Despite their simplicity, portable ladders and stepladders are used almost everywhere. These structures made of wood or metal profiles are used both in everyday life and in production. In the second case, of course, there are rather strict restrictions regarding their dimensions and configuration, but the general scheme of the device remains unchanged.

Make a portable stepladder or ladder with your own hands is quite simple. The main thing is to choose the right material and meet a number of requirements. It is to these questions that our article will be devoted.

Requirements according to GOST

A portable wooden or metal ladder is a fairly simple device. It is based on two wooden beams - bowstrings, to which horizontal steps are attached. However, if such a structure is to be used in construction or production, all its parts must meet a number of requirements.

Dimensions and performance characteristics of portable ladders are regulated by GOST 26887-86 "Ladders used for construction work".

In addition, the safety of workers largely depends on the state of the ascents, and therefore some of the requirements for stairs are set out in such documents:

- Interdisciplinary rules of labor protection when working at height (POT RM-012-2000).

- General provisions of labor protection in construction (SNiP 12-03-2001).

Of course, if you are going to use the structure in a private courtyard, it is not necessary to strictly follow the requirements, but it is still worth knowing them..

What are the restrictions on the dimensions and operational characteristics imposed by the mentioned standards?

- The maximum permissible overall length of the structure is 5 meters. This applies to both attached and sectional models.

- The load-bearing capacity of the ladder is at least 150 kg.

- The steps should be made of even and strong wooden beams with a cross section of at least 30 mm on the smaller side. Fastening the step to the bowstring is allowed only according to the “thorn in the groove” scheme.

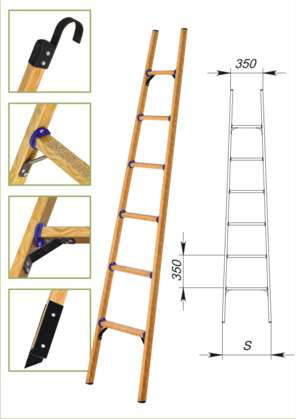

- The distance between the steps is from 300 to 340 mm.

- Bowstrings are additionally connected with tightening metal elements. Metal screeds must be installed under the first and last steps, as well as every 2 m of the length of the structure.

- To ensure stability, steel pointed shoes are installed on the lower supports. If the ladder is supposed to be operated on dense surfaces (asphalt, concrete, etc.), then plastic or rubber corrugated pads are used instead of metal shoes.

As for the ladders, the requirements for their design are described by GOST 24258-88:

- Beginning at a height of 2 meters from the ground level, arches must be installed on the stairs.

- The maximum deflection of the handrail under a weight of 150 kg cannot exceed 5 mm.

- In the unfolded state, the parts of the stairs must provide sufficient strength and stability.

- Structures should be equipped with locks that prevent spontaneous opening.

According to the requirements of all the documents mentioned in the section, the test of portable ladders and stepladders should be carried out at least once every six months. The results of the control are recorded in the log book, and information about the date and results of the check is applied to the staircase itself.

Making stairs

Materials used

The price of most industrial staircases presented in the trade network is quite low. And yet, many people prefer to make such designs on their own.This approach is quite justified, especially in the context of the relative availability of cheap lumber.

In this section, we will tell you how you can quickly and easily make a portable ladder with sufficient bearing capacity. Of course, if you are looking for how to move the piano up the stairs, the proposed design will definitely not suit you, but for most household needs, the margin of safety will be enough. (see also the article 4x4 transforming ladder - a convenient and versatile design)

Advice!

Attachable and folding models are intended primarily for moving people.

For the transportation of goods, and even more so heavy as the aforementioned piano, it is worth considering other options such as a telpher or stationary stairs.

To make a portable structure, we need:

- Two bursa with a section of 100x50 mm for making bowstrings. If we make a stepladder, then, accordingly, the number of elements will double.

- Bars not less than 30x30 for steps.

- Steel studs with a diameter of 10 mm and a length of at least one meter.

- End caps for supports (steel or plastic).

- Loops for connecting parts of the ladder.

Preparing parts for assembly

In order for our ladder to be reliable enough, all the blanks must be processed:

- We carefully examine the bars for the bowstrings of the stairs, revealing cracks and defects. According to the standards, only longitudinal cracks with a length of no more than 15 cm and a depth of up to 5 mm are allowed.

- We cut the bars to size. We cut the lower parts of the supports so that the installed ladder rests on flat edges.

- We process the blanks first with a plane, and then with a grinder.

- We cut out the steps from a thinner beam. Since the top of the ladder is usually made narrower, the blanks should be numbered to avoid confusion.

- Like bowstrings, we carefully grind the steps. Sharp edges can also be chamfered for a more comfortable ride.

To ensure maximum durability, we impregnate all wooden parts with an antiseptic. You can also treat the workpieces with a flame retardant.

We mount the stairs

For most ladders, the knot that is most stressed is the point where the rung meets the string.

Several options can be implemented here:

- The first - the simplest - involves laying the steps on top of the bowstring and fixing them with nails and screws. This method is easy to implement, but only suitable for temporary structures.

- The installation of steps into recesses is somewhat more difficult. In this case, grooves are made in the bowstring, into which an overhead step is inserted. The main disadvantage of this method is the weakening of the supporting structure.

Still, the most reliable is a straight or oblique tenon connection. By the way, it is provided for by the requirements of GOST and SNiP.

The instruction advises to make it like this:

- We make square grooves on the inside of the bowstrings.

Note!

In order for the ladder to be level, the indentations on both parts must be placed strictly symmetrically.

- We cut the ends of the step blanks in the form of thorns. The size of the spike should slightly exceed the dimensions of the groove.

- Having laid the bowstrings on the ground, we insert the steps into the nests, hammering in the details with light blows of a mallet. To increase the strength of the joint, we apply wood glue to the joints.

- From the outside, we additionally fix each step with self-tapping screws.

- We connect the bowstrings with steel tie rods, securing them to each bar with a nut with a wide washer.

If we plan to make a ladder, then we repeat these operations for the other half of the ladder. We set both parts opposite each other and fasten them at the top with special loops.

Output

The requirements for portable stepladders and ladders may well be met even with the independent manufacture of the structure. (see also the article Telescopic stepladder - design features and application) At the same time, we get a certain guarantee of our safety - and when it comes to work at height, labor protection issues come to the fore! The video in this article will offer additional information on this topic.