After the completion of the main construction work, the question arises - how to decorate the stairs in the house? Indeed, in most cases, the result of construction is either unpresentable metal carcass, or a concrete monolithic product.

They look, frankly, not very good, and therefore we will have to work hard to put these structures in order.

Working with concrete structures

Preparation of steps for work

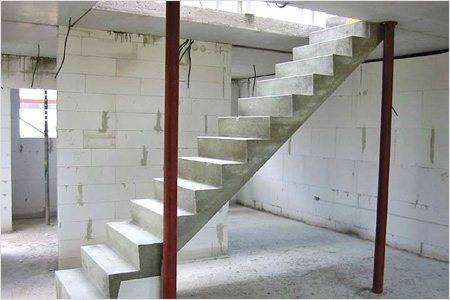

In houses built according to a standard design, reinforced concrete stair modules are most often used. Among their advantages are high manufacturability and a solid margin of safety, but such steps cannot boast of a presentable appearance.

Choosing how to decorate the stairs in the house, we can choose either wood panels or ceramic tiles.

But in any case, first we will need to prepare the base:

- At the first stage, we carry out measurements of all steps.It is very important that their height differs by no more than 1 mm.

- If the height difference is less than a centimeter, then apply a layer of self-leveling mixture on the tread.

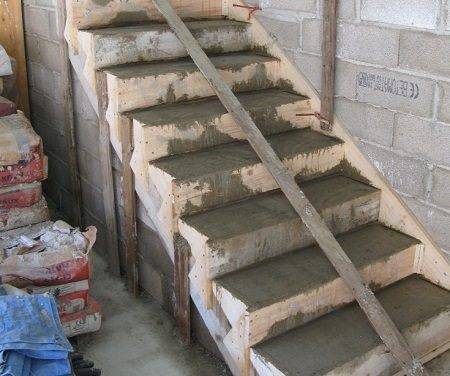

- In case of more serious discrepancies in height, we install the formwork on the problem steps and pour the solution into it. The thickness of the layer should ensure perfect alignment of the planes.

Advice!

To ensure maximum adhesion, all surfaces must be treated with a primer such as "Betokontakt".

Filling is carried out only after the soil has completely dried.

- Immediately before starting work, using a perforator and a grinder, we remove all irregularities (sagging, bumps, etc.). We clean the surfaces using an industrial vacuum cleaner.

Base installation

The finishing of monolithic stairs with wood panels or ceramic tiles can be carried out directly on concrete... But to improve the quality of the connection and maintain perfectly flat planes, experts recommend installing a plywood base on the steps.

In addition to the actual leveling, the glued wood veneer backing is a kind of waterproofing, which will prevent the wooden sheathing of the steps from swelling due to the collection of moisture from the concrete.

Do-it-yourself installation of the substrate is done as follows:

- For fastening on treads, high-quality plywood with a thickness of 10 mm or more is used. The sheets are cut exactly to the size of the step.

- Apply a primer to the tread surface. After drying, we put a layer of adhesive mastic on the ground.

- We glue the plywood backing onto the mastic and let stand for about an hour.

- Using a perforator with a drill, we make holes in the plywood and steps into which we insert plastic anchors. We fix the anchors with locking screws.

Advice!

So that the sides of the anchors and screw heads do not interfere with the finishing, we pre-drill secret slots in the surface of the plywood using a larger diameter drill.

We position the laid plywood vertically, horizontally and planes using a water level. If necessary, tighten or release the locking screws additionally.

Wood cladding

How is a monolithic staircase finished with wood panels?

First, we cut out the blanks from the edged board:

- To facilitate the work and reduce the number of rejects, we make templates for treads and risers.

- We cut out the panels according to the template, after which we carefully process them with a grinder.

- We round off the ribs of the tread from the side of the overhang of the step so that the sharp edge does not bite into the sole when walking.

Next, we proceed to the actual installation.

The board mounting scheme is as follows:

- We screw two or three bolts with a diameter of 6 mm into the lower edge of the riser. We cut off the caps so that about 50 mm of the screw part protrudes beyond the board.

- Attaching the riser to the concrete stairs, mark where the bolts will be installed. Drill holes according to the marks.

- We fill the nests with epoxy glue, and grease the concrete riser with “liquid nails” for wood.

- We install the wooden panel, leveling it.

- Apply glue to the plane of the concrete step and lay the wooden tread blank.

- We connect the tread to the riser with self-tapping screws. We clog the secret holes with wood corks, which we then shave off in the plane of the step.

According to this scheme, we finish all the steps.

Laminate panels can be used instead of wood. The main difference of the technology here is the almost complete absence of metal fasteners: all parts are fixed exclusively with glue. (see also article Laminate steps for stairs - material advantages and finishing methods)

Installation of ceramic tiles

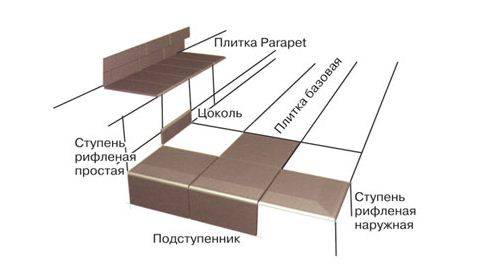

Ceramic tiles are used as an alternative to wood panels. Moreover, staircases can be finished both with ordinary tiles intended for flooring, and with specialized clinker. (see also the article Tiles for stair steps: choice, nuances and recommendations)

Extruded clinker tiles, which have recently been widely used in finishing works, have a number of advantages over ceramics. It is more durable and does not slip even when wet, which is very important when finishing stairs. A significant disadvantage of clinker is its relatively high price, but its long service life partially compensates for this disadvantage.

Both ceramics and clinker tiles mounted on pre-aligned steps.

Do-it-yourself staircase decoration in this case is carried out according to the following algorithm:

- In the process of laying, we first veneer the treads, and then the risers. The decorative corner covering the edge of the step is glued either last, or at the very beginning of work - as a beacon.

- Apply tile glue to the surface, mixed to a creamy consistency.

- With the help of a notched trowel we form furrows on the glue.

- We put a thinner layer of mortar on the tile itself.

- Press the facing element tightly to the surface and align it along the plane.

- To maintain a constant width of the joints between the tiles, we use plastic spacers in the form of crosses.

Advice!

After all the steps are lined, you need to wait about a day for the glue to polymerize.

Only then can you move carefully up the stairs.

The finishing of the stairs to the second floor is completed by grouting the joints between the tiles, and thorough washing of the lined surface.

Metal stairs

Technologies used

Often, in newly built houses, instead of concrete staircase modules, welded frames from a profile pipe or steel corner are mounted. As a rule, both the treads and the risers are made in the form of empty rectangles, and therefore, in order to give the structure an aesthetic look, it is necessary to cover the stairs.

The finishing of a metal staircase in most cases is carried out according to a single scheme:

- Steel parts that will be visible are cleaned of rust and painted in the appropriate color.

- We trim steps and risers with wooden panels.

- We mask the side surfaces of the stairs with plasterboard sheathing with subsequent finishing, or decorate with clapboard.

Below we describe this technology in more detail.

Installation diagram

Before finishing a metal ladder, it must be thoroughly cleaned:

- With a steel brush, we remove all the rust that has formed since the installation of the structure.

- We clean the welded seams especially carefully, after which we grind them with a grinder.

- We paint all parts with paint for metal products: this way we will not only give them a more presentable look, but also protect them from corrosion.

Then you can proceed to the actual cladding:

- According to the scheme described in the previous section, we cut out blanks for treads and risers from the board.

- Having laid the tread on the metal staircase, use a drill to drill through the wood and metal corner.

- Using a thicker drill bit, we make a pot for the screw head in the step blank.

- Insert the screw into the hole and fix it from the seamy side with a nut with a padded washer.

Note!

In the presence of a powerful screwdriver and a small thickness of the metal from which the frame is made, instead of screws, you can use self-tapping screws for metal with a drill.

- We attach the vertical risers in the same way.

- We insert wooden plugs into the secret slots, which we then shave off. An alternative to such stoppers can be special plastic or metal pads that are glued into the sweat.

- A long longitudinal panel made of wood or laminated plywood can be installed on the side surface of the stairs. The panel can be either flat or cut in the form of steps.

- Then we install the support pedestals, balusters and handrails. The method of mounting railings on metal, concrete and wooden stairs is practically the same.

After the completion of all installation work, we must open the wooden parts with varnish. Treatment with fire and bioprotective impregnations is also desirable, but it is better to carry out it even at the stage of cutting out blanks.

Output

If it is enough to sand, varnish or paint a wooden structure, then decorative finishing of a staircase made of metal or reinforced concrete is a much more difficult task. At the same time, it is very important to observe all the nuances of the technology - then the new casing will serve you for many years. And the video in this article will highlight additional information regarding this topic, let's watch!