Actually, the name itself - a plastic porch, is not entirely correct, because at the moment it is unrealistic to build a porch made of 100% polymers. In any case, supporting structures and flights of stairs are made of concrete, brick, wood or metal. Finishing and some structural fragments fall to the share of polymers. We will talk about the most common sectors for using plastic in porch furnishings.

Features of the arrangement of any porch

Before moving on to the polymer construction details, we decided to focus on the basic rules of construction.

In this case, it doesn't matter if you build the porch yourself or hire third-party craftsmen, the instructions and basic parameters will remain the same.

- Staircase width is one of the main parameters... If a structure is mounted for a utility room with periodic operation, then 80 cm is quite enough. But for the central entrance to the building, it is important that 2 people can simultaneously pass the stairs and here it is already necessary at least 1 meter.

- On small spans, up to 3 steps, railings are rarely used as support structures.... They are often mounted on high staircases. But at the same time, their height remains standard, ranging from 80 cm to 1 m.

- Do not make the stairs at a large angle, this is inconvenient... Experts limit the maximum slope to 45º. At the same time, a staircase that is too flat will not look, here the minimum limit is 26º.

- You may have noticed that some beautiful and well-made marches are inconvenient to walk... Often the reason lies in an even number of steps. It doesn't matter how high the porch is, the main thing is that the number of steps is odd.

- You can achieve the required number of steps by varying their height... But here, too, there are certain limitations. Firstly, the size must be the same for the entire march, a difference of 5 mm is allowed. And secondly, the risers should not be below 12 cm and above 20 cm.

- If you walk comfortably and confidently stand on any step of the porch, then their width should be at least 25 cm... As for the maximum, you can vary in different ways, but according to the standards, this limit should not exceed 35 cm.

- Some steps on wooden or stone marches are made with a small visor, this gives a certain charm to the structure, but here, too, there are limitations.... This visor will not interfere only if its size does not exceed 3 cm.

- Do not raise the slab near the door too high or lower it too low relative to the lower edge of the door leaf.... There is also a standard for this, a gap of 5 cm is considered optimal.

- You can make a porch as wide as you like, but if space is limited, then for comfortable operation the stove in front of the door should be 15 cm wider than the door sill, it's minimum.

The use of plastic in structures

Modern polymers have a number of indisputable advantages, and now they are widely used in finishing works. Some types of plastics perfectly imitate natural materials, at the same time having an affordable cost and incomparably greater durability.

Polymers for steps

Wood structures are not durable, and the stone coating is too slippery and dangerous for injury. Plastic porch treads can protect the base material and most importantly, they can increase the level of grip of the outsole.

Polymers can be attached to such structures in different ways.The most common options are plastic or rubber bands, which are glued directly to a smooth surface, and also placed on aluminum strips mounted on the steps.

Another common option is to use polymer rugs. As a rule, they are produced on a self-adhesive base and are securely fixed to the surface.

An imperfect wood or concrete surface can be filled with a polymer adhesive of a suitable color. And finally, laminated plastic panels are produced, which are rigidly fixed on the march, imitating any natural material.

Handrail polymers

Plastic porch railings are almost ideal. Most often, such structures are made of PVC polyvinyl chloride. This material is versatile, along with unique characteristics of strength and wear resistance, it has amazing elasticity. When heated to 95 ° C, it can be given any desired shape.

Important: the latest innovation in this market is the railing made of wood-polymer composite or WPC.

Woodworking waste is used as a filler, but a high-strength polymer acts as a connecting link.

The result is a "wooden" plank that has all the advantages of a composite.

Polycarbonate visor

Plastic canopies over the porch are now found at every step. The most common material for the manufacture of such structures is polycarbonate. Along with a rather attractive appearance and high resistance to weathering, the price of this material is affordable for almost everyone.

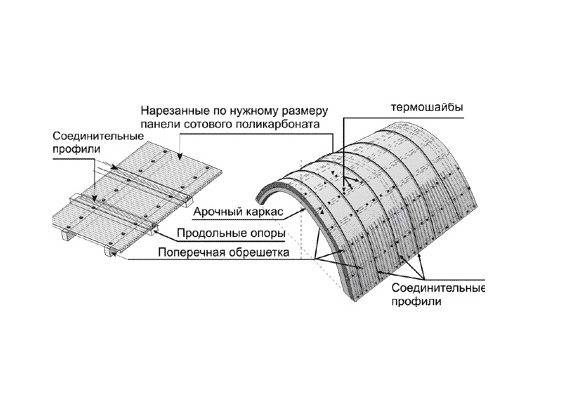

Polycarbonate is a synthetic polymer that comes in the form of transparent sheets with a cellular structure. Between the two sheets, so-called stiffening ribs are provided, which form separate cells, giving the structure strength.

It is quite possible to mount a plastic visor on the porch made of polycarbonate with your own hands. As a frame, profiled metal pipes are used, which are mounted at a frequency of no more than half a meter.

In addition to the sheets themselves, you will need a tape for mounting polycarbonate and necessarily special profiles that cover the hollow honeycomb on the sides. Although the sheet is mounted at an angle and moisture ingress is excluded, the profile is necessary to protect the honeycomb from dust or insects.

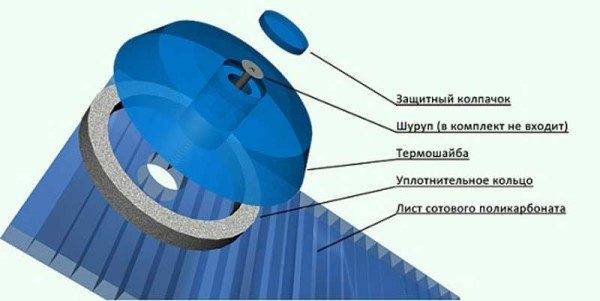

Important: polycarbonate is attached with self-tapping screws.

So the hole for the self-tapping screw needs to be made half a millimeter larger, since plastic is able to expand when heated.

In addition, special thermal washers must be used.

Designers and installers advise using polycarbonate roofs only for light, unheated awnings. The most important is their use on open terraces or canopies with openwork supporting structures.

Porch glazing

Porch glazing can be cold and insulated. The insulated version is attractive because, in addition to aesthetic beauty, such a design will add extra square meters in the house and become a buffer pad on frosty winter days.

Glazing the porch with plastic is possible, but not advisable. Today, completely transparent polymer sheets of high quality are produced, but their price is too high. And a cheap product will quickly deteriorate. In this case, for solid large stained-glass windows, it is more reasonable to use thick tempered glass.

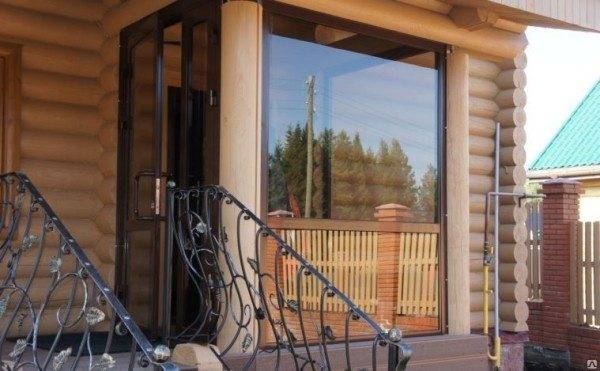

Advice: the most affordable and reasonable, both in terms of cost and quality, will be a porch made of plastic windows.

Such structures are now manufactured in all shapes and sizes.

In addition, with proper care, such a porch will serve for more than a dozen years.

The video in this article contains additional material on this topic.

Output

The use of polymers in finishing works is becoming more and more widespread. In particular, for facing the porch, plastic is one of the most durable and attractive options. For reasonable money, you can make a real home decoration out of your porch.