Often, the desire to convert the attic space into a practical attic appears during the operation of the house. Of course, this amount of space should be used profitably. And if you finally decided to start the alterations, then you should start by creating a staircase.

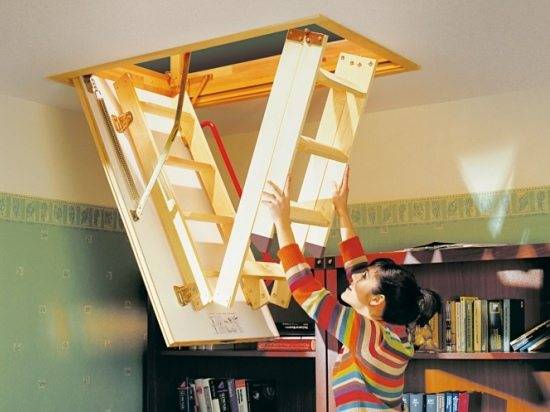

The staircase structure must be durable, comfortable and easy to manufacture. The tenants of the house should not have doubts about the comfort and safety of the ascent to the attic floor. Folding attic stairs are an excellent option, but we are not talking about them today.

We will look at how to make an attic staircase to meet all of these requirements.

Stair plan and calculation

type of instalation

It is good when the planning of the stairs to the attic was made by the designer, and the structure was made in accordance with accurate calculations. But we are considering the case when everything needs to be done independently.

The first question that will arise even before the calculations begin is how to arrange the stairs to the attic? The easiest way is to install a staircase from the street. This method is simple because you do not have to make a hatch and make changes to the interior.

However, the location of stairs in houses with an attic is more often internal, since most owners of even small country houses prefer to install a staircase in the house. Firstly, such a ladder is much more convenient to use. And secondly, it will not attract representatives of the criminal world with another, front door, which, most often, is not reliable.

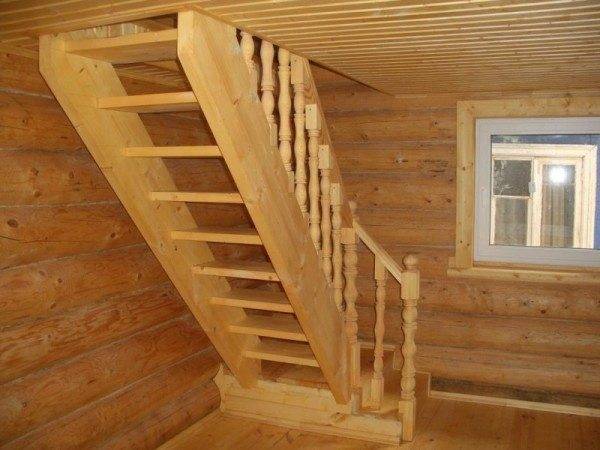

Material

After you decide on the place of installation of the structure, you need to decide what material the staircase will be made of. Usually homemade attic stairs are made of hard wood. This is due to the fact that the tree is much easier to work with, and the structure will look more attractive. This staircase looks very nice.

Advice! Before the construction of the stairs, the lumber must lie for at least three days in the room in which it is planned to install the structure. It is recommended to use kiln-dried wood.

Ladder type

Of course, the desire of any home owner is to save as much space as possible. Also, a homemade staircase to the attic should be made in compliance with all safety standards, while the structure should not greatly shade the room.

The safest and most gentle staircase will take up a lot of space in the house. A steep staircase will take up less space, but will make climbing and descending it difficult and dangerous. Therefore, a compact folding ladder is an excellent option, especially for small houses. It can be made from wood and several metal elements.

However, this is far from the only design option that can be located in a small area.

Also, it will not take much space:

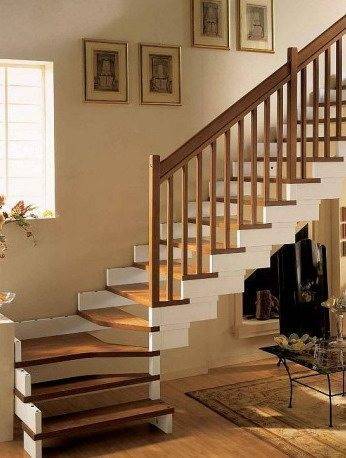

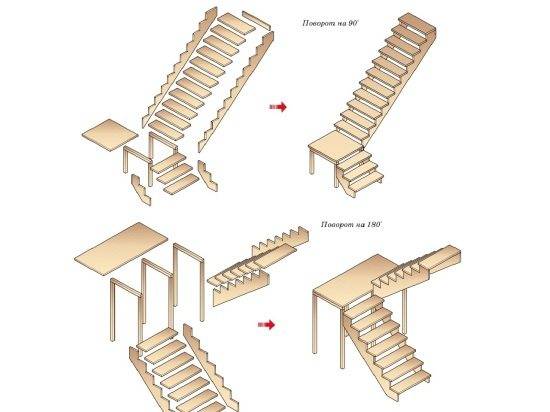

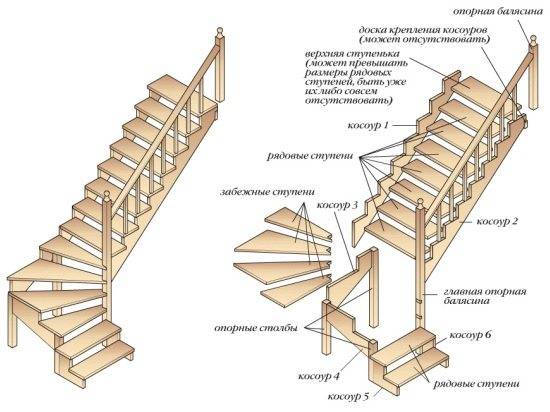

- Marching staircase. Such structures can be erected on the basis of kosour, bolts, and two supporting bowstrings can also be used. In order to save space, stairs are usually made with two flights, between which there are run-down steps or a landing. The single-marching option will take up a lot of space, but for that, you can make a closet or utility room under it.

- Spiral staircase. It looks great and takes up a minimum of space, but at the same time it is quite difficult to do it yourself. It is much easier to purchase a ready-made kit with a stringer.Collecting it is not difficult, since there is always detailed instructions from the manufacturer.

- Ladder "Duck step".This is the simplest type of ladder, which we will discuss below.

Design

The design of the future staircase is determined by the following parameters:

- Lifting height. It consists of the distance from the floor to the ceiling plus the thickness of the top slab pie.

- Construction area in plan. The steepness of the stairs, its width and the size of the hatch to the attic depend on this.

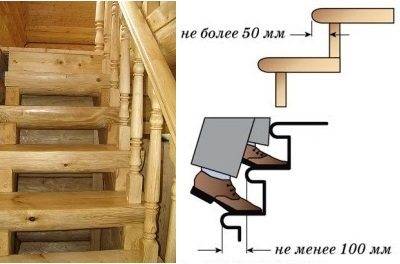

- Tread width. This is a very important characteristic that often forces you to change the type of construction and completely redesign the project. Therefore, it should be calculated in advance that the leg rests completely on the step, but at the same time there should not be an extra distance. The most optimal tread width is 30 cm, the march width is 80-100 cm, and the riser height should be within 15-19 cm.

So we examined how to calculate the staircase to the attic, and now you can proceed directly to its creation.

Construction of a flight staircase

Preparation

If there was no hatch of the appropriate size in the upper ceiling, and most often it does not, then the construction of the stairs to the attic begins with it. The slab and floor covering are sawn with a circular saw according to precise markings. The size of the hatch determines the dimensions of the stairs. When the cut is completed, you need to remove all unnecessary.

Before proceeding with the marking of materials and cutting, it is necessary to complete a drawing of the future staircase. It can even be done by hand. The main thing is that all the details and their dimensions are applied to the drawing. This will simplify further work and will prevent markup errors.

Then, according to the data obtained during the design, the kosoura are marked. The easiest way to cut them is with an electric jigsaw. In this case, there should be a "clean cut" outside. The outer edges of the stringers must be milled, then processed with sandpaper and brought to perfection with a grinder.

Advice! It is imperative to ensure that the cuts are parallel, even and that the level of the step indentations is the same. It depends on how smoothly the steps will be installed.

The number of steps is also determined by design parameters. In accordance with this, the required number of cuts is made. To facilitate installation by means of milling, a lock groove is made. In this case, it is necessary to strictly observe the parallelism of directions.

Mounting

The installation of the structure should begin with the installation of a wall stringer, which rests with its lower part on the floor, and with its upper part on the support. A similar opposite structural element is mounted according to the design dimensions opposite the first part, while checking the location and parallelism using a level.

Please note that when constructing a two-flight staircase, powerful supports will be needed, to which the flight of stairs will be attached. For these purposes, you can use a bar or metal pipes. For strength, they can be concreted.

Then the frame is completely constructed and its openings are finished with furniture boards, if their use was planned initially. At the end of the work, risers are installed in the places prepared for them, and then the steps. After that, the elements of the railing and the balustrade are mounted.

Advice! The space even under a two-flight staircase can be used profitably. For example, you can make a pantry there for all sorts of rubbish.

The assembly of a multi-flight ladder is a sequential connection of individual parts. If all the elements were made exactly in accordance with the drawing, then the process takes place very quickly and resembles the assembly of a constructor. However, the possibility of fitting parts in place is not excluded.

If grooves were made for fastening on the strings, and ridges were made on the steps, then the elements can be connected using two-component glue, for example - Titebond... Otherwise, screws are used.

To give the structure a more attractive look, it is varnished. However, it should be borne in mind that a staircase covered with varnish can be slippery, especially if it is supposed to climb it in socks. Therefore, it is better to simply cover the structure with a special compound with antistatic and flame retardants.

Advice! While the paintwork is drying, the room must be ventilated.

Construction of the stairs "Duck step"

Another way to save space and make a comfortable structure for descent and ascent is the "Duck step" ladder. Its peculiarity lies in the fact that the tilt angle can be up to 65 degrees.

The safety and comfort of movement on such a staircase is achieved due to the steps of a special shape - one half of the step is wide, and the second is a third narrower. Such steps are installed on bowstrings and alternate - a wide step is installed above the narrow part of the step, and then vice versa. As a result, wide and narrow parts are staggered.

When climbing such a ladder, the lower leg of the leg does not rest on the upper step, and when descending, the foot can confidently stand on the wide part. Thus, the ascent and descent is carried out in a roll-over, which is why this structure is called "duck gait".

One should be careful to walk on such a ladder, and not to get confused in the alternation of steps. Of course, this design is less convenient than a flight ladder, but for that, it is more compact.

Manufacturing staircase elements

First of all, you need two bowstrings. They must be of a length capable of providing the required angle of inclination of the stairs. The thickness of the boards can be about 40 mm and the width is about 150 mm. For the installation of steps, it is necessary to make secret grooves with a depth of 10 mm in them.

In accordance with the height of the future staircase, the required number of such grooves is determined. You can cut them with your own hands using a hacksaw.

Advice! In order not to worry about the depth of cuts, holes should be drilled in the blade and the stop plate should be screwed on.

The width of the steps (wide part) is selected in accordance with the angle of inclination. The greater the slope, the wider the step should be. On average, the step width can be from 200 to 250 mm. In narrow places, wood must be selected one third of the width of the step.

Then the treads must be inserted into the grooves on the supporting beams and fixed with screws. After installing all the parts, the surfaces must be sanded. If you plan to cover the stairs with paint, then you may not sand so thoroughly.

Output

Now, knowing how to build a staircase to the attic, you can decide for yourself whether it is worth starting this procedure. Your household will surely enjoy the result of labor with pleasure and a sense of reliability.

However, if you are not confident in your abilities, then it is better to purchase a finished product. True, the price for it will be much higher than the cost of building it yourself. You can get more information on this topic from the video in this article.