Installation features

The peculiarity of the structure of the block itself, namely the presence of a "groove" and "ridge" (hence the name) turns the masonry process into assembling a Lego constructor. All you have to do is spread the mortar over the top of the lower block and place the other on top. As practice shows, the preparation of the solution takes longer than the masonry itself.

To create maximum stability of the structure from the bottom, the solution will not be enough. It is best to make a small gutter that will serve as the first groove for the entire building. To do this, you will need a small scrap, but do not overdo it so that the neighbors below do not have to make repairs too. Lay down the seal in the form of a foam rubber fabric with a thickness of no more than 2 mm.

Peculiarities

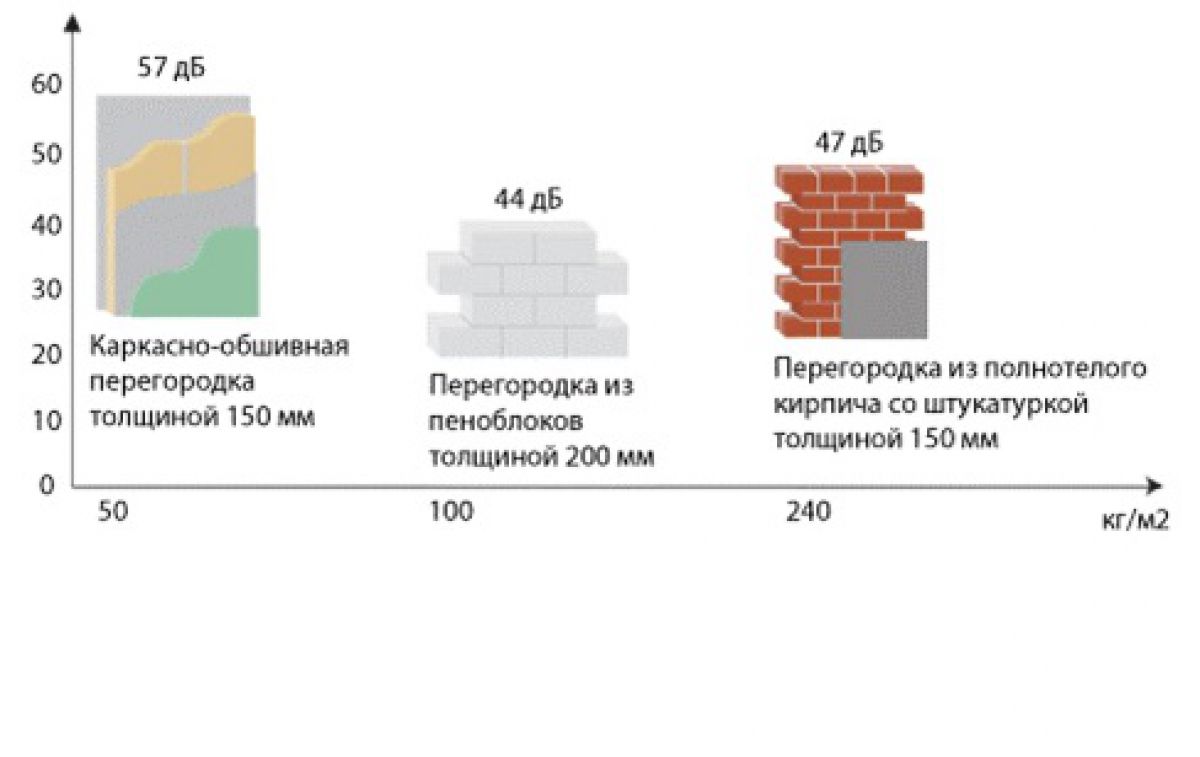

Partitions and walls in an apartment should protect a person from noise that can be heard from the premises in the neighborhood. Pets, children at play, TV, stereo, hairdryer and some other household appliances can be sources of loud sounds. That is why the selection of material for walls and their sound insulation must be approached very carefully, especially if you live in a multi-room apartment in a large family.

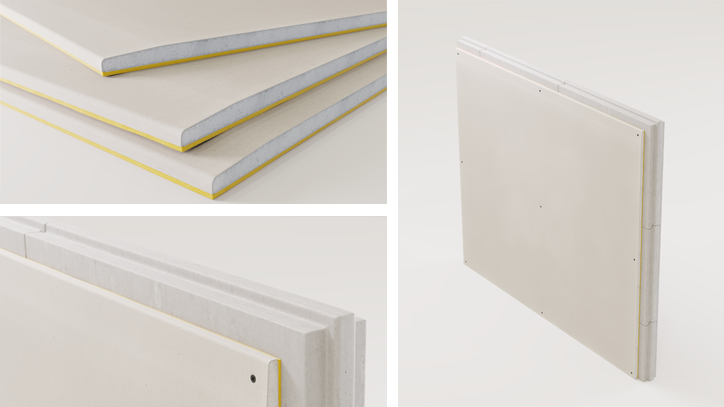

Most often, partitions in living quarters allow you to effectively zone the space, ensuring the functionality of the house and comfort for all household members. One of the most demanded materials for such structures is the tongue-and-groove slab.

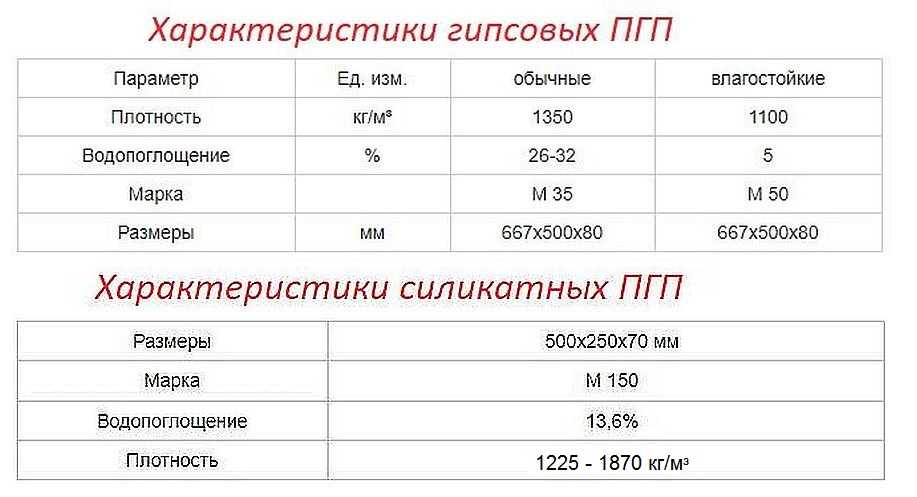

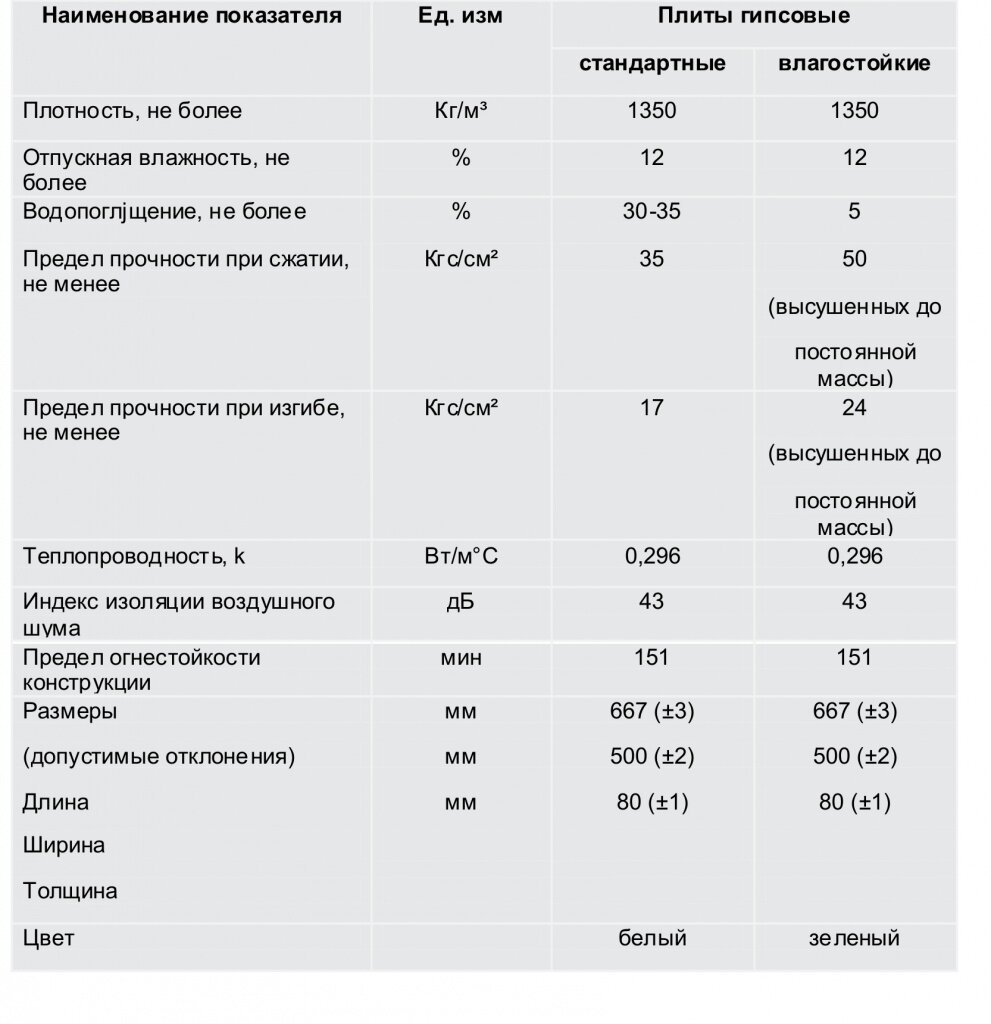

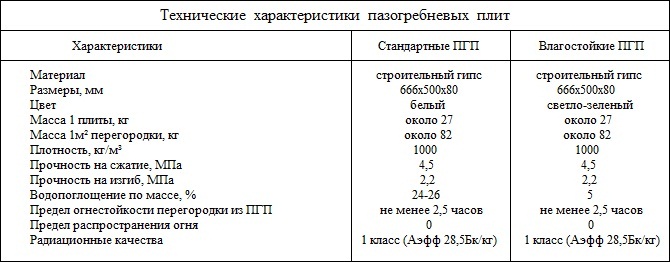

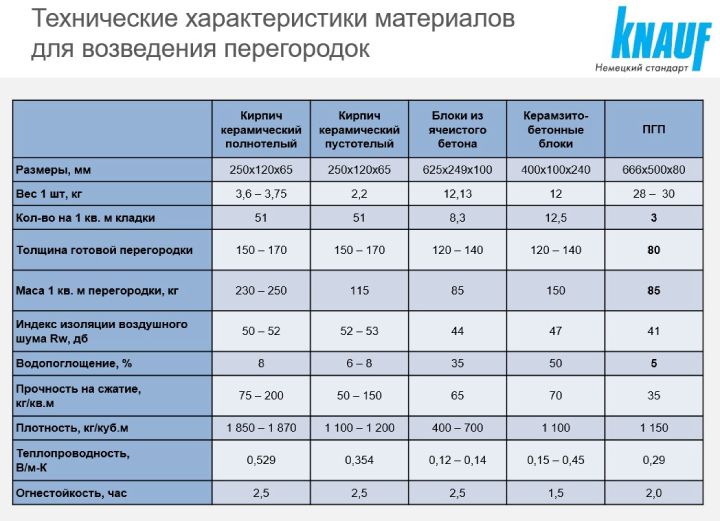

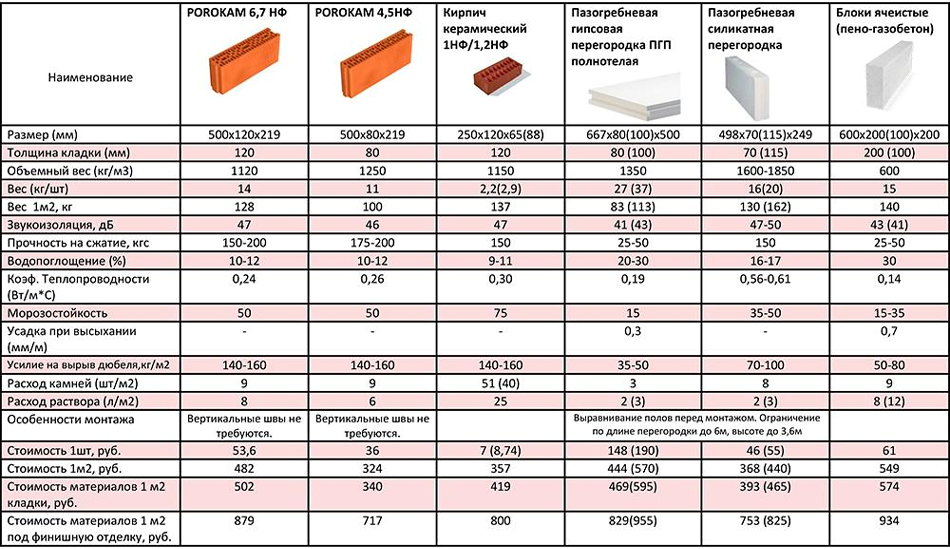

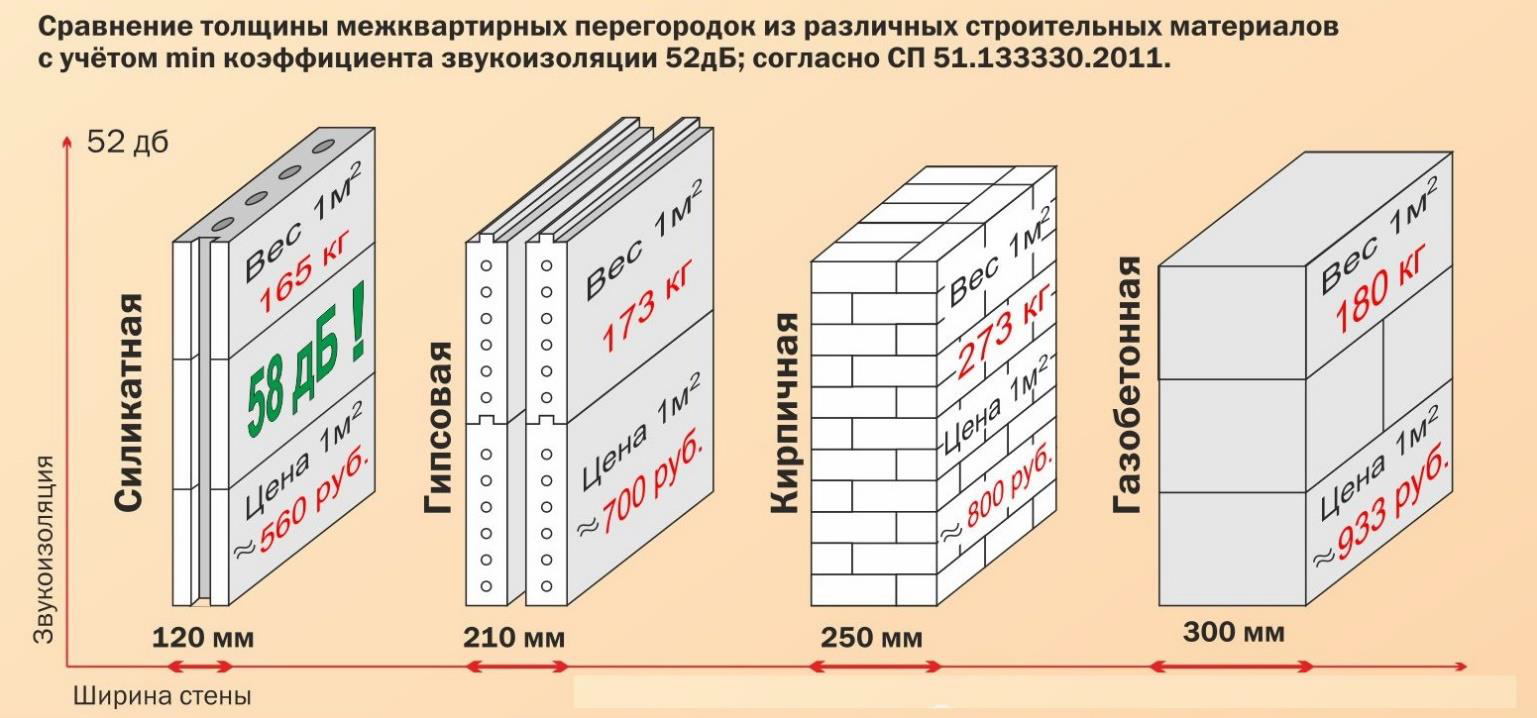

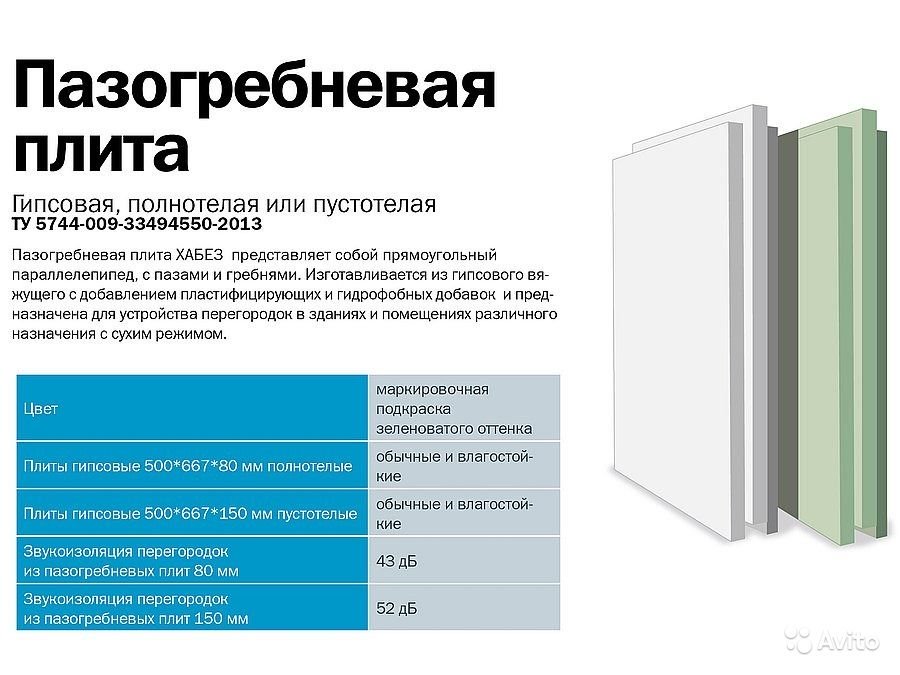

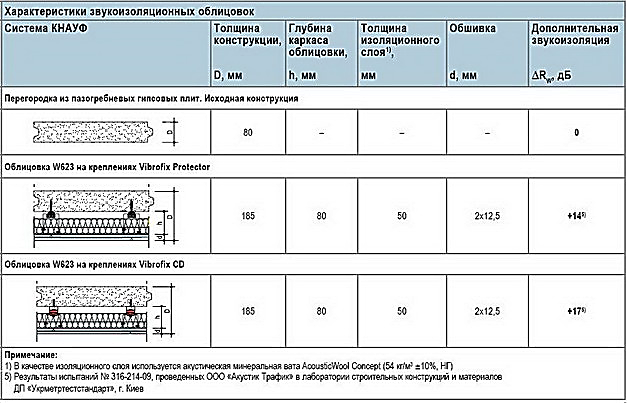

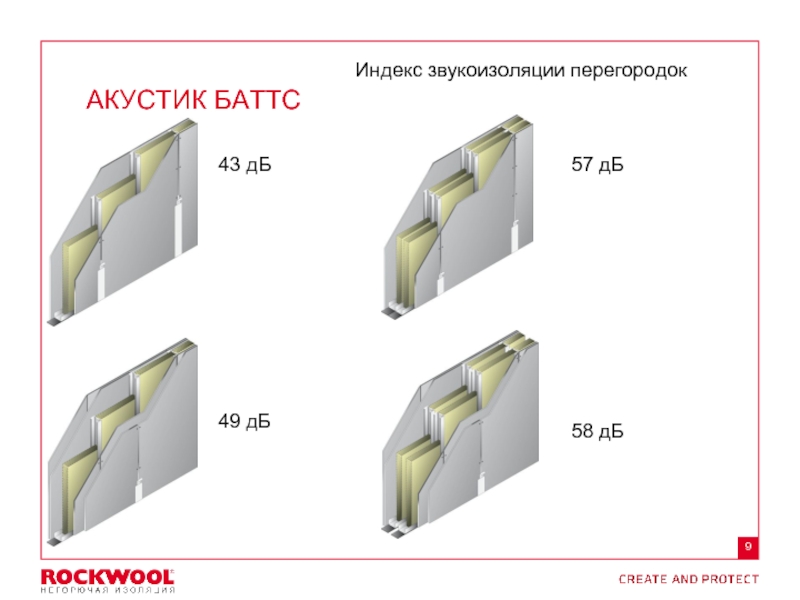

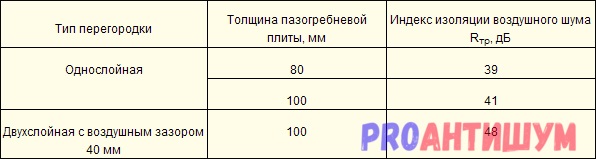

As you know, GWP is made on a gypsum or silicate base. In terms of sound absorption parameters, both options are approximately the same. Plates with a thickness of 100 mm can keep noise not exceeding a level of 41 dB, however, according to reviews, this is not enough for a comfortable stay in the room. Such noise insulation is not able to effectively muffle the background noise from the next room; moreover, it creates a feeling of 100% presence.

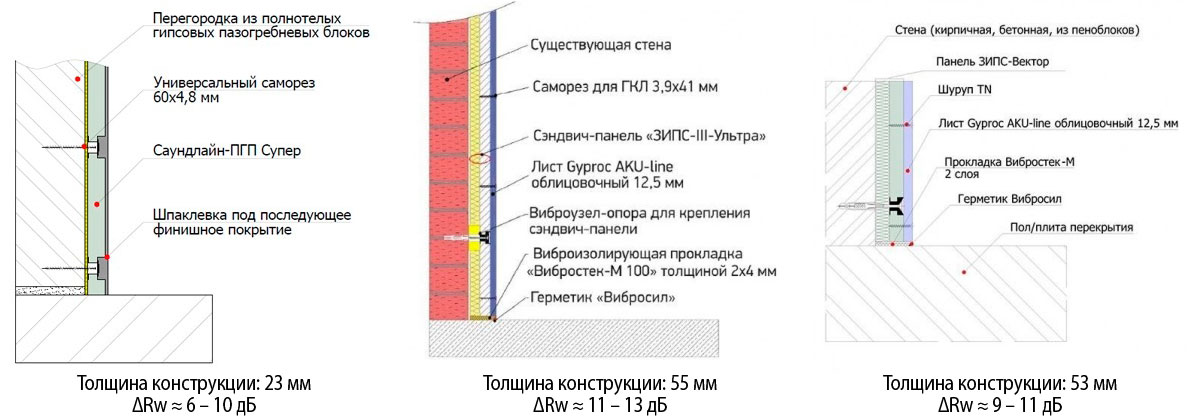

This problem can be solved by additional soundproofing of the partitions from the tongue-and-groove.

If you are just planning to erect a wall, then it is better to immediately abandon this material, otherwise you will have to make significant efforts and spend a lot of money and time to achieve the desired silence. If you are determined to use this material, it should be borne in mind that maximum sound absorption can be created only if you soundproof not only one wall, but also other partitions, as well as ceilings and floors. The fact is that even if this partition is not a carrier, then from a rigid fixation it begins to transmit vibration along with structure-borne noise. Therefore, tongue-and-groove partitions can be built after all work on the floor and ceiling has been completed.

Errors in arranging sound insulation

Let's list the main ones:

- Covering of offices / apartments with sound-absorbing raw materials. It is possible to enhance sound insulation by combining it with sound-insulating elements and using barriers with acoustic decoupling in the connecting gaps.

- Finding loud equipment in soundproofed buildings. Soundproofing materials have a limited degree of protection, so they are not always saved from the noise generated by powerful mechanisms. This technique is located at some distance from the premises.

- The use of soundproof interior screens with a high sound insulation index. Material alone is not enough - sounds spread over structures, communications.

- Noise insulation for three-layer plasterboard partitions with internal filling.To increase efficiency, select sound absorbers, use strong spacers between the "skeletons", seal the seams.

- Sheathing with thin soundproof screens. The soundproof barrier is created only with the help of the “mass-elasticity-mass” formula, in which the minimum thickness is 5 cm.

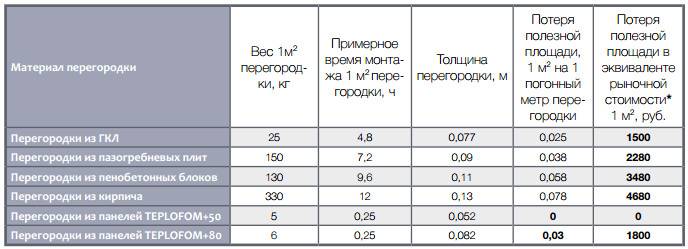

Comparison of drywall and tongue-and-groove partitions

Drywall and tongue-and-groove slabs have both advantages and disadvantages.

There is no ideal building material, it is important that both types meet standards, requirements and regulations

- The tongue-and-groove plates are more durable, they can easily withstand the load created by hanging elements (furniture or household appliances) up to 200 kilograms. Plasterboard walls will need to be supplemented with wooden inserts into the frame, or only special fasteners should be strictly used.

- The tongue-and-groove plates also benefit from the preparation time for installation. Drywall needs preliminary assembly of the base from a metal profile or a wooden bar. Plasterboard panels can be installed on a pre-leveled floor.

- GKL walls require at least minimal finishing, it is imperative to seal the seams at the joints of the sheets and the points of its attachment. Gypsum boards are assembled into a single structure without unnecessary joint gaps and crevices. After assembling such a wall, you can immediately start pasting it with wallpaper.

- The tongue-and-groove plates also have high heat resistance, they are absolutely non-combustible, while drywall must be used fire-resistant gypsum board, and this increases the cost of the wall being mounted.

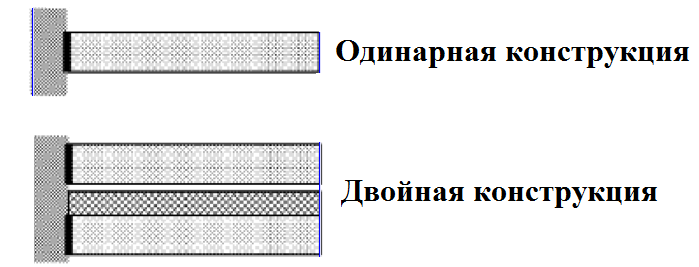

- A significant advantage of plasterboard walls is that you can easily hide any communications in them: lay wiring, water pipes, or lay insulation. In this case, tongue-and-groove plates must be installed in two rows, which increases installation and material costs.

- The cost of tongue-and-groove plates in relation to drywall sheets is almost the same, but the gypsum board allows you to cover a large area, which in turn is leveled by the purchase of additional frame profiles, fasteners and other components for drywall.

- In terms of sound permeability, tongue-and-groove slabs are significantly superior to gypsum boards in terms of sound insulation. The partition, assembled on the frame, requires an additional layer of insulating material.

Layout of tongue-and-groove slabs What is worth knowing about the rules for installing walls and partitions from gypsum-polymer tongue-and-groove plates?

Layout of tongue-and-groove slabs What is worth knowing about the rules for installing walls and partitions from gypsum-polymer tongue-and-groove plates?

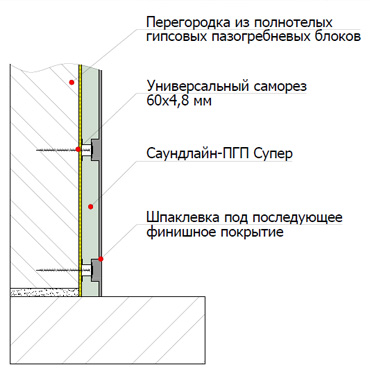

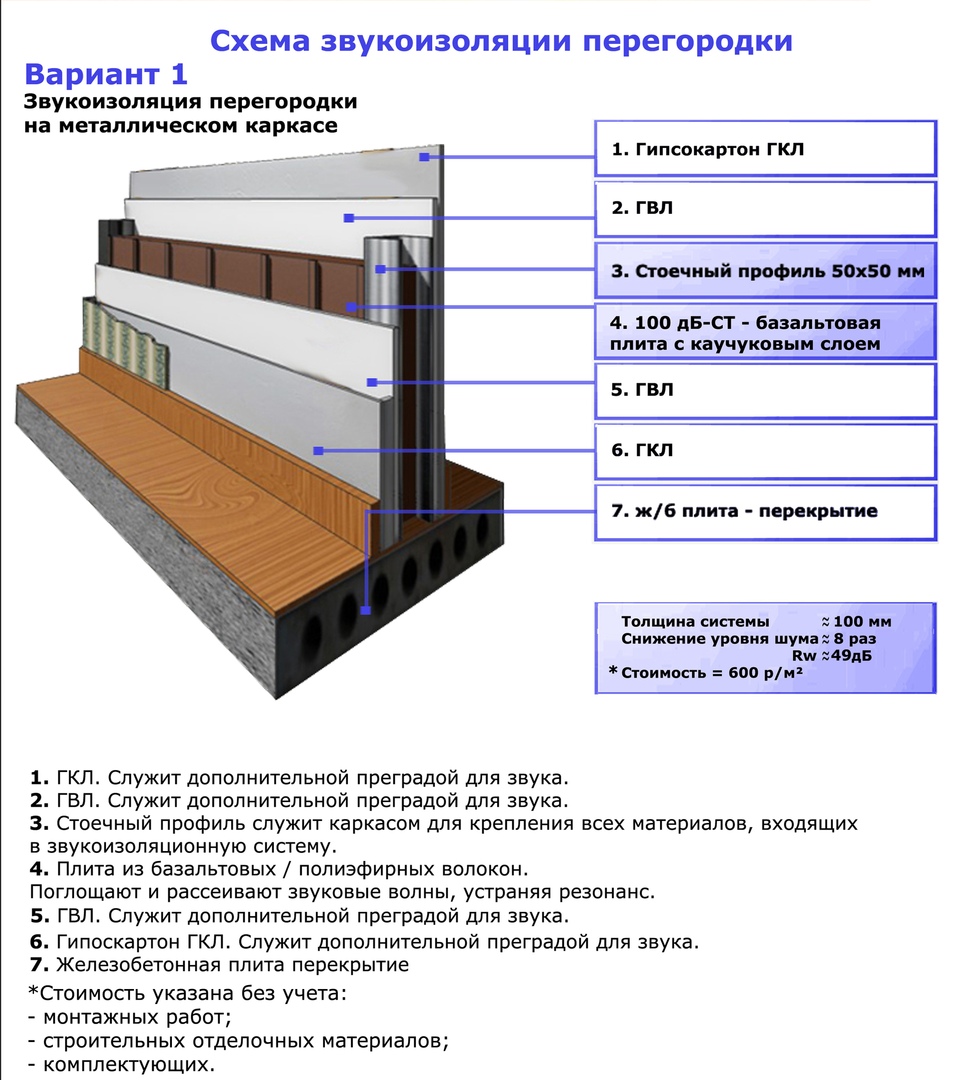

Sound insulation of tongue-and-groove plaster partition

When a major overhaul with installation is planned in the apartment

interior partition, then most people prefer inexpensive

building materials, these include tongue-and-groove plates. These products are easy to

installation, have a low weight and their cost is quite acceptable. The only one

the disadvantage is poor sound insulation. To maximize the partition

effectively kept extraneous sounds, it must initially be correctly erected

taking into account sound insulation.

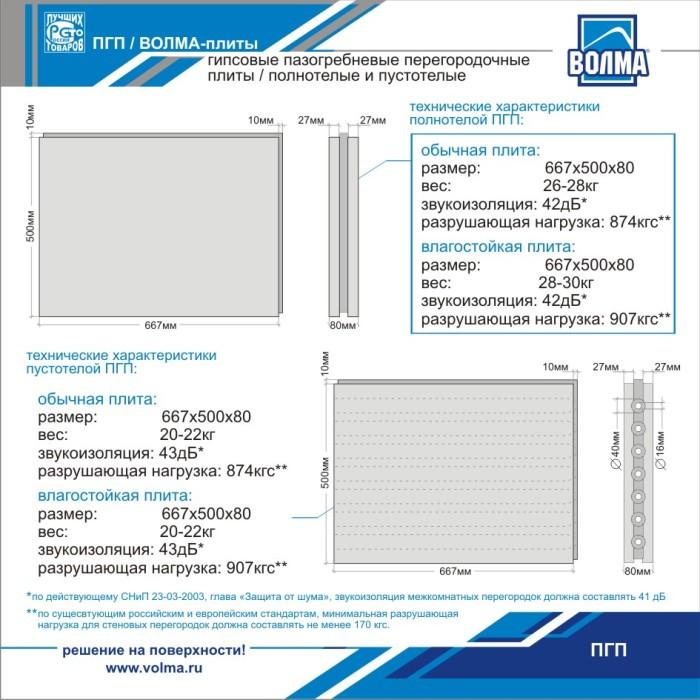

@PGP

@PGP

As you know, to provide coziness and comfort in an apartment can

noise insulation, while not one surface, but completely walls, ceiling and floors.

It is worth noting that the construction of a partition from PPG should be done only

after the floor and ceiling work has been completed. The thing is that

the partition, even if it is not a carrier, can

transmit vibrations and structure-borne noise. To exclude this possibility, initially

complete insulation of the ceiling and floors is made.

For the floor, a floating floor will be the optimal solution, so that it will be possible to protect the flooring from unnecessary vibration. Installation of GWP plates is carried out in such a way that the blocks at the top do not fit tightly to the ceiling. If you make a rigid screed, you can forget about the soundproofing of the partition.Some people use polyurethane foam to blow in the upper space, but in fact, this is not correct.

Construction foam becomes hard when it dries, so all vibrations will be transmitted to the partition, if used, then special soundproof materials. Alternatively, you can put mineral wool in the opening and cover with a sealant that will keep vibration.

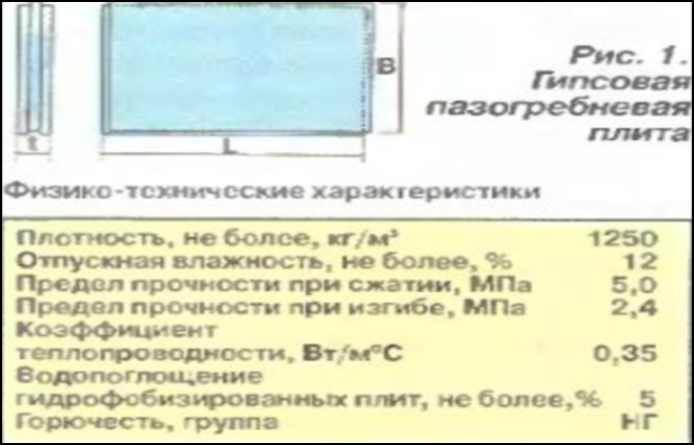

Sound insulating properties of GWP

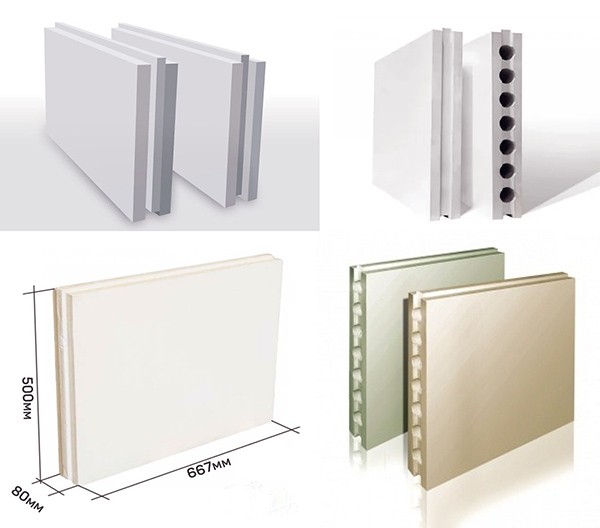

Today, two types of GWP are used in construction.

slabs: gypsum and silicate. As for the former, they are made by casting

from plaster and special additives. Due to the production technology of the product

get the correct shape with grooves. Slabs are also made from quicklime lump

lime, sand and other additives for pressing technology. It should be noted that

in gypsum structures, heat and sound insulation indicators are slightly higher than in

silicate blocks.

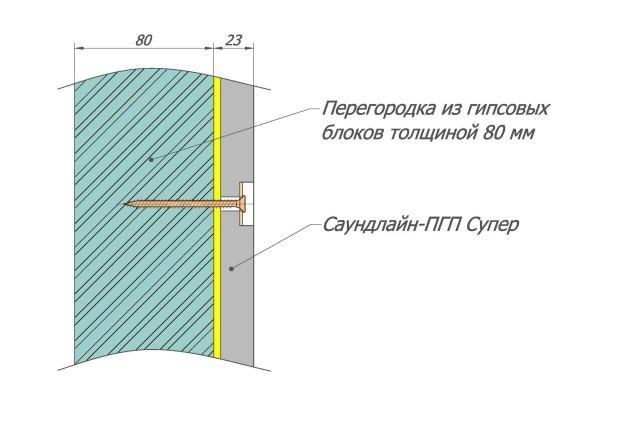

@PGP

@PGP

Both materials

are made on the basis of environmentally friendly materials, due to which they are widely

used in frequent construction, and in particular for the construction of interroom

partitions. Also, the features of the building material include incombustibility.

products and hypoallergenic characteristics. If you install a partition from

tongue-and-groove plates, then it is imperative to do an additional

noise isolation, since the degree of retention of sound waves is only 41

decibel.

Installation features

The laying of partitions from tongue-and-groove blocks is carried out after the completion of the installation of load-bearing and enclosing structures of buildings, before the start of the installation of a clean floor and finishing works.

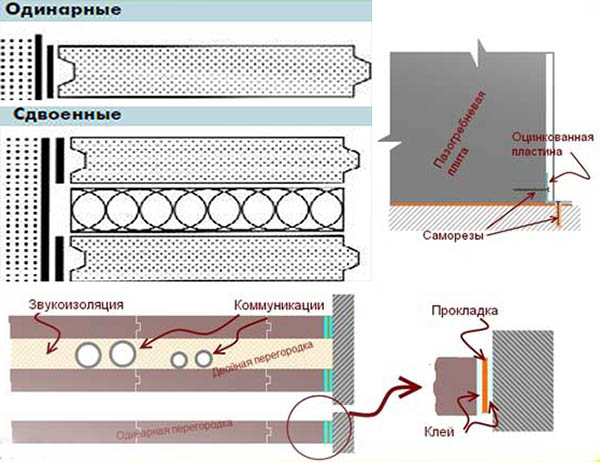

When redeveloping or reconstructing residential and civil facilities, tongue-and-groove partitions can be erected not only single, but also double. The latter option is used in cases where it is required to perform a hidden laying of engineering networks or insulate a partition, one side of which goes into a cold room.

At the facility, the installation of tongue-and-groove plates is reduced to joining along the seams, with periodic monitoring of the verticality and horizontalness of each row. When assembling interior partitions, the plates are placed both with a groove down and up. The norms recommend that they be laid with the groove up, since in this case the mounting adhesive mixture is evenly distributed in the groove-and-groove space.

Standard aerated concrete glue or Fugenfüller putty can be used as an adhesive base for installation.

Installation sequence

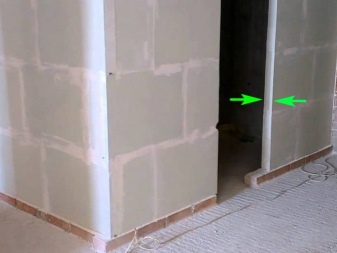

The base for the partition is leveled with a cement-sand mortar, after which the first row of partition plates is placed on it according to the level. Before joining, the surfaces of the groove and the ridge of each plate are covered with an adhesive solution so that the thickness of the seam at the joints does not exceed 1-2 mm.

Installation is carried out with the bandaging of the joint seams. To create an elastic abutment to the enclosing and supporting structures, tongue-and-groove partitions are fastened with special brackets.

The bracket is installed in the groove of the slab and fixed with a self-tapping screw to the floor panel or with an anchor dowel to the enclosing structure.

In addition, in such joints, the standards recommend the use of cork or bitumen felt gaskets, installing them around the entire perimeter of the external joint.

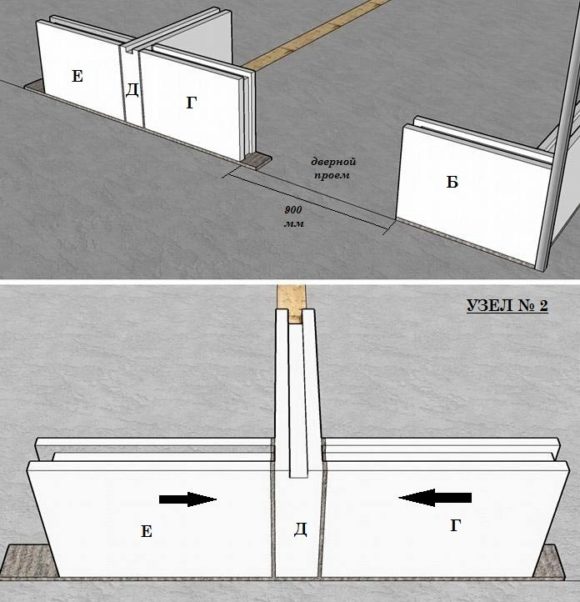

If the width of the doorway does not exceed 80 cm and only one row of tongue-and-groove plates will be installed above it, then the norms allow not to use a lintel. Its role is played by a door frame or retaining structure, which is removed after curing with an adhesive solution (Fig. 1)

Picture 1

With a larger opening width, the installation of a steel or wooden lintel over it is required (see Fig. 2)

Picture 2

All contact zones of partitions with load-bearing walls and ceilings are sealed with gypsum mortar.

Reviews of tongue-and-groove partitions are mostly positive. They emphasize not only the simplicity of their installation, but also good soundproofing properties.

An obligatory moment to which you need to pay attention is priming the surface of the slabs before finishing. Reliability of adhesion of paint and wallpaper to the surface of the plate depends on its quality.

This work is best done using a deep penetration primer.

Latest developments

Manufacturers of building materials regularly invent new products and improve the quality of their raw materials. The work is carried out in such areas as:

- production of acoustic gypsum boards;

- use of special filler under soundproof partitions;

- spraying cellulose fibers;

- creation of false walls;

- filling of barriers;

- production of elastic pads that reduce impact sound.

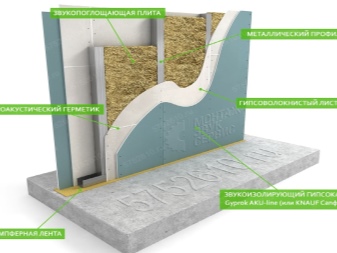

Acoustic drywall

Knauf is a manufacturer of acoustic drywall, which reduces the effect of noise during sound insulation for interior partitions, wall cladding. The security level of the fences is increased by the many openings. They reflect incoming sound waves. From the inside out, the cardboard is pasted over with a special canvas, but not with a cloth.

Sound-absorbing filler inside partitions

In plasterboard partitions, sound insulation requires the presence of a noise absorber. Foamed thermoplastic, consisting of merged granules with many air chambers, is in great demand, it is also expanded polystyrene. The material does an excellent job of keeping warm. If you add a fire retardant, then the fire resistance will also increase.

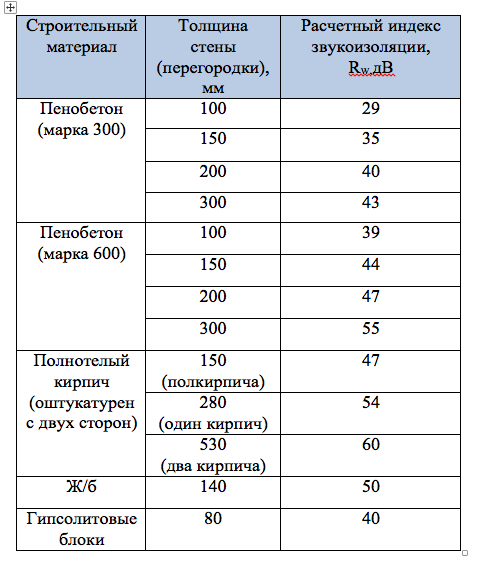

Basalt / mineral wool slabs are produced with high sound-scattering properties. Of these, for sound insulation of walls, products with a thickness of about 4 cm are used. For effective dispersion of noise waves, panels that are homogeneous in structure are used. It is recommended to use a filler of small thickness for them - this will save the room from loss of volume. Membranes made of thin cloth and covered with pile are recognized as worthy noise absorbers.

Spraying sound-absorbing coatings

Spraying cellulose fibers with an adhesive mixture is a popular finish. The method is used to correct the acoustics of the internal space of public, entertainment premises.

On sale there are Sonaspray coatings of the type of plaster with a "fur coat" texture. It can be uniform or rough. The coatings look beautiful, but to give a greater effect, dyes are mixed into the solution. Tinting is carried out after laying the material.

Spraying foamed cellulose solution on walls / ceilings frees from the creation of frames that hold the plasterboard cladding. Using special equipment, cellulose is applied from the inside.

Mounting

Before installing the slab partition, it is necessary to check the condition of the base. It must be strong, horizontal and motionless. If the old screed does not meet these requirements, a new one is made. The installation technology resembles the creation of a partition from polystyrene concrete blocks

The differences in the height of the base should not exceed 1 cm, if this is not done, then it is leveled.

To carry out the installation of a tongue-and-groove partition, you need to have the following tools and materials:

- tongue-and-groove plates;

- adhesive composition;

- gaskets, they can be felt or cork;

- putty;

- construction mixer or drill with a special attachment;

- hacksaw;

- level;

- plumb line;

- rule;

- measuring instruments;

- rubber hammer;

- putty knife;

- wedges.

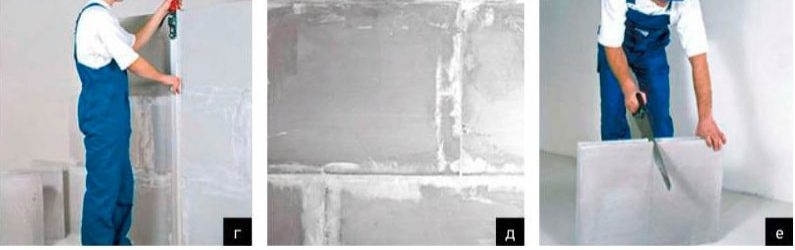

Before starting the installation of the plates, the base must be cleaned of debris, dust, after which it is covered with a layer of primer.

The marking of the future partitions can be done after the primer layer has dried.

The doors are marked, and to facilitate the installation work, you can pull the cord.

The markings are applied to the walls and ceiling, for which they use a plumb line and level.

Now you can prepare the solution, for this, water is collected in the container and the dry mixture is gradually poured, everything is constantly mixed well, they do it with a mixer or a drill with a special nozzle. The composition should be infused for several minutes and you can start installing the plates.

It is necessary to prepare the glue in small portions so that you have enough of it for 30-40 minutes of work.

You can lay the slabs directly on the floor, then you get a rigid mount. The glue is carefully applied to horizontal and vertical surfaces; on average, you will need 1.5-2 kg of glue for mounting 1m2 of a wall.

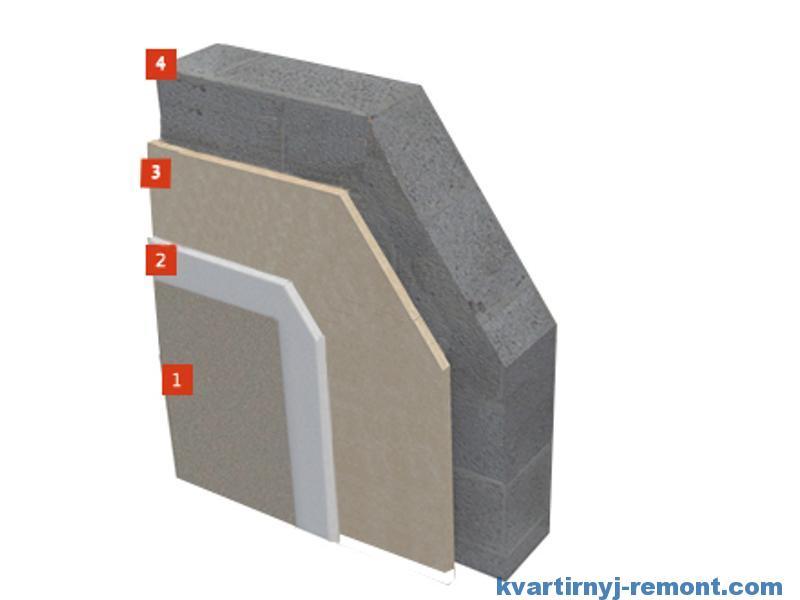

When using the second method, the slabs are laid on a special cork gasket, which makes it possible to increase the sound insulation of the walls. To do this, use a tape 7.5 cm wide, which is glued along the perimeter of the partition.

The gasket is mounted on glue, its horizontal position is checked and it is necessary to give 20-30 minutes for it to fix well.

Plates can be laid both up and down with a groove, but it is more convenient to place it up, since the glue is easier to apply in the groove than on the ridge.

In this case, on all plates used for the installation of the first row, it is necessary to remove the comb, do this with a chisel or hacksaw, and then level the plane with a plane.

The laying of the slabs is carried out in the same way as the laying of a brick or cinder block: glue is applied to the base, the plate is installed, upset with a rubber hammer and its horizontal position is checked. If alignment is required, wedges can be used.

The first row of tongue-and-groove plates must be laid correctly, check its verticality and horizontalness, since it will serve as the base of the entire partition.

During the installation of the next rows, glue must be applied both on the horizontal and on the sides so that the boards are securely connected on all sides.

The thickness of the seam is about 2 mm, all excess glue that has protruded beyond the board is removed with a spatula.

To carry out the wiring, grooves are made in such partitions, and to install the sockets, holes are drilled with a special nozzle installed on an electric drill.

If it is necessary to install large diameter pipes, then a double partition is mounted.

Advantages and disadvantages of GKL partitions

Among the positive qualities of this material for creating interior partitions, the following can be distinguished:

Light weight - this quality is especially important when constructing partitions in multi-storey buildings

Easy assembly - DIY installation of drywall partitions can be done by people who do not have special education and construction skills

Low cost - the construction of plasterboard structures will cost significantly less than the installation of a conventional brick partition. The production of gypsum plasterboards is a fairly cheap process, so the retail cost of the material is also not too high.

High thermal insulation - the construction of walls can be carried out without the use of additional insulation

Small size of the area - the thickness of the drywall sheet for the partition usually does not exceed 12 mm, so such a wall will "eat" a very small area

Environmental friendliness - the building material does not contain any harmful impurities

Laying of communications - the width of the plasterboard wall allows you to place electrical cables in the cavity between the sheets

Installation of arches - the material bends easily, so it will be possible to easily make both a rectilinear partition and curved structures, and the doorway to the room can also be made in the form of an arch

With the help of this material, you can assemble a structure of the most bizarre and non-standard type.

The disadvantages of plasterboard partitions include:

Low mechanical strength of the structure - a wall made of this material is not able to withstand excessive loads and can be significantly damaged if furniture falls or when bulky objects are carelessly moved

Low moisture resistance - even special moisture resistant drywall should not be exposed to direct liquid

Poor sound insulation - gypsum plasterboard is a poor barrier to the propagation of a sound wave

As you can see, there are not so many drawbacks of this material, and if it is necessary to fence off a room in which the air humidity is low, and to fix a mineral sound-absorbing mat between the sheets of gypsum board for its sound insulation, then during the operation of the partition, only its fragility will be the only drawback. If a decision is made to use this material, then before proceeding with the manufacture of a drywall partition with your own hands, the step-by-step installation instructions for which will necessarily be described in this article, it is recommended first of all to purchase the necessary materials and tools.

Soundproofing materials for partitions

Solid sound insulators such as drywall, metals, bricks resist sounds, while porous ones absorb them. Absorbers are divided into three groups:

| Hardness | Absorption coefficient | Base / base | Properties |

| Solid | 0,5 | Minvata in granules, pumice, vermiculite, perlite | Resistance to chemicals, ignition, good frost resistance, low thermal conductivity |

| Medium hard | 0,5-0,75 | Fiberglass, mineral wool, polyurethane foam | Excellent thermal insulation and adhesion, light weight, environmental friendliness, wear resistance |

| Soft | 0,75-0,95 | Fiberglass, felt, mineral wool | Light weight, excellent vapor permeability, fire resistance, non-hygroscopicity, extensibility |

These are all inorganic insulators. For interior decoration, materials with a sound absorption coefficient of at least 0.4 are used. It is indicated on the label in the accompanying documents.

In some cases, an organic look is used, such as fiberboards. They are used in the construction of temporary structures. It is forbidden to use fiberboard for residential areas, since it is highly flammable. Of solid materials that reflect and damp the background noise, aerated concrete, ceramic block partitions can be noted due to their high porosity.

Leave an air gap during laying to achieve perfect silence. Soundproofing the walls with plasterboard will also help. For soundproofing brick surfaces, frame plasterboard screens, you need a special self-adhesive tape. She trimmed the metal profile, then mounted. Joints, seams, small cracks will certainly be rubbed with putty. Fans of absolute silence prefer soundproofing sealant.