A simple wooden staircase made with your own hands and designed with your own brains is a pride for every artisan, and the guests of the house have something to show, having received well-deserved praise.

The construction of wooden stairs with your own hands can be divided into several stages:

- Acquaintance with the types and types of flights of stairs.

- Updating or obtaining new knowledge on the requirements of normative and regulatory construction documents for these types of structures and their fences.

- Selection of material for staircase elements made of softwood and hardwood;

- Measurement of the space allocated in the house for the staircase.

- Selection and calculation of the staircase itself, in accordance with the current recommendations of GOST and SNiP.

- Purchase of quality lumber.

- Correct processing (cutting out elements, grinding them, impregnating, painting) and direct assembly of a wooden staircase with your own hands.

Construction documents, norms and rules

To take into account the safe and convenient standard sizes of staircases and their fences even at the design stage, first read the problem-oriented information in the construction documentation, which regulates these characteristics:

- NPB 245 - 2001 and GOST R53254 - 2009 “Fire fighting equipment. External stationary fire ladders. Roof fencing. General technical requirements ".

- SNiP 2.08.01 - 89 "Residential buildings".

- SNiP 31 - 01 - 2003 "Residential apartment buildings".

- SNiP 31 - 02 - 2001 "Single-family residential houses".

- SNiP II - 25 - 80 "Wooden structures".

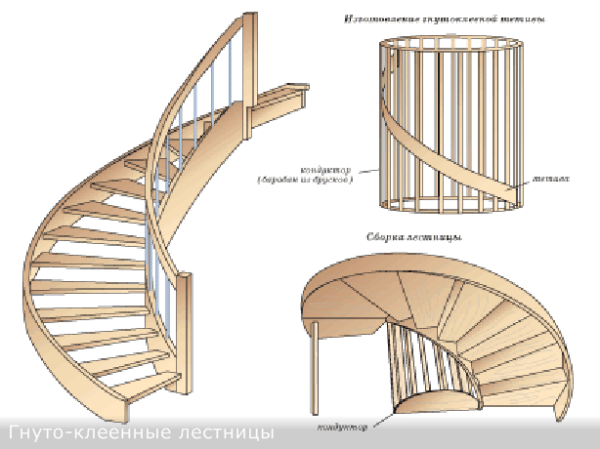

If you are going to build labor-intensive, but advantageous for the interior, bent-glued stairs or their elements, then check out GOST 20850-84 "Glued wooden structures".

The choice of construction lumber

When we build a wooden staircase with our own hands, then the selection of construction timber, with which we ourselves will have to work, must be treated responsibly and competently. Mistakes when choosing a tree are fraught with low durability of the ladder, its constituent parts and assemblies.

Note!

Some wood, selected as a building material, will purify and disinfect the air in the premises of a residential building.

For example, cedar is a medicinal tree that kills pathogenic bacteria, is rich in essential oils and phytocides, which have a beneficial effect on the human nervous system.

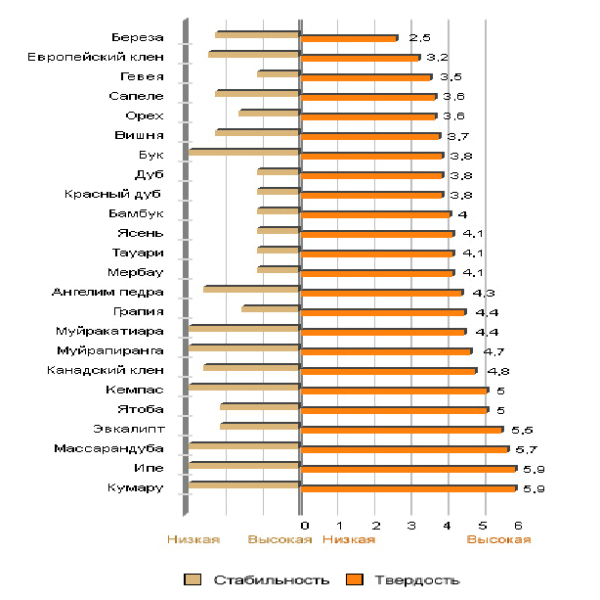

Do-it-yourself wooden staircases are recommended from hard and durable types of wood, such as:

- oak - practically suitable for the manufacture of all constituent elements of staircase structures;

- larch;

- beech;

- cedar.

The price of these types of wood is relatively high, for example, in comparison with spruce, pine, fir, but the potential of their operational and consumer characteristics (wear resistance, durability) is higher.

Note!

It is strongly not recommended to use as a material for steps, light for carpentry, but easily abraded soft coniferous wood.

Having chosen the type of wood for construction lumber, in terms of mechanical properties (density, strength), pay attention when purchasing it:

- its moisture content (an acceptable indicator for dry sawn timber is 12 percent);

- on maturity, structure (presence of knots, cracks, wormholes and other violations of integrity, biological flaws and violations).

Note!

It is believed that it is more correct to carry out the entire structure entirely from the same type of wood.

Choosing the type of stairs

When a staircase is being built with your own hands from wood, then at the stage of choosing the type and shape of staircase structures, the following factors must be taken into account:

- Place and dimensions of the space allocated for the staircase (length, height, possible maximum and minimum angles of inclination of the march);

- Operational purpose of a wooden staircase:

- external structure, for example, entrance for a porch;

- internal marches, between floors;

- auxiliary ladders, for example for cellars, basements, attics.

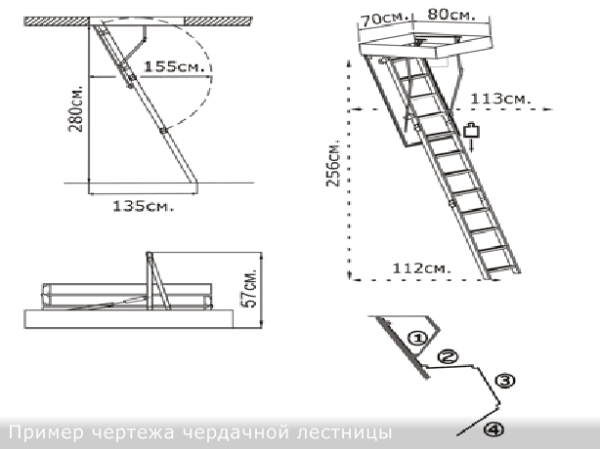

Stationary, folding or sliding attic stairs (retractable into the ceiling of a staircase with a hatch) are usually used for not frequently visited rooms of the upper attic floors and in conditions of a large deficit of space.

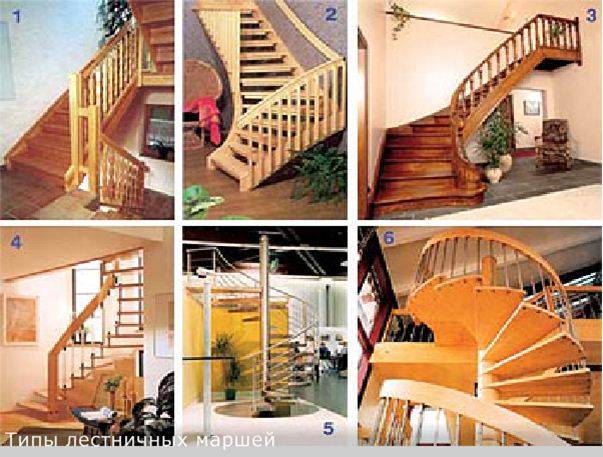

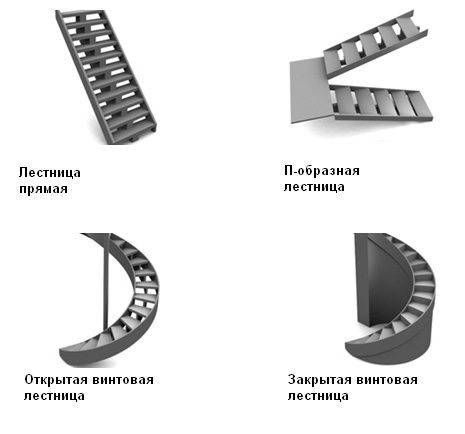

- The shape of the staircase, which is safe, convenient for use, will fit into the space allocated for it, and will organically look in the interior of the room:

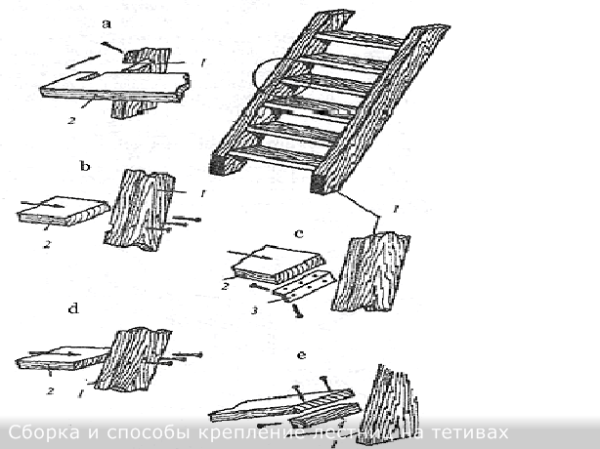

- marching, for example, on bowstrings, when the ends of the steps are adjacent or embedded in a beam, or on kosoura, where inclined bearing beams support the treads from below;

- screw and its spiral analogs (involute);

- combined.

- Selected method of fastening ladder elements (steps, load-bearing beams and nodes):

- on stringers or bowstrings;

- on the central bearing rod, beam, casing (screw and their spiral varieties);

- on bolts (console self-supporting options);

- combinations of fasteners.

Calculation of flights of stairs and the size of its elements

Having decided on the place for the staircase, with the type of march, we proceed to its calculation - the length of the carrying stringer, the determination of the number of steps (misdemeanors) on it, their size. Consider the calculation procedure, widely used in construction, stairs on kosoura, although the calculation for other types of marches is similar.

Instructions for calculating a flight of stairs, without "fillies":

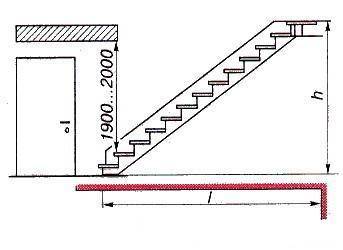

- Before calculating and making wooden stairs with your own hands, you need to decide on the location and dimensions that the staircase will occupy.Taking into account the convenient for operation tilt angle range of 23 - 37 degrees, we measure and determine with the following values at the installation site:

- l - The length of the horizontal projection of the march on the floor (one of the legs of the ladder triangle).

- h - The vertical distance between the two upper levels of the finished floors of the floors, which will be connected by a flight of stairs (another leg of the staircase triangle).

- We determine the required length of a solid beam blank (at least 80 mm thick) under the kosour, as a hypotenuse in a right-angled triangle with the well-known legs l and h (according to the Pythagorean theorem).

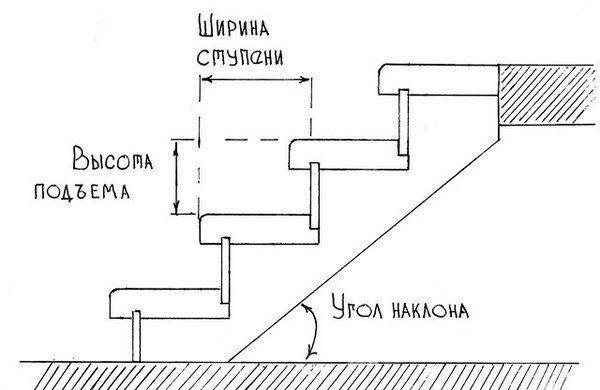

- We calculate the number of steps (50 mm thick). Knowing that the safest, most comfortable for a person, treads with a depth of 250 - 400 (mm), we choose the optimal size for ourselves from this range. We divide the length of the stairs by the selected size and get the number of steps.

- Determine the dimensions of the riser height, dividing the height of the stairs (h) by the number of previously calculated steps. Convenient, ergonomic riser height ranges from 120 to 220 (mm). Comparing the calculated and recommended values, we choose a specific compromise size.

- Taking into account the free space at the installation site, the size of the staircase to the upper floor, we choose the following staircase standards:

- The width of the staircase is at least 600 mm, and the comfortable one is more than 900 mm.

- Height of fences - not less than 900 - 950 (mm), safe from 1000 mm ..

Note!

When choosing the width of the staircase, do not forget to take into account the fact that the pillars and balusters under the fences will hide 5 cm.

Layout of the load-bearing beam for joinery processing for kosour

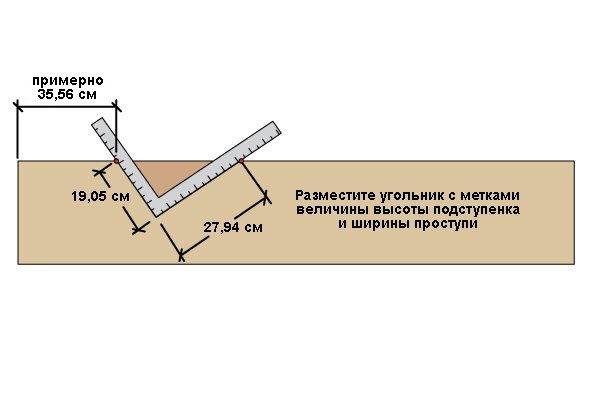

The stages of marking a beam or board are as follows:

- Using a square with a right angle, we mark the places of the cutouts for the steps. After marking the first step, moving the square along the length of the workpiece, we outline all the corners under the steps, which we then cut out with a saw.

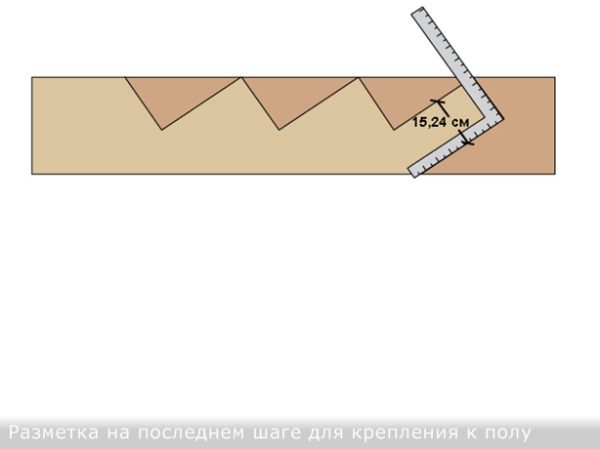

- We make markings at the bottom step, taking into account the fastening of the supporting structure to the floor.

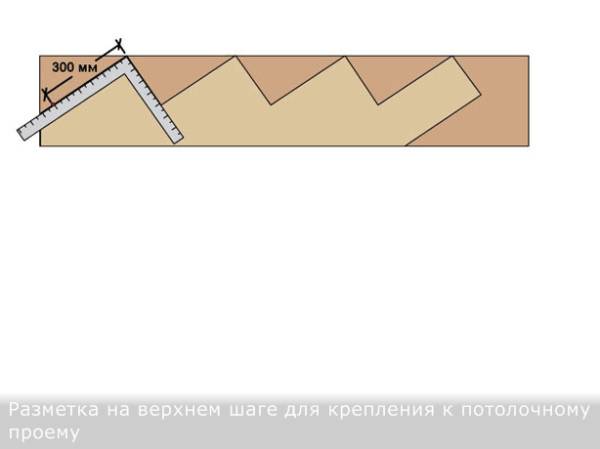

- We mark the upper step of the kosour for adjoining the ceiling opening (the supporting beam of the opening).

Methods of fastening the elements of the staircase

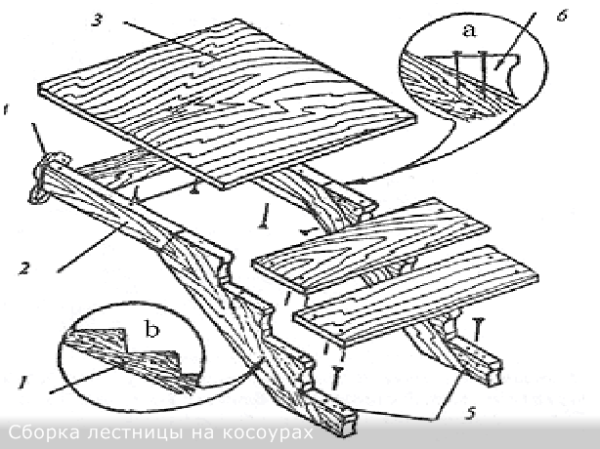

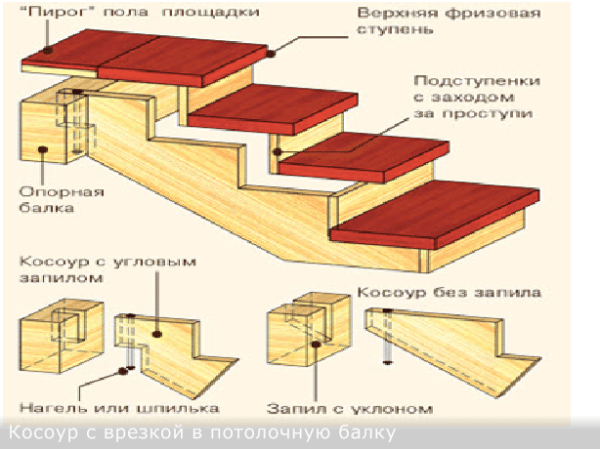

The steps can be attached to one (central), two or three kosour, directly to it or to "filly" (additional stuffing elements attached to the kosour with wooden dowels or hardware).

The very assembly of the stairs on the stringers is not particularly difficult, the installation of flights of stairs on bowstrings is more difficult.

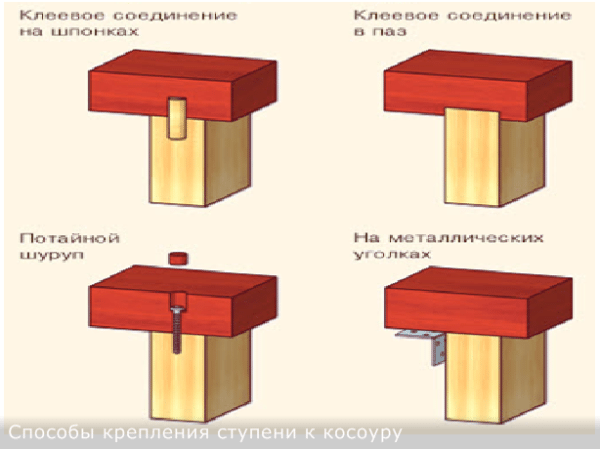

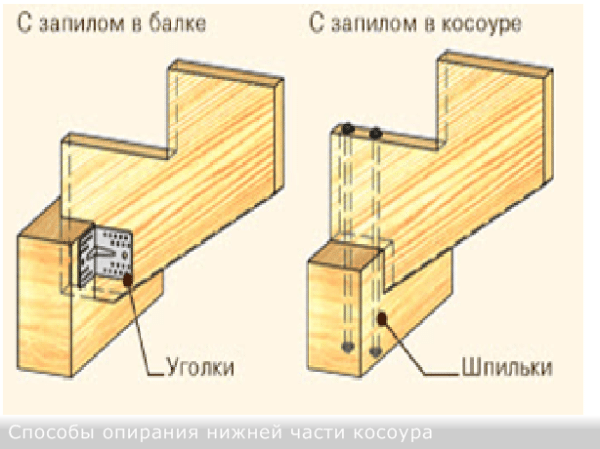

After carpentry processing the marked beams, sawing out steps from lumber with dimensions for the calculated march, we determine the method of fastening the steps, bearing beams and boards of marches to the floor and ceiling. We select standard sizes of fastening hardware (nails, screws, anchors, bolts, self-tapping screws), pins, studs, metal corners or wooden blocks, carpentry adhesives.

Fixing steps

Do-it-yourself assembly of wooden stairs is carried out using a drill with a set of drills for wood and metal, a screwdriver, a hammer, a hacksaw and a chisel with a mallet (for sawing and adjusting the tight fit of elements), screwdrivers, a dobolnik, a file. It is not a fact that you will need all this set of tools, but it never hurts to have it handy when installing wooden structures.

Note!

Now you can buy a multifunctional power tool, convenient to work with wood (and not only), with batteries, with versatile equipment for sawing grooves, grinding.

Fastening the stringer to the ceiling

You can use metal corners to adjoin the stringer (without cuts) to the ceiling support beam.

Fastening the march to the floor

Note!

With heavy and large staircases, it is safer to use its support on the floor slab, using saws on the stringers.

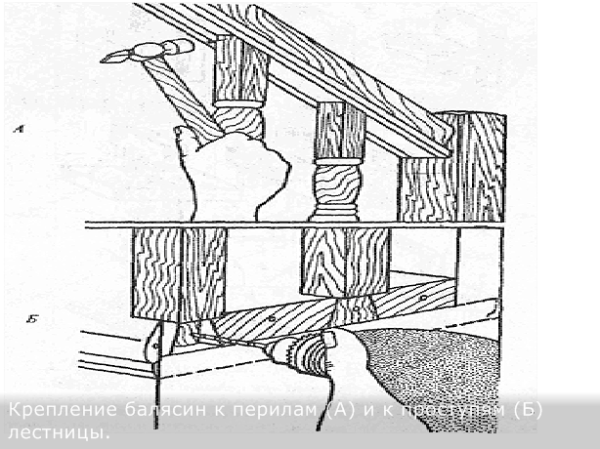

Installation of stair railings

You can get more information on the topic by watching the video in this article.

After the final installation and staircase construction, especially from straight flights on a bowstring and stringer, it is worth considering the possibility of using the space under it. So, a dressing room under the stairs - made with your own hands in the country - is not a bad idea for a rational and functional arrangement of the space under the stairs.

conclusions

Read the recommendations and requirements for the safety of construction documents (norms, rules) before designing and building stair structures and their fences.

When choosing a balance between the beauty, comfort and safety of a staircase, balance towards the last two positions.

I made my staircase out of foliage, I wanted a spiral staircase, but it didn't work out, somewhere in the middle, I still got a kink. I ordered balusters and capital from cabinetmakers, the rest is all by myself. it turned out well.

With such prices, the only thing left is to make a ladder with your own hands. and why do I need those norms and rules, they only complicate the work, I’ll better watch myself a video and immediately start working.