The staircase may well be, if not the main, then certainly one of the main architectural moments in the house. Moreover, this fully applies to structures both indoors and outdoors.

Choosing a cover

The first thing that externally defines the staircase is the cladding. At least, this is what catches the eye right away.

What should be the facing: there are several possible answers to this question:

- Not slippery... In this case, the practicality of the coating will come first.

- Durable... The cladding material will be subjected to constant stress.

- Wear-resistant.

- Attractive in appearance.

Each of the above requirements is fully suitable for the material, both for external work and for interior work. You can also add that the cladding should correspond to the general design line that is chosen in the room.

Cladding options

In the matter of choosing a material, you can rely on the above facts and combine them with personal preferences. Naturally, you will have to make a serious adjustment for the type of work or the location of the stairs.

However, there is a cladding material that is ideal for both the exterior and interior - stair tile on the steps.

Today, the most popular and demanded in repair and finishing works are ceramic and clinker tiles.

Clinker option

This material originates in the Netherlands, it is this country that is a kind of "parent" of clinker products, which were originally used as a material for paving roads, as it turned out to be strong and quite durable.

Later, clinker became widespread in the construction and finishing industry, including in the finishing of staircase steps.

Clinker is a completely natural, natural material that is obtained by mixing several varieties of elastic clay. Then the product is given the desired shape and firing occurs at high temperatures, up to 1300 C. This produces a perfectly flat tile surface, without voids inside and without impurities.

We can say that clinker tiles for steps stairs gives hollow freedom for architects and designers. Moreover, the properties of this material are perfect for cladding outside, and the only product that can compete with clinker is natural stone.

The main properties include:

- Ability to withstand heavy loads.

- Natural production, environmental friendliness.

- Thermal insulation performance.

- High resistance to atmospheric precipitation.

- Frost resistance.

- Resistant to acid and salt.

- Low moisture absorption.

Self-installation

You can put clinker tiles with your own hands, and this is quite simple to do. The whole process consists of several stages.

The first stage is the preparation of the foundation. A concrete or brick staircase must be free of debris and the surface must be dry and level.

Advice! If there are small defects on the surface, you can seal them with glue, on which the tiles will be laid.

For work, you need either glue or a regular cement mixture, technically, both of these options are suitable. However, it is easier to work with glue for those who do the laying for the first time and do not have all the necessary knowledge.

When buying an adhesive composition in hardware stores, it is imperative to clarify that it should be intended for laying a certain material.

Some tools are required for installation:

- Rubber hammer.

- A notched trowel, a regular metal one is quite suitable.

- Cutter.

- Building level.

- Tile crosses.

- Drill and mixer attachment.

The glue is diluted according to the manufacturer's instructions and mixed with a drill attachment until creamy. Then it is applied with a notched trowel to the surface of the step.

Advice! When working on a flight of stairs, laying begins from the top step and goes down. This is the only way for already tiled steps to remain intact until completely dry.

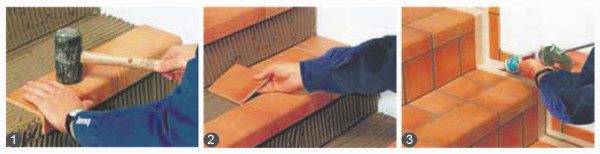

Next, the first tile is placed on the glue, of course, its position is checked by level. You can gently knock on it with a rubber mallet, thereby leveling. The second piece is placed in the same way, in addition, crosses are installed between the two products, which determine the thickness of the future seam.

Clinker tiles on stair treads require the obligatory use of a corner, which is installed at the corners of the steps. You can use a simple, budgetary option, a plastic corner, or a more expensive metal one, it all depends on the design of the stairs.

Important! The protruding glue must be removed immediately, and, if possible, as soon as the step is laid out, wipe the tile with a damp cloth.

The jointing is processed with a special grout for joints, and it can be not only white.

Ceramic option

The choice of ceramic tiles should always be approached responsibly, because these are not just external indicators, but also a coating that will be in use for a long time.

The main problem of any staircase is high wear and tear, so absolutely all experts advise to choose a material for facing steps that fits the definition of "public use". The service life of this type of coating is much longer.

Ceramic tiles for steps and stairs must have certain qualities, which, however, are in the main properties:

- High strength... The tensile strength of a tile product can be 10-12 times higher than cement and reinforced concrete. The main thing is to correctly lay the material, then the strength will be maximum!

- Rigidity... The material is able to withstand severe pressure and stress, while absolutely no deformation is noted. Rigidity here increases in proportion to the thickness of the product.

- Refractoriness... Even after prolonged exposure to fire, the product does not burn and does not emit toxic gases.

- Color fastness... The material does not change color even after prolonged exposure to sunlight.

- Electrical insulation and antistatic... If we compare tiles with a synthetic coating, then there is not the slightest option for the formation of a static discharge. In addition, even if a cable is laid under the ceramics, you do not have to worry, there will be no electric shock even when the wire is exposed.

- High resistance to chemical attack... The only compound that can harm tiles is hydrofluoric acid.

- Hygiene... Microbes and bacteria do not linger on the surface of the product.

There is also a minus of this cladding option, the fact is that ceramics always have high thermal conductivity. And if in the device of a stove or underfloor heating, this is a huge plus, then for a staircase, on the contrary, a minus. Barefoot on such stairs is not very pleasant to walk, it is constantly cold.

The nuances of selection and installation

Basically, the nuances of choosing the type of ceramics relate to the types of work, if it is an exterior, then it makes no sense to choose a gloss, which, moreover, in the winter season turns into a perfectly sliding surface.

The best option for all types of work is matte tiles. It is non-slip, durable and has a rich color palette.

The instructions for installing tiles are practically no different from the above-described method of working with a clinker product, and, nevertheless, it is necessary to make some clarifications:

- It will be correct to lay the glue on the vertical plane first. It is on her on the steps that the greatest load is placed.

- It is necessary to leave a gap between the rows under the corner.

- The seams are determined by crosses, and you can choose a fairly wide jointing.

The seams can be sealed not only with a special grout, but also filled with a sealant if the joint is supposed to be white.

From tools for masonry, you can use the same as for clinker, only if there is no ceramic cutter, here you can use a grinder with a diamond disc.

And yet, a lot of controversy is occupied by the moment of joining the horizontal and vertical seams. On the one hand, the requirements of the appearance imply an even seam guiding and its full compliance in any plane.

However, this again raises the question of expediency regarding the strength of the vertical masonry. In order to strengthen it as much as possible, jointing can be done like a brick ligation, that is, not to connect the vertical and horizontal seam in one line.

Output