Four ways to calculate flow

Mathematical

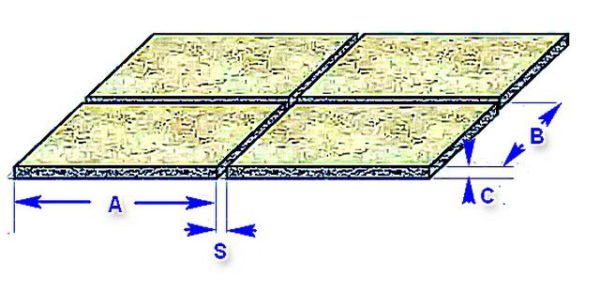

You need to know the dimensions of the tiles - length (A), width (B), thickness (C) - and joint width (S). These data are substituted into the formula, where 1.6 is the average density coefficient of the fugue.

Flow = (A + B) xCxSx1.6 / (AxB)

By simple calculations, the required amount of material in kilograms per square meter is obtained. It is better to add 5-10% to the obtained value.

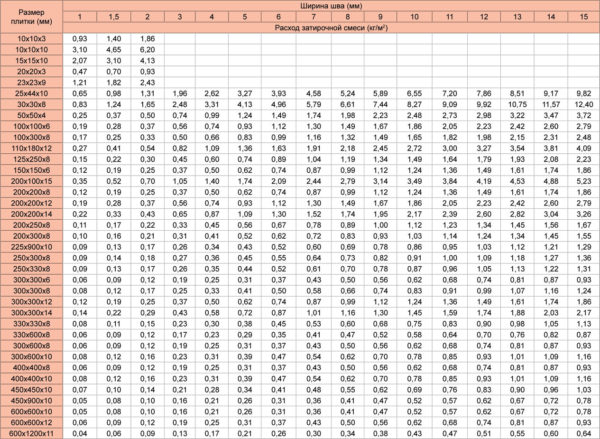

There is no need to remember mathematics, for the standard tile parameters everything has already been calculated and entered into the table.

Experimental

This method is the most accurate. The joints of adjoining tiles are filled around the entire perimeter with a small, precisely known amount of grout (100 g, for example). When all the material is consumed, the treated area is determined. The general square is divided by the result obtained, then multiplied by the weight of the material consumed (0.1 kg in our case). The final figures will show the real volume of the planned consumption, because do not follow from the average, but from the actual filling of the joints.

Calculator

The easiest way is to use our calculator:

* Density of grout:

- Ceresit CE33, CE40, CE43 - 1.75

- KERAKOLL Fugalite Eco - 1.55

- KESTO Kiilto - 1.6

- LITOKOL Litochrom - 1.9

- LITOKOL Litochrom Luxury - 1.9

- LITOKOL Starlike - 1.55

- MAPEI Ultracolor Plus - 1.6

- MAPEI Kerapoxy Design - 1.6

Cement or epoxy grout - comparison of properties

Which grout to choose - cement or epoxy, everyone decides for himself, taking into account the material with which to work, and the operating conditions.

| Cement mix | Epoxy mix |

| This is a classic composition based on finely ground cement, pigments, additives and plasticizers, which is brought into working condition by adding water to the dry mixture. Sometimes water-based latex is used. | Due to the content of additives, quartz sand and hardener in the epoxy resin composition, the strength of such a mixture is higher. In the process of preparing a dense, elastic working solution, epoxy resin is mixed with a hardener. |

| The solution is easy to work with, and even without skill, you can get an excellent result at the exit. | To work with such a composition, certain skills are required, since the finished solution turns out to be more viscous, and it is more difficult and longer to work with it. |

| To work with wide seams, sand is introduced into the traditional composition, and the wider the seam, the larger the sand granules should be. | Epoxy grout is best used where grout will not cope with its tasks in difficult operating conditions - in a pool, laboratory, on a kitchen apron and worktop, which are exposed to grease, moisture and dirt. |

| The material is sold in the form of a dry mixture or a ready-to-use solution. The latter cannot be stored after opening the package and must be used immediately. | Such grout is not afraid of exposure to chemicals, fungus or mold, it is durable and has a high decorative effect due to the addition of glitter. The brightness of the color remains for more than a dozen years. |

| It is removed from the tile surface with a foam rubber damp trowel. | |

| It is profitable to purchase powder cement grout for large volumes of work. | It is necessary to remove excess from the surface of the tile within 24 hours, later this will not work. Use a special remover to remove the frozen mixture, which can be purchased at a hardware store. |

| The cost of the material is low, it is easy to choose a shade for any tile color, since the assortment is quite wide. | |

| When exposed to household chemicals and dirt, this grout is destroyed over time. | Among the shortcomings, the high cost of the material and the complexity of working with it are noted. |

Cement trowel mixture is produced in dry form and packed in bags

Cement trowel mixture is produced in dry form and packed in bags

Instructions for use

Each package of Litokol epoxy tile grout comes with detailed instructions, which are recommended to be read before using the material.Here are the main provisions of the instructions, as well as advice from experienced craftsmen who will help you master high-quality sealing of tile joints with epoxy-based grouting.

How to dilute?

To obtain a working mixture, it is necessary to mix the bulk with a liquid hardener. The main thing to know before starting mixing: the mixture should be consumed in 40 minutes. After this period, the epoxy grout hardens and becomes unusable.

In 40 minutes, it is necessary not only to seal the joints, but also to rinse the treated surface with water. Therefore, you need to mix the components of the mixture in small portions. For beginners for the first time, it is enough to dilute 200-250 g of the mixture.

To prepare the grout you will need:

- scales;

- clean plastic container;

- mixing spatula;

- latex gloves.

Dilute the mixture in a proportion of 8 g of liquid hardener for every 100 g of epoxy mass; this proportion should be clarified in the instructions for grouting.

Let's describe this process step by step:

- A corner of the hardener bag is cut off to make a small hole. This will allow the opened packaging to be stored for a long time.

- Place the container on a scale and pour the calculated amount of hardener into it, for example, 20 g.

- Using a spatula, add the calculated amount of epoxy mixture to the same container, for our example - 250 g.

- Remove the container from the balance and mix the contents thoroughly with a spatula until the liquid fraction completely disappears and the mixture becomes homogeneous.

It is not recommended to use mixers with a high speed for stirring, because if the mixture is turned too fast, the mixture heats up and the setting time is shortened.

How to apply?

Before preparing the grout, the surface for its application must be completely prepared. The optimum air temperature for work is + 18-23 ° C, at temperatures below + 12 ° C it is not recommended to use epoxy grout.

It is convenient to rub the seams with a special rubber float. The grout is applied on a trowel with a spatula, then the material is spread over the tile surface with diagonal movements, rubbing into the seams. With the edge of the float, clean the mixture from the tile and rub it into the seams again.

To grout the corners, use a spatula and a special corner with a 45 ° bevel. After using the entire diluted mixture, the treated area is cleaned with a clean rubber float and poured abundantly with cold water, after which it is wiped with a cellulose sponge, rinsing it thoroughly. This helps to create an even and smooth seam surface.

After grouting, a film appears on the surface of the tile from the epoxy mixture, which must be removed the next day, otherwise there will be indelible yellow stains. This is done using a special tool Litonet, which is applied every other day in accordance with the instructions and left for half an hour. After that, the surface is washed with water using a stiff brush or white felt and wiped dry with a cotton cloth.

Only on the fifth day after cleaning, you can start using the treated surface. Prior to that, it must not be covered, splashed with water and other liquids, walk on it, put objects, expose to temperature extremes. Therefore, it is advisable to install floor tiles last.

Scope of epoxy grout

Due to its performance and different component composition, the areas of use of epoxy grout are significantly expanding:

for tiles. Similar compositions are used to fill the seams of ordinary tiles located on work surfaces in different environments, and the intensity of exposure to aggressive environments - bathroom, kitchen (catering facilities), hallway, swimming pools (even with sea water), baths, saunas, public spaces with high requirements to sanitization (hospitals), any industrial premises with an increased level of pollution;

Epoxy grout Litokol Starlike is widely used, including for tiles in saunas and baths

Epoxy grout Litokol Starlike is widely used, including for tiles in saunas and baths

for clinker. There are entire lines of epoxy-based joint compounds designed specifically to complete the masonry of clinker tiles. Such solutions represent specialized fugues with a special component composition that reliably fills the joints between clinker tiles;

Jointer for clinker tile joints

Jointer for clinker tile joints

for a stone. Both natural and artificial stone can be laid with large jointing. But the unrealistic plasticity of the epoxy fugue makes it possible to fill any gaps between the stone elements. And a special composition reliably holds the "capricious" rough sides together, creating an absolutely sealed surface;

Natural stone in the shower - what could be better?

Natural stone in the shower - what could be better?

for marble and granite. Such material, despite its high cost, enjoys unprecedented popularity. Outdoor and indoor stairs, countertops, aprons, floors, sinks are made of it. Marble and granite are incredibly durable materials, and the grout for these slabs must match. The special composition of the fugue for such a stone allows you to make the seams not only beautiful and neat, but also durable;

Marble in the interior - cold luxury "forever"

Marble in the interior - cold luxury "forever"

epoxy grout for mosaic. Working with mosaic tiles is not easy even for professionals. Laying out the mosaic is the work of a jeweler, and its grouting is just aerobatics, since it is on such a surface made of small-piece products that the first thing that catches your eye is the accuracy of the seams.

This is especially important when whole compositions of such tiles are laid out. Epoxy fugue allows you to accurately fill any inter-seam space and give the entire surface a finish;

Mosaic drawing - a little miracle in your room

Mosaic drawing - a little miracle in your room

for drywall. The seams between the drywall sheets take on all the loads and, often not withstanding them, are deformed. Specially for this purpose, special compositions based on gypsum have been developed, which have increased elasticity and strength.

Sealing plasterboard joints

Sealing plasterboard joints

Related article:

Features of epoxy grout for tiles Litokol and Ceresit

Special attention should be paid to professional epoxy fugues from Litokol and Ceresit. Both of these brands are incredibly popular with consumers.

Despite the fact that their assortment is about the same, Litokol grout stands out for its large tint variety (there is even a backlit joint compound) and versatility (from home tiles to tiles working in aggressive environments).

Litokol grout, glowing in the dark

Litokol grout, glowing in the dark

Many also note such a negative side of the Ceresit fugue, such as discoloration (darkening) after drying (which was not noticed with Litokol). Also, a big disadvantage of this composition is the paper packaging of the product of almost the entire line, which is capable of passing moisture if stored incorrectly, which only harms the quality of the fugue.

If we consider both fugues, from the point of view of ease of use, then Ceresit has a more pliable structure, it is more pleasant and easier to work with the bark. This is probably why, for self-filling of the seams, it is first of all advised to acquire a fugue from Ceresit.

Ceresit compound for joints of any thickness

Ceresit compound for joints of any thickness

The more you learn about epoxy grout, the more often you ask yourself - how did you do without it before? How did the finishers get out, and how did consumers live without such beauty?

Mosaic grout which one to choose

To give the interior design individuality and, often, practicality, a modern type of decoration - mosaic is widely used. The latest technology has made it possible to create mosaic chips and make this type of finish available to everyone. The final appearance of the mosaic takes on after grouting, and many are faced with a problem: which one is better to choose.

Types of grout for mosaic

- Cement. They can be produced in dry mixes or ready-made formulations.If the joint is more than 3 mm, then the use of grout with the addition of sand is not recommended. Cement grouts are easy to use and inexpensive. The disadvantage is their relatively short lifespan.

- Epoxy.

They are produced in the form of two components - epoxy resin and hardener. They are more expensive than cement ones and require careful adherence to the instructions for use. At the same time, they have a number of undoubted advantages: durability, resistance to aggressive environments, a wide range of colors. Sometimes it is transparent, which gives an additional plus when working.

- Furan. They are produced on the basis of furan resins and are difficult to use: before processing, the surface is covered with wax, and the remains of grout are removed with steam. Grout color does not vary - almost always black. Recommended for industrial use due to its increased resistance to aggressive environments.

How to choose a mosaic grout color

When choosing the color of the grout, you should have a sample of the mosaic in front of your eyes, so as not to be mistaken with the tone. Manufacturers offer a wide range of colors. To obtain the desired result, you can use a mixture of neutral or contrasting colors.

- To create the effect of integrity in a monochromatic material, choose a grout to match the mosaic;

- A dark color will create contrast in the composition or highlight a separate area of it;

- For multi-colored coating materials, the tint of the grout should correspond to the lightest or darkest color;

- Contrast grout is used on very flat areas, it can emphasize all the disadvantages of styling;

- If it is necessary to grout on a contrasting pattern, then the color is selected neutral or transparent ("chameleon" effect).

- To get a complete picture of the final result, it is recommended to apply a small amount of grout to the material and allow to dry.

Be very responsible when choosing a white mosaic grout. It is worth making an experimental smear here, otherwise the white grout can shade the mosaic, and it will look dull or the color of baked milk.

When making the final choice, it is better to give preference to brands where constant quality control is carried out and the assortment is constantly improving through the introduction of innovative technologies.

STARLIKE CRYSTAL. The grout is made on the basis of epoxy resins, transparent, has a "chameleon" effect. It is characterized by increased chemical and mechanical resistance, light transmission, has a fine filler fraction, which makes it possible to use it for the narrowest joints. Possesses high adhesion and frost resistance, easy to apply and washable.

Ceresit CE 79 Ultra. Two-component epoxy grout with high resistance to aggressive environments. It can be used as an adhesive due to its high adhesion. It is used for work in any environment in industries, farms, laboratories. Contact with drinking water is allowed.

Litokol Litochrom Starlik. The epoxy mixture can be used as glue and grout for indoor and outdoor use. Has a long-lasting color (95 different shades) and is waterproof. The composition is highly resistant to aggressive environments, which makes it widely used in manufacturing workshops, swimming pools, spas.

Using grout

Branded tools from Litokol

- Combined cellulose sponge. It costs about 500-600 rubles. You can replace it with regular foam rubber, but it quickly deteriorates. The sponge forms seams better and faster, and it lasts about 20-30 squares of tiles.

- Skipper. This is a special bucket with rollers for squeezing. Convenient if you are constantly working with epoxy grout.

- Grater with replaceable cellulose attachment. Also used to clean up residues.

Mixing the mixture

The mixture is sold undiluted; to get started, you need to mix 2 components. Component A is an epoxy resin with added silica sand, colorant and plasticizer. Component B is a hardener.

After mixing the two components, there is no more than 60 minutes to use the mixture. Certain difficulties are associated with this. Initially, the components are packaged in certain proportions, and they must be observed. But it is unrealistic to use a full package alone in an hour, so you will need to manually divide the package into parts using an eye gauge or scales.

For example:

- Components A and B in Epoxystuk X90 are mixed at a ratio of 100 to 7.2 by weight.

- Starlike C.350 Crystal is 100 to 8 by weight.

- There are no proportions in the instructions for Litochrom Starlike on the official website, but the figure was experimentally set to 14 parts of filler to 1 part of hardener by weight (almost the same 100 to 7.2 comes out).

We mix 2 components

Mapei Kerapoxy

To begin with, I do not recommend kneading more than 200-300 grams of the mixture.

Filling and shaping the seam

Joint filling

- We fill the joints with grout in the usual way on a small grip, there is nothing special here.

- When working with epoxy grout, the formation and grinding of the joint must be done even with the wet mixture, since it hardens for a long time.

- Immediately we take a foam sponge, clean water and begin to wash out the seams using the traditional method. The grout must be applied to a dry surface, so we do not reach the very end with a sponge so that the border of the rubbed seams remains dry.

Blurring the seams

When the seam is almost ready, throw out the old sponge and take a new one, change the water and bring it to the end. In this case, the grout will remain liquid.

We knead a new portion of the mixture and repeat all operations.

Internal corners are best done in two passes: on the first day, one side of the corner is rubbed, on the second day, the other. Otherwise, when forming one side, the second will be violated, and you will need to devote a lot of time to this site.

Removal of plaque

The next day, remove the epoxy with Litonet. It is not cheap, but it is a concentrate, so it will last for a long time.

Apply the product to the surface

- We spray the surface with the product, wait for the time according to the instructions and clean it. There will be a lot of foam, it is most convenient to remove it with a self-wringing mop or a washing vacuum cleaner.

- With the help of a “hairy” dishcloth (or a special cellulose sponge), remove the remaining grains of sand and plaque.

- Glossy tiles are easy to clean, so the product can be diluted with water 1 to 4. For matte surfaces, it is better to work with a concentrated solution or thin it in small proportions (1 to 1).

- After cleaning, let the surface dry and check the gaps, where the plaque remains. If you paid little attention to rinsing with water, or you use clinker, clay tiles, terracotta - even 2-3 passes may be required. If embossed decors are used, it is better to glue them in advance in order to reduce your work.

Varieties of mixtures and release forms

The Litokol brand produces various grouting products. On sale it is easy to find Litokol tile grout, the main component of which is a cement mixture or epoxy. In addition to them, adhesives, self-leveling mixtures, latex additives, plaster mixtures and other products of this brand are presented. It is the products for grouting that can be recognized as the specialization of the brand. For a variety of tasks, a suitable option is selected from several types of trowels:

-

Mix Starlike C. 350 Crystal Litokol. Its area of application is for grouting the seams between glass elements, which are made from decorative smalt when creating a mosaic panel. Litokol Stirlike grout adapts to the color shade of the material;

-

Translucent grouting mixture Starlik Color Crystal Litokol. It is used to create a mosaic finish when it is necessary to obtain an accurate color of the finishing material. Well tolerates the effects of an aggressive environment. A beautiful effect is obtained on the surface, it "takes" the colors of the finishing material. The application of the composition must be done quickly, it dries up in an hour;

-

Antibacterial grout for ceramic tiles Starlike Defender High performance against mold and mildew, also resistant to acids. It is used to close the gap between the joints when laying ceramic tiles. It is permissible to apply in places where food products will be located;

-

Epoxystuk X90 grouting mixture. A high indicator of resistance to the influence of water, it is most often chosen for surface treatment in bathrooms, swimming pools, in kitchens. A wide variety of colors. Can be applied to wall and floor coverings;

-

Decorative grout Litochrom Starlik. It has a long service life, it can handle seams with a thickness of one to fifteen millimeters. Suitable for work outside and inside the building. Differs in good indicators of strength and density of filling of seams;

-

Epoxy grout Starlike Litokol C 310. Differs in impact resistance, water-repellent, tile coating does not stain, does not crack over time. Has anti-fungal properties. Easy to apply, prolongs the life of the tiles, long-lasting color;

-

Grout Litokol 1-6 C. 00 based on cement. It is used for sealing floor and wall tiles. Designed for seams from 1 to 6 millimeters. It must be diluted with water before use in order to obtain a creamy consistency that is easy to apply to the surface. Frost-resistant, high-strength, UV-resistant.

The best manufacturers of tile grout - which company to choose

If you want to be confident in the reliability and durability of the grout - give preference to well-known brands with a good reputation. They strictly adhere to the recipe and use quality ingredients for their mixtures.

So if your goal is to make a repair once and not think about it again for many years, do not spare money on products of worthy manufacturers:

- Ceresit;

- Litokol;

- Mapei;

- Sopro.

The assortment of grouting from these companies is quite wide, so it will not be difficult to choose a tile joint that is suitable in terms of characteristics and color. The best products can be found in this review, and our article will help determine the specific type of grout.

Recommendations:

Nuances of choice

It is worth considering whether all the advantages of the materials considered are important for operation in the bathroom. For example, the immunity to ultraviolet radiation, which is simply not in the bathroom.

Resistant to food stains and household dyes. On the one hand, few people drink wine and coffee in the bathroom, eat blueberries. However, hair dye leaves traces that are difficult to wash off. So stain protection comes in handy.

Antifungal properties are important: the bathrooms are humid, and tiled surfaces begin to get dirty and moldy from the seams.

Resistance to temperature extremes seems to matter - after a hot shower, the bathroom gets hotter. But here much wider fluctuations are meant - from -20 to +80, or even 100 ° C. This does not happen in apartments.

Abrasion resistance matters for floor joints, but the bathroom is not a place where a lot of people go around all the time. In addition, part of the surface is usually covered with a rug.

Water resistance is an important quality for a fugue in a bathroom, but resistance to acids and other aggressive substances is useless in our case. One final tip - use a darker grout for your floor tiles than for walls.

Light-colored grout on the floor gets dirty very quickly and does not look beautiful, you are tortured to clean

One final tip is to use a darker grout for the floor tiles than for the walls. Light-colored grout on the floor gets dirty very quickly and does not look beautiful, you are tortured to clean.

How to properly dilute the grout?

Next, we will consider the rules for preparing decorative mixtures of the four most popular brands in construction.

Ceresit

As an example, let's take Ceresit CE 33 grout, designed for finishing narrow joints of stone, ceramic and glass tiles.

Solution preparation rules:

- Prepare water at the rate of 330 mm per 1 kg of dry mixture. The permissible water temperature is from +5 to +30 ° C.

- Pour about ¾ of the required amount of water into a prepared container.

- Pour the dry mixture into the water according to the indicated proportions.

- Stir the mixture well until there are no lumps. For this purpose, you can use a spatula or drill. Work with a drill should be at 400-800 rpm.

- When the composition is mixed, you can add the remaining water so that the mixture acquires the consistency of thick sour cream. If the solution is already plastic, the rest of the water need not be added.

The finished grout should “ripen” - it will take about 5 minutes, after which you can start processing the tile joints.

Unis

Cement grout Yunis Color is suitable for filling joints with a width of 1 to 10 mm in rooms with moderate to high humidity, as well as in "underfloor heating" systems.

Instructions:

- Pour water at room temperature into a container at the rate of 0.25-0.35 liters per 1 kg of dry grout.

- Pour in the cement mixture. A trowel is suitable for stirring such a volume. If you need more mixture, it is better to use a drill mixer.

- Stir for a few minutes until a homogeneous, viscous mass without lumps is obtained.

- Stir again 3-5 minutes after settling the mixture and apply.

You can add dispersion colorants from the proposed palette to Eunice grout. The colorant is diluted in water at the rate of 1 to 10, and grout is prepared on the basis of this solution.

Litokol

Litokol Starlike is an epoxy grout suitable for interior and exterior use with porcelain stoneware, tiles, mosaics and natural stone. The color scheme of the product includes 97 shades, including a metallic palette.

The grout package contains a paste with epoxy components and a catalyst solution in a separate bag. According to the instructions, you just need to mix both components - the paste and the liquid catalyst - right in the packaging.

Prospectors

Grout Prospectors - a cement mixture with mineral fillers, polymer additives and pigments. For dilution, it is recommended to focus on the proportions of 0.26-0.3 liters of water per 1 kg of dry mixture.

Prepared according to the following scheme:

- Dry grout is added to a container with clean water in small portions, mixing thoroughly by hand or with a mixer.

- After 5 minutes, stir the solution again.

- It is necessary to use up the grout within an hour after preparation.