Profiled polycarbonate: material specifications

The dimensions of the profiled polycarbonate and other parameters differ both for sheets of different brands and for the material of the same brand, but with a different profile shape. However, despite this, there are characteristics common to the polymer corrugated board of all manufacturers:

- light transmission - up to 90%;

- density - 1.2 g / cm³;

- thermal conductivity - 0.21 W / (m · ° С);

- ultimate strength - 65 MPa;

- impact strength - from 50 J with a thickness of 0.8 mm;

- long-term temperature range - −50 ° С ... + 100 ° С;

- short-term temperature range - −50 ° С ... + 120 ° С;

- softening temperature - 145–150 ° С.

In addition, the maximum permissible load on the sheets is approximately the same, provided it is evenly distributed. It is shown in the table below. Please note that these values are valid for roofs with a slope of at least 10%. They are indicative and determined in practice, therefore, they do not replace design calculations according to current building standards.

| Load (kg / m²) |

Maximum distance between cross supports (mm) | |||

| 0.8 mm | 1.0 mm | 1.2 mm | 1.5 mm | |

| 50 | 975 | 1050 | 1125 | 1225 |

| 75 | 850 | 925 | 975 | 1050 |

| 100 | 775 | 850 | 900 | 950 |

| 125 | 725 | 775 | 825 | 900 |

| 150 | 675 | 725 | 775 | 850 |

| 200 | 625 | 650 | 700 | 750 |

| 250 | 575 | 625 | 650 | 700 |

| 300 | 525 | 575 | 625 | 675 |

| 350 | 500 | 550 | 575 | 625 |

With vertical installation of sheets, the permissible load can be increased by 10%. If you do not know how to calculate the snow and wind load, read it - there is a step-by-step method with examples and standards.

To make it convenient for you to compare different monolithic profiled polycarbonate, the dimensions, thickness, weight and other characteristics of the material of the four popular brands have been brought together in one table.

| Brand | Thickness, mm |

Length, m |

Width, m |

The weight 1 m², Kg |

Views profile (step / height) |

|

| Trapezoid | Wave | |||||

| Borrex | 0,8–1,4 | 2 | 1,05 | 1–1,7 | 70/13 | 76/13 |

| Plastilux | 0,6–2 | 2 | 1,15 | 0,75–2,5 | 70/18 | — |

| Palram SUNTUF |

0,8–2 | 1,5–11,5 | 0,48–1,87 | 1,17–2,9 | 76/18 137,5/18 190/27 87,5/24 250/40 183/38 |

32/9 76/18 76/15 177/51 107/27 |

| Polygal | 0,8 | 1,5–11,8 | 1,26 | 1 | 137,5/18 | — |

Three out of four manufacturers produce a universal polycarbonate profile that is suitable for both roofing and wall cladding. Only Palram has specialized profile polycarbonate for roofs with wave heights of 24 and 27 mm, as well as industrial profiles with wave heights of 40 and 51 mm.

The thickness of Borrex corrugated sheet changes in increments of 0.1 mm. For Plastilux it depends on the series of profiled polycarbonate, while for Palram SUNTUF it depends on the shape of the profile: the higher the wave height, the thicker the sheet.

Properties and parameters

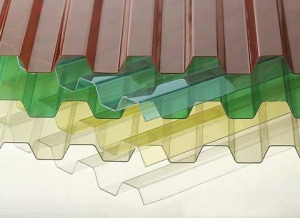

The main spectrum of polycarbonate colors is shown in the photo in the following variants: transparent, white, bronze, green and blue. If necessary, the customer can offer another color saturation, suitable specifically for his object.

Cellular polycarbonate consists of two or more plates, interconnected by stiffening ribs, which in cross-section are very similar in structure to cells. The thickness of the sheets ranges from 4 millimeters to 42 millimeters, depending on the number of layers of the product. This kind of material has many distinctive characteristics that distinguish it favorably from a number of construction products familiar to all. Excellent heat and sound insulation is the main strong point of carbonate. This material with a thickness of up to 10 millimeters is not inferior to a glass unit in terms of its functionality. In the case when the thickness of the honeycomb two-color polycarbonate exceeds 16 millimeters, then it surpasses the glass unit in terms of its main properties:

The lightness of the material. Cellular polycarbonate, with the same thickness and area, weighs three times less than acrylic and sixteen times less than glass;

- Excellent insulating and heat saving characteristics.The heat transfer coefficient is equal to 2.5 W / m2K, ordinary glass is inferior to polycarbonate in these characteristics;

- High light transmission, with transparency up to 85%;

- Impact resistance allows you to withstand various mechanical influences;

- Tensile and flexural strength is practically unparalleled in the range of similar materials;

- Resistance to atmospheric and temperature influences. Temperatures in the range from -35C to + 120C degrees will not have a destructive effect on polycarbonate;

- Protection from ultraviolet rays, due to the application of a special coating on the outside of the sheet;

- Good refractory properties prevent the material from igniting, and being in the epicenter of the flame, polycarbonate breaks down into flakes, practically without emitting toxic substances.

The use of plastic profiled sheet with examples [19 photos]

Plastic sheeting is used quite widely: from the roofs of residential and industrial buildings to light-permeable inserts in noise-absorbing road fences. Let's dwell on the most common options with illustrative examples.

Plastic corrugated roof

Both PVC roofing sheeting and polycarbonate sheets can be installed on pitched roofs with a minimum slope of 6%. The main thing is to follow the manufacturer's instructions for installation and the step of the lathing.

Transparent plastic decking on the roof of the attic

Plastic profiled sheet as a translucent insert in the roof

Summer house made of transparent plastic PVC sheet

Usually, a plastic roofing sheet is used to create "windows" in unheated attics, since standard dormer or dormer windows are much more expensive. Not to mention the significantly greater risk of leaks with improperly made junction points.

Not for residential attic

If you plan to make living quarters in the attic in the foreseeable future, then a transparent corrugated board for the roof is not the best option. After all, windows are not only a source of light, but also a way to quickly ventilate a room. In addition, in case of excessively bright light, they can be curtained or shutters can be closed, which is difficult to do with transparent inserts in the roof.

Plastic corrugated board for a fence

Transparent durable plastic is an alternative to a chain-link mesh at the dividing lines between plots in summer cottages or cottage settlements. Solid non-translucent fences on the border are prohibited so that there is no shading of the neighboring area, and the picket fence or netting does not prevent animals from entering your territory. A plastic profiled sheet for a fence solves both problems at once: it does not interfere with the passage of sunlight, and the smooth surface does not allow even a tenacious cat to climb over it.

Also, corrugated plastic sheeting is actively used as inserts in solid metal fences located along roads, all with the same purpose of minimizing shading.

Verandas, gazebos, awnings

Fully or partially transparent roofs are perfect for gazebos, terraces, verandas, awnings. Plastic corrugated board will trap ultraviolet rays, allowing you to enjoy the sun's warmth and light without the risk of getting a sunburn, and its transparency will make any structure airy and light, visually reducing its dimensions. Thanks to this, the same gazebo or shed will not clutter up even a small area.

Gray PVC corrugated board on the roof of the veranda

The roof of the veranda is made of PVC corrugated board

Canopy made of blue plastic corrugated board

Balcony covered with corrugated plastic sheet

Canopy made of transparent profile sheet

Large closed gazebo with a transparent roof

Canopy made of gray transparent corrugated board

Self-cleaning roof

The profiled plastic sheet is a very slippery material.Therefore, with a roof slope of more than 10%, moisture does not linger on the overhang and carries away any pollution. Therefore, any rain washes such a roof, keeping it transparent without additional maintenance.

Greenhouses

Roofing plastic sheeting transmits up to 90% of sunlight, which, combined with durability and self-cleaning, makes it an excellent material for the construction of greenhouses and conservatories. Moreover, both small greenhouses on personal plots and large-scale industrial structures.

Greenhouse with corrugated PVC roof

Profile sheet on the roof and walls of the greenhouse

Large greenhouse made entirely of PVC corrugated board

Greenhouse with two lifting sections for ventilation

Plastic profiled sheet for warehouses, workshops and shopping centers

For this task, corrugated plastic sheet is used as roof and wall inserts. This allows you to fill the room with sunlight.

Natural lighting is important as it improves employee productivity, visitor mood and, trite, saves energy.

Arched hangars with transparent inserts - "windows"

Granary with transparent plastic corrugated sheet windows

Large canopy made of green plastic profile

A canopy made of blue translucent profile over the pool

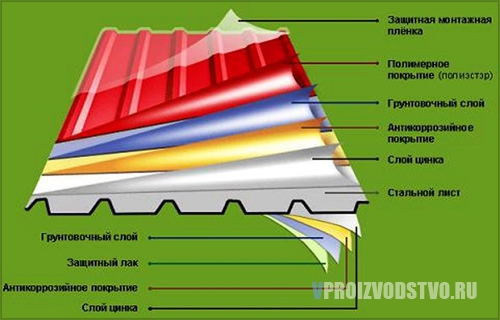

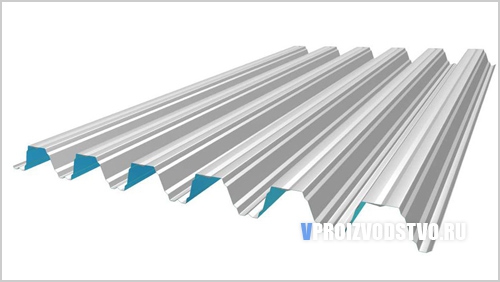

Sheet structure and features of various coatings

In addition to the decorative outer coating, the steel in each profiled sheet is covered with several protective layers that protect it from destruction and increase the service life of the material.

By type of anti-corrosion coating:

- zinc plating is a standard and reliable coating of zinc steel that protects against corrosion. The higher the quality of the sheet, the more zinc was consumed per 1 m2 (indicated in grams).

- aluminum zinc plating (a mixture of zinc and aluminum) is an economical coating option used by manufacturers to reduce the cost of the material. Due to the addition of cheap aluminum, the price of corrugated board becomes lower, but the protective properties also decrease proportionally. Therefore, aluzinc sheets are produced with only one more decorative coating, most often polyester.

The upper protective layer has a decorative or decorative and protective function, enhancing the strength of the corrugated board. The cheapest corrugated board is galvanized without color coating. The quality of such material is lower and the appearance is unpresentable, therefore it is used in large areas, for floors or barriers, where the lack of color aesthetics is compensated by a low cost. Slightly stronger is galvanized with the addition of silicon.

Possible color options:

Polyester (gloss) is the simplest decorative coating for a galvanized or alumina-zinc layer of corrugated board, it is used as an additional protection of metal against corrosion. Disadvantage - due to the small thickness of the sheet, it quickly deforms, glossy surfaces are easily damaged and lose their appearance due to scratches, dust.

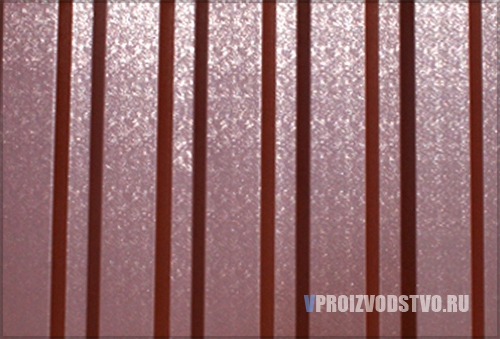

Polyester (matte) - a more reliable coating, resistant to various damages due to the special structure, reminiscent of velvet, and the thickness of the top layer. It retains its original color for a long time, does not give glare, scattering light.

"Pural" - a coating based on a mixture of polyurethane with the addition of polyamide, 50 microns thick. Possesses high reliability, resistance to low temperatures and ultraviolet radiation, it is recommended for roofing sheeting.

Plastisol (and its latest modification, HPS200) is the most durable of all types of coatings (thickness - 200 microns), based on polyvinyl chloride (PVC). This polymer coating with relief embossing and a special line notch is designed for difficult climatic conditions, is resistant to mechanical damage, and is durable.

Useful on the topic:

Useful on the topic:

- We start the production of corrugated board

- Overview of equipment for the production of corrugated board

- Scopes of corrugated board

- Analysis and prospects of the Russian market of corrugated board

PVC corrugated board Ondex: installation instructions

Time usually elapses between the purchase of the material and its installation - often several weeks, sometimes months, even years

At this time, it is important to properly store the profiled PVC, otherwise it may deform, lose transparency, become less elastic.

To avoid this, after purchase, place the Onedex profile in a warm, dry place where it will not be exposed to direct sunlight. The plastic slate should lie on a flat horizontal surface, and you should not put anything on it, especially heavy objects with sharp edges.

Immediately before installation, the sheets need to be taken out, cleaned, made a layout diagram, cut, if necessary. After that, wait for a temperature of + 5 ... + 25 ° C and proceed with the installation of Ondex according to these instructions:

- The plastic profiled sheet is laid from bottom to top. Installation is started from the side of the roof opposite to the prevailing wind.

- Lay the first sheet with an overhang of 100-200 mm, mark the points of attachment of the Ondex to the batten. Drill holes at these points with a diameter of 3-4 mm larger than the screw diameter of the fastener.

- Ondex is fastened to the top of the wave using special brackets with a rubber lining every 2-3 waves, depending on the profile shape, wind and snow load.

- After fixing the first sheet on the side of it, lay the next one with an overlap in one or two waves.

- After completing the row, begin to lay the next one with an overlap of 150-200 mm.

- The final stage of installation is the installation of the ridge and other additional elements.

When mounting on a facade, the rules are the same, but Onedex is mounted at the bottom of the wave. In this case, special fasteners are not needed - a high-quality self-tapping screw with a rubber lining is enough.

be careful

Do not step on the plastic profile as this may damage it. Use a substrate to move on the roof: board, plywood, chipboard at least three meters long.

Types of corrugated board depending on the type of protective coating

All coatings used to protect corrugated board can be divided into two large groups - zinc or aluzinc coating and polymer coating.

Galvanizing - the simplest basic protection

Profiled sheet of any type is made of cold-rolled steel with a thickness of 0.5 to 1 millimeter. Various coatings are used to protect the metal from corrosion. The overwhelming majority of these coatings are based on the familiar hot-dip galvanizing. This means that the steel sheet is dipped in molten zinc, creating a protective layer with a thickness of 25 to 30 microns. It turns out galvanized corrugated board - a ready-made material that is the cheapest. It is used for repair, construction and restoration work.

Aluminum-zinc coating - protects against aggressive substances

Instead of galvanizing, the steel can be coated with a more resistant zinc-alumina, which is also called galvale. It consists of three components: zinc (43.4 percent), aluminum (55 percent) and silicon (1.6 percent). The last element is needed for a strong bond between the first two metals. Decking with aluzinc protection will be good for the roof of a house near a busy highway, on the seaside or in an industrial area. The aluminum included in the coating will protect the roof from all kinds of "chemicals" or marine vapors contained in the air.

Plastisol - will save from mechanical damage

For greater strength, the galvanized profiled sheet is primed and then covered with an organic polymer. The most durable of these polymers is a plastisol coating with a thickness of 175 to 200 microns. Such a solid layer will help to withstand blows with honor, as well as avoid scratches. Also, this plastic and durable material is not affected by aggressive environments. But it also has disadvantages: fading over time, instability to ultraviolet light and temperature extremes.

The appearance of the plastisol coating.

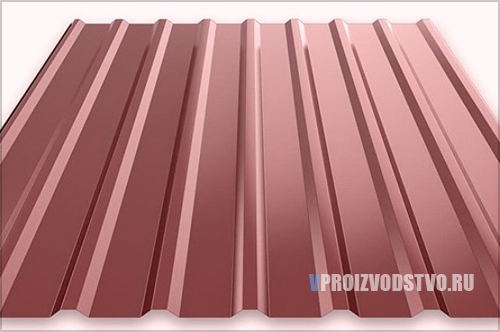

Polyester - popular, decorative, reliable

According to statistics, about 85 percent of roofing materials are covered with polyester. After all, it perfectly resists corrosion, and at the same time is not at all afraid of frost and heat, and also does not lose its bright color for a long time. Look very impressive, decorating buildings, corrugated board with a matte polyester coating.

Profiled sheeting covered with a polymer protective coating Polyester.

Pural is a beautiful and durable novelty

To be more precise, this material, developed not so long ago by Ruukki, is called PURAL matt. Its main component is polyurethane. A professional sheet covered with pural does not need to be afraid of sunlight, chemical aggression or corrosion. It can be used to construct not only the roof of the building, but also beautifully revet its facade.

The texture of the Pural polymer coating.

PVDF coating - the best in color fastness

This material (otherwise, PVF2, or polydifluorionate) is particularly resistant to negative weather conditions. Corrosion is not able to damage it, and the juicy color does not change at all for many years. Therefore, the facades of houses are most often faced with such corrugated board. This is especially successful if the color scheme of the finish is important.

Whatever the composition of the polymer protection in various types of corrugated board, it should be fixed. For this, a thin, shiny film of paint and varnish is used. It consists of several layers, reaching a thickness of 40 to 300 microns. This makes it possible to reduce the likelihood of corrosion to zero, and also has a decorative function. After a few years, this layer should be renewed - it is quite easy.

How to work with the material?

At home, a sheet of monolithic or molded polycarbonate can be subjected to different types of processing. Most often, bending, cutting, connection of individual layers to each other by gluing are carried out. This polymer does not create any particular difficulties in processing, it is well suited for cutting with hand or power tools.

Home cutting

Cast or extruded polycarbonate without meshes cannot be simply sawed without prior preparation. Best of all, it lends itself to cutting with a grinder with a disc for metal No. 125 installed on it. In this case, the cut is obtained without burrs and chips. And you can also perform laser cutting of sheets, use a jigsaw with a fine file. The sharper the cutting element, the better the procedure will be.

In the course of cutting, it is worth adhering to certain recommendations.

- The sheet is cut only in a horizontal position, placing it on a clean, flat surface. Any protrusions or other obstructions will lead to cracks or deformation.

- The cutting line must be applied in advance. The most convenient way to do this is with a marker.

- Panels less than 2 mm thick are cut in a stack, connected with clamps. This will avoid cracking the material.

- Cutting must be done from the side with UV protection. The protective film is not removed until the completion of the work.

Elements that are large in size are easiest to cut by placing them on a flat floor surface. A board is laid on top, on which the master can freely move.

How to bend a sheet at home?

Monolithic polycarbonate lends itself quite well to bending, but taking into account its characteristic radius. You can give the sheet the desired shape using a locksmith's workbench and a vice. Transparent or colored material is placed on a workbench, clamped, and then manually adjusted to the desired bending level

It is important not to use excessive force to maintain the integrity of the slab.

Bonding technology

The need to glue polycarbonate most often arises when joining sheets in greenhouses or other structures. The connection of the elements is carried out using special chemical compositions that do not affect the main characteristics of the material. In light, unloaded products - greenhouses, sheds - you can use several options for adhesives.

- One-component adhesives.They are also suitable for mounting polycarbonate sheets on rubber, metal, glass or polymer surfaces. There are many products in this category, you can choose Vitralit 5634, Cosmofen, Silicone mastic. One-component adhesives are characterized by fast curing, they are not afraid of moisture and high temperatures.

- EVA. Adhesives based on ethylene vinyl acetate are suitable for connecting polymeric materials to each other in different planes. It is a good choice for creating multi-layer products.

- Hot curing adhesives. Provides maximum bond strength. The best formulations have a polyamide base.

In structures operated under loads, two-component adhesives should be used - Acrifix, Altuglas. Formulations on a polyurethane base, which form a transparent elastic seam, are suitable. Silicone adhesives are often used to seal joints. Polycarbonate can be attached to flat surfaces with a special double-sided tape on an acrylic foam base. It is recommended to apply adhesives of thermoplastic, silicone, polyurethane types, as well as fast curing with a mounting gun.

Slate Ondex, Salux ↑

Many are interested in where and which transparent slate to buy.

However, it is very important to know which manufacturer you can trust unconditionally.

Ondex. This is a profiled board that is more durable than conventional plastic sheets. They are manufactured using a unique technology - "biaxial orientation".

Ondex. This is a profiled board that is more durable than conventional plastic sheets. They are manufactured using a unique technology - "biaxial orientation".

The essence of the patented development of the Solvay company in stretching a plastic sheet in the vertical and horizontal direction. At the same time, its characteristics are significantly improved, for example, a unique resistance to mechanical loads, in particular, shock, is acquired, which does not change at low temperatures.

Salux. Transparent profiled PVC slate Salyux has convenient dimensions that simplify installation. The coating has a long service life, it retains its qualities under adverse external, chemical influences. The undoubted advantage of the material is the budget price.

Advice

It is not recommended to install such a roof in areas where the temperature rises above 60⁰C, and in confined spaces it is necessary to provide for ventilation of the sheets.

2020 .

Major Brands of Corrugated Polycarbonate

Basically, in Russia, polycarbonate corrugated board of four brands is sold: Russian Borrex and Plastilux, Israeli Palram SUNTUF and Plazit Polygal CURROGAL (GRECA). There are also British polycarbonate sheets Marlon and products of Chinese manufacturers, but rarely.

Polycarbonate profiled sheet Borrex is produced by the Yug-Oil-Plast company with the main plant in Karachay-Cherkessia. Sheets are made from German or Japanese raw materials on Italian lines, so the material is of relatively high quality. But the price of Borrex polycarbonate profiled sheet is the lowest, except for the products of Chinese brands: 400 rubles per 1 m² with a thickness of 0.8 mm. However, for such savings you will have to pay with versatility - Borrex sheets can have only two profile shapes: wave and trapezoid, both 13 mm high.

Borrex profiled polycarbonate

Details about the material: technical characteristics, comparison with PVC corrugated board, table of permissible loads, possible colors and prices. Read, compare, choose.

Company Plastilux produces profiled polycarbonate under four trademarks at once: ROYALPLAST, POLYNEX, SUNNEX and GREENHOUSE-nano. These grades belong to different segments - from premium to ultra-budget - and differ in sheet thickness, density and thickness of the UV protective layer, as well as expected service life. At the same time, the shape of the profile is the same for all sheets - the company produces only profiled polycarbonate MP-20. Unlike Borrex, Russian raw materials are used for sheet extrusion, and the cost of the material is about the same - from 415 rubles per 1 m².

Palram SUNTUF - Israeli-made corrugated polycarbonate.Strong, durable material with a 10-year guarantee against haze, yellowing and damage to the sheet, provided that the rules of installation and operation are observed. There are five types of this material, including UV protection sheets on both sides and a specialized type for greenhouses with anti-condensation coating. Unlike Russian polycarbonate corrugated board, Palram SUNTUF has more than 20 possible profile shapes, including Greca 76 and MP-20, but it also costs almost twice as much - from 765 rubles per 1 m².

Profiled polycarbonate SUNTUF Palram

Find out all the most important about the material before making a purchasing decision: types, colors, profile drawings, characteristics and price comparisons. Polycarbonate corrugated sheet Plazit Polygal CURROGAL (GRECA) is very similar in characteristics to SUNTUF

This is due to the general conditions for both companies: they were founded at about the same time in Israel, and their products had to meet the same requirements. But these are, nevertheless, different materials. Polygal profiled sheet has fewer varieties, only one profile shape, but more color palette. In addition, in addition to the UV filter, you can choose to apply one of several selective coatings that allow only the desired spectrum of sunlight to pass through. Material costs from 640 rubles per 1 m², taking an intermediate place between SUNTUF and Russian brands

Polycarbonate corrugated sheet Plazit Polygal CURROGAL (GRECA) characteristics are very similar to SUNTUF. This is due to the general conditions for both companies: they were founded at about the same time in Israel, and their products had to meet the same requirements. But these are, nevertheless, different materials. Polygal profiled sheet has fewer varieties, only one profile shape, but more color palette. In addition, in addition to the UV filter, you can choose to apply one of several selective coatings that allow only the desired spectrum of sunlight to pass through. Material costs from 640 rubles per 1 m², taking an intermediate place between SUNTUF and Russian brands.

What is SALUX: PVC sheets of different shapes, colors, purposes

SALUX profiled PVC sheets are of seven types. Of these, five are transparent, and two are opaque, which are positioned as a replacement for euro slate or corrugated board.

Transparent views:

- SALUX W... The basic type of transparent PVC slate, budgetary, and therefore the least durable of the line. SALUX W sheet can be transparent colorless, bronze, smoky. Only this series is produced both in standard profiles 76/18 (wave) and 70/18 (trapezoid), and in a wave-like profile 146/48 of increased - 1.3 mm instead of 0.8 mm - thickness, which corresponds to the shape of a standard slate with seven waves.

- SALUX HR... High-strength material in the shape of a trapezoid 70/18, which is more resistant to hail compared to the W series, and also fades more slowly in the sun. It can be colorless, blue or green. Transparent slate Salux HR is available in three lengths: 1.8 m, 2 m, 3 m.

- SALUX STRONG... Extra strong corrugated PVC in a wave-like shape. Thanks to special additives, SALUX W STRONG slate is resistant to cracking, cloudiness, hail of any intensity. Available only in 2 m length and 1.2 mm thickness.

- SALUX PRISMA 3D... A wavy sheet with an original light-scattering structure in the form of many convex polygons. Due to its large thickness of 2.5 mm, SALUX PRISMA is a very durable material for PVC. Available in two colors: transparent colorless and bronze.

- SALUX WHR... Modification of the base series. SALUX WHR PVC sheets are thicker - 0.9 mm instead of 0.8 mm - and therefore more durable. In addition, they are 200 mm shorter for the 76/18 profile.

Regardless of the type, the purpose of all Salux series is the same, although the difference in strength is very significant. Thicker sheets are needed for regions with snowy winters, as well as for buildings with a relatively large roof area with a minimum slope. The thin profiled sheet is suitable for conventional pitched roofs.

Opaque views:

- SALUX WBS... Opaque lightweight PVC sheets SALUX WBS are positioned as a replacement for standard asbestos-cement slate or ondulin. They have increased thickness - from 1.2 mm to 2 mm - and temperature resistance - up to 86 ° C. Sheets can only be wavy and are available in six colors: black, anthracite, gray-green, terracotta, brown, silver.

- SALUX WS... Matt SALUX profiled sheet with a thickness of 1.2 mm and a length of up to 6 m. The purpose is the same as for the WBS series, but the WS material is intended to replace metal corrugated board, not slate. PVC profiled sheet withstands up to 80 ° C, is available in three colors: brown-green, brick, metallic.

Unlike the transparent Salyux slate, its opaque types are rarely used in Russia. This is mainly due to the price - that metal corrugated board, that ondulin cost either the same or cheaper matte corrugated plastic.

Profiled PVC is available in three profile shapes. Their drawings are shown in the table below.

| Profile | Drawing |

| SALUX Sinus 76/18 | |

| SALUX Trapez 70/18 | |

| SALUX Sinus 146/48 |

The table shows that the trapezoidal profile coincides with the shape of the C20 corrugated board. Its dimensions make it possible to lay PVC profiled sheet without the formation of gaps in the same way as a metal profile. At the same time, with a sufficient slope of the roof from the corrugated board, additional sealing of the joints is not needed.

Advantages and disadvantages

Slate Salux is a light material. One 0.8 mm thick transparent sheet weighs only 2.2 kg, which is approximately 1.35 kg per 1 m². It does not require powerful supporting structures and foundations, it is convenient to cut and fasten it on the roof: SALUX can be easily installed by yourself, and alone.

SALUX profiled sheet is strong enough for plastic. With a thickness of 0.8 mm, it can withstand the "bombardment" of hail with a diameter of 20 mm, and with a thickness of 1.2 mm, it effectively resists hail with a diameter of 40 mm. Despite this, the material is flexible - the minimum rounding radius is only 2.5 m.

SALUX profiled PVC sheets are not destroyed by corrosion, are not damaged by fungi, and are not suitable for food for insects and rodents. Polyvinyl chloride, from which the material is made, is resistant to most acids, alkalis, salt solutions, petrochemical products. Therefore, SALUX roofing lasts a long time, even near a port or a chemical plant.

The Salux price is low. In any case, in comparison with the price of other brands of plastic corrugated board. Moreover, this applies to both PVC profiled sheets and polycarbonate ones.

Since PVC is a smooth material, SALUX translucent roofing is literally washed with every rain. When the slope is more than 10º, dirt, dust, pollen, fallen leaves do not stay on the slope and are carried away by the water. Therefore, the Salux roof remains transparent, even if it has not been cleaned for several years.

Summarize. Advantages of SALUX transparent corrugated board:

- ease,

- impact resistance,

- flexibility,

- low price,

- transparency,

- ease of installation,

- chemical resistance,

- corrosion resistance,

- color fastness,

- self-cleaning of the surface.

Now about the disadvantages.

First of all, the service life of Salux is short when compared with traditional roofing materials. And we are not talking about tiles or slate, the roofs of which serve for centuries. Even the corrugated board or metal tiles with a polymer coating will have to be changed not in 10-15, but at least in 20-25 years.

The second drawback is gradual clouding. After ten years of service, SALUX slate will no longer be 88% transparent, but at best 82–84%. Yes, this is not critical for a gazebo or a canopy, which cannot be said about a greenhouse or greenhouse. This also happens with polycarbonate or Ondex, but they age more slowly.

The third drawback is brittleness at low temperatures. According to the manufacturer's instructions, SALUX PVC sheet can be used from -40 ° C to + 80 ° C, but already when the thermometer crosses 0 ° C, this material begins to rapidly lose its impact strength.And at -20 ° C, a moderate blow is enough for the plastic to crack. This drawback is typical for any PVC profiled sheet, but for polycarbonate profiled sheets, the temperature range is much wider.

The last drawback is the small variety of colors and profile shapes. This is critical when you need to choose the shape of the profiled Salux for the profile of the corrugated board. In addition, the transparent slate cannot be walked on, which complicates the maintenance of the roofs.

So, the disadvantages of PVC Salux:

- service life is shorter than that of traditional roofing materials;

- grows cloudy over time;

- narrow temperature range;

- fragility at low temperatures;

- a small number of possible colors and shapes;

- difficulties in roof maintenance.