The staircase is one of the most important elements in the house. It must be reliable, safe, have a good appearance and have precise dimensions for ease of use. That is why a concrete staircase with your own hands must be made in compliance with all installation standards and safety precautions, and at the same time it needs correct calculations and design solutions to give the structure beauty and strength.

Concrete products

First of all, it should be noted that this type of construction is considered one of the safest and most reliable. They do not burn, are not exposed to moisture, are among the strongest and most durable spans, and can also withstand heavy loads.

It should be noted, however, that finishing concrete stairs with a tree with your own hands can give it not only additional reinforcement, but also a stunning appearance, and if you use forged elements and natural stone as additions, then the whole structure can become a real work of art.

Project

Calculations always underlie any construction and repair, since it is on the basis of them that all work is carried out, which allows you to create precise structures of high strength (see also the article Staircase lighting with LED strip: implementing an unconventional approach).

However, when creating concrete stairs with your own hands, it is necessary to pay increased attention to this stage, since not only the appearance and ease of use depend on it, but sometimes the health of the residents of the house.

- First of all, you need to decide what the width of the stairs will be.... It is worth noting that for this there are certain parameters that may not always meet the needs of residents. Therefore, the width of the span should be determined based on personal preference.

- Also, a guide telling how to make a concrete staircase with your own hands suggests doing the height of the steps. However, it is necessary to take into account the coating or skin layer, if any.

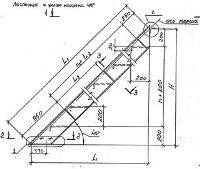

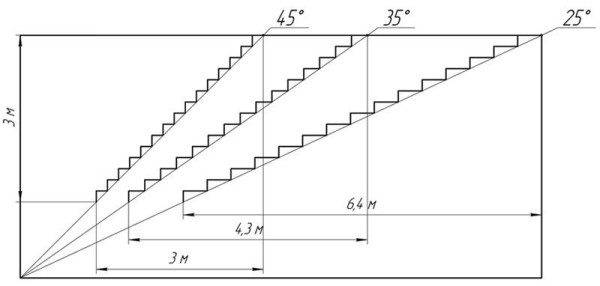

- Special attention is paid to the angle of inclination... The fact is that when you create a concrete staircase to the second floor with your own hands, you should be guided by the economy of space and at the same time not forget about the convenience of lifting. That is why the angle of inclination is made no more than 45 degrees and not less than 25 degrees.

- At the same moment, the projection of the staircase onto the floor of the first floor at an angle of 45 should not exceed 3 meters, and at an angle of 25, its length can reach 6.3 meters. These are the optimal parameters, which are calculated in such a way that a self-made concrete staircase made of concrete would not only be durable and comfortable, but also take up little space.

- Also, when making a project, you should pay attention to the railing.... It is necessary to take care of the method of their installation and dimensions. This element is simply necessary for safe operation and at the same time it can become an excellent decorative element.

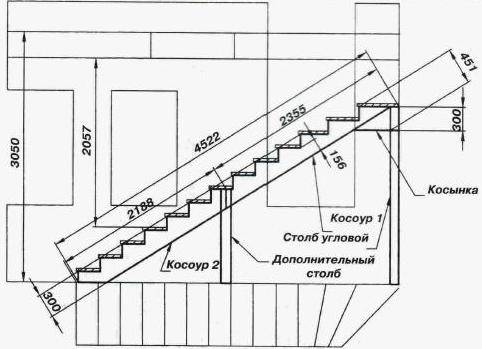

- Since concrete stairs are made together with the stage of erecting walls and installing floors, the project for their manufacture must be tied to the house drawings and the building plan... Otherwise, there is a possibility of a discrepancy between the dimensions of the product and the volume of the room and the impossibility of making a reliable binding.

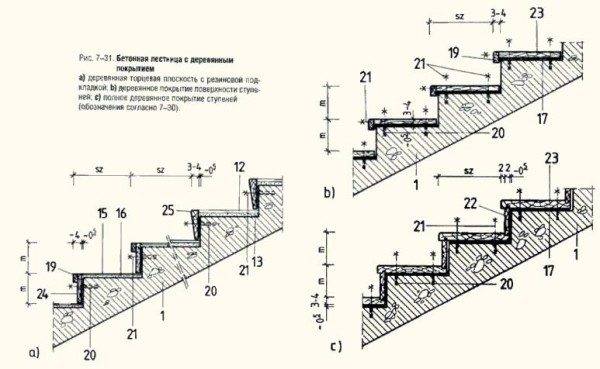

- Many instructions on how to decorate a concrete staircase with wood with your own hands are advised to take into account the thickness of the cladding material and its fasteners when creating a project. If this is not done, in the end, the product will have completely different dimensions from those that were originally conceived.

Advice! Stairs are typical structures, which means that you can use ready-made projects to create them. This will save time and will save you from various types of calculations.

Formwork

The purpose of this structure is to hold concrete at a certain height and in an appropriate volume, preventing leakage. That is why the installation instructions recommend using moisture-resistant plywood or board to create the formwork. At the same time, it is necessary to assemble the structure quite rigidly and firmly, which will be better when using self-tapping screws.

There should be no gaps, cracks or other defects in the finished formwork. When making it, it is necessary to remember that the structure itself will have significant weight, and finishing the concrete staircase with your own hands will add additional kilograms to it. Therefore, in advance you need to take care of installing solid supports under the span itself or making them from cement mortar.

Advice! Some craftsmen put a layer of film on the bottom of the formwork, which is an excellent insulator and prevents the outflow of liquid from the mold.

Reinforcement

This process is interconnected with the construction of walls and the installation of a concrete belt between the floors. The fact is that the cladding of a concrete staircase with a tree with their own hands is usually joined with other elements of the interior, and the ligation of metal reinforcement should be connected to the supporting structures. This point should also be reflected on the project in order to take into account all the features of its organization.

It is believed that to create staircases made of concrete, reinforcement follows, which are connected to each other by welding. Unlike the foundation, this product must have a strong frame, which means that manual knitting must be reduced to a minimum. At the same time, the price of the entire structure increases, but at this stage it is not worth saving.

Advice! In order to accurately maintain the distance from the bottom of the formwork to the reinforcement, special supports can be used. They will help to correctly distribute the metal in the cavity and save the performer from unnecessary waste of time.

Fill

Many instructions on how to sheathe a concrete staircase with wood with your own hands advise, before pouring concrete, to prepare fastening strips or wooden blocks in advance so that they can be embedded in the structure if the installation method requires it.

This is usually done in order to immediately create seats or install a soft material for the convenience of fastening wood. If this is not done, then you will have to drill holes in the hardened concrete, weakening the span.

Also, before pouring, you must immediately install the railing supports.

This is done in accordance with the installation instructions, depending on the type of material selected.

- The further manufacture of concrete stairs with your own hands involves the production of pouring the formwork.

- To save and facilitate this process, it can be combined with the installation of ceilings or with the organization of a reinforcing belt between floors. As a result, you can get an almost monolithic structure, which will significantly strengthen it.

- When pouring, it is necessary to compact the mortar in the formwork using improvised means or a special vibrator.

- Also, at this moment, the surface is leveled and fasteners are installed so that the subsequent sheathing of the concrete staircase with wood with your own hands can be carried out without weakening the finished product.

- Next, you need to cover the span with a film until it dries completely.

- It is recommended to disassemble the formwork only after a few weeks, so that the concrete can gain strength.

Advice! To speed up the drying process, you can put pieces of rags soaked in ammonia solution under the film.

Sheathing

It is believed that after the solution has hardened, the structure is ready for use and has a finished look. However, to give it aesthetic beauty, you can sew up the surface with any available material.

The most common do-it-yourself wood cladding of concrete stairs. This is due to the fact that this material is quite common and does not require expensive installation.

However, for the same purposes, you can use tiles, natural stone and any other covering for floors and walls. The main thing is that it is strong enough, and its installation does not take up much space.