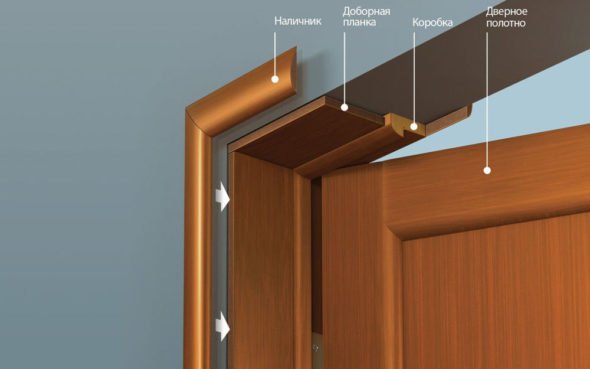

What are finishing nails

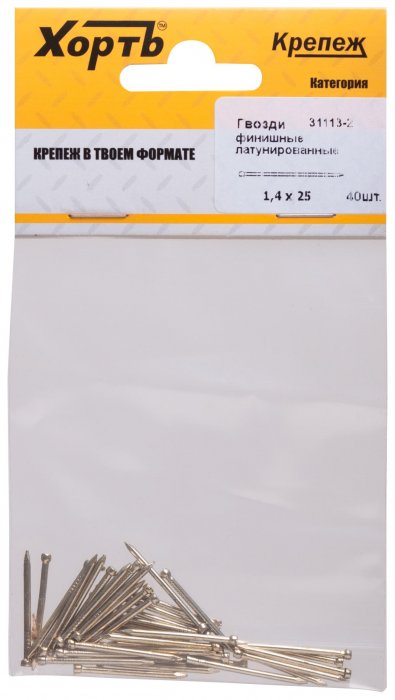

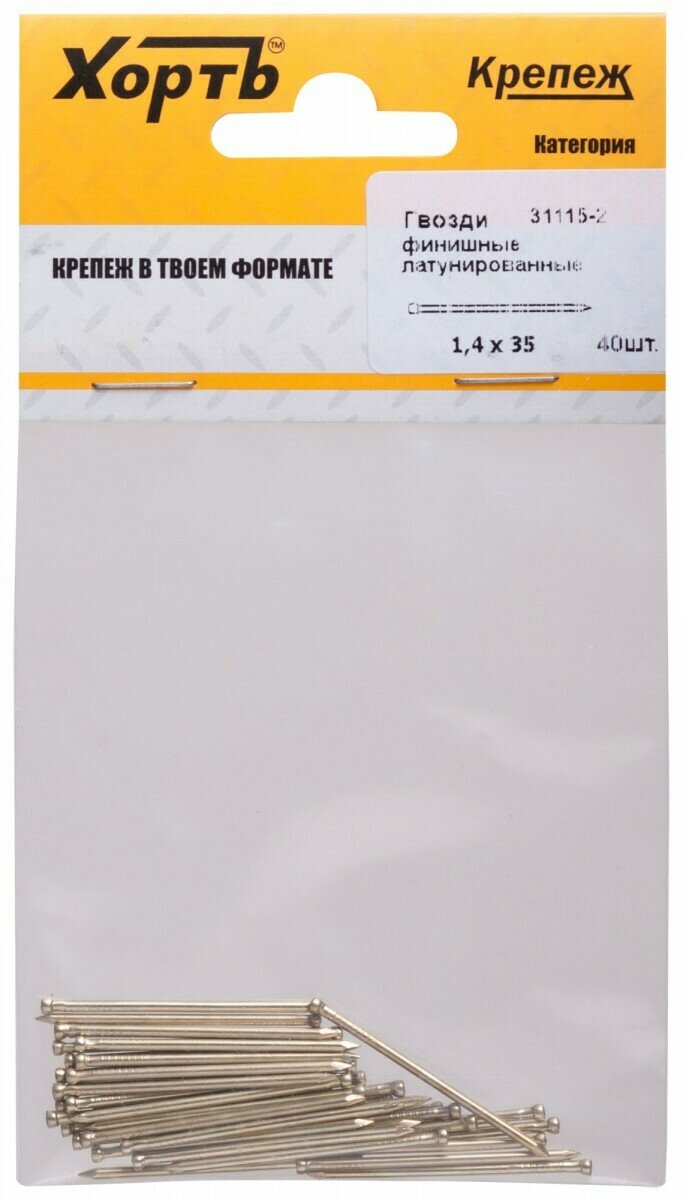

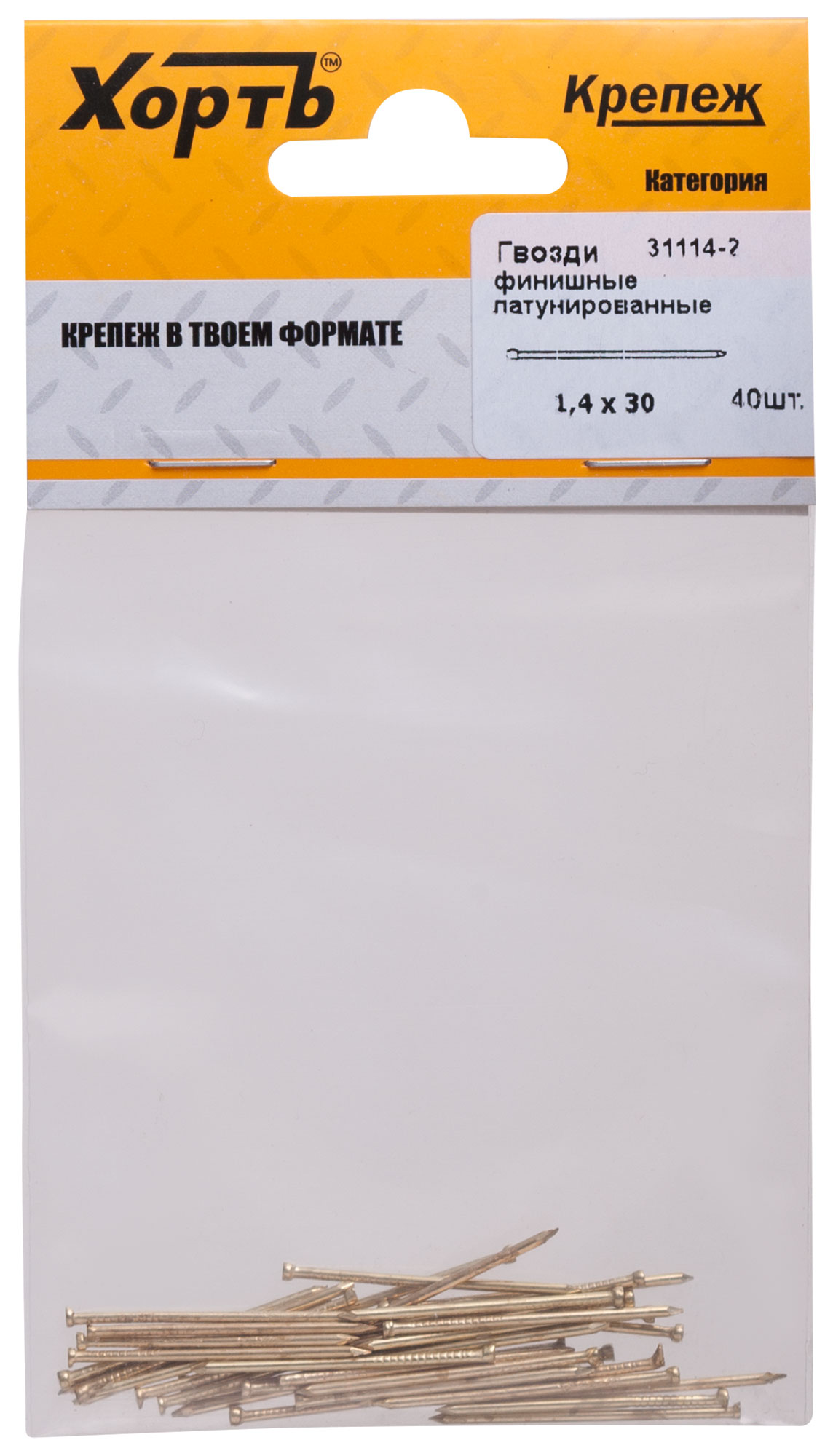

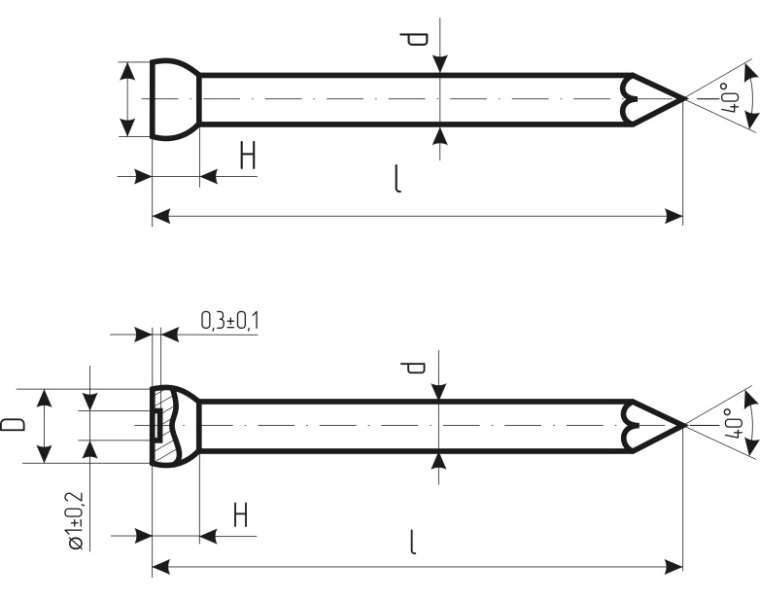

This is the name for nails with a small cylindrical head, the diameter of which is only slightly larger than the diameter of the rod. They are designed specifically for fixing decorative trims, as they provide a secret fastening. These nails have a small thickness, as a result of which they easily enter the wood without causing cracking. It is easy to drown a small hat in the thickness of the material using a doboiner.

Finishing nails

In the photo - the finishing nail next to the doboinik

Specifications

The rods of such hardware are smooth, with notches in the upper part, with a length of 20 to 90 mm. The hat has an oval shape, and its height corresponds to the diameter of the shaft. The diameter of the cap itself varies from 1.6 to 3.4 mm. The material for the manufacture of fasteners is low-carbon steel, and anti-corrosion compounds are used as a protective coating.

Unlike simple construction nails, finishing nails are not designed for high loads, since finishing materials are usually lightweight. They can be used only in structures that are not subject to shrinkage and mechanical stress on bending or tearing. It is also undesirable to use them for temporary coatings: not a single tool makes it possible to pick up and pull out a nail because of the small cap sunk into the tree. For the same reason, they cannot be reused.

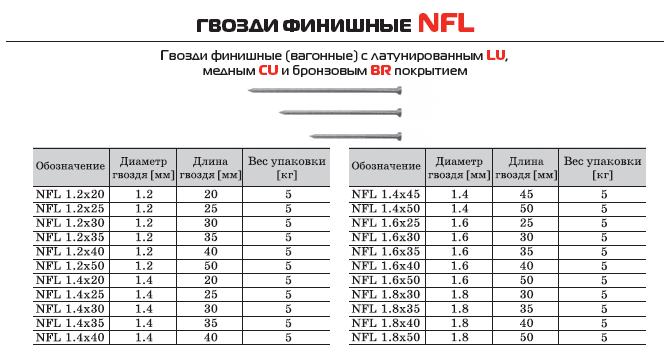

Finishing nails NFL

Finishing nails, galvanized 1.8x40

Scope of application

Finishing nails are used not only for fixing the lining, the scope of their application is quite wide:

- furniture manufacturing;

- installation of small decor in interiors;

- decoration of window and door openings with platbands;

- fastening thin slats, glazing beads and skirting boards.

Some craftsmen use them when laying parquet and laminate, when it is necessary to fix the planks, but since the flooring is subject to constant mechanical stress, ordinary nails are more suitable here.

Driving in the finishing nail. Using a doboinik

1 What nails are called finishing nails?

Finishing nails are mainly used for finishing (facing) work. This is their intended purpose, which consists in an inconspicuous or hidden fastening of wood materials. For these tasks, their design is also provided - in comparison with other types of nails, the head has a greater height and a smaller diameter. The hardware industry produces fasteners of this type with a length of 12–250 mm, a rod diameter of 0.9–7 mm, and a slightly larger head.

The height of the head is usually equal to the diameter of the nail. In finishing works, the most widespread fasteners are 35–50 mm long, with a head diameter of only 2–2.4 mm. Particularly good are nails with a recess (depression) in the center of the head, designed to "drown" the finishing fastener when driving in by placing a center punch, nail or special device. It is for this operation that a high head is provided that can withstand such an impact.

Fasteners are made on automatic nailing machines from low-carbon steel wire by cold forging. If quality material is used for manufacturing, then the products are durable and durable. In addition to size, nails differ in the type of coating that determines the purpose (location) of the finish (fastening):

- uncoated - the simplest and most common type, corrosive and least durable. Typically used for interior decoration. Room humidity should be low;

- galvanized - silver color, for rooms with low humidity;

- copper-plated - reddish, for conditions with high humidity;

- chrome-plated - shiny silver, for high humidity conditions;

- brass finishing nails - yellow, decorative, made of thinner wire. They are used in works where high corrosion resistance and aesthetics are required.

The main advantage of finishing hardware is that they are almost invisible on the surface of the fixed material. But there are also some disadvantages:

- not subject to extraction and subsequent reuse;

- in terms of bond strength, they are inferior to construction nails.

Wholesale packaging of finishing fasteners - boxes from 5 to 25 kg. For retail - it can be from 10 pcs to 200 g in polyethylene bags and 1 kg in small packs.

You can fix the platbands with the door frame in different ways.

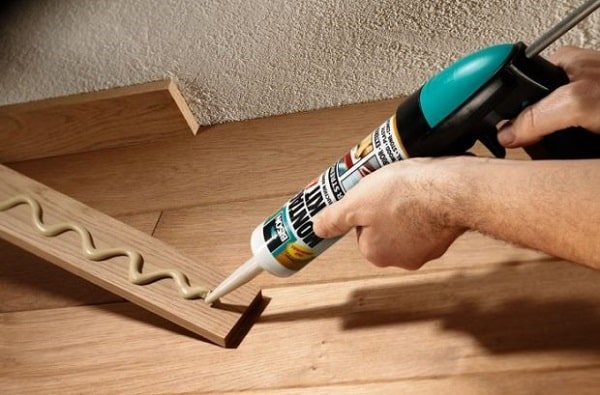

- On liquid nails

Photos 3 and 4 show platbands glued to liquid nails. This is the most aesthetically acceptable, but also the most unreliable way of fixing platbands. It is advisable to use it only when the walls are well aligned and the platband will adjoin both the door frame and the wall.

- Thin nails

Recently, door installation companies have been using this method, since the platbands, fixed with nails with bitten off heads, can be easily removed, and this allows you to finish the walls after installing the door. Photo 2 shows the platbands nailed with copper nails 1-1.5 mm in diameter with bitten off heads, one of these nails can be seen in the photo. The disadvantage of this method is that a nail with a bitten off head holds worse than an ordinary nail, and even more so a self-tapping screw, but on the other hand, the hole from the nail does not strike the eye. However, sometimes such platbands lag behind, especially if the door is installed in a thin, not rigid enough partition, and there are enough of those who like to bang the doors in the apartment, then the platbands often have to be knocked out or additionally planted on liquid nails.

- In a combined way

Photo 1 shows the platbands, which were glued to liquid nails and additionally fastened with nails with bitten off caps.

Since the platbands supplied with the door were curved enough, it was not possible to fix them only on liquid nails, and I did not want to fix them only on thin nails.

- Nails or self-tapping screws

Photo 5 shows the platbands screwed on with self-tapping screws. This method is only suitable for unpainted or primed wooden platbands. However, recently, nails have been increasingly used to imitate antiquity, and sometimes you have to specially select nails with large textured heads and nail them as roughly as possible, it all depends on your aesthetic preferences.

Secrets of installing platbands on the door with your own hands

If high-quality material is used for production, then the products are durable and wear-resistant. The marking of finishing nails refers to the diameter of their shank and their length, which most often varies from 35 to 100 millimeters with diameters from one and a half to three millimeters, less often nails of a shorter length of 20 and 25 mm and, accordingly, with diameters of up to 1.4 mm are required. Hats are also found in different heights and diameters, depending on the selected bar parameters.

For bulk purchases, finishing nails are packed in boxes from five to twenty-five kilograms, but smaller ones are also found in retail - from 10 pieces to 200 grams in plastic bags and small packs of 1 kg.

Unfortunately, finishing nails also have some disadvantages, for example, in terms of bond strength, they are significantly inferior to construction nails and cannot be removed and reused.

Prices

The cost of the casing directly depends on several factors.The main criterion for pricing is the material of manufacture. The price of wood products starts at 150 rubles and increases depending on the value of the species and the class of wood used. Budget door trims can be made from MDF sheets.

The price of polyurethane platbands depends on the dimensions and texture of the product. The minimum price starts from 700 rubles. The finished product in the kit contains a casing of 2 bars and a capital or a sandrick. On average, such a kit is estimated at 4,500 rubles. Knowing what, in essence, door trims are, doubts may arise about the adequacy of the price. However, given the resulting appearance of the embossed structure, similar to plaster molding, all questions are dispelled. Thanks to this type of design, it is easy to achieve in the interior the creation of a design with an original antique style.

Structures made of cedar lumber or beech look very presentable. However, it is worth knowing that door trims in most cases are sold with a veneer coating or painted over. Therefore, selection by photo in online stores is not recommended and the product should be evaluated live before purchase.

Some installation secrets

- If, with the help of such nails, the elements of MDF are fixed, a hole must first be drilled in the material. The drill for this is no more than 1.5 mm in diameter.

- Driving the nail vertically will provide a secure hold.

- The use of an electric drill is not limited to drilling holes, there is another option. The cap is clamped in a chuck, and a nail is screwed into the material that is nailed. You only need to twist it to the width of the finishing material. With this option, there is no swelling of the surface. The remainder of the nail is hammered in with a hammer.

- To hide the cap, a metal add-on is used.

- The easiest way to mount finishing nails is with a pneumatic gun.

- Platbands are nailed at right angles or at 45 degrees, and even this inconspicuous fastener needs to be mounted not in the middle, but closer to the edge.

Air gun for nail mounting

Related Posts via Categories

- Bolt strength class - how well do the hardware resist shattering?

- Anchor bolt with nut - proven fastening option

- Dowel-nail - which fasteners are of the highest quality?

- Anchor bolts - a special type of fasteners for complex structures

- Bolt designation in accordance with GOST - we are guided in the world of hardware

- How to rivet a rivet - automatic and manual methods for different materials

- Bolt manufacturing - straightforward workflow

- Spring Cotter Pin - Eared Fastener for Mechanical Engineering

- High Strength Bolts - Complete Fastener Information

- Blind rivet sizes - what should you think about when calculating?

How to install?

Overhead platbands made of any material are not recommended to be installed on ordinary metal nails, as their head will stand out sharply on the surface and spoil the whole picture. In addition, such fasteners can rust under the influence of moisture, which is also a negative factor.

The best option for attaching overhead platbands to the wall of a wooden house is finishing nails. They can have narrow flat caps to match the color of the surface or be without them at all. The standard length of finishing nails is 4 cm, it is necessary to choose such that they are 1.5 cm longer than the platband itself. Fasteners are driven in at a distance of 0.5 m from each other so that the cap does not sink into the bar, you can use a doboiner. The advantage of finishing nails is also that the platbands are easy to dismantle later.

To avoid any traces of fastening, you can use "liquid nails".This is a special glue that is applied to the inner surface of the casing, then the part is pressed against the window or doorway and held for several seconds. After that, the decorative element can be used for a long time. A more reliable fastening than nails are self-tapping screws, which, thanks to the thread, rigidly fix a wooden or plastic part. It is possible to choose a mount with a cap to match the surface color. First, holes of the required width are drilled in the casing, then recesses are made for the cap. After that, the element is attached to the wall of the house with self-tapping screws.

For attaching plastic platbands to the wall of the house, you can use special staples that are nailed with a stapler. This method is quite convenient and does not require any skill. Telescopic platbands are attached to the wall using a special slot. It must be fixed in the groove of the extension or window, door frame.

Installation of platbands on the door

As already mentioned, the method of fixing the platbands is chosen based on its reliability and the evenness of the wall surface. Wooden or MDF strips are attached with screws, glue or nails. If the wall is not very flat against the box, then you should refuse to plant the strips on the glue.

How to install platbands on interior doors and where to start? And they begin the installation from the side where the canvas opens. It is on that side that the hinges are located, which prevent the installation of the strip flush with the box, and in this case it is necessary to indent. It must be the same on all three sides. If there are no loops, then this question disappears by itself.

Docking planks at an angle of 45 degrees

Most often, door trims are installed at an angle of 45 degrees. Do-it-yourself installation using a miter box for even cutting the bar. This method of joining is used for embossed or rounded platbands. Since not everyone has a miter box, then a regular protractor is perfect for marking. The required height of the vertical planks is measured directly from the floor covering. It is necessary to start from the side of the loops, taking into account the width of the indent. The bottom point of the corner is marked on the plaque and a mark is placed.

The bar is placed in the miter box and a part is sawn off from the set mark at the required angle. Now the blanks need to be slightly baited with carnations, the caps of which are removed with pliers. One carnation is hammered at a low height from the floor, and the second at a height of 100 cm.

The length of the protrusion of the nails remains somewhere around 5 mm, after which the platbands are attached to the box. In the place where the nail is located, a wooden block, previously wrapped in fabric, is applied to the platband and the bar is carefully planted with a hammer.

When the vertical planks are attached to the studs from below, you can start marking the upper vertical plank. To do this, the vertical platbands are slightly bent from above, a horizontal part is placed under them. Use a pencil to mark the required corner line. The excess part is cut off and the bar is ready for fastening.

Docking planks at an angle of 90 degrees

Only flat platbands are installed at an angle of 90 degrees. The cut points must be lubricated with acrylic-based varnish before attaching them.

In addition, the upper horizontal casing can be made in the form of a protruding lintel. To do this, its edges should protrude several centimeters beyond the vertical bars. Thus, they will be installed at a 90 degree angle with horizontal seams.

Installation of plastic platbands

How to install plastic platbands on the door with your own hands? Some put them on glue, but this method is not reliable, so they are mainly installed using a profile.

To do this, adhere to the following installation scheme:

- A profile is cut for the required door parameters.Even if it is shorter by 5 mm or 1 cm, it's okay, it will still hide behind the cash;

- It is necessary to cut 2 long and 1 short elements on one side of the door. Cut off their ends at an angle of 45 degrees.

If a cheap Chinese door was purchased, then it will not work to attach the profile to self-tapping screws, since it will not be possible to tighten them securely due to the thin metal of the box. Then the profile is fixed directly to the wall, but it is desirable that it be without plaster. If the structure is strong enough, then the mounting profile is attached directly to the box.

It is necessary to start screwing the profile not from the bottom to the top or from the top to the bottom, but from the center. While screwing in the self-tapping screws, use a plumb line to control the evenness of the profile.

After the profile is screwed on, the strips are cut to the required length and the upper ends are sawn off at an angle of 45 degrees. The workpiece is inserted into the groove of the vertical profiles.

Corner fittings are placed on the cut of the platbands and the installation of the upper horizontal strip is started. It is trimmed on both sides at a 45 degree angle and mated to the vertical planks. Thus, the fittings will hide the joint between the planks.

Docking the skirting board and platband

In this case, it is not the platband that is cut, but the skirting board is fitted. If it is plastic, it will fit nicely with the casing with the help of special decorative plugs. If the skirting board is wooden, then it is sawn at an angle of 45 degrees so that the adjacent side is aligned in thickness with the strip.

Methods for attaching platbands to interior doors

Side view of the joint.

In addition, in this case, the platbands were attached to two adjacent door frames installed in the toilet and bathroom, but this is another story.

But that's not all, for example, platbands can be used to imitate a lintel over the door:

Photo 5. Wooden platbands imitating the lintel over the doorway. Fastening with self-tapping screws.

In this case, the photograph was taken after the platbands were painted with the first layer, so that in the photograph you can see the attachment points with self-tapping screws. This door is installed in the country house, so when the platbands are painted with a second layer, and at the same time the walls are tinted, no one knows for sure.

Varieties

There are several types of such fasteners. There are screw, construction, zinc, roofing, wire nails. Their use is determined by the purposes of the work during construction, as well as by the material.

In its form, such a building element is as follows:

- pyramidal;

- conical;

- in the form of a parallelepiped;

- in the form of a cylinder.

Additionally, it is customary to distinguish nails depending on what materials they were made for.

- For decoration and furniture production, it is customary to use aluminum and copper parts.

- If the humidity in the room is too high, then acid-resistant nails will do.

- Copper models and elements with a brass element are practically not used in construction. The main reason is that they are too expensive. Often used as decorative elements.

- Galvanized nails are convenient in that virtually no corrosion process occurs on them. They are used for both indoor and outdoor work.

- Black details are only applicable as a temporary option. In construction, they are subsequently replaced with more reliable analogues.

Before carrying out construction work, it is recommended to determine the nature of the varieties of products.

- Conventional fasteners are used to connect wood products. This is a classic option that is more popular when choosing building materials.

- Screw nails are available in black and galvanized. In the first option, it is an exclusively temporary solution, in the second, it is rather a solution to practical problems.Such elements are in the price category available to the average buyer (both individuals and legal entities).

- Galvanized slate nails are used exclusively for fastening slate. To ensure the most snug fit to the material, the product has a matching cap. Galvanizing method - galvanic, it is able to protect against rusty streaks.

- Cliff nails are required to secure soft roofing and roll materials. They perfectly hold wood due to their structure.

- Finishing elements are used exclusively for fine fixing of the finish. The main feature is that it is one of the most durable methods for fastening materials.

Varieties of products

The use of finishing nails depends not only on the design, but also on the material of manufacture, or rather, additional coating.

- Black finishing nail - this is the name of any fastener without a protective coating. It is made of low-carbon steel and has no corrosion resistance. Fasteners are used in dry living areas.

- Galvanized is the most popular option as it is quite cheap to manufacture. A zinc layer on the finishing nail - at least 6 microns, prevents the appearance of corrosion. The nail has a dull silver color, it is used when decorating rooms with medium humidity - kitchens, for example.

- Copper-plated - the copper layer gives the product a red tint and excellent water resistance. Fasteners are used for cladding dressing rooms, baths, balconies, and are even used for external finishing work.

- Brass Plated - The brass plating gives the product a beautiful golden hue. At the same time, the brass layer absolutely protects the fasteners, so that brass finishing nails are used in the wettest rooms, but, as a rule, only in areas where aesthetics are high: the product is relatively expensive.

- The chrome finish nail has a silvery glossy color and higher corrosion resistance than galvanized finish. Chrome-plated products, as well as brass-plated ones, are readily used in the manufacture of furniture.

- Coating finishing nails with bronze is even less common than with brass, although protection against water and corrosion is equally reliable. The point is in the cost of the product and in the noticeable weighting of the nail itself.

Brass, copper and chromium coatings are more resistant to corrosion than the zinc layer. However, the cost of such products is also higher.

Finishing nails for platbands (photo)

Dismantling

Removing the casings is usually required when the casings are being replaced. There is no need to worry about their safety, but the work is done neatly. Taking an ax with a sharp blade and a hammer in hand, they begin to dismantle:

- To remove the platbands neatly, the interior door is given an open position. Having settled in the doorway, the tip of the ax is inserted in the upper corner between the plank and the box.

- A hammer is struck on the butt of the ax until the blade is immersed under the cash.

- Pressing the handle on the ax, separate the bar from the box. The further procedure consists of similar actions. They walk with an ax in a circle until the platbands are completely dismantled.

The procedure must be carried out carefully so that no dents remain on the door frame. Instead of an ax, homemade sharpened strips of durable metal or other similar devices will do.

What it is?

If we compare ordinary carpentry hardware and finishing nails, then the latter look in such a way that you can notice the difference in their head. At the finishing hardware, the hat has a small diameter, but a large height. According to GOST standards, the height of the head is the same size as the diameter of the nail. In addition to the usual models of such finishing hardware, options are also available that have a small depression located in the middle of the cap.Such a recess is needed in order to abut the end of the punch against it and, with the help of this device, drive the rod of the finishing hardware deep into the material.

Finishing hardware, besides the advantages, also has some disadvantages:

- if it is necessary to remove this finishing nail from the material, it will no longer be possible to do this;

- Compared to construction nails, finishing hardware creates a weaker connection.

The release of finishing hardware is carried out in compliance with technical conditions, that is, according to TU, although the drawings for this product are regulated by GOST. Modern manufacturers make finishing hardware according to GOST standards only from unhardened steel wire rod.

The characteristics of hardware finishing products are as follows:

- permissible errors in the size of the section, regulated by the standard;

- the cut angle of the nail point must be at least 40 °;

- deflection of the product by a certain factor of the total length of the bar is allowed.

Checking the quality of hardware in the factory is carried out by laboratory tests. A lot of nails can be considered suitable if the percentage of deviation from the standards does not exceed 0.5% of the total weight of the hardware.

Tools and materials

To complete the installation work, you will need a set of such tools and materials:

- construction level;

- carpentry hammer;

- side cutter;

- drill;

- screwdriver;

- drill;

- self-tapping screws;

- nails (finishing and liquid);

- latches;

- pencil.

Finishing nails

In cladding work, finishing nails are often used. The main advantage is their inconspicuousness, which is achieved due to the small size of the "hat". Under the influence of the impact, the nails are flattened and become invisible.

Liquid Nails

With the help of the glue base of liquid nails, the fastening of the platbands is more durable and resistant. The front panel is fixed by applying an adhesive base to the inner side of the casing and pressing it against the wall. In this case, you must follow the rules for working with liquid nails:

- Apply to dry and degreased walls.

- Taking into account the fast solidification of the applied glue, the platbands must be properly pressed to the wall surface for 1-2 minutes.

- To improve adhesion, it is advisable to apply the glue pointwise or in stripes, excluding the surface treatment completely.

- Due to the toxicity of the material, the safety regulations must be observed.

- To apply the glue, use an assembly gun, which is well suited for gluing in hard-to-reach places.

Self-tapping screws

The assembly of platbands with self-tapping screws is considered one of the highest quality. To simplify the process, with the help of a drill, holes are prepared into which screws with a length of at least 2 centimeters can be easily screwed in.

Latches

Snap fastening is a simple and popular method. The use of a casing with a snap makes installation simple, while a wide section of the part needs to be placed in a special gap and snap into place without much effort.

The only drawback of this method is based on the fact that the platband made of MDF, with constant removal, undergoes rapid wear and tear and delamination, which causes the destruction of the joint.

Telescopic way

The name of the method implies the conditional ability of the platband to adapt to the thickness of the wall. The transformation is usually performed using an adjusting angle that moves into a special groove located on the end side of the door structure.

In the process of such movement, it becomes possible to narrow or expand the details of the casing.