The most reliable and durable ladders are those structures that are made on the basis of a metal frame. In addition, the use of metal as the basis of the structure allows you to create unique compositions with unimaginable turns, complex fences, heavy spans, etc. Thanks to this, you can create a staircase for any interior.

The increased strength of the metal frame allows the staircase structure to withstand not only the mass of people, but also the weight of massive railings, handrails and other decor. Next, we will take a step-by-step look at how to make wooden stairs with a metal frame with our own hands.

Types of frames

There are several types of stairs:

- Zabezhnaya.

- Normal marching ladder (there are both single- and multi-marching).

- Arcuate.

- Screw.

Also, the structure can be rotary or spiral with a platform, hidden or open. Depending on the type of ladder, the appropriate metal ladder frames are made.

Hidden frame

Closed frames are the cheapest option. They are designed so that all of their elements will be hidden under the panels and steps. Therefore, there are no requirements for the appearance of such frames. As a result, such structures are usually made from cheap channels and corners.

The only thing that needs to be taken seriously, even when creating such a frame, is the strength calculation. Failure to follow this point can result in serious injury while using the ladder.

Closed metal ladder frame most often it is a supporting frame, which is made of channels connected in pairs in several places. Corners are attached to them, which are also called kerchiefs. Sometimes the corners are replaced with sheet metal, which significantly complicates the manufacture of the metal frame of the stairs.

The side of the structure is subsequently covered with a decorative panel made of plasterboard or wood.

Open frame with two stringers

Such metal frames for stairs are made from a metal profile of a rectangular cross-section. Both kosour are made in the form of a "ladder", after which they are covered with enamel. After that, the fence is installed and the steps are mounted.

As a result, the staircase takes on an exquisite finished look. A small disadvantage of this design is that the price for such a frame will be slightly higher than for a closed frame. In addition, welded seams, when self-made, must be performed very carefully so that they are not visible after coating.

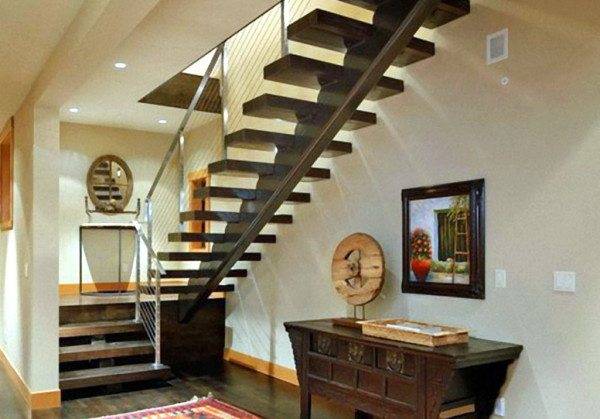

Open frame with one stringer

Most often, an open frame with one stringer is a single supporting beam, to which platforms for steps or kerchiefs are attached. In this case, the risers are not installed. Such designs look very attractive due to the effect of transparency and airiness.

However, if you plan to use wide marches, then it is recommended to weld additional consoles on the side. In this way, sagging of the steps will be prevented in case of heavy loads.

Frame fabrication

The manufacture of metal frames for stairs implies the presence of at least minimal welding skills.

In addition, you will need the following set of tools:

- Welding machine.

- Bulgarian.

- Drill.

- Protective transparent glasses.

- Welding mask.

- Roulette, pencil, square.

- Clamping clamp.

- Welding table.

- Vise.

- Transducer and primer brushes.

- Leggings and gloves and welder.

- Rags to degrease the metal.

In addition, you will need auxiliary materials:

- Grinding discs - 3 pcs.

- Cutting discs - 12 pcs.

- Welding electrodes 3.2 mm in diameter - 5 kg.

- Welding electrodes 1.6 mm in diameter - 1 kg.

- White spirit - 1 l.

- Rust converter - 2L.

- Metal primer - 2L.

Conventionally, the entire process of creating a staircase can be divided into several stages:

- Creation of a drawing with dimensions of parts.

- Cutting the material.

- Welding parts.

- Deburring of seams.

- Assembly of parts into a single structure.

- Rust removal, priming and painting of the structure.

- Wood paneling.

Next, we will consider the technology for creating several options for simple stairs.

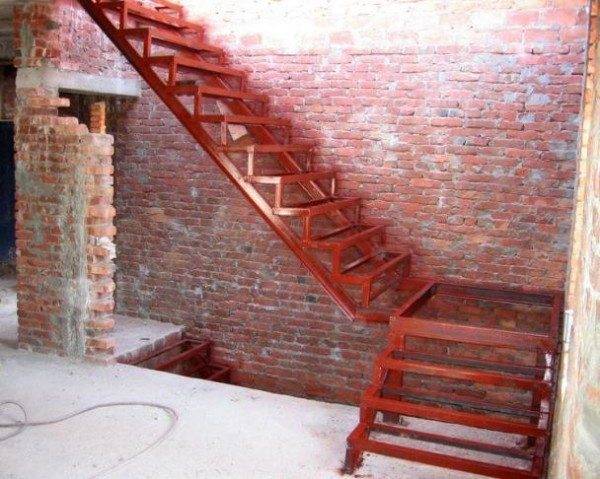

Marching stairs

It is quite simple to make such a frame. For this you need corners and a channel. Before starting work, you need to make a drawing. To find out how the calculation of the stairs is carried out, we suggest watching the video in this article.

Also, ready-made drawings of the metal frame for the stairs can be found on the Internet. In this case, all you have to do is adjust the dimensions.

After that, you can get to work:

- First of all from channels the frame is welded. Instead of a channel, it is better to use a profile pipe. In this case, the ladder will not vibrate when moving, since the pipe has greater rigidity than the channel.

- Corners are welded to its side faces.

There are two ways to attach steps:

- Regular laying on a corner, which in this case will be completely under the step.

- Two more corner pieces are cooked to the corners attached to the channel. As a result, a frame is formed on which the steps will subsequently be placed.

If desired, sheet metal can be used for the steps. Upon completion of the work, the seams must be filed to remove the resulting burrs. Before painting the structure, it must be carefully primed with a special solution to prevent the formation of rust.

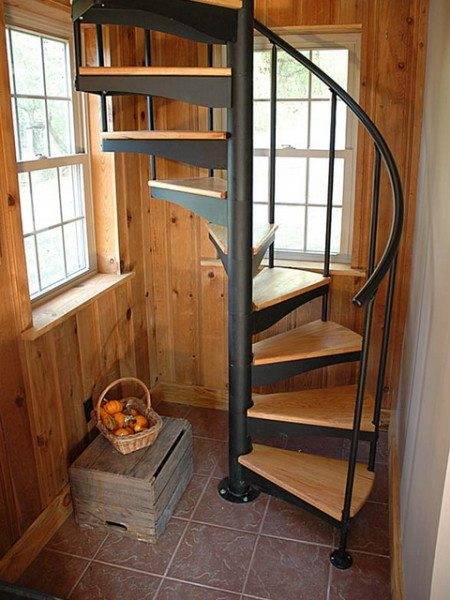

Spiral staircases

To create the frame of the spiral staircase, you will need a pipe for the central pillar and a pipe of a larger diameter, but the same length, for mounting the steps. The pipe for the steps must be cut strictly perpendicularly into sleeves of length about 260 mm.

Please note that the pipe must be cut exactly perpendicularly. Otherwise, it will be difficult to set the steps at the correct angle.

The sleeves should fit snugly on the B-pillar, without backlash and distortions. If such diameters cannot be selected, then the result can be achieved with the help of sealing rings made from a bar of the corresponding diameter.

Tip: To make the rings of the desired size, the bar must be wound onto a pipe of a smaller diameter.

When the rings are ready, they can be welded into the sleeves, after which they should be sanded with a hand mill. To make the steps the same size, it is better to immediately make a special conductor for them. This will require several wooden slats and a pipe mandrel. The slats should be glued, giving the structure the shape of a step (pictured).

Advice! A pipe mandrel is not difficult to make from several pieces. Chipboard.

With the help of such a jig, you can quickly and easily weld the steps by inserting tubes into it and exposing them at a certain angle. Thanks to the conductor, the parts will not disperse during welding. After this, the steps must be welded to their sleeves.

Upon completion of this work, you should clean out all burrs that may have formed on the seams of the steps. Then you can start assembling the frame. The sleeves must be carefully put on the central post and the structure must be installed in the prepared place.

For greater reliability and strength, it is advisable to concreate the lower part of the rack.After installing the steps, they should be set at the desired angle and welded together with small rack strips. This will give the structure more rigidity.

Sheathing of the metal frame of the stairs with wood is carried out only after painting and priming of its entire surface.

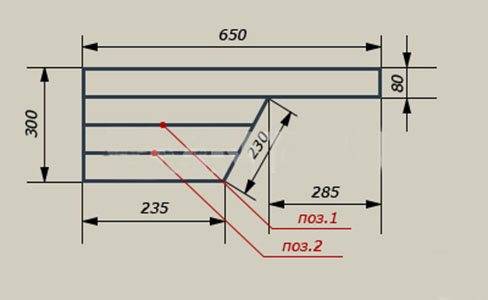

Duck step ladders

Ladders with a slope of more than forty degrees are very uncomfortable to walk. To eliminate this drawback, the steps are made in an oar-shaped form and installed crosswise. As a result, no matter how steep the staircase turns out, the tread will be of sufficient width, and it will be convenient to put your foot not only when going up, but also when going down.

The disadvantage of such ladders is only that it turns out to be waddling to move along them, hence the name - "Duck step".

Thus, if a staircase with a metal frame will have a slope of more than 40 degrees, then the "duck step" design would be the best solution. True, the frames of such steps are much more complicated than ordinary straight lines. But, to make the task easier, you can make frames with right angles, and round only wooden steps that are installed on top of metal ones.

It is best to use a square pipe as a material. 20 x 20 mm... The steps must be made separately, after which they must be welded in place on stringers.

Output

If you have the skills to work with metal, making a metal frame for a staircase is not too difficult work. Of course, it is impossible to prevent all mistakes, but after going through this stage, you will create a staircase in accordance with all your requirements and wishes, which is almost impossible when buying finished products (also learn about the main features of the restoration of a wooden staircase).