In modern industrial complexes, factories and factories, as well as in small workshops, metal industrial ladders are widely used. Reinforced concrete products and structures made of various alloys are also common.

We will consider the main types and characteristics, as well as the functions that stairs perform in industrial buildings.

Industrial stairs

General requirements

Industrial and factory premises are hazardous areas. Accordingly, special requirements are imposed on all building structures aimed at ensuring maximum safety and reliability of all structures.

An industrial staircase poses a particular danger to humans, since this structure is designed to communicate between floors and platforms with an unsafe height difference.

Considering the presence of powerful machines and mechanisms, energy-intensive devices and apparatus, loads of large mass and dimensions, the requirements for production ladders are drawn up in accordance with GOST and SNiP, and also comply with safety standards, labor protection and human life safety.

In general terms, these requirements are reduced to the following list:

- Ladders intended for the main movement of personnel, workers and employees must comply with the requirements of GOST for all types of civil buildings and structures;

- The number of interfloor staircases should correspond to the number of enterprise personnel, and during the movement of people during rush hours in the most populated areas and floors, there should be no traffic jams and congestion; the minimum ratio of the width of flights of stairs per person is taken for the most populated floor at the rate of 0.6 m / 100 people;

- All stairs must be equipped with a system of fences, handrails and railings in accordance with GOST and SNiP;

- Service structures should be designed for the expected loads with a specified margin of safety;

- When calculating and designing interfloor staircase communications, the dimensions of the goods that will move along these structures must be taken into account;

- All structural parts must have adequate durability for the conditions in which they will be used;

- All surfaces must be resistant to electrochemical, biological and other types of corrosion typical for the environmental conditions of a particular production. This is especially important for chemical, metalworking, processing and smelting industries;

- Materials of construction should be selected taking into account the temperature regimes of production, the amplitude values of temperature differences and the coefficients of thermal expansion of the materials used are especially important;

- Products should not contain sharp parts, edges at seams and joints, uncleaned cuts and ends, sharp corners and protrusions that can injure a person.

Materials (edit)

Two materials meet these requirements best of all: metal and reinforced concrete. For the main stairs, reinforced concrete structures are most often used, as in general civil buildings..

Service, fire and emergency structures, as a rule, are made of metals:

- become,

- cast iron,

- aluminum,

- stainless steel and other alloys.

You can also find products from various combinations of materials. It can be metal and wood, metal and concrete, metal and glass, various plastics and polymers.The almost ubiquitous presence of metals is simply explained: it is metals that have a sufficiently high strength, ease of assembly, wear resistance and availability.

Important!

The price of steel is relatively low for the unique qualities of this material, because it does not burn, does not melt, is not susceptible to damage by rodents and insects, is quite inert and resistant to aggressive environments.

Also, an important role is played by the possibility of coating steel and other metals with protective layers of paints, enamels, anticorrosive primers and other metals that are more resistant to chemical influences.

The parameters of protective coatings and paint layers are regulated in GOST and SNiP for coatings of metal structures.

Types of structures

All industrial ladders can be divided into four main groups:

- Basic;

- Service;

- Firefighters;

- Emergency.

All these groups are formed according to the main purpose of one or another interfloor structure, although in addition to functional differences, there are also some structural features. Let's consider each group separately.

The main

The main structures are intended for communication between the floors of multi-storey buildings and structures of industrial and industrial complexes. In terms of type and structure, they differ little from ordinary civil structures. As the main interfloor complexes, it is customary to use straight and rotary marching structures made of reinforced concrete.

According to their location, such stairs are built into the building or taken out beyond its contours. Built-in models are placed inside multi-storey buildings with a grid of columns of 6x12, 6x9 and 6x6 meters and are composed of unified structures. The staircases and their walls are made of concrete panels, which are supported by foundation beams and floor-to-floor closed-type beam frames.

The main stairs are characterized by the following parameters:

- Geometric dimensions of the steps - 300x150 mm;

- The value of the slope of marches is 1: 2;

- The width of the march from the wall to the railing installation site is 1350/1500/1750 mm.

Important!

The main structures can be used not only for the regular movement of the enterprise personnel, but also for emergency evacuation, therefore, during their operation, all the requirements adopted for evacuation routes must be met.

Service

Service stairs are designed to provide access to various work and production sites, mezzanines, remote and hard-to-reach parts of equipment, for maintenance and repair, supervision and control of mechanisms, machines, devices and systems.

Important!

Service ladders are used to transport goods, parts, components, consumables, fuel and raw materials.

Therefore, these objects must have increased strength and durability, have a safe fencing system and a convenient configuration.

As a rule, office buildings are made in the form of straight and rotary marching structures made of metals and their alloys.

Industrial stairs are characterized by the absence of decorative elements and ornaments, while all the standards and requirements of GOST and SNiP, safety and labor protection rules are strictly observed. All dimensions and parameters of structures are regulated, the manufacture of service ladders for do-it-yourself production according to independent projects is unacceptable.

Service items must meet the following parameters:

- The value of the slope of the marches is 45 and 60 degrees;

- The height of the steps for a slope of 45 degrees is 200 mm, for a slope of 60 degrees - 300 mm;

- The width of marches and transition platforms - 600, 800 and 1000 mm;

- It is customary to assemble steps and platforms from corrugated steel, 4 mm thick, as well as from a ribbed strip measuring 40x4 mm.

For service purposes, not only stationary, but also mobile structural models are used. As a rule, these are portable ladders of retractable, composite or folding types; one-piece straight ladders are also common, consisting of two bowstrings and transverse steps from a metal bar 18 mm thick.

Firefighters

As the name implies, the main purpose of the fire structure is to provide access for the personnel of fire brigades and rescuers to the emergency facility, as well as to ensure the delivery of fire and rescue equipment to the area of elimination of the consequences of accidents, fires and disasters. These products are manufactured in strict accordance with the accepted standards of GOST and SNiP for fire escapes and roof barriers.

Depending on the height and potential danger of the object, the fire structure can be a vertical straight line (with a height of no more than 10 m), consisting of two bowstrings and transverse steps from a steel bar 18 mm thick, or they can have a multi-march configuration.

Important!

All roof barriers and fire escapes are subject to mandatory testing and strength testing.

Based on the results of these checks, the product is approved for operation for a period of five years.

Inspections and tests can only be carried out by certified competent organizations that are authorized to carry out such activities.

Testing and inspection instructions are available online.

Evacuation

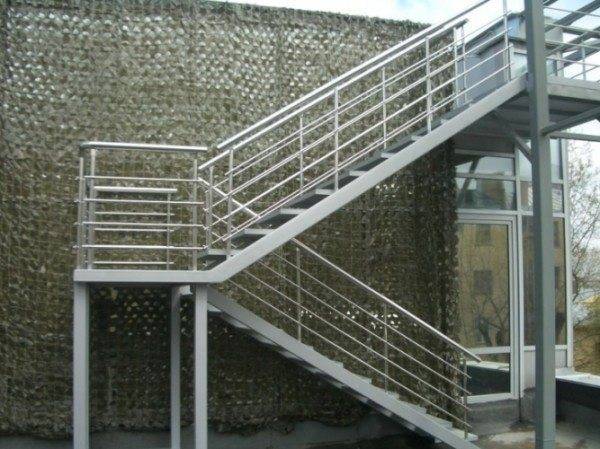

Structures intended for the evacuation of personnel and personnel of the enterprise are located outside the building. These are stationary flight ladders that are attached to the ground and building structures using beams, columns, brackets or anchors.

The width and number of flights are calculated in accordance with the maximum possible load in the event of an emergency or accident. The structure must be strong, stable, reliable and safe. All parameters must comply with GOST and SNiP.

Important!

Use evacuation ladders only for their intended purpose: to evacuate people in case of danger to their life and health in conditions of impossibility or undesirability of movement along the main ladders.

The use of these structures as main or service messages is undesirable.

Output

Industrial stairs must comply with fairly stringent safety requirements, standards and building codes. In accordance with them, products are made from steel, metal alloys and concrete, without decoration and frills, with an emphasis on strength and reliability. In the video presented in this article, you will find visual coverage on this topic.