The staircase is one of the most common structures used in the construction of a house. It not only performs the functions of organizing transitions between two rooms located at different levels, but is also considered the main element of the interior. That is why interfloor stairs in a private house have a lot of different types, which are designed to create a certain atmosphere and facilitate access between rooms on different planes.

Selection and manufacturing principle

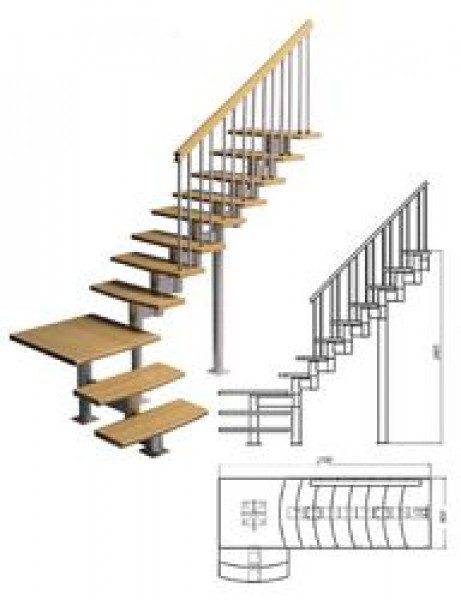

First of all, you need to choose the style of the future product and its shape. Some craftsmen believe that interfloor wooden stairs are ideal for private or country houses, but in modern construction, they have recently begun to give preference to other materials that have superior qualities. Modular designs that combine different elements have become especially popular. A modular staircase, if desired, can be built with your own hands.

Peculiarities

- All modular designs are characterized by low material consumption.

- They have great strength and, when properly manufactured, can withstand 250 kg per section.

- Usually, an interfloor wooden staircase is decorated with various decorative elements and panels, but modular products do not have free space for such decorations, and therefore designers try to give them a magnificent look using the beauty of shapes and colors.

- Separately, it is worth noting the fact that the service life of such stairs is very high, and the cost of their manufacture can be considered minimal.

Advice! If you wish, you can purchase a ready-made modular staircase, but you should not rely on its uniqueness and exact correspondence to the dimensions of the house.

Project

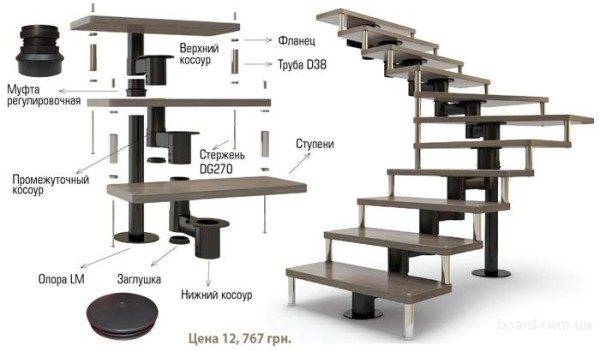

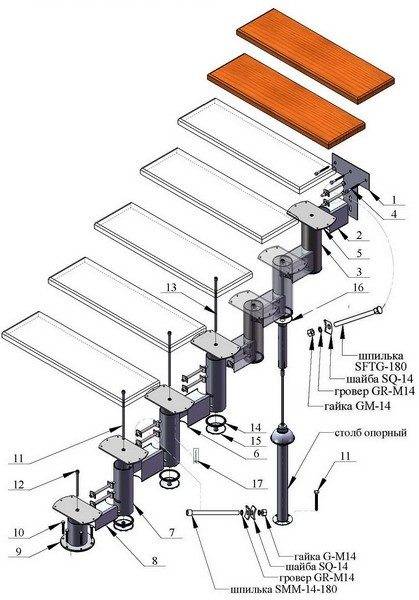

Conventional interfloor modular stairs are made of metal. At the same time, special fasteners are made as steps of the stairs, on which processed wood, natural stone or other available material will be installed.

Therefore, before starting to manufacture, it is necessary to develop a project.

- It is necessary to indicate the clear parameters of all metal structures and their relationship with the dimensions of the room.

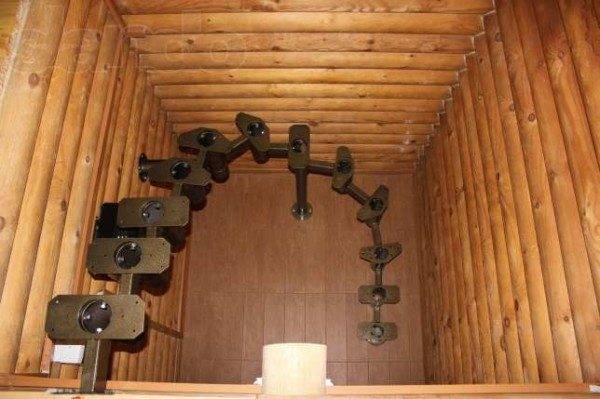

- Particular attention should be paid to ensure that the interfloor staircase for a private house is securely attached to the walls, floor and ceiling. This is due to the fact that it is on these parts that the entire load will fall.

- It is also necessary to consider in advance the method of installing the steps. Usually, for these purposes, metal pennies with holes in them are used, which are welded in the area of their intended location.

Advice! If there are no specific skills that are necessary to create a project, then you can use ready-made developments by changing them to suit the appropriate conditions. It will also save you time.

Working with metal

When creating various types of interfloor stairs, one has to deal with various types of metal processing. These include cutting, grinding and even welding. Therefore, when starting this type of work, it is necessary to have an appropriate tool and have certain skills.

You may also need various measuring tools that will allow not only to determine the dimensions, but also the location of the product in space.This is especially important when screw structures are created, since with the slightest error in the calculations, you can get a defect that will not only interfere with normal operation, but can also cause injury.

The finished product is attached to the supporting structures using anchor bolts or other strong connecting elements. Quite often, when erecting walls, parts of metal reinforcement are mounted in them, which protrudes to the surface and can serve as a support for a welded bond. Often, a modular interfloor staircase is simply concreted at the base, which can be a great solution as it will add extra strength to the structure.

To create unusual products or real works of art, you can use the blacksmithing method. However, only specialists have such skills, which means that all the necessary elements must be ordered. Moreover, such a staircase for the house will become one of the main interior items.

It is worth noting that at present there are specially manufactured elements, which are called modules and can be assembled into a separate structure. Therefore, sometimes it is better to purchase them than to make a frame yourself.

Advice! To organize reliable fixation, it is necessary to take care of the attachment points in advance and lay their placement in the project for the manufacture of a house.

Moisture protection

It must be remembered that the metal used to create the stairs must be practical and moisture-tolerant. If this cannot be done, then you need to use special protective coating... At the same time, one should not forget that elements made of wood can be installed on the structure, which means that they should also be protected.

The most common coating is considered to be any available dye that is applied to the metal after it has been primed. However, to create stunning decorative elements, they use the application of chrome, bluing or spraying of other substances. It is better to cover wood with a special varnish.

It is worth noting that the price of some materials for this purpose can be quite high, as well as the work itself. However, it is necessary to choose only the best types of coatings, since they will not only serve as protection, but also create an appearance.

Advice! To increase adhesion, the metal must be cleaned from rust before processing.

Installation of steps

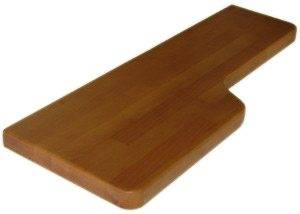

Treads made of any material can be installed on interfloor stairs of a modular type. Some of them can be purchased at the store, while others must be made by yourself. In this case, special attention should be immediately paid to the fastening element.

If you do the steps with your own hands, then you should not choose natural stone as a material. It may require certain skills and special tools to process it. It is much easier to work with wood or artificial components.

Self-tapping screws or special screws are used as a fastening element. At the same time, the installation instructions recommend that you immediately pay attention to the length of the joints and the thickness of the steps. The screws should not be too large or they will not be able to secure a secure connection.

Advice! Masters recommend installing dense gaskets on the metal before installing the steps. They will serve as a kind of shock absorbers and protect the product from the inside.

Output

In the video presented in this article, you will find additional information on this topic. Also, based on the text of the above, it can be concluded that in order to create a modular staircase on your own, you must have certain skills and appropriate equipment. Therefore, sometimes it is better to purchase ready-made components and install them.

It is also necessary to remember that the principle of creating modular structures was based on spiral metal stairs. Therefore, you can always use their projects for independent development. However, for this you need to understand not only the drawings, but also be able to calculate the loads.