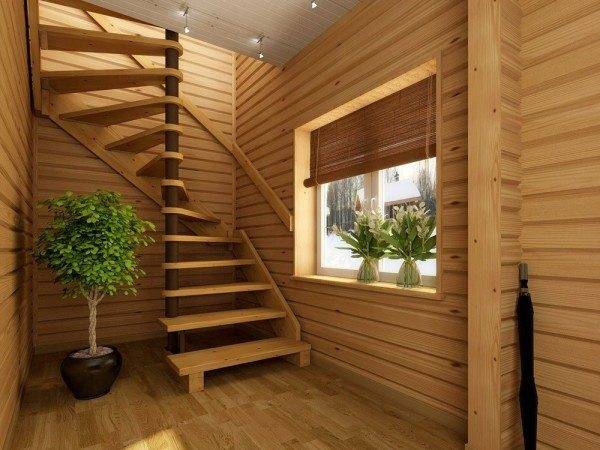

The style of the entire ensemble of suburban buildings dictates the design of auxiliary, but irreplaceable devices. For example, the cute and cozy country style wooden stairs to the country house are perfectly emphasized. Of course, its purpose is to facilitate the transition from one floor to another or to the attic, as well as to the basement.

Our tastes and the opinions of relatives are the determining criterion for the choice of configuration and materials. Although you can trust professional designers as well. And yet, a staircase made with your own hands will give an incredible charm to our dacha, and all owners of dachas have construction tools and the ability to do elementary calculations.

Design

We can go to the second floor or attic in 2 ways: outside or inside the house.

External staircase

- In the first version, before going up to the second floor of a private house, attic or attic, we build a balcony, to which our staircase, wooden or metal, leads. Reliable fastening is guaranteed by metal embeds in the concrete itself.

- The second method of installing an outdoor staircase involves welding a solid metal platform in front of the entrance to the metal march at the top. This platform is additionally supported by metal posts.

It is these two methods that are expedient and very convenient.

Internal construction

This method is especially suitable if the floor of the lower floor is wooden. It is more difficult with such a reinforced concrete floor: it is not easy to accurately cut off the required piece of the slab, then find a reliable fastener for the cut off part, if all this is not provided for in the summer cottage project.

Material selection

- It is more rational to build a front staircase without a canopy and a canopy of durable cast concrete. Although as an option - from a metal frame, but concrete steps. By the way, in basements, cellars, underground workshops are optimal to build just such eternal, sturdy staircases.

- However, experts guarantee the reliability of pine staircases in an aggressive environment with the most correct ventilation and careful processing of wood with high-quality modern chemical reagents. But the price of such an internal staircase will increase.

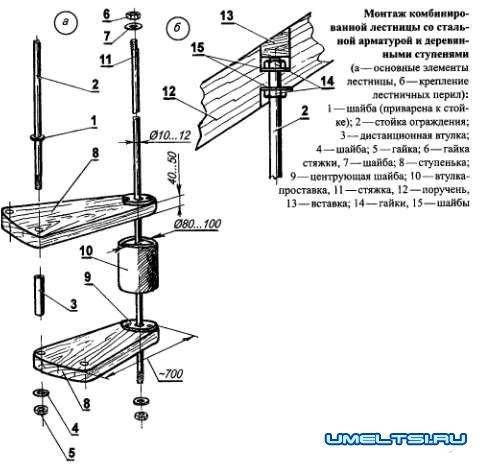

Combined ladder

Making a staircase with their own hands, many people prefer wooden steps. Railings with carved wooden balusters are spectacular, although metal forging and cast elements are also beautiful.

Calculation of elements

- The correct calculation of the amount of wood is possible with a thoughtful drawing of a wooden staircase.

- When buying, it is worth taking 20% more of all materials in order to avoid unforeseen moments and not to run after missing pieces to the store or to the base. And such leftovers will always come in handy both for repairing the stairs and for other master's ideas.

- Let's clarify that the safety and convenience of the stairs is determined by all other requirements: style, aesthetic.

- There are ready-made parts on sale - semi-finished products for future stairs.

Note! The length of the stringers of the stairs (its supporting beams) is calculated taking into account the thickness of the floor in the place of the staircase. And when building multi-flight stairs with their platforms, we also take into account the thickness of the platform.

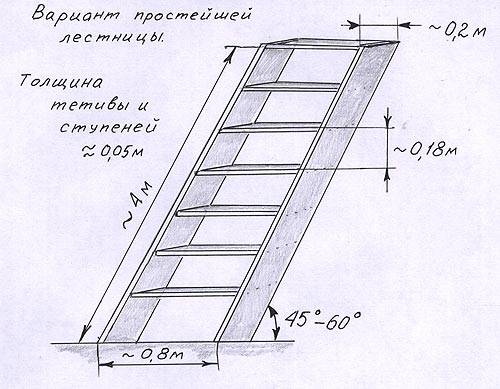

- The safety instruction recommends the optimal march incline - up to 45 degrees, although it still allows for a variation of up to 10 degrees.

- Let's clarify the dimensions of the supporting beams - at least 100x80 mm, and the thickness of the steps is more than 40 mm, the risers are over 25 mm.

Let's count the number of steps as follows:

- measure along a plumb line the distance from the very top of the staircase to the floor;

- we divide the resulting meters by 0.2 m - the height of the step itself;

- we can also change this height by 2-6 cm when receiving a fractional number of steps (but if there are children in the family, then it is better to reduce it);

- the width of the step is equal to our step, that is, up to 30 cm.

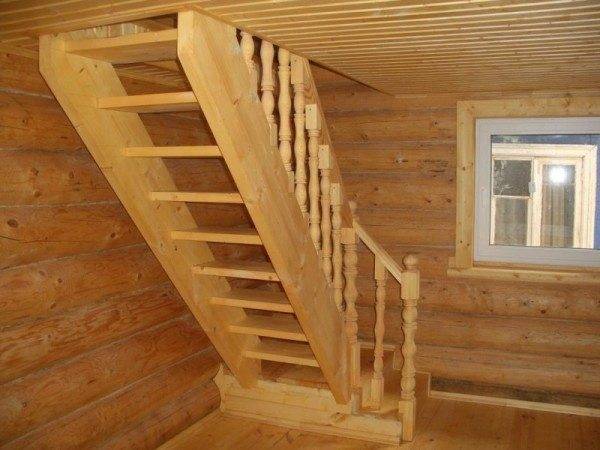

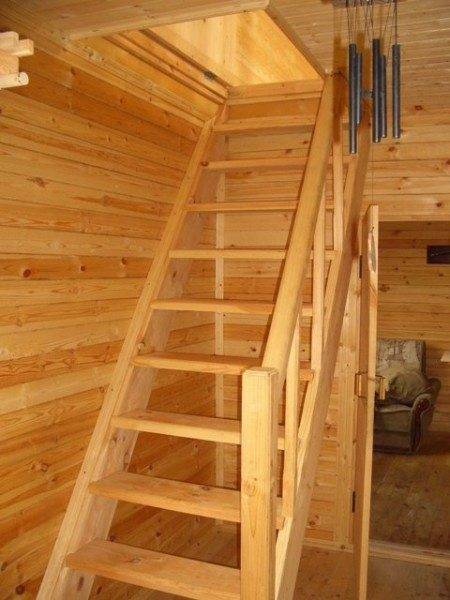

Wooden structure

Selection of material

- Conifers are more suitable for wood stairs. They are easy to process, inexpensive, but defects are immediately visible on them.

Advice! Stains, modern tinted varnishes and spectacular paints will give stairs made of such wood a very expensive, exotic look.

- To ensure safety, the bars of the load-bearing beams and step boards must be free of cracks, large knots and any other natural defects or traces of woodworm that does not react even to strong chemical treatment.

- The color of the wood is natural, without gray or greenish spots.

Mounting

The simplest wooden staircase to the upper floor up to 3 m is done as follows:

- to 2 boards of 6 m and a section of 200x40 mm we attach almost 20 m of the same boards, sawn for steps;

- march width 700-900 mm;

- we get a one-flight staircase with a slope of ½;

- we can make a slope of 30 °, but the maximum is 60 °.

Methods for installing stair steps:

- into the groove;

- on a bar;

- on the butt on nails;

- to the corner.

Metal ladder

We make a metal ladder for a summer residence by welding. Craftsmen can masterfully decorate with simple twisted or twisted wire, fittings, turning the staircase into a fantastic work of art.

Materials (edit)

- The bowstring of the structure is a channel or an I-beam.

- Also, from 2 corners, we can make a through string by connecting them in parallel.

- For a metal staircase, only I-beams, a corner or a profile pipe measuring 20x25 mm are suitable.

- For steps, a Z- is suitable, as well as an L-shaped profile, preferably corrugated.

- More economical steps made of Ø18-20 bar.

- The planes from corner 50 - 75 are also good: we weld the frame from it, and weld the mesh to it from below, then fill it with concrete.

- For steps, sheet metal thicker than 4 mm is suitable.

Output

- We assemble massive welded metal structures on site. This is how we mount complex twisted, spiral staircases with central supports.

- We also attach the console models immediately to the wall, of course, after preliminary adjustment of their parts.

- We mount all wooden and metal stairs from ready-made parts right on the floor.

- Then we install the assembled marches, which will eliminate distortions and other assembly defects.

- We need stainless bolts, self-tapping screws and all the rest of the fasteners.

The video in this article provides additional information on the topic.