What are wooden stairs on a metal frame? What, besides wood, can steps be made of? In this article, we will pay attention to the general principles of making stairs with a metal base and related terminology. In addition, the reader will find a number of practical tips in it.

Materials (edit)

What are the most common stairs used for indoor staircases? The answer is obvious: the cheapest and most affordable material is wood... No, do not think - from this material you can create luxurious staircases of the "Elite" class, but today we are not talking about them.

You can knock down an easy ladder from a bar and a board literally during the day; while the cost of materials will be minimal.

What's the catch? Unfortunately, wooden stairs have a number of disadvantages.

- Extremely moderate mechanical strength. Under a significant load directed across the fibers, the bar may well break.

- Creak. The notorious supporting elements made of wood deform under load; while the tree rubs against the tree, which people with sensitive sleep will definitely not like.

- Limited service life. Decay and wood borers have significantly reduced the strength of structural elements for a decade.

However: impregnation with antiseptic soil and drying oil is quite capable of increasing the life of the board and timber several times.

Alternatives? There are few of them - steel and concrete... And both are far from perfect:

- A concrete staircase can be made by hand, however reinforced concrete is too bulky and massive, and will not fit into any interior. For a house with hardwood floors, its weight is prohibitive; in addition, the material gains strength within a month. If you can wait during the construction process, then for an already inhabited house this is too long.

- Steel steps give the room a frankly official look. Making a steel staircase look pretty ... well, it's not easy.

The obvious solution is to make only the supporting frame from steel. At the same time, the manufacture of stairs on a metal frame is possible using a variety of materials for steps:

- Tempered glass will make the steps transparent and lightweight in appearance.

- The texture of the wood of noble species will add sophistication to the steps.

- For the street, reinforced concrete steps that are resistant to dampness and temperature fluctuations will be an excellent solution.

Theory

Terms

Construction terminology is quite specific in general. Ladders are no exception. Let's start by building up your vocabulary.

- Kosour is an inclined beam on which the steps are laid from above. If the frame is made of steel, typical solutions for stringers are a channel, a profile pipe and an I-beam.

- The bowstring is the same inclined beam, differing in a different way of fastening the steps. They fit into slots or slots.

- A march is called a continuous series of steps. From the point of view of convenience, they try to limit the marches to ten steps. With a greater length of stairs, it is divided into two or more flights with small horizontal platforms between them.

- The middle line of the march is a conditional line that runs strictly in the middle of a straight staircase. For curved stairs, it is carried out 40-50 from the edge of the spans; for screw - along the axis of the support in the center.

- The riser is a vertical step element. From the point of view of convenience and safety, its height is optimal at 15-18 centimeters.The permissible range of step heights is 12 - 20 cm.

- The tread is, accordingly, the horizontal platform of the step. Its optimal width for residential premises is fixed in SNiP and is equal to 30 centimeters. In attics and basements, it is permissible to reduce the tread width to 26 cm.

However: the narrow side of a curved stair tread can be narrowed down to 14 centimeters.

- Zabeznye steps are arranged instead of platforms on the stairs with straight flights. They are an excellent alternative to a staging area, especially in confined spaces.

- Balusters - vertical railing posts (as a rule, carrying not only functional, but also decorative functions). The maximum step between them - 15 centimeters - is designed to prevent accidental fall from the stairs.

In houses where there are small children, it is recommended to put at least two balusters on a step: in this case, the child will not be able to stick his head between them. Alternatively, large pitch balusters can be connected with frequent horizontal bridges.

- Bolt-stairs are devoid of a supporting frame. As a rule, one side of each step is attached to the wall, the other is connected to the lower and upper step with a short steel element - a bolt.

- The cantilever design looks even more elegant and unexpected. One side of each step is embedded in the main wall, the other hangs freely in the air. Of course, such a fastening scheme means high requirements for the material of the wall, and for the quality of fixing the steps, and for the strength of their material.

- The closed frame, as the name suggests, is completely hidden under the steps and cladding. A typical solution for such a scheme is a pair of kosour from channel and step frames welded from a 20 or 25 mm corner.

- Open frame for aesthetic reasons, it is usually cooked from a profile pipe (and often in the form of a kind of ladder from short alternating vertical and horizontal sections). The sides of the frame remain open; risers are also missing. At the same time, open metal frames of the stairs to the second floor are often cooked with only one stringer, in the center of the steps.

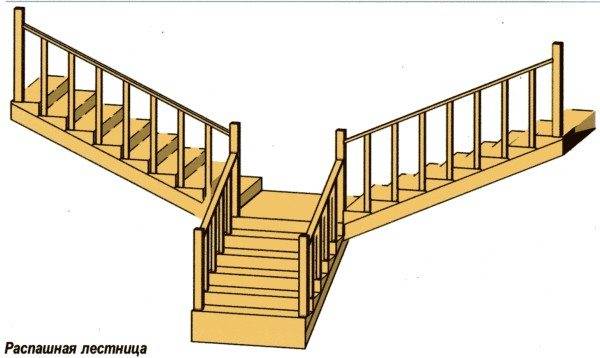

- A swing staircase is called a staircase with three flights, separated by a platform. One wide march leads to her; two narrow ones diverge to the right and to the left. Front staircases of this type are more than beautiful, but, as you might guess, they occupy a large area.

General points

A typical solution for a staircase to the second floor on a metal frame is two flights with winder steps between them. In this case, space in the room is significantly saved: only the corner is occupied; in addition, the space under the marches is quite usable.

If the length of the staircase is more than three steps, a handrail is required. In general, their height is 90 centimeters. Minimum comfortable step width - 80 cm.

For outdoor stairs, a reinforced concrete foundation is required. Otherwise, there is a risk, due to the subsidence of the soil at the fulcrum, to achieve the separation of the march at the upper attachment point: the fracture force even under the weight of one person will become enormous.

The optimum tilt angle is 38 - 45 degrees.

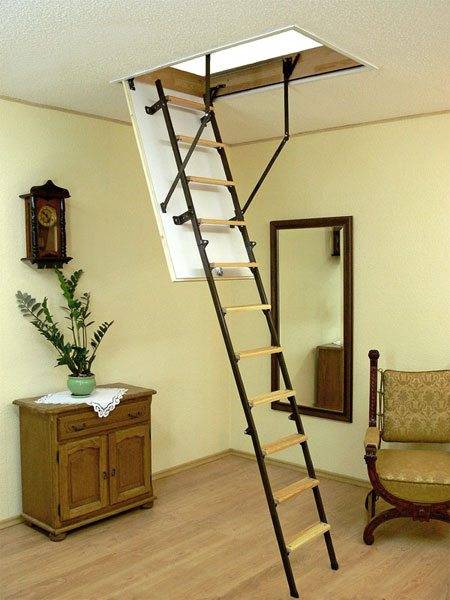

However: the exception is attics and basements. For them, 75 degrees are quite acceptable. It is understood that you will not have to visit these premises several times a day, and you can endure short-term inconveniences in order to save living space.

Tiling reinforced concrete steps on the street is a bad idea. The surface should not be slippery even after rain or snow.

The position of the corner in the elements of the frame of the steps depends on their material.

- If the steps are poured with concrete, the corner encircles the future step in the form of a bowl: you just need to fix the plywood from below as a formwork and lay the reinforcing mesh inside on low supports - and everything is ready for pouring.

- If wood or plywood is chosen as the material of the steps, it is better to cook the corner with the plane up. The appearance of the structure will be much more advantageous.

Simple constructions

Intricate, beautiful and elaborate staircases are not uncommon in today's cottages. However, in order to make the appropriate frame, the services of specialists are needed: the case when the owner of the house is a welder of the highest qualifications is rather an exception.

However, the simplest wooden staircase on a metal frame with your own hands can be made even by an amateur. Let's look at a couple of structures, the assembly instructions for which will not seem overly complicated to a person who does not have much experience in welding.

One march with two kosoura

- Two kosour from a profile pipe with a section of 80x40 - 100x100 (depending on the length of the march) are welded into a one-piece rectangular frame using two or more jumpers.

- Pads of 4 mm steel are welded to the professional pipe, which are anchored to the floor at the bottom and the wall at the top. The size of the anchors must provide a reliable fastening capable of withstanding a load of at least 300-400 kilograms. Location - where they will be unobtrusive.

Captain Evidence suggests: if at the top of the professional pipe rests on a wooden beam, studs or screws from 100 millimeters in length are used in an amount of at least 4 for each attachment point.

- To the top side kosourov pre-tacked assemblies are welded from the vertical and horizontal sections of the corner. After they are set on the level, the corners are tacked to the professional pipe; then the corners and horizons are checked again, and only then the seams are finally welded.

- Balusters, in their simplest form, are vertical posts made of 3/4 inch pipe. Handrail - professional pipe 20x40; if desired, it can later be finished with a wooden plate.

- Steps made of polished and varnished boards or plywood with a thickness of at least 22 millimeters are attached to the corners of the frame with self-tapping screws (from below, through pre-drilled holes). Of course, you will have to cut grooves under the balusters.

One march with bowstrings

The difference with the previous version is only that the corners are welded not from above, but from the inside of the professional pipe. Identical pieces of the corner are boiled strictly to the horizon; then steps are laid on them.

Since the bowstrings will not be covered with wood or plywood, such a scheme will make it possible to do without the grooves for the balusters.

In principle, nothing interferes with weld in the crossbars from the corner as a basis for each step; however, this not only increases material consumption, but also affects aesthetics. In the author's humble opinion, a 40-mm board up to a meter long can easily do without additional supports. The installation of jumpers is meaningful only if the steps are planned to be made of a relatively thin material with a solid length.