When talking about a ladder, every person has long formed the phrase ladder-miracle. And this expression is not just due to the appearance of the product.

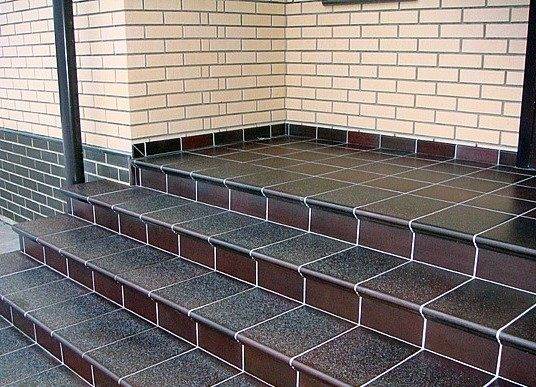

The structure can be turned into a real masterpiece, for example, if you use porcelain stoneware steps for stairs from China, which immediately transform it.

Features of some stairs

It should be understood that a staircase is not always an integral part of the house, so it can be presented as an independent element in landscape design. Agree, it is difficult to find a building in which it is not used for this. If the house has a porch, then there will definitely be steps.

They can be wood, stone or concrete. Everyone chooses according to taste and possibilities, but the steps from porcelain stoneware are one of the most competitive today.

Porcelain stoneware staircase

The material from which the stairs are made must have such operational characteristics that will allow it to function for a long time not only indoors, but also outside it.

Be resistant to temperature extremes, precipitation and abrasion. Using porcelain stoneware stair steps, you can get rid of many of these problems.

Tip: when laying porcelain stoneware steps, special attention should be paid to the corners, since the appearance of the cladding as a whole will depend on this.

Porcelain stoneware

It can be called a natural material, although in nature it does not exist as a whole. It contains clay, quartz, sand, mineral dyes, which are combined in a certain proportion at the plant.

Therefore, the technology for the manufacture of porcelain stoneware consists in grinding and subsequent mixing of all the constituent elements. Then the resulting mixture is subjected to high pressure and thermal firing.

After all technological processes, a dense homogeneous material is obtained without the presence of internal voids.

The subsequent finishing of concrete stairs with porcelain stoneware is possible due to the following material characteristics:

- Water repellency... Due to the fact that porcelain stoneware for stairs is made under high pressure, there are no cracks and cavities in it, which excludes the possibility of water getting into the steps. Thanks to this, the material has no restrictions on outdoor use;

- Chemical inertness... Porcelain stoneware is made under high pressure and high temperature (1300˚), a completely new material is created, which is not affected by many chemically aggressive compounds. Moreover, its price is lower than granite;

- Wear resistance... This characteristic is also a consequence of the complex technological process of manufacturing porcelain stoneware. On a ten-point scale of wear resistance, it has an indicator of 8. The most wear-resistant diamond is considered, whose analogous indicator is 10.

The listed characteristics make porcelain stoneware staircases durable and reliable structures capable of withstanding any weather conditions. Such products can be used both inside and outside houses.

Tip: when buying porcelain stoneware, pay attention to the absorption of moisture.

To do this, moisten the tile with water and watch the reaction. It should not be absorbed by the product.

Shapes and colors

Thanks to various fixtures and components, it became possible to create various porcelain stoneware steps for the stairs. This allows you to significantly expand the use of products.

It should be noted that the color range is also expanding due to the different surface of the steps. They can be either polished or matte.

When using porcelain stoneware products in the form of flooring, the second option is better suited. This is due to the fact that the shoes do not slip on such a surface, which means that the likelihood of falling is reduced.

Over the years, the opinion has been formed that the height of the step should not exceed 15 cm, and the lower mark should not fall below 10 cm. Manufacturers producing porcelain stoneware steps for stairs also operate with these values. All components of the staircase are made taking into account the first dimension.

Thanks to the variety of steps and stairs, the possibility of their use has increased. One has only to mention the most common - sustainer and screw. Initially, such stairs are made of different widths and heights, which means that any process of finishing with porcelain stoneware will involve adjusting the elements to the installation site.

What are porcelain stoneware steps?

Before you begin to understand the differences and preferences among the steps, you must clearly understand the subject of discussion itself. Otherwise, you can buy not what you wanted.

For example, ceramic steps for a staircase are a set of several elements that are made in the same style and make up a single set supplied.

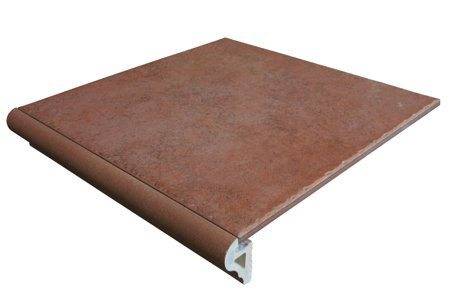

They consist of a tread, a riser and a skirting board. There are also monolithic porcelain stoneware stair treads. In this case, the riser is inextricably linked with the tread. (see also the article Do-it-yourself installation of a wooden staircase - we do the work ourselves)

Each component has its own characteristics and characteristics:

- A tread (or just a step) is a tile with cuts and embossed stripes, which are designed to eliminate the possibility of slipping. They can also be with strips of abrasive material. In this case, the surface of the tile is rough.

Porcelain stoneware steps for stairs are made solid and prefabricated. In the second case, each one consists of separate mounting elements. It is with them that the stairs are finished. The steps are also simple and curly. It should be noted that the curly edge is often made as a separate element. - A riser is a vertical wall that is located under the step. Its main characteristic is its height. During cladding with porcelain stoneware, it is this value that will be adjusted to the height of the step. It should be noted that the variety of shapes and colors of materials will give the stairs a unique and original look.

- The vast majority of stairs have a plinth in their kit. It is also used for general decoration of the premises. Therefore, if it is provided, then it should also be installed on the stairs along one or two walls.

Choice of porcelain stoneware steps

Since porcelain stoneware for stairs is a popular material, manufacturers produce separate collections and sets of steps, made in a variety of styles and having different names. When choosing steps, it is necessary to take into account the interior and the environment of the room. They should be in harmony with the elements of the already created design solution. (see also the article Interior of a hallway with a staircase - ideas and rules)

Using porcelain stoneware for stair steps, it is necessary to consider not only the aesthetic aspect, but also to understand that the process of adjusting the slabs to the parameters of a real staircase can be a big problem. Very often this moment is missed and then they have difficulties during finishing work.

It is worth considering the issue of choosing a solid or prefabricated step, usually instructions for installing them are in the package. Each type has its own advantages and disadvantages.The use of a solid step makes it possible to reduce the number of seams and butt grooves.

But you can make a prefabricated step from elements of different colors, which will make it possible to play out the violent imagination of the designer and make porcelain stoneware staircases a work of art.

The porcelain stoneware cladding of the staircase allows you to make it visually attractive. In addition, the characteristics of this material make it possible to carry out work not only indoors, but also under the influence of natural factors.

Laying ceramic steps

Any process consists of a preparatory stage, therefore, when facing the stairs with porcelain stoneware, do not forget about it.

Before you start laying with your own hands, you need to prepare the main steps:

- Cover them with acrylic. This will significantly improve the adhesion of porcelain stoneware to the natural material of the stairs;

- Check that the dimensions are correct so that you do not run into unexpected problems during operation. If a discrepancy is found, it is best to correct them using a water-cutting machine. This device leaves no chips or cracks on the tiles;

- Remove tiles from different packages and mix. Observe the recommendations for seam width. Check the color markings on the box and tiles;

Tip: When installing, leave an air gap of 3-4 mm between the ceramic corner and the riser.

- Start laying with horizontal elements, moving from top to bottom;

- Lay the vertical parts;

- Treat the corners of the steps with a plastic or metal corner;

- Fill the joints, the width of which should be 4-5 mm, with a special grout and sand them after finishing the installation.

Advice: lay horizontal tiles at an angle of 1-2 degrees to ensure an unobstructed drainage of water.

Output

If you use ceramic steps for stairs, it becomes possible to organically fit the stairs into the interior of the room. In addition, the material allows it not only to be distinguished, but to be made a center of attraction.

The ability of ceramics to be wear-resistant makes it possible to use it in places with high traffic. For example, in government agencies, at sports facilities.

The process of installing steps is not as complicated as it might seem at first glance. You just need to have the tools and patience, and the video below in this article will help you master the basic technique.

Awesome this staircase looks so cool! I want to put something like that on the transition from the first to the second floor! Everyone will be envious, it will look like in an elite mansion!

Well, it is now expensive to take from China, domestic manufacturers will become cheaper