Specifications

When purchasing a sand and gravel mixture, you must pay attention to the following technical indicators:

- grain composition;

- the volume of content in the mixture of sand and gravel;

- grain size;

- impurity content;

- density;

- characteristics of sand and gravel.

The technical characteristics of sand and gravel mixtures must comply with the accepted state standards.

General information about sand and gravel mixtures can be found in GOST 23735-79, but there are also other regulatory documents regulating the technical characteristics of sand and gravel, for example, GOST 8736-93 and GOST 8267-93.

The minimum size of sand fractions in ASG is 0.16 mm, and gravel - 5 mm. The maximum value for sand according to the standards is 5 mm, and for gravel this value is 70 mm.

It is also possible to order a mixture with a gravel size of 150 mm, but not more than this value.

The content of gravel grains in natural sand and gravel mixture is approximately 10-20% - this is an average value. The maximum amount reaches 90%, and the minimum is 10%.

Dimensions of doorways

The content of various impurities (particles of silt, algae and other elements) in a natural ASG should be no more than 5%, and in an enriched one - no more than 3%.

In the enriched ASG, the amount of gravel content is on average 65%, the clay content is minimal - 0.5%.

By the percentage of gravel in the enriched ASG, materials are classified into the following types:

- 15-25%;

- 35-50%;

- 50-65%;

- 65-75%.

Important characteristics of the material are also indicators of strength and frost resistance. On average, ASG should withstand 300-400 freeze-thaw cycles. Also, the sand and gravel composition cannot lose more than 10% of its mass. The strength of the material is influenced by the number of weak elements in the composition.

Gravel is classified into strength categories:

- M400;

- M600;

- M800;

- M1000.

Gravel of the M400 category is characterized by low strength, and M1000 - high strength. The average level of strength is present in gravel of categories M600 and M800. Also, the amount of weak elements in gravel of category M1000 should contain no more than 5%, and in all others - no more than 10%.

The density of the CGM is determined in order to find out which component is contained in the composition in greater quantities, and to determine the scope of the material. On average, the specific gravity of 1 m3 should be approximately 1.65 tons.

Not only the size of the sand is of great importance, but also its mineralogical composition, as well as the modulus of coarseness.

The average compaction coefficient of ASG is 1.2. This parameter may vary depending on the amount of gravel content and the method of compaction of the material.

The Aeff coefficient plays an important role. It stands for the coefficient of the total specific activity efficiency of natural radionuclides and is available for the enriched ASG. This coefficient means the rate of radioactivity.

Sand and gravel mixtures are divided into three safety classes:

- less than 370 Bq / kg;

- from 371 Bq / kg to 740 Bq / kg;

- from 741 Bq / kg to 1500 Bq / kg.

The safety class also depends on which field of application this or that ASG is suitable for:

- The first class is used for small construction activities, such as manufacturing products or renovating a building.

- The second class is used in the construction of automobile coatings in cities and villages, as well as for the construction of houses.

- The third safety class is involved in the construction of various high-load sites (these include sports and playgrounds) and large highways.

The enriched sand and gravel mixture is practically not subject to deformation.

Application of sand concrete

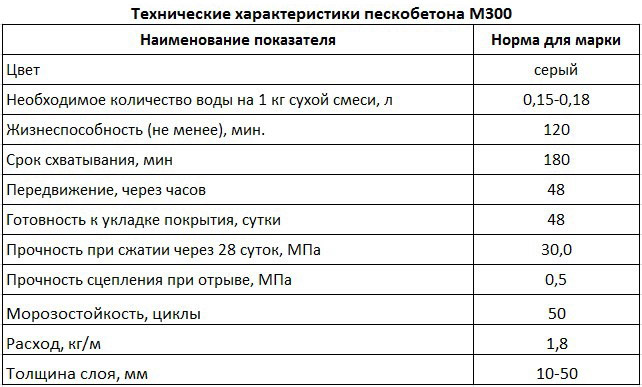

A branded cement mixture is selected for concreting coatings with a load of about 250-300 kg / cm². According to this indicator, the M300 is suitable for installing a high-strength, wear-resistant floor in a basement, utility, technical or residential room.

DSP depending on the sand fraction:

- Fine (0.8-1.2 mm). For external work with high-strength mounting mortar, masonry of critical structures, concreting of light screed (up to 5 cm thick).

- Medium (1.8-2.2 mm). Application from inside the premises, installation of curbs, eurofences, paving slabs, screed up to 10 cm, installation of a warm floor system.

- Large (2.5-4 mm). The presence of sand particles of this size in the M300 reduces moisture absorption. This sand concrete is used for strip, slab and columnar foundations, floor slabs, basement.

There are no restrictions on the thickness of the applied layer if structural reinforcement is used.

Component proportions and DSP consumption

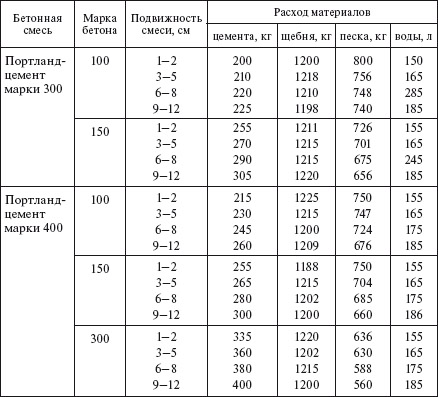

The standard cement composition includes 1 part of Portland cement grades PC400 D0, PC500 D20 2 times more than dried sand of normalized fractions. Polymer and mineral additives may be included to improve certain characteristics:

- plastic;

- frost resistance;

- moisture resistance;

- thermal conductivity;

- resistance to abrasion.

The manufacturer can add fiber, silica fume.

In terms of efficiency, the consumption of such a mixture per 1 m2 has a rather low indicator. With an increase in the size of the M300 layer, the costs of sand concrete increase:

- for 1 mm of mortar application thickness, about 1.7 kg / m2 is used;

- at 2 mm, there is an increase to 3.5 kg for the same area;

- for a 10 mm screed, 22 kg of dry composition per 1 m2 are needed.

Self-preparation of sand concrete

Technologically, it is possible to make a cement slurry with strict adherence to the ratio of components. For this purpose, the sand must be purchased separately. In ready-to-use form, it is sold in 25 kg bags. It is quite difficult to independently obtain clean and dry material of the desired fraction.

The proportions of cement and filler depend on the type of structure to be arranged:

- Portland cement M400 and sand are taken on the screed in a ratio of 1: 3. To increase the strength of the base, it is recommended to add fiberglass, if not reinforcing the monolith.

- In plaster, the proportion changes to 2: 3. The liquid mass needs to be worked out urgently, as it dries quickly and loses its plasticity. Mixing of the components begins dry until a mixture is obtained that is uniform in density and color.

M300 is mixed with cold water (up to + 20 ° С) without mineral impurities. Its consumption is determined by the ratio: for 10 kg of dry sand concrete, 1.7 liters of liquid are required. To mix the DSP, take an electric drill with a mixing attachment. The second step for large volumes is a concrete mixer. To improve the quality of mixing, 2/3 of the required amount of the composition is first poured into the drum, the rest is added in portions with constant operation of the equipment.

As a result, you need to get a homogeneous, viscous and plastic solution, which is kept in a calm state for 5-10 minutes before starting to use. It is poured and leveled on the basis of the rule (spatula). Air bubbles are removed with a bayonet or vibrator.

DSP price

Sand concrete is available for purchase from almost all distributors. The cost largely depends on the manufacturer and the weight of the package. The average price of a 40 kg bag of the M300 brand is in the range of 100-150 rubles. Self-preparation of 1 ton of a standard composition from prepared sand, Portland cement, adding granite screenings will cost 1500-1800 rubles.

Among industrial DSPs, the following brands are popular (and low cost):

- Stone Flower;

- Rusean.

The guaranteed high quality of Rusean is also manifested in the fact that the declared strength (30.4 MPa) is higher than the standard for the M300 line (30 MPa).

| 100 | Construction Alpha | |

| Finstroy | 95 | |

| Anchor | 105 | |

| Sand concrete300 | 133 | Leroy Merlin |

| 50 | 185 | StroyShopper |

Views

Granite

Many people are familiar with the scalar physical quantity of a substance (density) since school - to measure it, the mass of the substance and its volume are taken into account.

This number is several times lower than the specific gravity of crushed stone in its original state. This significant difference can be explained by the formation of air gaps. Because of this, the technologists themselves have derived a bulk scalar physical quantity.

Granite

Here, one of the essential roles is also given to the crushing fractions - when they decrease, the specific gravity increases. Therefore, the scalar physical value of the material is 20-40, several times higher than that of 40-70 (due to the fact that there are fewer air layers).

Also, the scalar physical quantity of the material exclusively in dry form is considered extremely significant. There is not only a granite product of rock crushing, as many are accustomed to think. In the construction industry, limestone, slag and gravel materials are used.

All of them stand out for their qualities and bulk scalar physical quantity. The density of crushed limestone is from 1.8 to 2.6 t / m3, the density of crushed gravel is 1.35-1.450 t / m3, the density of crushed limestone is 1.28 t / m3.

Calcareous (limestone)

Lime crushed stone stands out with its unique properties.

Limestone

Fractions from 5-40 mm are distinguished by the following indicators:

- bulk scalar physical quantity - 1300 kg / m3;

- flakiness - no more than twelve percent;

- the presence of remnants of dust and weak rocks - no more than two percent, no more than nine percent;

- strength grade - 600-800;

- the presence of pores - no more than 7.3%;

- the percentage of moisture accumulation, and resistance to subzero temperatures - no more than 4%, F-150;

- moisture absorption - 2.5%;

For more information about crushed limestone, see the video:

Gravel

It is more rational to use gravel as a filler for concrete and reinforced concrete structures, for the construction of monolithic objects, for overlapping objects with slabs.

Gravel

For him, the following indicators are allocated:

- bulk bulk density of building crushed stone –1400 kg / m3;

- fortress - 1200;

- resistance to subzero temperatures - F-350.

Specifications

Slag

If the crushed stone is slag, then its average scalar physical value can vary around 800 kg / m3. For strength, the required grade must be taken into account.

Slag

Strong: 800-1200, and the strongest - 1400-1600. For the secondary strength class, it can be in the border of 1.2-3 t / m3.

Black

The material in question is considered to be ordinary or fractional. It is also distinguished by the way it is produced and laid. It can be cold, warm, or hot.

Black

By the size of the grains stand out:

- massive - 4-7 cm (wedging is necessary);

- medium - up to 2-4 cm (acceptable size);

- the smallest - up to 0.5-1.5 cm (the crumb is used in the mixture).

Cold building

The cold type is used in the repair of highways, warm and hot can hardly be underestimated for all other construction purposes.

Cold

At the same time, indicators of the volumetric weight of crushed stone of such a specific color, in other words, its scalar physical value, must be at least 2.6-3.2 t / m3, with a strength of 80 MPa.

Dolerite

What is the difference from decorative stone? You can also find a material on the market called dolerite.

Dolerite

If moisture gets on the surface of the material, a gloss immediately appears on it. It is often used as a stone for decoration in landscape design, as well as for architectural structures.

Proportions for DSP

For the preparation of sand concrete, different proportions are used. So, if the construction of walls is planned, then they take a ratio of 1: 4 - which means that 350 kilograms of cement will be needed to obtain a cubic meter. When preparing a solution for laying silicate bricks, the consumption is 0.22 cubic meters.

When building load-bearing walls, high-grade cement is used. If lime is added to the composition, then the proportion is 1: 3. Water is usually added according to instructions or approximately, controlling the consistency of the solution until the desired density, viscosity, drying time, etc. are obtained.

General characteristics

In general, building material is a waste of granite and limestone formed during the extraction and processing of rocks, which contain fragments of crushed stone and quarry sand.

When crushing at a sorting plant, the mixture is sifted, crushed to running fractions, cleaned from small debris, as a result, different types of building materials are obtained based on the size of the grains of crushed stone.

If the composition contains 4 or more percent of clay and dust, the product cannot meet the standards of GOST 25607-94. In addition, it is required that the radioactive background be within 300 Bq / kg, which is considered safe and allows the mixture to be used in the construction of residential buildings.

Key features to know when stacking and transporting:

- volume weight;

- bulk density.

It turns out that not only the grain composition is important, but also the density, that is, the compaction coefficient of crushed stone, which characterizes the change in its volume during ramming, as well as shrinkage and transportation. One of the most demanded fraction sizes - 20-40 mm, is a C6 mixture with a bulk density of 1.35 t / m3. With a larger fraction, the tamping is less effective.

Why is it so important to know the quantitative characteristics of the material

If you are the owner of a private house, you have probably come across the need to calculate the bulk density of bulk materials. Particularly important is the question of how much a cube of a bulk mixture costs with delivery; for those who are planning independent construction, they need bulk purchases of raw materials. How many kg in a cube of sand is a guideline for determining the proportions of the concrete mix. It is of great importance to obtain accurate data in order not to disrupt the construction technology. Otherwise, you may encounter a number of difficulties, for example:

- the recipe for preparing a mixture of building materials will be violated;

- the finished solution will not be of the same consistency as the technology requires, due to which it will lose its adhesive qualities;

- the concrete will turn out to be bad, the duration of its hardening will increase.

Having information about how many cubes are in a ton of sand, as well as what weight of the material, you can be sure of the strength of concrete. It will not collapse under any circumstances before the expiration date.

Interesting! The described indicator in construction is called specific gravity. This measure ranges from 1500-2800 kg / m3.

Factors affecting the value of how much 1 cube of sand weighs include:

- components of natural bodies of homogeneous chemical composition;

- structure, dimensions of fractions;

- humidity indicators of air;

- % seals, presence / absence of additional elements.

Application

Sand and gravel mixtures are widely used in the construction industry:

- road construction;

- construction of civil buildings for various purposes;

- floor screed;

- construction of hydraulic and industrial structures;

- strengthening of coastlines, installation of retaining walls;

- backfilling of foundation pits;

- alignment of sites.

For the preparation of concrete solutions of different brands, use is made of pgs with different weights of 1 m³. It is determined based on the need as a placeholder. For example, for the preparation of concrete M500, ogs with an improved composition and strength characteristics are required, preferably with a content of large gravel stones of about 60-70%, while for the preparation of weak M 150, you can take the usual ogs.

When choosing a natural sand-gravel mixture, GOST requires taking into account the level of the radioactive background of the rock and applying the material in this way:

- Aeff up to 370 Bq / kg - for the construction and decoration of residential and office buildings;

- Aeff 370-740 Bq / kg - for the creation of structures and the construction of industrial buildings and structures, roads in populated areas of settlements and cities;

Aeff 740-1500 Bq / kg - for the manufacture of structural elements and the construction of roads and technical facilities outside settlements (airfields, intercity highways).

Building sand weight in 1m3

The mass of a bulk product, which is placed in a unit of volume (cubic meter), is called specific gravity. In the reference literature, it is indicated in kilograms or tons per 1 cm3 (cube).

To find out how much a cube of sand weighs, you need to know the volume and degree of compaction. Accurate parameters can only be obtained under laboratory conditions. Developers usually use averaged data from standard measurement tables.

The table of weight of all types of sand is 1 cubic meter.

| View | Specific weight of 1 cube, kg |

| River | 1500 |

| Career | 1500 |

| Nautical | 1600 |

| Expanded clay | 400-1000 |

| Slag | 700-1200 |

| Quartz | 1400-1900 |

Often, suppliers deceive their customers and do not fill up the sand, because they know that the client will never know exactly how many tons of the product were brought to him. But if you will at least roughly know the specific gravity of sand and know the cubic capacity of the machine in which the goods were brought to you, then it will not be difficult for you to at least roughly calculate how much product was brought to you, since you will see how full the car is. And in all other respects, a table will help you, which says how much a particular sand weighs in m3.

Varieties of sand.

River.

The one that is mined from the river bottom. It stands out for its cleanliness indicators. May have a yellowish or grayish tint.

River sand mass

Particle dimensions reach 0.3 to 0.5 mm. It is used at the stage of mixing mixtures for construction, as well as mortars, during the installation of drains. It is considered the most used and popular type.

Career.

It is obtained in the classic way. Its shade is brownish or yellowish. The composition of the material includes dusty impurities and small stones.

Quarry sand weight

In a purified and classical form, quarry sand is used for a thick lime mortar and a complex of construction work related to the exterior and interior decoration of buildings; on its basis, a cement screed is created.

Nautical.

Sand from the seabed is a natural material with a unique composition.

How much does sea sand weigh.

And although the level of demand for it in the construction industry is quite small - after all, it is more expensive than quarry and river sand - there are areas where you cannot do without it.

Artificial.

Sand is a sedimentary rock and artificial material, which contains a fraction of rocks.

Artificial sand

Quite often, it is composed of mineral quartz, which is a substance called silicon dioxide. If we are talking about natural sand, then it is a loose mixture, the grain fraction of which reaches 5 mm.

Conclusions!

Here you can order high-quality construction sand at a competitive price with delivery in Moscow and the Moscow region. Delivery of sand is carried out by our own vehicle fleet, so you can be sure that the sand will reach you in the required volume and at a minimum price for 1m3.

Basics of calculating the tonnage of sand in m3

When working with a translation from one quantity to another, it should be remembered that the fact how much a cube of sand weighs is influenced by two parameters:

- compaction and moisture of the material;

- density of raw materials.

Fine-grained open-pit sands contain many impurities that strongly compact the raw material. In this case, the density of the material will be in the range of 1700-1800 kg / m3.

To determine how much a cube of sand weighs, you need to multiply the density of the raw material by the volume.

Coarse sand has a density of 1400-1600 kg / m3. The weight of any bulk material is affected by its moisture content. According to the standard, the moisture content of the sand should be about 6-7%.If this indicator varies within 20%, then the mass of the entire material will exceed the calculations by about 5 tons. And this is provided that the useful volume of an average dump truck is 12 m3.

So, figuring out how to convert cubic meters to tonnage turned out to be not so difficult. The main thing is to know a few parameters.

Comments (1)

Loading ...

Similar materials

Home comfort How much does a pine cube weigh, depending on humidity?

In life, there are situations when you are faced with seemingly simple questions, but you cannot give the exact answers to them. During construction, for example, you may need to answer the question: how much does a cube weigh ...

Home comfort How to calculate how much it costs to renovate a bathroom?

A person strives for coziness and comfort, therefore, repairing an apartment or house is very relevant today. As you know, this process is complex and rather laborious. But some areas require special attention. T…

Home comfort Determine how much a cube of concrete weighs

On numerous forums devoted to repair and construction, new branches appear with surprising consistency, in which the question of how much a cube of concrete weighs is considered. Although often, instead of a sensible answer, h ...

Health How to calculate how many calories are in green tea

If you decide to lead a healthy lifestyle and even lose a few extra pounds, then you are probably interested in the calorie content of many foods. So, now you can find a lot of reference tables, calculators, which ...

Home comfort How much does a cube of a board weigh: basic characteristics

You can clearly see that the cut board has the shape of a regular rectangle in cross-section. This fact distinguishes it from an uncut board.

Thanks to such an important feature, it can be laid evenly in ...

How much does 1 cubic meter of sand weigh?

Home comfort How to calculate the volume of concrete - formula. How much does 1 cube of concrete weigh? How many cubes of concrete do you need for a foundation

Concrete is an artificial stone building material. You can make it yourself or buy a ready-made one at the factory of reinforced concrete products, which reduces the construction time.

Business How to calculate how many boards are in a cube?

Before we start calculating the cubic capacity of different types of boards and answer the question: "How many boards are in a cube?" - it is necessary to consider what the concept of "cubic meter of lumber" means, and what before ...

Home comfort How to calculate how many square meters of building material in one cube

During construction, the question often arises of how many square meters are in one cube. This applies to a variety of materials, which in their parameters have three indicators: length, width, height. To obtain…

Home comfort How to calculate how many cubes in a ton of asphalt?

Today, the transport network is one of the indicators of the level of economic development. A high-quality road surface contributes to an increase in freight traffic and reduces transport costs, and in urban infrastructure it increases ...

Home comfort How to calculate how many tons of rubble in a cube

To carry out various construction work, even on a small scale, it is necessary to first calculate the amount of material required. Calculating piece building materials will not be difficult. A little …