Monolithic concrete stairs are a practical solution for a private house. While they are not yet as common as traditional designs, they are gradually gaining more and more popularity.

There are many reasons for this, because concrete is rightfully considered the most durable of modern building materials. It is not easy to build a monolithic concrete staircase with your own hands, but if you have some experience, it is quite possible to cope with this business, even without the involvement of specialists.

Advantages of concrete stairs over analogues

Monolithic concrete stairs are good for a private home for many reasons. These complex architectural structures are not only very durable, but also beautiful, so they can become a real decoration.

The main and obvious advantages of monolithic reinforced concrete staircases include the following:

- Absolute security. Unlike wood, concrete does not rot and is not at all afraid of various pests. A rotten fragile step of a wooden staircase can result in serious injuries, and a concrete base can withstand even very serious blows of fate;

- Concrete does not burn, therefore, the use of this material for interior work increases the fire safety of the house;

- Such a staircase will be completely silent. Even if you use wood for decoration, the steps will not start to creak even after many years of use;

- The reinforced concrete staircase will remain intact as long as the house itself exists. This is an almost timeless material that can be easily restored to its perfect look with the simplest cosmetic repairs;

- The ability to create various design options. Concrete allows you to create screw, marching, curved and other structures that can be found in any house. In addition, all finishes and a wide variety of materials will be available: it is easy to decorate the steps with tiles or natural stone, wood or plastic cladding, etc.;

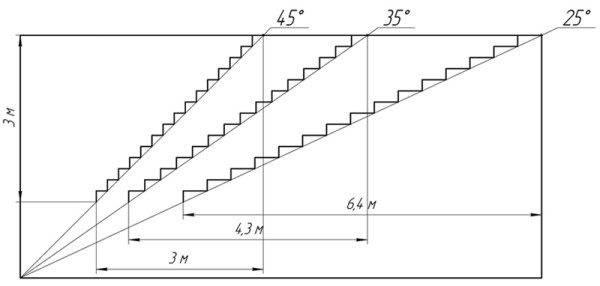

However, it should be noted that monolithic flights of stairs require a lot of space. The shorter the span, the more steep the steps will have to be made, so it is worth considering this issue carefully, or better, agreeing it with a professional architect.

Staircase design requirements

The calculation of a monolithic staircase is not an easy task, since many factors and safety requirements have to be foreseen. This is the only way to ensure that the staircase is not only beautiful, but also comfortable.

There are building codes that are fully applicable to such structures. When designing, it is worth considering the following factors:

- The distance from the ceiling to any step should not be less than 2 m;

- The angle of inclination of the ladder should not exceed 45 degrees. This is an important point because the optimum tilt is considered to be 30 degrees. Too steep steps will turn out to be very inconvenient for climbing, and if there are elderly people in the house, then such a staircase can be traumatic;

- The width of the step must be comfortable, so it is at least 30 cm. Otherwise, an adult will not even be able to completely put his foot on the step. The width of the march should be such that two people can easily disperse on the stairs. Then it will not be difficult to carry some large-sized object up it;

- Concrete is a heavy material, so the total weight of a monolithic staircase can eventually exceed 2 tons. Think about whether the foundation can withstand such a load, and whether additional concrete foundation is needed;

- The height of the fence should subsequently be at least 90 cm, and if children live in the house, then the distance between the railing posts must be closed with something;

- If marble or other slippery material is used for cladding, the staircase must be provided with a special coating of rubber or carpet.

Important! Do not neglect safety requirements for the sake of aesthetics. Even the most reliable ladder requires certain precautions.

How to make a monolithic staircase?

Do-it-yourself monolithic staircase will be a great decoration for your home. Its installation is carried out in several stages: this is the preparation of the formwork, the assembly of the reinforcing system and the actual casting of the steps. Step-by-step instructions will tell you how to make a monolithic staircase in your own home.

Formwork preparation and installation

The formwork can be purchased ready-made, in this case it is guaranteed to be smooth and very reliable. However, there are not always opportunities for this, and most often the formwork has to be assembled independently.

This will require a timber beam with a section of 100x100 mm - racks and support beams will be assembled from it. You will also need edged or unedged boards, from which the formwork for the steps will be assembled. You will also need a waterproofing layer that can be made from plastic wrap.

The formwork is assembled using self-tapping screws and represents the base of the future staircase. This means that it completely copies it in terms of the size and width of the steps. In addition, the smoother the formwork, the easier it will then be to trim the finished staircase with tiles or any other materials. To make the steps strictly horizontal, the correct location of the formwork steps is checked by the water level.

Monolithic spiral staircases are especially complex in design, as they require considerable experience in carpentry work and accurate calculation. In any case, the supports must be very strong so that the formwork can support the weight of the concrete solution.

Installation of the reinforcement system

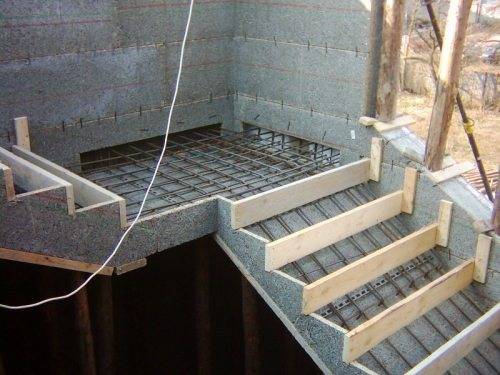

To give strength, the concrete structure must be reinforced. For this, metal reinforcement A400C with a section of 8 to 14 mm is used. Stairways must have a mandatory double reinforcement, as they will have an increased load. The spacing between the rods should be 200 mm, where the platform will be mounted to the walls, the reinforcement spacing is reduced to 150 mm.

The photo shows how a properly reinforced monolithic staircase should look like. A double layer of reinforcement at the sites significantly increases its strength and durability. Drawings of a monolithic staircase should take into account that its thickness usually does not exceed 200 mm.

Pouring concrete mortar

It is preferable to perform monolithic steps for stairs in 1 day so that the solution does not freeze. For this, it is better to prepare a sufficient amount of concrete solution in advance, and several people are required to complete the work.

The composition of concrete for monolithic stairs usually includes 1 part of M400 cement, 2 parts of sand, 4 parts of crushed stone, water and a plasticizer to make the structure more smooth.

When making a solution, it is better to use a concrete mixer, as it will help to significantly speed up the process. The solution is carefully distributed over the steps and leveled.

Important! The smoother the step, the easier it will then be to lay the finishing material on it. Until completely dry, the steps are covered with plastic wrap.

The video in this article will show in detail the process of reinforcement and creating a full-fledged concrete staircase, which will stand without the need for repairs for many years:

Concrete staircase finishing

The total cost of a self-made monolithic staircase will depend on the final finish. There can be a lot of varieties: wood cladding, natural stone, and other modern materials.

Handrails and the fence itself provide ample opportunities for decoration. You can use a forged pattern of curly metal lattices, which is often a real work of blacksmith's art.

A staircase for a home will become not only an obligatory functional addition, but also an elegant decoration. Wooden trim looks great in combination with wooden railings. Although wood is used for the steps, thanks to the solid base it will not start to squeak after many years.

The facing of the steps with porcelain stoneware looks beautiful. However, such coverage is quite expensive, and it is important to correctly calculate the financial capabilities.

Conclusion

A concrete staircase is a reliable, durable, but at the same time very beautiful structure. A little building skill is enough to decorate your home with a solid staircase that will last for decades. The variety of finishing options will allow it to harmoniously integrate into any interior.

Once I had to deal with a monolithic staircase ... I thought that we had grief, we took it for the first time)

The staircase was straight, everything, in principle, turned out well, but !!! be sure to think about how you will compact the concrete mix (this is a must), in general, nothing super complicated.

Denis, it seems to me that such monolithic stairs are the most reliable in design and durable to the same. And the cladding will be made of wood.

Denis, in our village, one family has rebuilt a luxurious two-story house. It is noticeable already at the entrance to the village. They decided to build a monolithic staircase, but this decision was made after the foundation was laid ... in the end, this staircase fell through. The whole village was laughing, now this is one of the most popular anecdotes in our country.

140, minus 10-15 for the pole, minus 7.5 for the railing. That leaves 120, or 60 for the usable width of the stairs. Expand at least 160.

In general, if they were concreted, it didn't go where, the tree creaks, the piece of iron springs a little, you can't do it hard, but the monolith is solid. And if your hands are not made of well .. then you can beautifully sheathe, even with natural stone, even with wood.

Of course, you can try to make monolithic stairs durable yourself, in our time this is the only way out, with our salaries ..Guys, who has already done this, how much did it cost?