At industrial and residential facilities, metal stairs are installed, which can be divided into two main types - with and without a stringer. The latter include spiral structures, where the steps are fixed to the handrail and the upright on which the entire device is based. Also, instead of stringers, bowstrings can be used, but we will talk about this below, and in addition to the topic, watch the video in this article.

Arrangement of metal stairs

Since we will talk about metal stairs, you should pay attention to the type of inclined beams. If the kosour is a profile with a comb, on top of which treads are installed, then the ladder string (see photo above) is an even paired profile and the steps are mounted between them on special fasteners or welded. Both types of beams can be made with your own hands, if you correctly calculate the slope and steps, as well as select the material.

Calculation of marches

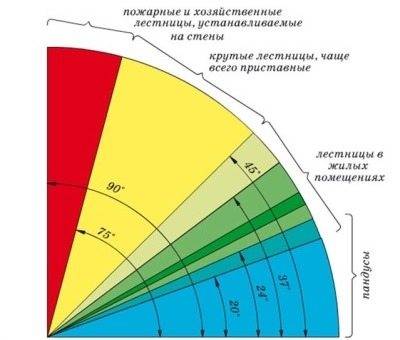

- In the diagram above, you can see the slope angles that are used for ramps, marches and ladders. But at the same time, we can say that metal staircases, unlike wood and concrete, can be equipped in the widest range - from 25⁰ to 75⁰... And a small gap between 75⁰ and 90⁰ again, it is suitable for metal - here they use attached and folding ladders, as well as stepladders.

- Nevertheless, despite the wide range of applications for metal stairs (steel, aluminum), there are comfortable, difficult and critical slopes. A comfortable descent is called a slope from 30⁰ to 35⁰, as the most suitable for movement, and a critical one is any angle from the entire range, where the steps are divided with large fractions and it is almost impossible to make them the same. But starting from 40⁰ and more, the ascent will be inconvenient, that is, only trained people can easily overcome it, therefore they (steep marches) are used either as emergency or for messages with low traffic.

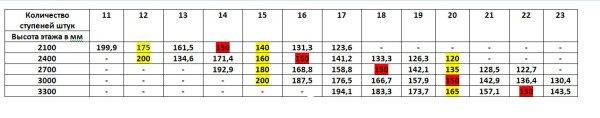

Explanations. The red color in the table indicates the most acceptable dimensions for which the ladder is called "tireless". The sizes for which the ladders are the easiest to perform are indicated in yellow.

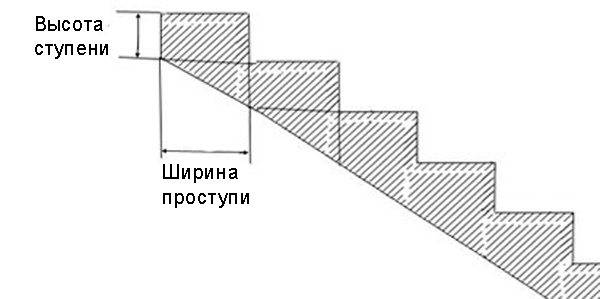

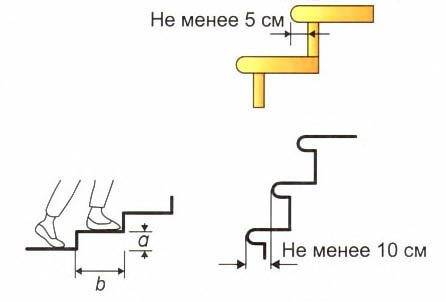

- To calculate the steps for metal stairs, however, like for any others, it is necessary to adhere to certain rules and the basis for them is the step length of an average adult (with a height of 160-180 cm, the step length is 60-64 cm). Also, do not forget about safety, and for this, the foot needs to feel about 70% of the hard base, which means that the optimal tread width will be from 25 to 30 cm.

- Now, if we denote the height of the step with the letter h, and the width of the tread with the letter d, then we get the formula 2h + d≈60≈64 cm (we multiply the height by two). For example, if the height is 17 cm and the width is 30 cm, then 2/17 + 30 = 64 cm.

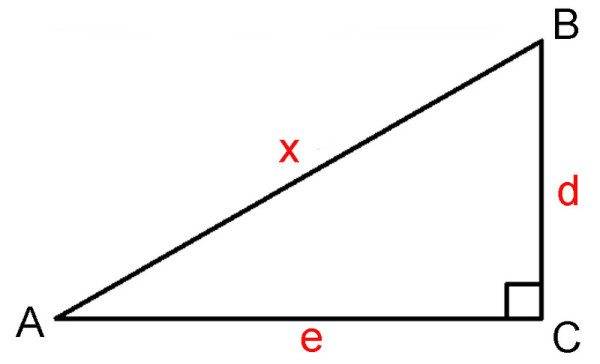

- Let's try to calculate metal steps for stairs in a room with a stringer height to the desired point by 3m, and use the principle of a right-angled triangle for this. Here, the segment CB will denote the height of the stringer or bowstring, the segment AB - the length of the stringer, and the segment AC - the length of the march.

- Let's say we need to raise the ladder to a height of 2.85 m, then this distance needs to be divided into the number of steps. The most convenient step height is 16-17 cm, but this way we get too long a march and a fractional figure for the parameters, so the height can be increased to 19 cm and we get 285/19 = 15 pieces.For convenience and safety, we need the average step size, then 19 * 2 + 26 = 64 cm.

- Now that we know the length of the segment AC, which the metal flight of stairs will take - 26 * 15 = 390 cm and the height of the bowstring - CB = 285 cm, we can find out the length AB in order to understand how much material will go to the stringers or bowstrings. We use the formula as required by the instruction e2+ d2= x2=3902+2852= 152100 + 81225 = 233325. From the result obtained, we extract the square root √233325 = 483 cm or 4.83 m of the working length and about 5 m of the profile for the workpiece.

Recommendation. Do not forget that the cost of a metal staircase directly depends on its size, therefore, with an increase in the steepness of the rise, the price will fall, and with a more gentle slope, on the contrary, it will rise.

Advice. On steep climbs, it is not always possible to withstand the width of the tread more than 24 cm, therefore, you can resort to such an option as the winders. This means that the upper tread will hang over the lower one by 3-4, but not more than 5 cm.

Materials for making

- For inclined beams of an internal staircase, as a rule, a channel or an I-beam is used, but sometimes a hollow rectangular profile is also used. Of course, with hollow elements, the weight of a metal ladder is reduced, but this design is not suitable for heavy loads. For fillies, a corner or hollow profile can be used, as well as a steel strip.

- If the structure is mounted on the street, then for the steps, either a metal notch for stairs or ordinary corrugated reinforcement is used, which is welded to the bowstrings at a distance of 5-7 mm from each other. This is necessary so that snow does not linger on the steps in winter, otherwise accidents are possible. For internal use, it is possible to use a steel smooth or corrugated sheet, or in general, wooden or concrete steps are mounted on metal stringers.

- For fences on metal stairs, ordinary or stainless steel is used, as well as aluminum, sometimes making a combination of them. In this case, the balusters are fastened in two ways - directly to the front of the treads or to the side of the inclined beam (of any type). For fixing in both cases, both welding and bolts can be used, or maybe both ..

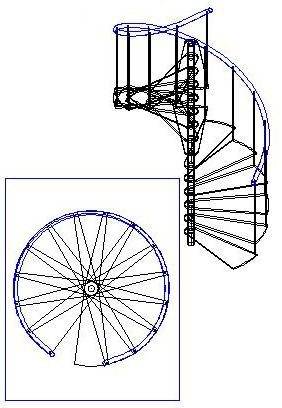

- There can also be designs without a kosour, and this applies to spiral stairs, but they should not be confused with spiral ones, since the kosour is present there. For the spiral arrangement of the steps, first of all, you need a vertical support in the center, around which the entire device unfolds. In such cases, the requirements for the width and height of the steps remain unchanged, but here one problem arises.

- The fact is that at the base (of a metal pipe) the treads turn out to be practically one above the other and their width disappears from one side. Therefore, the minimum span width should be about 80-90 cm, so that the leg can freely stand on the step.

- In such cases, the cost of metal stairs in terms of material turns out to be much lower, but the labor intensity of the process increases, because here you need a spiral bowstring and handrails similar in shape. It is extremely difficult to make such a structure at home, so purchased items can be used for assembly.

- In the photo above, you see a spiral metal staircase on one central stringer - such structures are also called spinal... Of course, making parts for assembling such a device at home is unrealistic, so they are bought ready-made, or ordered for individual projects.

- For emergency evacuation in case of fire, a variety of types of metal ladders are used. So, among them there can be marching, screw, spiral and attached structures. It all depends on the location of the object or communication routes, where you have to install the structure. Such devices can be with or without handrails, as well as in attached options, sometimes a steel strip is welded to the handrail, forming something like a pipe for safe movement.

Conclusion

For the installation of such structures, steel is most often used and in most cases, these are metal fire ladders. Nevertheless, metal is successfully used in design, so this material is perfect for ordinary communications between floors, especially since it has high strength and a long service life.

I'm just doing repairs in the country, the stairs look cool, of course, but I'm wondering if such a structure will cost much more than wooden stairs? I think that in any case it's worth it if you can save on materials at a loss. You can still make yourself out of wood .. but here you have to pay a tidy sum