How to insulate a house using perlite

Perlite as insulation is used in the form of sand (bulk insulation); component in heat-insulating products and dry ready-made building mixtures.

Perlite sand as insulation for walls

Perlite sand for arranging the thermal insulation of a house is an excellent material with which you can not only effectively insulate a home (heat losses are reduced by 50%), but also significantly lighten the structure of the building.

We begin the arrangement of foam perlite thermal insulation after part of the bearing wall (internal) and external brickwork (4-5 rows) have already been erected. Backfilling of coarse perlite expanded sand (with a granule size of about 6 mm), previously dedusted, is carried out in the gap between these two walls and carefully compacted (the volume should decrease by 10%). We fill the sand by hand or using a sandblasting machine. We repeat this operation several times until the walls are fully erected. By the way, in terms of heat-saving properties, a perlite layer with a thickness of about 3 cm corresponds to a brick wall of 25 cm. When building panel houses, sand is poured between sheathing sheets (internal and external).

If you are insulating an old house, in the walls of which there are voids, then sand filling can be done in two ways:

- carefully pull out a few bricks from the wall and pour perlite through the hole formed;

- drill a hole in the wall (with a diameter of 30 ÷ 40 mm) and through it, using a special installation, inject heat-insulating material.

Perlite sand is a versatile non-combustible building material that has a number of advantages:

- excellent sound, noise and heat insulation properties (moreover, it can be used to insulate walls from any material);

- environmental friendliness;

- lightness (by weight);

- resistance to temperature extremes;

- durability.

Advice! You should not use perlite sand, which is a very moisture-absorbing material, as insulation in places with high humidity.

The only drawback of sand is that it is very dusty: therefore, it is recommended to slightly moisten it before use.

Floor insulation with perlite

For thermal insulation of the floors, we use expanded perlite, which we pour onto the cement-sand base of the floor and level it with the building rule. The height of the sand insulation layer is the desired thickness plus 20% of the additional volume for shrinkage.

Unevenness and pipelines are sunk in a layer of bulk material, on top we lay slabs and flooring. If there is no basement under the house, then in order for moisture to accumulate and drain away, we put drainage pipes and absorbent pads under the perlite.

Another effective way to insulate a concrete floor can be laying a kind of "pie": we equip a perlite screed between two layers of concrete. First, we prepare a perlite solution with the following components:

- cement - 1 m2;

- perlite - 3 m2 (grade M75 or M100);

- sand - 2.2 mᶟ;

- water - 1.5 mᶟ;

- plasticizers - 3 ÷ 3.5 l.

Stir all the components of the mixture until the water comes to the surface: this is a sure sign that the solution (perlite screed) is ready for use.

Advice! Since perlite is a very light material, it is recommended to carry out all work with this material indoors, so that the wind does not interfere with the work process in any way.

After the perlite screed is applied to the concrete base, we leave it to harden.After 1 week, we get an excellent thermal insulation layer for the floor, which will last for many years. On top of it we lay the second layer of concrete.

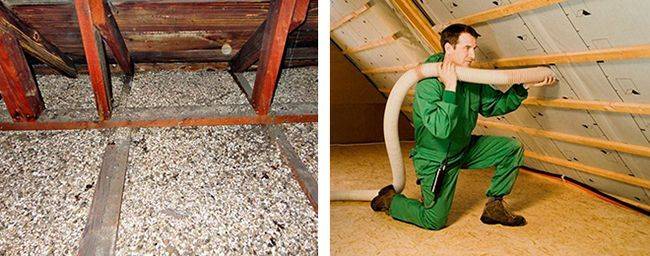

Roof insulation

If you do not intend to equip a living space in the attic, then it will be quite enough to insulate only the attic floor with expanded perlite. Otherwise, we put perlite between the beams of the roof slope into boxes that are specially made for this purpose; then we carefully tamp the sand. The job does not require specific skills and knowledge.

Views

There are two types of lime, which are distinguished by the amount of silicates and calcium aluminoferrites in them: air and hydraulic. They perform various functions, for example, air accelerates the process of concrete hardening, and hydraulic accelerates reactions in water.

It is important that all fragments of the substance are the same size. This moment indicates that the raw material was completely calcined in the furnace.

If there are too large or too small pieces, then they may not completely undergo heat treatment, and this will reduce the quality of the finished material.

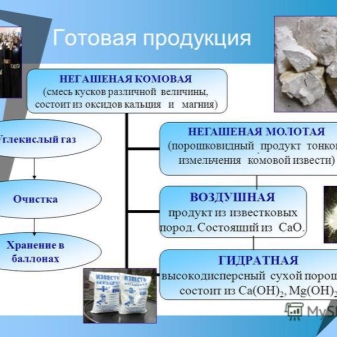

There are several types of material according to the type of processing:

- quicklime lump (boiling pot);

- quicklime ground (powdery);

- quenched hydrated - Ca (OH) 2;

- lime dough;

- lime milk.

Lump lime

Lump lime is a mixture of lumps that differ in size. It is composed of calcium oxide and magnesium, as well as materials such as calcium carbonate, aluminates, silicates. Ferrites of magnesium or calcium can be added, which are formed during the roasting of raw materials.

Good concrete strength is ensured due to the fact that lump lime requires very little water (due to fine grinding of the material) and practically does not generate waste.

Ground lime

Ground lime has the same composition as lump, but the difference is that the lumps of raw materials are ground much harder and more thoroughly.

The main advantages of ground lime:

- strength;

- water resistance;

- fast hardening.

To increase or decrease the rate of hardening, calcium chloride or sulfuric acid is often used (gypsum material is also suitable).

Hydrated lime

Hydrated lime (also called fluff) is a slaked type of material with a highly dispersive composition. Quenching takes place by adding water to the raw lime. To prepare such a solution, 70 to 100% water is added to the powder.

In order for the lime to go through the slaking process completely, it must be placed in a special pit for 2-3 weeks. So it will gain optimal strength and ductility. The shortest maturity period is 36 hours. In order to prevent the raw material from burning out, it is advisable to add water gradually until the moment when steam ceases to be emitted.

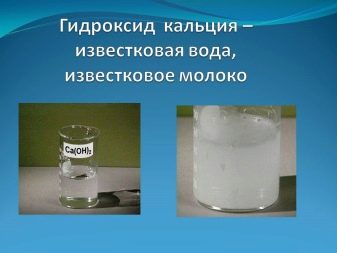

Lime dough is formed when enough water is added to form a plastic material. You can also find a solution such as milk of lime (mainly used to whitewash tree trunks). Milk of lime is made by adding excess water to the dough of lime.

General information

Lime itself is a mixture of substances that are a product of the calcination of limestone rocks. Most often on the shelves of our stores there is quicklime, or lumpy, there is also "fluff" lime.

Lime treatment of walls is the most hygienic way of finishing. The fact is that this material neutralizes any microorganisms that get on it. In addition, lime has excellent strength and moisture resistance.

This finishing method has its drawbacks. If the person performing the work does not know how to dilute lime, and does it wrong, then streaks, bubbles and stripes will necessarily remain on the treated surface.A too liquid solution will not give a beautiful, even color, and an excessively thick solution will become poorly on the wall, and after a while it will rise and fall off.

Like all other building materials, lime is subject to standardization. The quality of the material depends on the percentage of magnesium in it. In lime of the first grade, the total amount of these substances must be at least 90%. The lower the grade, the less oxides. In lime of the lowest, fourth grade, the total amount of oxides of magnesium and calcium does not exceed 60%.

In agriculture, lime is used:

- for the production of lime fertilizers;

- when preparing the necessary for the treatment of trees and shrubs from pests;

- for treating beds from pests and combating diseases of some plants;

- when tanning animal skins;

- for the preparation of calcium compounds used for wastewater treatment;

- for the preparation of E 526 - an additive used in the food industry.

Applications of lime

Lime in ground form is usually used as a fertilizer. But it should be noted that this is not the only place where lime is used. Almost every summer cottage has a special cellar for storing the harvested crop and the necessary gardening tools. Lime here acts as an excellent means of fighting mold. They just whitewash the cellar with it.

Slaked lime can be used as an effective remedy for combating larvae and bugs, for the next whitewashing of trees and for processing various wooden objects that actively interact with the soil (these can be fences, bench legs, plant supports, etc.).

Ground limestone has also found its use in agriculture, it serves as an excellent raw material in the production of feed for livestock, feeding poultry

Quicklime is a popular product in the food industry. It is found in the complex composition of many food products in the form of the E-529 emulsifier. This component serves to mix substances that are considered immiscible in nature, such as oil and water.

LIME-CONTAINING HYDRAULIC SUBSTANCES.

They are subdivided into lime-slag with the addition of granular slags, lime-pozzolanic with the addition of sedimentary or volcanic active rocks, lime-ash with the addition of ashes of some types of fuel. Lime-containing substances are involved in the preparation of low grades of concrete and mortars, which are used in underground structures.

Lime-containing hydraulic substances are produced in grades 50, 100, 150, 200.

When buying lime, you need to pay attention to the presence of instructions for the preparation and storage of the solution. There are two known methods for preparing lime: dry and wet.

The second method is most suitable for construction. This method requires a box and a soaking pit. The box, or created, should be 30 cm deep, 2 m wide and 1 m long.You will need to make a hole in the wall of the box with a flap that will hold back large pieces of lime

There are two known methods for preparing lime: dry and wet. The second method is most suitable for construction. This method requires a box and a soaking pit. The box, or created, should be 30 cm deep, 2 m wide and 1 m long. You will need to make a hole in the wall of the box with a flap that will trap large pieces of lime.

Take the crushed lump lime and place it in the box, gradually fill it with water. When steam is generated, the lime will decompose, turning into milk of lime. Use a rake to stir the milk well and dilute again with water. After that, open the drawer flap, release the contents of the drawer into the pit and leave it to get wet for the time specified in the instructions.If for some reason you do not have instructions, you can determine the readiness of lime by cracks (1–1.5 cm wide) that have appeared on its surface. To prevent foreign objects from entering the lime pit, keep the pit closed. When preparing the mortar, do not use the lower layers, because they may contain unextinguished particles of material that will cause the plaster to crack.

How to use fluff for the vegetable garden and garden?

There are the following main ways to use fluff:

- deacidification (liming) of the soil;

- use with other fertilizers;

- as a means for controlling weeds and pests.

With fluff, they not only process trees and large shrubs from pests, but also feed the soil in order to increase the fertility of the soil, as well as reduce the level of its acidity.

When using fluff in the garden, you must remember the following nuances:

- On the time of fertilizer application. If the soil has not been exploited too much, then liming the garden is enough every 4 years. Otherwise - every 3 years.

- It is forbidden to use in parallel with humus.

- Recommended for use on heavy ground.

- Do not store indoors, because upon reaction with water, it will begin to heat up and evaporate, thereby harming the human body.

- It is allowed to use in parallel with wood ash, especially for processing plants that do not react well to chlorine.

Soil deoxidation with slaked lime: when and for what purpose?

Deacidification (liming) of the soil is a process to improve the quality and structure of acidic soils. It is carried out through the application of fertilizers that contain a large amount of calcium. This also applies to fluff.

This is required for the correct process of soil formation, increasing yields, and improving the availability of nutrients for plants. Soil acidification in the garden indicates that calcium is being displaced by hydrogen ions. The mineral deficiency is replenished precisely by liming. The procedure improves metabolic processes between plant cells, saturates the soil with magnesium and other useful substances, helps to loosen the earth, improve air exchange in it.

It is required to alkalize the soil with the help of fluff if there are plans for the future planting in the garden of such crops as: cabbage, carrots, garlic, onions, beets, spinach, celery, alfalfa. They will not yield a good harvest if the soil is acidified. They will not be able to fully develop on such a site. This also applies to some colors.

For cucumbers, grapes, corn, cereals, legumes, sunflowers, lettuce, neutral soil is required, but adding fluff will not harm them.

For fruit and berry crops, the acidity should be as follows:

- pears and apple trees - up to 6.5%;

- plums - up to 7%;

- raspberries, gooseberries, blackberries - up to 5.5%;

- currants - up to 6%;

- strawberries - up to 5.2%.

If there are deviations from such indicators, then it is required to deoxidize the soil in the garden.

Fluff is supposed to be brought in during plowing the soil in the fall. After that, mix with the soil to activate the action. If the territory of the garden is small, then the powder must be scattered by hand and immediately mixed with the soil. Fertilization is required gradually. The algorithm of actions is as follows:

Initial introduction. First you need to determine the exact acidity level. The deoxidation procedure is carried out in parallel with digging. The main fluff addition is usually done once every 3-4 years.

Re-adding. This is required if the acidification level of different areas in the garden is different. The procedure is carried out dosed and only on the necessary areas

Particular attention should be paid to those plants that are most affected by a decrease in the level of calcium in the soil.

It is recommended to carry out the main deoxidation in the garden 2 years before the trees and shrubs are planted. During this time, the acidity level will have time to recover.

For 1 sq.m. sour land requires up to 650 g of fluff. If the soil is moderately acidic - 520 g, and if it is not too acidic - 450 g. A 10-liter container can hold 25 kg of fluff. The composition must be distributed as evenly as possible.

Use with other fertilizers

If you plan to use fluff together with other compositions, then you need to take into account some features:

- do not mix with crushed chalk, dolomite flour, marl;

- it is allowed to make a mixture with ground limestone (calcium-type organic matter).

To the question of which dolomite flour or fluff is better for the garden, you can give the following answer. If we compare the calcium content, then in fluff it is 8% less than in dolomite flour.

As for magnesium, the fluff does not contain such an element, but its specific gravity in dolomite flour is 40%. Thanks to this compound, photosynthesis takes place.

Fluff works faster than dolomite flour, but after using it, the plants are more difficult to absorb phosphorus. The only advantage of fluff compared to dolomite flour is its lower cost.

How to use?

When preparing lime mortar, it is important to ensure the safe interaction of raw materials with water for humans. It is advisable to carry out work in a well-ventilated area, and preferably in an open space.

Since the substances used are chemistry, it is necessary to adhere to safety rules when working with such materials.

Powder can be used both dry and liquid. To prepare a liquid solution, the powder is poured into a container and filled with water. The solution must be mixed and diluted to the required consistency.

To whitewash trees, the raw material is diluted with water and applied to the tree trunk using a wide brush. But due to the liquid consistency of the solution, you will have to process the barrel several times. In order to shorten the work time, you can add clay, milk, PVA glue to the solution. These ingredients will make the mixture thick and viscous, and it will lay evenly on the surface. Before processing the tree, you need to remove all the dead layers of bark, while not damaging the trunk.

To protect plants from fungus, you can use soda ash instead of lime, because soda dissolves faster and completely in water.

Before using bleach, it is necessary to check the reaction of the surface. To do this, you can treat a small area, and if it remains intact after about 10 minutes, then you can use bleach on the entire surface. First, water is added to the raw material in a small amount and stirred until sour cream, and then more water is gradually added, also stirring, until a liquid solution is formed. Dry bleach is used only on damp surfaces.

In construction, it is recommended to use quicklime ground lime for the manufacture of plasters, cinder concrete, and coloring elements. In other cases, slaked lime is used, which, due to its moisture resistance, prevents the formation of mold.

The fluff has a wide range of applications: from household needs to construction. To prepare the fluff, it is necessary to pour the raw materials into a metal container without rust (or into a plastic one) and gradually add water, stirring the solution. Once the mixture is ready, you need to leave it to infuse for several hours or days. The longer it will stand, the higher its quality and strength indicator will be.

Help with burns

A lime burn is a chemical damage to the skin, which is fraught with the most unpleasant consequences. Quicklime is an alkali that emulsifies and dissolves sebum, penetrating into the deep layers of the epidermis.Outwardly, the burn looks like a complex necrosis of tissues of an off-white hue with the formation of loose scabs. When in contact with the skin and mucous membranes, alkali penetrates in all directions, therefore the lesion focus is much larger than the zone of contact with lime. Damaged tissues partially lose their ability to regenerate and wounds heal for a very long time.

In case of defeat, medical assistance should be provided immediately. It is necessary to promptly call a doctor, and while she is going to try to improve the condition of the victim. If slaked lime gets on the skin, then rinse the affected areas with cold water for at least 15 minutes, and then treat with chamomile infusion or anti-inflammatory ointment.

But if a quick burn occurs, then rinsing the skin with water is strictly prohibited, because this can aggravate the situation and cause irreparable damage to health. Most of the substance will come out with tears, and its remains must be removed with a cotton cloth and greased with oil or grease. Incidentally, this is the only type of chemical damage that can be used. For any other types of damage, such reagents are strictly prohibited. The wound should be covered with sterile tissue and then immediately taken to the hospital.

The situation is more complicated in the case of contact with lime in the eyes. It causes rather dangerous consequences, up to partial or complete loss of vision. Small and medium fractions are not so dangerous, they can only cause conjunctivitis. Large parts literally stick to the mucous membrane of the eye and actually corrode them, penetrating inside and causing sharp pain, burning and spasm of the eyelids.

First aid includes:

- instillation of disodium salt, which binds metal ions;

- use of pain relievers, including local ones.

For information on how to extinguish lime with your own hands, see the next video.

How to breed?

There are 3 ways to create hydrated lime.

- In the first version, lime clods are used. They are laid out in layers 0.25 m thick. These layers are poured over with water. Wet sand is also added. After a couple of days, the quenching process will be completed, and the mixture will be ready for use.

- In the second option, you need to dig a hole and install a wooden box in it, at the bottom of which there should be a damper made of a fine mesh. The lumpy material is placed in a box, then it must be filled with water. Liquid is added as the lumps break down into smaller fractions. As soon as the extinguishing process occurs, it will be necessary to drain the excess water through the damper, while the mixture must be covered with a 10-centimeter layer of sand. This technique protects the composition from drying out.

The third option involves slaking lime by mixing it with water. You can prepare a calcium hydroxide solution using the third method yourself, by analogy with the production process.

It is important to follow a certain algorithm of actions.

- Take care of safety measures. To do this, be sure to wear tight clothing, gloves and protect your eyes. Remember that if the composition comes into contact with the mucous membrane of the eye, vision can be severely affected.

- Use a plastic container to dilute the compound. If you chose a container made of metal, then check it for rust. There should not be such formations.

- An ordinary wooden stick or even a stalk from a garden appliance is suitable as a tool for mixing the composition.

- Before preparing the mixture, measure out the required amount of dry lime and calculate its proportions with water. Remember that the consumption of the substance per 1 sq. m. will depend on its consistency and on the number of layers that you plan to apply to the surface.

- Pour lime into the container first, and then add water in portions. In this case, be sure to stir the composition throughout the entire time. The water should be cold.If you add water at high or even room temperature, then the quality of the final composition will significantly deteriorate.

- The readiness of the solution can be determined by the trace on the stick. If it has a pronounced white tint, then the composition has reached readiness.

- In order for the solution to infuse, after stirring it should be left for a while. If possible, wait a few days, but if this is not possible, insist the slaked lime for several hours.

A separate process is the dilution of the fluff to the consistency of milk of lime. After obtaining calcium hydroxide by mixing an equal amount of lime and water, the substance is left for some time to dry out. Then the resulting composition must be diluted with 9 liters of water. The finished milk of lime is a 10% mixture of lime.

Views

Quicklime is classified according to many indicators, allowing it to be subdivided into different subspecies. According to the degree of particle size reduction, there are lumpy and ground lime. The lumpy type is characterized by lumps of various shapes, fractions and sizes. In addition to calcium oxides, which are the main component, and magnesium oxide, to a lesser extent in the composition, there may be other additives in the mixture.

Depending on the degree of calcination of the lump material, a distinction is made between medium calcined, soft calcined and highly calcined lime. The degree of firing of the material subsequently affects the time spent for the extinguishing process. During the firing process, the composition is enriched with aluminates, silicates and magnesium or calcium ferrites.

The degree of firing is influenced by the residence time of the product in the oven, the type of fuel and the temperature. In the bulk firing method, where coke is used as a fuel, and the temperature in the furnace is maintained at about 2000 ° C, carbide (CaC?) Is obtained, which is subsequently used in various fields. Lumpy lime, regardless of how and to what extent it was calcined, is an intermediate product and therefore undergoes further processing: crushing or slaking.

The composition of the ground mixture is not much different from the lumpy one. The difference lies only in the size of the lime particles. The grinding process is used for more convenient handling of calcium oxide. Crushed granular or ground quicklime reacts faster with other components compared to the lumpy form.

According to the degree of grinding of particles, crushed and powdered lime are distinguished. For grinding, depending on the required particle size, crushers and mills can be used. When choosing mills and grinding schemes, they are guided by the degree of lime burning, and also take into account the presence of solid inclusions and flaws during the burning process (underburning or overburning). Particles of material, fired in a strong or medium degree, are crushed by impact and abrasion in special containers of ball mills.

The lumpy mixture is used to obtain different types of hydrated lime. The quenching process (inorganic chemistry) is very violent, the water boils during the reaction, so the lumpy mixture is called "boiling water". Different percentages with water give compositions of different consistency. There are three types of slaked lime: limestone milk, limestone dough and hydrated fluff.

To obtain a lime dough, less water is required, but its amount is still several times more than the mass of lime prepared for slaking. As a rule, in order to obtain the desired pasty consistency, water is added to the product, which is 3-4 times the mass of the main substance.

A powdery mixture or hydrated fluff is obtained in the same way, but the amount of added water is less than for a pasty or liquid composition. Fine powder or fluff, depending on the percentage in the composition of aluminoferrites and silicates, is divided into air and hydraulic types of lime.

The time taken for the quenching reaction allows quicklime to be classified into fast-quenching, medium-quenching and slow-quenching. Fast-extinguishing formulations include formulations that take no more than 8 minutes to transform. If the quenching reaction takes longer, but the transformation does not last longer than 25 minutes, then such a composition is referred to as a medium quenching form. If the quenching reaction takes more than 25 minutes, then this composition is of the slow-quenching type.

How to whiten?

If you decide to whitewash the walls with slaked lime at home, consider the method of obtaining the composition. If you made the mixture not using a special hydrator-separator, but manually, then you must thoroughly mix the solution immediately before whitewashing. The composition is applied to the ceiling and walls with a large brush. The procedure starts from the left corner of the window

It is important to try to apply the solution without gaps, but in any case it is more advisable to apply several layers of the substance.

If a lime composition is used to whitewash trees, a certain sequence of actions must be followed.

- Fill a bucket with a volume of approximately 10 liters with water.

- A couple of kilograms of fluff should be diluted with 1.5 kilograms of clay and 300 grams of copper sulfate added to the solution.

- Then all components should be thoroughly mixed in water until a finished composition with the consistency of sour cream is obtained.

- The resulting solution is applied to the tree trunk. When doing this, do not scoop too much of the substance to avoid smudges. The finished layer should not exceed a thickness of 4 millimeters.