The thickness of polycarbonate for the greenhouse: types and tips for choosing

Greenhouses and greenhouses are present in almost every summer cottage, allowing you to grow a wide variety of fruits and vegetables. However, for the construction of a greenhouse, you need to choose the right material: the film turns out to be too short-lived and quickly deteriorates, the glass does not retain heat very well and, moreover, is too fragile. The best option is polycarbonate sheets: this is a polymer material, equal in translucency to glass, but at the same time much more durable and convenient. How thick should polycarbonate be for a greenhouse?

Content:

- Types of polycarbonate sheets

- Which polycarbonate is better to choose

- Basic rules for the installation and storage of polycarbonate

- How to choose the right polycarbonate

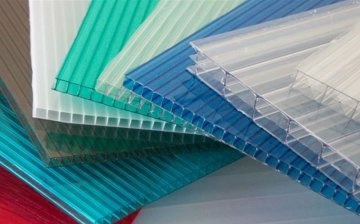

Types of polycarbonate sheets

On sale you can find two types of polycarbonate sheets: cast and cellular polycarbonate. The first option looks more like glass and conducts light well, but it cannot provide sufficient heat protection.

Much more often, cellular (cellular) polycarbonate is chosen for greenhouse structures, which has several important advantages:

- The ability to scatter the sun's rays. They will not burn delicate leaves seedlings, therefore, cellular polycarbonate will be very convenient and effective.

- Protection of plants from ultraviolet radiation - the most dangerous component of the solar spectrum.

- High strength. Unlike glass, polycarbonate does not shatter into fragments, even with a strong impact. This material will be both more durable and safer.

- Plasticity and flexibility. A wide variety of greenhouse types can be built using polycarbonate sheets, with the large sheet sizes keeping the number of joints to a minimum.

- Low cost. This is an affordable solution that will allow you to build any greenhouses.

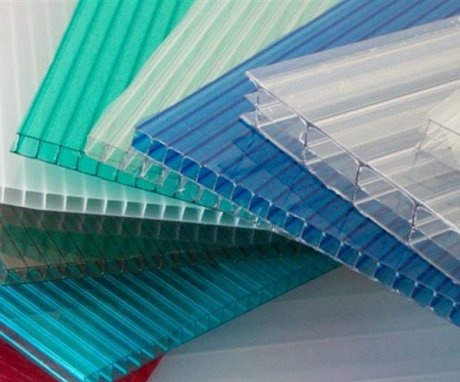

The optimal thickness of the polycarbonate sheet is 4-10 mm: this material will be both strong enough and quite durable. The greenhouse will effectively withstand wind and snow loads and will not break down over the winter. A thicker sheet is more expensive, moreover, it will be less flexible and its use in a greenhouse does not make much sense.

Which polycarbonate is better to choose

Polycarbonate sheet sellers usually recommend 4mm thickness, which is the cheapest and most affordable material.

However, it has its drawbacks, so it is worth exploring all possible thickness options:

- 4mm sheet. This is a cheap enough flexible material that is easy to install, and with it you can erect structures of various configurations. The main disadvantage is the relatively low strength. The walls and roof of the greenhouse may not withstand the snow load or hail, they will not last long.

- 6mm sheet. This is a stronger and more durable solution, such a sheet is able to withstand any whims of nature. It conducts heat well, the room will have the temperature required for plants... However, it has less flexibility, which limits the possible configurations, and requires correct installation.Usually such a solution is chosen by experienced gardeners, who immediately build a greenhouse with the expectation of many years of use.

- 8 and 10 mm sheets are almost never used in the construction of greenhouses, despite their high strength and durability. They have a very large bending radius, so their installation in a conventional garden structure will not be possible. However, it is a very reliable material that can be used for all types of canopies and awnings.

While all options are readily available commercially, a 6-millolimeter sheet is still the best solution.

It is sold in a wide variety of colors, and the lighter the leaf is, the more heat and light it will pass through. In any case, it is undesirable to purchase cheap material: it will quickly collapse under the influence of ultraviolet rays, in addition, after 2-3 years the sheets will become cloudy. It is better to give preference to a quality product so that the greenhouse does not have to be repaired.

Basic rules for the installation and storage of polycarbonate

Polycarbonate requires careful handling and strict adherence to the basic rules for its installation. It allows you to build like regular rectangular greenhouses, as well as more complex structures, it all depends on the installed frame.

In any case, you will need to follow a few basic rules:

- The polycarbonate sheets should have a layer of UV protective film on the outside when installed. If the builders did not pay attention to this, the sheets will very soon become fragile and quickly begin to collapse.

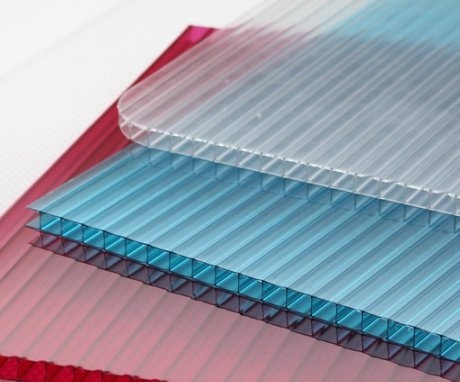

- Colored sheets are rarely chosen for greenhouses; it is better to give preference to plain white polycarbonate. It allows maximum sunlight and heat radiation to pass through, so it will be able to provide plants with good conditions. Colored polycarbonate sheets can be used on awnings and canopies, they will partially isolate the light and provide a pleasant coolness.

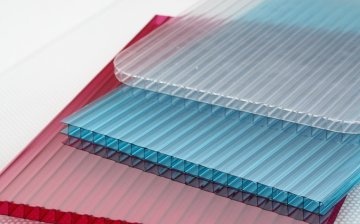

- All polycarbonate sheets are placed in the same direction, the stiffeners should be parallel to the length. Stiffeners should be strictly straight, and the cells should be the same size. Poor quality material will be much less durable and quickly fail.

- To connect two polycarbonate sheets, it is necessary to use a special H-shaped profile, end parts are inserted into its sides. When attaching the sheet to the frame, you cannot use nails; self-tapping screws with special rubber washers are required. Self-tapping screws should not be located closer than 5 cm to the edge of the sheet, the sheet is attached along its entire length. The distance between the screws in a row should be about 30 cm.

- When choosing, you need to pay attention to the storage of polycarbonate in the warehouse. Sheets should not stand on the ends, or lie rolled into rolls. When properly stored, they are placed horizontally on pallets.

How to choose the right polycarbonate

High-quality material is sold with a manufacturer's certificate, which indicates the thickness, density, and other characteristics. However, the quality can also be determined by its appearance: the material should not be cloudy, the edges should be smooth. Polycarbonate is available with square, rectangular or hexagonal cells: the first two options are suitable for any greenhouse, but polycarbonate with hexagonal cells absorbs a lot of light. It is recommended to use it only in greenhouses with additional artificial lighting.

When choosing a material for thickness, you need to take into account the type of construction of the greenhouse.

The roof can be straight or pitched, respectively, the snow load and the requirements for the sheet thickness change. If the frame is made of metal rather than timber, it can handle much heavier loads, so the sheets themselves may be less strong.

Another condition for choosing is the time of using the greenhouse.Often, such structures are erected only during the summer cottage season, and in the fall they are disassembled and placed for storage. In this case, 4 mm sheets will be enough: they will not have to endure the snow load, and they will be able to serve for many years. if the greenhouse will be used year-round, it is necessary to take the most responsible attitude to the choice of materials. It is better not to save on either the polycarbonate itself or the frame for the sheets. Lower purchase costs will translate into higher costs when the greenhouse needs renovation, which will happen very soon.

Polycarbonate is the most practical and profitable material for construction greenhouses and greenhouses... The correct choice and installation will ensure durability of garden buildings, and they will help to get excellent harvest.

More information can be found in the video.

We decided to put a greenhouse in the country in the spring, now I'm carefully studying everything, useful tips, the frame has already been ordered and made, but they did not know which film to choose. Now you can go and choose!

Thin sheets of polycarbonate break through with hail, therefore, the thickness of the sheets must be at least 10 mm. The frame of the greenhouse, for covering with this material, is best done arched, so it will be most simple and with the least waste to fix the polycarbonate.

The thickness of 4 mm is not an option for our region, the very first hail will turn polycarbonate into a deplorable state. Thickness of 10 mm requires a more reinforced structure if the greenhouse is semicircular. Therefore, I would take a thickness of 6-8mm, the price difference between them is small.