Where reliability and durability are needed, metal is always present. Moreover, the more massive the metal, the stronger it is. However, when designing and assembling stairs, excessive massiveness can do a poor job.

And instead of an elegant and solid structure, at the exit you will have a massive, heavy and very angular staircase, into which you will have to invest more money in order to bring this statue to any acceptable option. In order to avoid unnecessary expenses, and the initial finding of the golden mean in resolving the issue, we have prepared this instruction.

Profile selection and its capabilities

The idea of assembling a metal ladder is not new. On this way, there were several intermediate solutions, in which the main role was given to the channel and the metal corner.

The assembly principle was very simple:

- two channels were installed parallel to each other;

- contours from a metal corner were welded between them;

- in which it was possible to fix a wooden step or use a metal embossed structure.

However, practice has shown one very unpleasant feature of the metal corner - the ability to deform under load. An alternative to it was found very quickly, this is a metal profile.

For your information! A metal pipe with a square section of 40x60 mm is considered optimal for this type of product. Smaller sections behave the same way as corners, are capable of deforming, large, too massive, and do not have a "marketable" appearance, bulky.

A ladder made of a metal profile has those advantages that are difficult to overestimate, namely:

- The profile pipe allows you to recreate any type of staircase from a stationary one for several flights, to an attached and spiral staircase. Bends, angles of turns are not decisive (at least 30, at least 180 degrees);

- Metal accepts any combination of materials, using it with wood, glass and even plastic will significantly enrich not only the appearance of the finished product, but also color possibilities;

- You can use only the profile for the stairs. Modern technologies for painting metal products will give it any of the possible colors using the powder method. While the most popular metal colors are: gold, silver and retro black with shiny light metallic accents;

- The profile ladder, of course, is reliable and will last for more than a dozen years;

- The assembly of the entire structure is carried out quickly, with the skills of welding, in a short time, you will assemble the entire structure;

- The complexity of the frame does not play a decisive role in the assembly speed, since the solution to the problem will be in the preparatory stage (much depends on the correct cutting of the blanks, but more on that in a separate chapter);

- Fasteners for such stairs can be prepared at any stage and during the construction of a house and in a finished box;

- The price of the profile is not prohibitive and is quite affordable for an ordinary family;

- A ladder from a profile pipe is calmly assembled with your own hands, a household welding machine will greatly facilitate the work.

Features of working with material in the manufacture of stairs

The profile ladder is strong and durable, however, metal also has its limit, observing the rules below will help you avoid troubles when working with the profile. So:

- Whatever one may say, but metal belongs to heavy materials, therefore additional weighting of the structure is not recommended, moreover, the priority is the use of materials that can lighten the weight of the stairs, but do not change its strength, for example, birch plywood can be used for steps, and plastic for handrails lattice. Although in this matter the choice of materials depends entirely on you;

- There is no big difference where you plan to install the staircase indoors or outdoors, in all cases, the product will require anti-corrosion treatment and painting, only on an external staircase this will have to be done more often;

- To complete the work, you will need a machine and welder skills. Otherwise, you will have to either invite a specialist or use bolts for fastening. Let's just say it's better to abandon the idea altogether than to use this type of fastening;

- And about the mounts separately. There are situations when a ladder from a profile is installed outside as a fire or emergency. Regardless of the strength of the material, vibration processes are possible when descending along it. To avoid these phenomena, it is recommended to reduce the spans as much as possible (but within reasonable limits) or strengthen them.

Preparatory work started

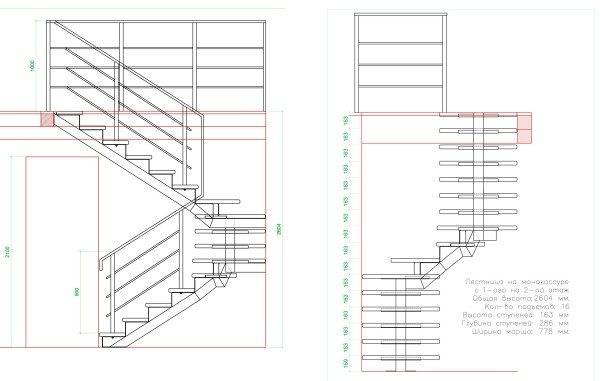

Any work begins with calculations and images on paper. Calculation of a ladder from a profile pipe will allow you to calculate the amount of material that will go to the production of load-bearing elements, foundations for steps, as well as the amount of other materials.

The scheme will put everything on its shelves and allow you to carry out your project "in sight". At this stage, you will need to assemble a tool, which will not be so much.

But nonetheless:

- Welding machine and a pack of electrodes to it;

- Grinder and circles for metal;

- A hammer drill and a set of drills (of the appropriate nature) for the possibility of installing fastening crutches;

- Hammer and markers with meters.

Also at this stage you mark and cut the metal to the planned dimensions.

Advice! If you are not preparing a complex structure of a spiral staircase or staircase using a profile with kosoura, then you can neglect this advice. In a more complex construction, it is better to number the blanks from bottom to top, so that there is no confusion or docking during the assembly process.

If you use wood or plywood to make your steps, you need to prepare the material for the steps as well.

To assembly

At the stage of direct assembly, it is very important to correctly assemble the supporting beams, since it is on them that all the load will fall from both the structure and from the people passing through it, the transported goods.

The simplest construction of a metal staircase is assembled as follows:

- The contour is scalded, the result is a rectangle on which a wooden step will be installed. Although the contour itself can already be used as a step, for external stairs, instead of wood, reinforcement rods can be welded into the contour (or onto it);

- The basis for the stairs can be: either a channel of at least 100 mm, or a profile pipe 100x100 mm. It is believed that the pipe is a more preferable product and when using it, the effects of vibration are reduced, however, if additional fastenings on the ground are thought out for the channel, then these processes will not be noticeable (just a little extra cost);

- Working with guides. The channel or pipe is cut in such a way that the cut piece fits snugly on the support, and the second end fits snugly against the second upper support. To do this, platforms are welded to the lower and upper edges, which will be fixing. In this case, the platform of the bottom of the stairs will be tightly fixed to the floor, and the upper one - to the floor platform;

- Further, with a certain step between the two supports, a support frame is welded, into which the steps will later be installed;

- Railings and other stair attributes are inserted at the final stage of the assembly if these elements are represented by other materials. then the place for their fastenings is prepared in advance, and the installation of these elements occurs after painting the main body of the staircase.

Advice! In some sources, you will find recommendations to leave a gap between the stairs and the wall so that you can glue the wallpaper or use other materials to decorate the walls.

We recommend that you, even if you decide to make these slots, make additional reinforcement of the structure, namely, hammering three crutches into the wall (for this you can use pieces of reinforcement) under the main supporting inner pipe and weld this structure.

For the outer rack, you can use a metal pipe, on the bottom of which you weld the same platform as at the end of the channels, and cut the top off to the slope of the supporting beam and weld it up. In this case, you will forget about vibration altogether, and the pipe that will be visible can be used as a support for flower pots and other decorative elements.

Finally

If you decide to complicate your staircase, this is not a problem, the profile will hold up. The video in this article also prepared material on this topic.

in our time and with our salaries, we only have to do it with our own hands. I began to make the ladder in the house from metal because it turns out to be more protic from it and lasts longer. the procurement is already ready. guess which tree is better to lay on the procurement