Following the script already written

When fastening stairs - everything has been thought out for us for a long time. All we have to do is follow the assembly instructions exactly and not fuss, showing complete respect for all the advice offered.

If you take inappropriate initiative and try to improve the finished ladder, or, even worse, replace one fastener with another, then disaster cannot be avoided.

Since the quality of the fastening used in this method and the fasteners are fundamental for the whole structure called "DIY staircase at home". The cost of wrong decisions is very high here, up to the destruction of part of the house itself. Therefore, first about the immutable rules.

Rules to be followed in any case

In whatever conditions the future use of the ladder is not expected, it is strongly recommended to observe the following postulates:

- ladders are attached only to load-bearing walls, made of concrete, brick or timber, at least 25 cm thick;

- asbestos-cement, plasterboard walls and walls in one brick are absolutely not suitable for these purposes;

- if the main supporting element is a vertical pillar, then it must be fixed at the bottom in a concrete screed on a wide slab in order to reduce the specific pressure of the pillar on the floor;

- if a vertical pillar for a spiral metal staircase is installed above the first floor, then it must be supported by the supporting pillars of the building structure on the lower floors.

Just a recommendation

There are also rules for the installation and fastening of stairs, which are recommended for use, they largely depend on the type of stairs being built.

For example:

- straight and one-flight staircase - then its upper edge is attached to the ceiling, and the lower one to the floor of the lower floor, everything keeps the stringer and there is no need for additional intermediate fasteners;

- spiral staircase, but one turn - most likely not to avoid one fixing to the wall;

- spiral staircase, but already two turns - then, in addition to fastening at the top, bottom and to the wall, it is impossible to avoid the installation of a vertical support post;

- Multi-turn staircase - already the structure itself is complex and heavy, therefore, through and multiple attachments to the walls cannot be avoided.

Fasteners

Actually, fasteners can be carried out not only with mechanical fasteners, although they are the main ones. Thorns and glue are also at your disposal as aids.

But the conversation about the fastening of the stairs can be translated into another plane - you rarely have to puzzle over this question, how to fix the steps on the stairs, or how to fasten to the support. After all, any staircase is a ready-made constructor in which everything is already provided for - both the elements themselves and their fasteners. All you need to do is not forget, along with a complete set of all parts, to have with you instructions for installation and fasteners.

The matter is further aggravated by the fact that there are a huge number of staircase designs, and there are even more types and methods of fastening. Therefore, for example, consider the nuances of the most common option - fastening wooden stairs.

Fasteners for wooden stairs

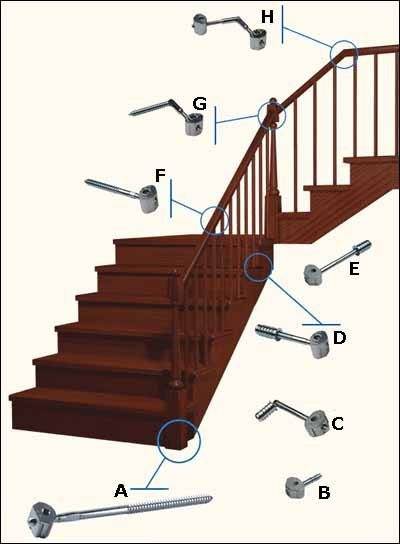

A feature of fastening such ladders is the practical complete absence of such a universal means of connection as welding. Hence the large range of fasteners (see.photo above), depending on the type of joint (we also indicate the number of fasteners according to GOSTs).

- A - a reinforced screw tie with a reducer for fastening the posts of wooden stairs (14.100);

- B - a coupler for connecting furniture parts at the ends at an angle of 90 degrees (12.600);

- C - knee-joint coupler with a foot for connecting wooden parts with a mating angle from 90 to 180 degrees (11.720);

- D - tie for fastening steps to the stringer, balusters to platforms and steps (13.500);

- E - fastening element for fixing drawers and other pieces of furniture made of soft wood (12.720);

- F - straight screw tie for splicing handrails and bent ends (13.600);

- G - cranked screw tie for fastening handrails to posts with a mating angle of 90 to 180 degrees (11.550);

- H - elbow brace with two reducers for joining railings at an angle, as well as for corner joining of furniture boards (11.600).

In addition to using specialized fasteners, the following can be used:

- nails,

- screws,

- wood grouse,

- bolts,

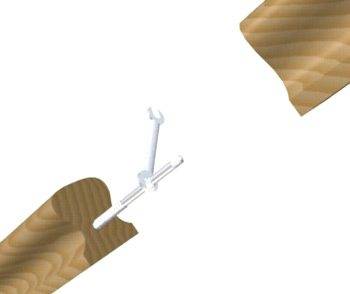

- pegs,

- squares,

- lining, in general, the assortment is endless, and the use of each type has its own characteristics.

So, if nails are used for fastening:

- it is fundamentally important to choose the right length and thickness of the nail, depending on the size of the parts to be connected and the type of wood of the stairs;

- the main thing is that the thickness of the nail should not exceed 10% of the thickness of the part;

- the point of entry of the nail should be at least 15 times the diameter of the nail from the edge of the part, in order to avoid splitting the part.

- if the wood contains tannins, then the nails should be galvanized to avoid corrosion;

- it is preferable to use square nails instead of the usual round ones.

Helpful advice! The use of ordinary nails for fastening ladder structures can be said to be yesterday. Perhaps such a "secret weapon" of all craftsmen as "liquid nails" will not work here, but the screws will be much more reliable. We advise you to use them instead of nails wherever possible. To attach the handrails to the racks, it is very convenient to use pins - wooden nails - only here it is important to choose the right thickness of the dowel. It is highly recommended to use locking washers on all threaded connections. Always tighten it with the required torque.

Helpful advice! We strongly recommend using self-locking washers on all threaded connections. Always tighten it with the required torque. For accurate control of the tightening torque, you cannot do without a suitable wrench, which does not interfere with taking care of if there are a lot of threads in the structure.

conclusions

Convenient thought-out design, reliable fasteners that match the design and pleasing to the eye design - these are the three pillars on which the success of the staircase rests, regardless of the purpose for which it will serve.Treat this "gray cardinal" of any staircase - fasteners with the utmost care and great respect, then you will not have to constantly struggle with it already during the operation of the staircase.

In the video presented in this article, you will find additional information on this topic.