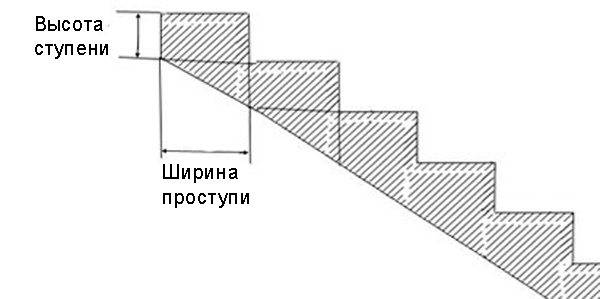

- For any slope of the span of a reinforced concrete staircase, it is necessary to calculate the number and size of steps, and convenience and safety will depend on these parameters. So, the width of the tread should be 70% of the foot of an adult, which is about 25-39 cm. In addition, you need to take into account the height, which depends on the average step of a person.

- So, a person with a height of 160 to 180 cm takes steps 60-64 cm in size, which is taken as a standard for various calculations and generalizations. To bind the step to this parameter, let's designate the height with the letter h, and the width with the letter d, but we need two heights, which means that the formula 2h + d≈60≈64 cm is applicable.If this parameter is made more or less, then on descent- Ascending, the step is confused and movement causes inconvenience.

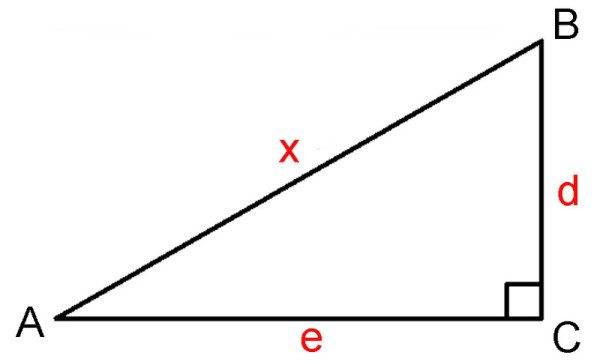

- The length of the flight of stairs or segment AB in the upper figure will be equal to the sum of the segments AC and CD squared, that is, e2+ d2= x2... Now we have instructions for calculations in the form of formulas, and we will now make demo calculations for a room where from the finished floor of the first floor to the finished floor of the second floor is 270 cm (this number was taken so that the calculation was without fractions).

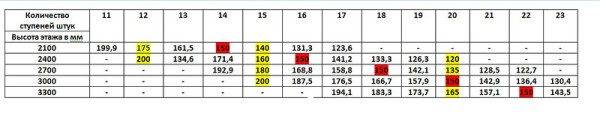

*Note. The most "" convenient "dimensions for movement are highlighted in red in the table above, and the most" "convenient" dimensions for mounting and pouring the formwork are highlighted in yellow.

- Let's try to use the table, and divide this height by 150 - we get 270/15 = 18 pieces, which means d = 15. Now we use the familiar formula, substituting 30 cm for the d value: 2h + d = 2 * 15 + 30 = 60 cm - a step very convenient for walking. This means that the segment AB = 30 * 18 = 540 cm, that is, etriangle=540.

- Now we need a segment AB or an x value: e2+ d2= x2=5402+3002= 291600 + 90000 = 381600 = x2... To determine the net value of x, take the square root: √381600 = 617.7 cm or 6.18 m in length. Of course, such a staircase will take up a lot of space and it can be made L- or U-shaped, but the slopes and steps will still remain the same, and our task is to make demo calculations.

Advice. The presence of free space, or, more precisely, its absence, does not always allow making the treads of the required width, so you can equip the run-down steps by finishing the treads with wood. In this case, the frieze will overhang by 3-4 cm, or, in extreme cases, 5 cm.

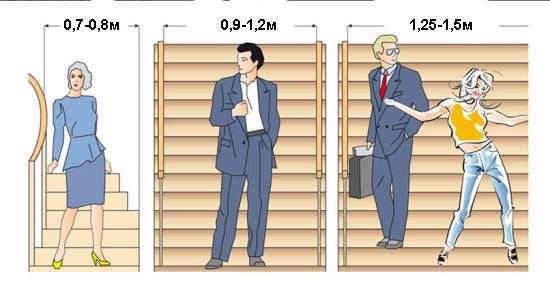

- According to GOST 9818-85 "Marches and landings of stairs are reinforced concrete" the width of the march should be at least 0.7 m, although such structures are mainly used for communications with not frequently visited premises, such as a basement or cellar. The recommended size is from 0.9 to 1.2 m, but wider spans are found only in elite and public buildings, where there is enough free space for their placement.

Recommendation. Railings on a concrete staircase are usually attached over the treads, that is, they occupy at least 5 cm on each side. This must be taken into account when calculating the width of the structure, paying attention to the final result.

Installation of formwork with concrete pouring

- After correctly performed calculations, you need to start assembling the formwork with your own hands, and we will now turn our attention to the materials. At the bottom of the formwork, as an ideal option, laminated plywood with a thickness of 10 mm or more is used - this material is waterproof, but there will still be joints when joining the sheets, which will lead to ugly scars after pouring. To prevent this from happening, the joint can be sealed with tile glue (the cement-sand mortar will not hold) or smoothed with a grinding carpentry machine.

- After installing the plywood pallet, flanging is made, which consists of the same plywood and board (in this case, a board of 150 × 50 mm is used). Fastening is done with self-tapping screws for wood, with a step of at least 30 mm, and sometimes it can be even smaller.

- When a pallet with a flange is ready, you get a kind of box in which you need to install a reinforcing cage. For this, a corrugated rod with a diameter of at least 12 mm is used, and the knitting is carried out with a soft steel wire using a hook (you can make it yourself from the same reinforcement by grinding the end onto a cone and bending it). The frame is made double - two battens with a cell of 200 × 200 or 200 × 150 mm are interconnected at the edges and grabbed after 50-60 cm in the center, but you need to try to install the structure so that the metal is covered with a layer of concrete at least 5 cm.

- For the transverse rod, you need to build vertical fasteners in order to keep the two battens forming the frame at a distance. If there is a wall on one side of the staircase, then the transverse reinforcement can be fixed in it, after having drilled holes with a puncher, and the lower part of the frame should rest against a rigid artificial barrier. There is no clear regulation for fixing the frame in the formwork, but only general requirements, which have already been described above.

Recommendation. To install the handrails in accordance with GOST 25772-83, they must be connected to the reinforcement cage of the march. Therefore, after installing the frame, take care of this by welding the fasteners on which the balusters will later be installed.

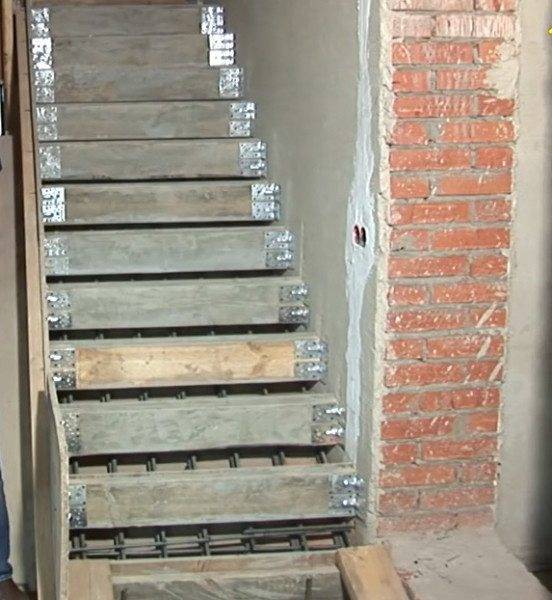

- For the formwork, the same material is used on the steps, that is, 10 mm plywood, which is fixed from the outside with the same board. Such transverse partitions are rigidly screwed to the flange and to the wall with metal corners, so that at the moment when the formwork takes on a large load, there is no shift between the elements even by 1 mm.

- In the photo above you can see the elements of the formwork fasteners, made with the same boards of 150 × 50 mm, both for horizontal and vertical supports.There are no conditions and dimensions here - the more often the supports are installed, the better the formwork will behave when pouring, since no plywood is able to withstand such a mass of concrete without additional insurance. No matter how tightly the boards are installed on the retaining elements, they must be pulled together with self-tapping screws in order to avoid even the slightest shifts when pouring.

Advice. Of course, the price of the formwork will turn out to be considerable and may turn out to be more than the cost of concrete, but in this case, to paraphrase the saying, “the game is worth the candle”, since this is not only beauty, but safety. Moreover, the formwork material is dismantled entirely, without damage and can be reused.

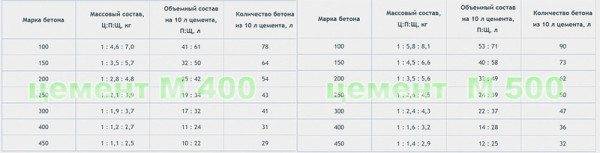

- After you have assembled and strengthened the formwork, concrete pouring begins, and you can either order a ready-made solution at any concrete unit and it will be delivered to you in a mixer at the time and intervals specified by you, or prepare the mixture yourself. For self-preparation of concrete, you can turn to the table above for help. With its help, you can make up a solution of exactly the brand you choose, although M 300 is often chosen for stairs of this design, but for mixing you will definitely need a concrete mixer for the speed of preparation so that the monolith is poured in one go.

- You need to start pouring from the lower steps, since the solution will slide from top to bottom. At each step, it is imperative to make a notch with some kind of rod (shovel, stick), or even better with a vibrator, so that there are no voids left in the monolith that weaken the structure. The steps must be smoothed out with a trowel so that when the tread hardens, the tread surface is even.

- If you are wondering how much it costs to fill a concrete staircase, then calculate the volume of each step and add it all together, and you can calculate the cost of the ingredients by their number using the table above. Formwork from the steps can be removed after 2-3 days and grout and sand. The main formwork, with pallet and supports, is removed after three weeks.

Conclusion

When you remove the formwork, you will certainly be interested in the question of how to cover a concrete staircase. To do this, use almost all the finishing materials with which the finished floor is tiled, so you have a wide choice.

we hired a team two years ago, we were building a house on the site.So our crack went in a month and a half. We are still struggling with her. So in this case, the main thing is to find a good contractor and not save like we do, it would be better if they made a good one right away. And then they have already given three times more

I urgently need help, now I’m finishing the house, we’re going to fill in a similar staircase, they thought it was a designer, but it’s just standing on an ordinary void, I’m afraid that it will not withstand such loads, can a monolith be poured in this place, some kind of reinforced one? Or am I worrying in vain? The height of the floor is exactly 3 m, the stairs will feel really heavy

Well, in principle, nothing new is described here. On my own I will add that you can save a little and when knitting a frame, a dozen fittings are perfect. We did this at the same facility about 5 years ago, everything is worth it.

Vladimir, I think it's not in vain that you are worried. It is impossible to save on such a matter. It is better to really some kind of reinforced monolith

Vladimir, it is imperative to strengthen the support points of the stairs. If there is a void, then you can reinforce the corners and put a metal rack, you just need to decide where to transfer the load from the rack.