Application and consumption rates

Instructions for the use of sand concrete M300 should be indicated on the package. If for some reason it was not there, you can use the following recommendations:

- The solution is mixed with water at room temperature.

- The proportions of M300 sand concrete and water depend on the composition of the initial mixture, therefore it is strongly recommended not to deviate from the manufacturer's advice. Typically, 10 kg of mixture requires 1.7 liters of water.

- Do not pour water into the building mixture. The dry powder should be gradually poured into a container with water with constant stirring and diluted until the lumps are completely dissolved. To do this, use a special device or drill with a special attachment.

- You can control the proportions visually, guided by the density of the solution. You should get a rather viscous homogeneous mass with high plasticity.

- Before use, it is advisable to let the solution brew for five to ten minutes.

- The optimum temperature range for laying mortar is from +5 ° C to +25 ° C. However, the technology can be used at temperatures as low as -15 ° C.

- The properties of the mixture ensure good adhesion. To further increase this indicator, it is recommended to carry out preliminary cleaning and preparation of the base.

- The finished solution is viable for two to three hours. During this time, you need to have time to complete all the work provided.

- The solution hardens in a day. The structure gains maximum strength after 28 days.

The composition and proportions of sand concrete M300 have a negligible effect on the required amount of water and the volume of solution output. Usually, one and a half to two tons of dry mix is required to fill one cubic meter. The calculation of the consumption for the screed can be carried out in the same way, if you decide on the required thickness. For a standard screed with a thickness of 1 cm, 20 kg of the mixture will be required.

Sand concrete is a modern building material, lightweight and easy to use. The quality of the mixture is highly dependent on the production conditions. You should not trust unverified suppliers, especially if the packaging does not indicate all the characteristics of the product and instructions for its use. The use of a ready-made construction mixture allows you to save time when searching for the right sand in the sale and mixing it with cement.

Formulation types and requirements

Despite the fact that any composition of CPB contains cement and sand, the final characteristics of the mortar can be very different. The main parameter is strength, which depends on the ratio of components. The level of strength and resistance of the cement-sand mixture to various influences depends on the scope of the mortar. Therefore, for different jobs, the DSP mixture is prepared according to a specific recipe.

Types

The proportion of cement and sand affects the characteristics of the mixture. As a rule, one brand of cement is used in common mortars. But the brand of cement is not equal to the brand of the solution. So, from it is possible to make a cement-sand mortar M150 or M300, taking a binder in a certain volume. On the other hand, for the desired grade of cement, they take grades an order of magnitude higher. Binder is supplied in bags of 25 kg or 50 kg.

The main brands of cement-sand mixtures:

- М100 - high strength, made of cement М200-М500, with a certain amount of sand.

- M200 is the most common type of mixture, relevant for creating a coating and paths in everyday life, withstands small loads, dries quickly and is not demanding on conditions.

- M300 - floor slabs are made from mortar, foundations of good strength.

- М400 - strong concrete, prepared on the basis of cement М400 / М500, is used for multi-storey construction, reinforced concrete floor slabs, etc.

- M500 is the most durable concrete used in private housing construction (there are also brands M600, M700, but they are prepared for special objects). Withstands high loads, retains its original properties for many years, is not afraid of external negative factors.

In addition to the above, there are also intermediate grades - it can be a cement-sand mixture M 150, M250, M350, etc. But their characteristics do not differ significantly from those of concretes of the main brands.

Additives

Before diluting the cement with sand (choose the correct proportions, measure everything), you should think about the possibility of using additives that change the properties of the mixture. Additives are introduced into the composition to adapt the mixture to the desired conditions, increase / decrease certain indicators. So, using additives, you can even get liquid glass used for plaster.

Dry cement mixtures, as a rule, do not need to be refined, but they are also more expensive. But if it was decided to implement the preparation of DSP independently, then the list of possible additives and their properties will come in handy.

What can be added to the sand-cement mixture:

- PVA - makes the solution more plastic and increases adhesion to other materials. Before starting work, you need to correctly select the proportions for the cement mortar.

- Lime - only slaked lime is used. The additive slightly increases strength and vapor permeability, but requires strict adherence to the ratios. Most often, lime is added to plaster solutions.

- Graphite and soot - they do not affect the physical properties of DSP, but they are relevant in the form of dyes.

- Detergents - improve the plasticity of the solution, are introduced into the mixture after water in an exact proportion.

You should think about additives before mixing the mixture, since not all substances can be added after adding to the water composition - some only at the stage of mixing the dry components.

Calculation for materials

Sand concrete M300 is mixed with cold water at temperatures up to +20 degrees without any impurities in the composition. Water consumption is determined by proportion: for 10 kilograms of dry mixture, 1.7 liters of water are needed. Mix the solution with an electric drill with a special nozzle.

If you plan to cook large volumes, use a concrete mixer. To improve the quality of mixing, first, two-thirds of the volume of water required for the composition is poured into the drum, then added as the concrete mixer operates. The solution should turn out to be viscous, homogeneous, plastic. Before starting work with it, it is advisable to withstand the concrete for 10 minutes.

Then you can work with the solution: pour out the concrete and level it with a rule or a spatula, then remove air bubbles with a vibrator or bayonet.

For plaster

To prepare the mixture, the ratio is 1: 3. You will need about 17 kilograms of cement per square meter with an average thickness of the plaster layer.

For masonry

Here, special attention is paid to sand - it must be clean, without impurities, inclusions. Only in this case it will be possible to knead a homogeneous mass that can reliably fasten the masonry material

The proportions used are different: both 1: 3 and 1: 6. The flow rate per square centimeter is 0.05 m3.

For screed

For floor screed, a solution of the M150 / M200 brand is usually used. Take in a ratio of 1: 3 or 1: 2 (depending on the brand of cement used). Fiber is often added to the solution in volumes of 800 grams per cubic meter. Consumption is equal to 20-21 kilograms per square centimeter.

The cement-sand mixture is one of the most demanded repair and construction materials. But the wide range of products makes it difficult to choose the optimal composition.

Therefore, calculations must be performed carefully and accurately, observing the technology and taking into account the scope of application of concrete

Technical characteristics of sand concrete M300

Before proceeding to the consideration of the section - sand concrete instructions for use, let's find out what features and technical characteristics the dry mixture in question has.

The first parameter that we will consider will be the brand compressive strength. It is immediately worth noting here that after 30-40 days after hardening, M300 sand concrete is able not to deform under a pressure of 29 MPa (if it is really a high-quality material). Due to the fact that fine sand, dust and a precisely calculated dosage are in the building suspension, it is impossible to create a similar material with the same technical characteristics at home.

The filling fraction can be different, it depends on the purpose, that is, the purpose of using the M300 mixture. If it is necessary to use sand concrete for casting slabs and structures from reinforced concrete, then gravel is better suited as filling fractions, but if it is necessary to use such material for the production of concrete products, then screening is an excellent option.

One of the main advantages of the material in question is almost zero permeability to water. After the cured material reaches its highest level of strength, the moisture in it will be no more than 0.9%. If you purchase high-quality sand concrete M300 with correctly selected additives, then the indicator in question will become even lower.

Frost resistance. In this case, we can immediately say that this indicator is quite high, and in practice this has been proven more than once.

The color of sand concrete is gray (depending on the amount and type of additives, it may be slightly lighter or darker). Material consumption is 2 kg per meter, layer thickness ranges from 15 to 50 mm.

Peculiarities

Sand concrete is often referred to as an intermediate element between cement and concrete mixture. Dry material is often used for restoration work, repair and construction. It is lightweight and easy to use, does not shrink, and has proven itself well on unstable soils. M200 sand concrete is irreplaceable in the arrangement of concrete floors where serious loads are noted - garages, warehouses, shopping centers.

The mixture contains crushed stone and chemical additives, which guarantees the absence of material shrinkage even with a fairly thick layer. Strength can be increased due to plasticizers, as well as to provide sufficiently high frost resistance.

When adding various additives (especially in order to make the mixture workable), it is necessary to correctly determine the optimal volume in order to provide the desired consistency without compromising the strength characteristics.

Pigments give the desired color to sand concrete - a fairly wide variety is also presented here. The main thing is to choose the right additive and follow the instructions.

Preparation of sand concrete for work

Sand concrete dry mix, presented on the construction market, is an almost ready-to-use material. Add clean water to the dry mixture in the recommended proportion and stir with a drill with a nozzle until a homogeneous consistency.

The low cost and ease of working with sand concrete of this brand is a convenient option for use on private construction sites.

To prepare a ready-made solution, it is required to carefully calculate the correct proportions of the required amount of dry bagged mixture. For example, a package of 50 kg m150 sand concrete will require about 6 liters of clean water.

To obtain the declared strength of the solution, it is necessary to strictly adhere to the permissible proportions of water + dry mixture. The proportion of water for mixing the ideal solution is indicated in the instructions attached to each bag. It is not recommended to dilute the ready-made solution with water during operation.

Basically, 10 kg of dry mix requires 1.6-1.8 liters of clean water. It is allowed to change the proportional amount of incoming ingredients, depending on the required mechanical parameters of the solution.

2> Concrete preparation

For large volumes of work, it is better to order concrete from the factory.Making a large amount of mortar by hand or even using concrete mixers is a difficult task, and laying in portions requires additional efforts to ensure that the layers adhere well. However, you can also make concrete by hand. In this case, there are two sequences of actions:

- First, concrete and sand are mixed dry. It is mixed until the color is uniform. Then crushed stone is poured, everything is mixed again, and water is added last.

- First, water is poured, cement is poured into it. When everything is mixed, add sand and then coarse aggregate.

The order of adding components for concrete during mixing can be different

In the first option, there is a possibility that with manual mixing, an unmixed composition will remain at the bottom, near the walls of the container, which will lead to a decrease in the strength of the concrete. The way out is to mix everything well and thoroughly. But you cannot spend too much time on this: the solution will begin to set.

The second option has its disadvantages: it sometimes takes a lot of time to obtain a homogeneous cement milk (a mixture of water and cement). As a result, it is simply not enough for the formation of bonds with the backfill: the cement "seizes" and the strength of the concrete also decreases.

All this is not so critical when using concrete mixers, but also imperfect. There is another complication here. Concrete is usually delivered to the construction site in trolleys. The whole volume does not fit in one, and the remainder is left to spin in a concrete mixer. This is better than leaving it just standing, but if you stir it for too long, the mortar may begin to exfoliate, the result is that the strength of the concrete will be lower. Exit - two carts and two people who will take them. The filling method - the first or the second - choose yourself.

For small volumes, concrete can be mixed by hand

So after all, how to prepare concrete. The choice is yours. If the volumes are small, you can knead by hand. Just do it carefully. For pouring the foundation, it is better to order a mixer after all, but you can also handle it with a concrete mixer (or two, depending on the volume). And to solve problems with the heterogeneity of the mix (although it is better that it be good), process the concrete to be placed with a vibrator. Most of the problems will go away.

Next, we will talk about the requirements for concrete components, their sizes and qualities.

Tips & Tricks

In the process of mixing dry mix M300, it is important to strictly follow the instructions from the manufacturer indicated on the package. A 40 kg bag usually requires a maximum of 7 liters of water

It is advisable to seal only with cold water, mix thoroughly with a mixer or a drill with a special nozzle.

A suitable temperature for work is in the range from +5 to +50 degrees, but if concrete is used at a lower temperature, it does not change its properties, but hardens longer and gains strength.

It is advisable not to mix the composition by hand, as this can cause the mixture to be inhomogeneous, lumps and air pockets appear. After the solution is mixed, you need to let it rest for 5-10 minutes, then stir again and use in work.

Several recommendations for working with dry mix M300:

- It is better not to cook a large volume of the mixture at a time, counting in such a way that the mixed mixture is used within an hour and a half.

- All working containers, tools must be prepared in advance - they must be dry and clean (necessarily degreased).

- All highly absorbent and porous surfaces are pre-primed, collapsing structures are pre-reinforced.

- Leveling and installation of fill beacons are required. When pouring the floor screed, it is enough to simply pour concrete over the surface, and then gently level it with the rule.

- During the first 3 days after pouring, it is necessary to prevent excessive evaporation of moisture by covering the poured concrete with a tarpaulin or film.

- To level a surface with minor defects, a layer of 10 millimeters is enough, if you need to make a strong layer between the base and the finishing floor, it is allowed to fill in a layer of up to 100 millimeters.

Dry mix M300 is a versatile building material that is suitable for a wide variety of tasks and, subject to the preparation instructions and application technology, provides high strength, durability, reliability and durability.

Number of PCS bags for brickwork and calculations on the calculator

Brick walls should be laid using a mixture with a grade corresponding to the brick. Such a structure is obtained as strong and uniform as possible. In general, M100-M200 is used for masonry.

So it is necessary to take into account the quality and strength of the material (both mixture and brick). Using the basic standards, approximately 250 kg of M100 mixture should go per 1 m3 of the wall.

If you prepare the solution yourself, you should keep a ratio of 1 to 4. Liquid should be added to the DSP, which is usually half the total weight of the mixture.

Of course, the laying of the wall strongly depends on the thickness of the joints, as the space between the bricks expands, the amount of mortar per 1 m3 also increases. The thickness of the walls also plays an important role, as for facing bricks laid in 1 layer, much less cement is required than for bearing walls of 2-4 bricks.

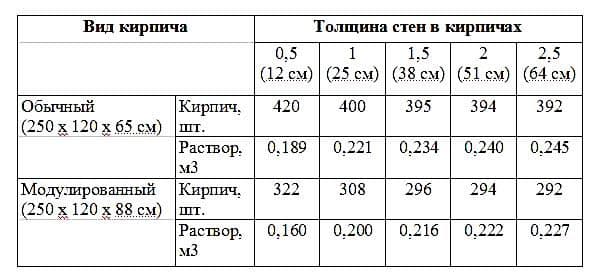

Calculation for masonry

Normative documents contain detailed recommendations and the dependence of the wall thickness and the amount of mortar used.

Examples are presented on the basis of conventional bricks and the required quantity per 1 m3:

- wall 12cm - 420 bricks and 0.19 m3 of mortar;

- wall 25cm - 400 bricks and 0.22 m3 of mortar;

- wall 38cm - 395 bricks and 0.234 m3 of mortar;

- wall 51cm - 394 bricks and 0.24 m3 of mortar;

- wall 64cm - 392 bricks and 0.245 m3 mortar.

A mixture of cement and sand - characteristics and preparation of the solution

As a result of mixing cement and sand, a sand-cement mixture is obtained, which, when water is added, becomes suitable for use. On a large scale of construction, self-preparation of the mixture is often used, although there is also a specially prepared CPF at the enterprise.

Cement sand mixture

If you purchase a factory-made DSP, then in its composition, in addition to the basic components, there are plasticizers and other additives. They are used to give the solution homogeneity, plasticity, some add frost-resistant additives to work in the cold season.

Factory mix

Preparation of cement - sand mortar

The preparation of the cement slurry is highly dependent on the brand of cement and the required mortar. The required ratio of ingredients is calculated from this.

The number of components also strongly depends on the purpose of the mixture, since some types of work involve less sand (concreting) or, on the contrary, more (masonry).

For a more flexible preparation of the solution, sand and cement should be manually mixed, the ratio is usually 1 to 3, but it can be 1 to 2-4. Mixes are also different, a huge assortment covers most of the ordinary needs.

But it is not always possible to achieve an accurate value due to the lack of information on the density of the material, because it may differ.

The purpose of the cement plays an important role in the choice of the brand:

- m100 is used only for plastering walls, approximate consumption 550-570 kg / m3;

- m150 is usually used for bricklaying, cinder block or installation, in rare cases, for concreting, the consumption is 570-590 kg / m3;

- m200 masonry and assembly mixture must be prepared 590-620 kg / m3;

- m300 is used for concreting and pouring sites with increased load, consumption 620-660 kg / m3;

- m400 for extra strong concrete structures, consumption ranges from 660-710 kg / m3.

When calculating the required materials per 1 m3, it is possible to accurately determine the brand and number of PCBs.They are also interchangeable, if the use of M150 is recommended, cement can be substituted for M200 and M100 without much compromising the design and strength of the structure.

The main method for calculating the required amount of sand concrete mortar

Professional and private builders know how to calculate how much sand concrete is needed for 1 cubic meter of concrete. After all, such a building material is one of the most important components at various stages of repair. The cost of building materials depends on the quality of the raw materials. The component part of the sand concrete mixture includes the following components:

- a special chemical substance with high strength and astringent properties - Portland cement of the first grade;

- sand with a fraction size of no more than 3 millimeters;

- plasticizers, which have properties to increase moisture resistance and strength of building materials;

- in order to improve the properties, granite powder is added to the solution.

How many bags of sand concrete are in 1m3? The mixtures are sold in prepackaged packages weighing 25, 40 and 50 kg. Such building material is included in the type of heavy concrete, for this reason, the mass of one m3 is approximately 2.4 tons. With the help of special calculations, when the consumption of sand concrete is 20 kg per 1 square meter, with a layer thickness of 1 cm, then the amount is calculated using the following formula:

- the volume of a forty-kilogram bag is divided by 20 kg, it comes out 2 cm.In order to process 100 cm / 2 cm of area, 50 bags are needed;

- if the volume is 50 kg, then 40 packages will be needed to process an area of 1 m.

Before determining the required amount of sand concrete per 1m3 of mortar, it is recommended to take into account the condition of the surface layer, the required proportions of the mixture and the thickness of the coating.

It is recommended to determine this by the following parameters: 1 m3 of sand concrete has a weight of 2400 kg, which must be divided by a package weight of 40 kg. The total comes out:

- 0.010 cubes in a bag of sand concrete 25 kg;

- 0.017 cubes in a bag of 40 kg sand concrete;

- 0.021 m3 in a package of 50 kg.

Advantages of the M300 brand

Sand concrete M300 has earned its popularity due to its high versatility. It is very convenient when one material is suitable for different purposes. The main features of this brand are as follows:

- fairly high strength;

- sufficient density;

- the possibility of using for external and internal work;

- high resistance to mechanical wear and shock loads;

- ease of use;

- long service life of products;

- fast hardening of the solution;

- resistance to sudden changes in weather conditions;

- corrosion resistance;

- acceptable price.

At home, the simplest version of M300 sand concrete can be obtained by mixing one bucket of sand and 3.5 kg of M500 Portland cement. To obtain a ready-made solution, this amount of the mixture will require 2.3 liters of water. It is advisable to use river sand. If it is not there, you can take a quarry one, but pre-washed from inclusions of soil and clay.

How to make a solution

So, we have found out how much is needed to fill the foundation or screed of such material as sand concrete M300. Its consumption is quite large, but in general, the use of this material in private housing construction seems appropriate. Of course, when using this material, the kneading should be done correctly. It is best to perform this operation in the following sequence:

- Warm water is poured into a container of the required volume (from +15 to +25 g.). Consumption, depending on the purpose of the solution, should be 0.18-0.23 liters per kilogram of sand concrete.

- Further, the dry mixture itself is poured into the water itself.

- The resulting mass is thoroughly mixed until all, even the smallest, lumps disappear. The finished mixture must be absolutely homogeneous.

The solution should be used within 2 hours. It is allowed to work with sand concrete M300 at temperatures from +5 to +35 degrees. Water cannot be added to a ready-made solution. During the pouring process, it is recommended to periodically pierce the mixture with a stake, rod or shovel to remove air bubbles.Drying time of the finished mixture is a day. It will be possible to walk on the screed in a week. The formwork is removed from the foundation on the second day. Sand concrete gains its final strength after 28 days, that is, like ordinary concrete. Reinforcement with a screed thickness of more than 2 cm is required. Of course, the frame will need to be installed when pouring the foundation. Crushed stone is not added to the mixture when used. Its role is played by large sand particles (3-7 mm). Waterproofing is done as usual.

From all of the above, a simple conclusion can be drawn. Sand-concrete foundations and screeds are more expensive than cement-sand ones. Therefore, it is advisable to use this material when cracking resistance of the finished structure is required or its final price does not play a very important role. Sand concrete, for example, is an excellent option when erecting walls from not too strong aerated concrete and foam concrete blocks.

Structural repair of surfaces

EMACO used for structural repair has high adhesion and is free from shrinkage. In addition, the mortar works in close contact with the restored structure.

Characteristics of EMACO structural compounds

EMACO S66 – S88 (bulk) and S88C (thixotropic) are made on the basis of Portland cement, quartz sand, modifying ligatures and polymer fiber. Reinforcement of the composition with fiber prevents the occurrence of shrinkage cracks, and Portland cement provides high-quality adhesion to the structure being repaired (see photo).

EMACO SFR

Compositions - SFR, S150CFR (bulk type) and S170CFR (thixotropic), are produced with flexible metal fibers and are used to repair stressed concrete structures with damaged reinforcement.

Thanks to nano technologies such brands as Nanocrete R3, R4, R4 Fluid appeared in the list of “Emaco” assortment. These are fast-hardening unique compounds that allow you to apply a repair coating of large thickness, moreover, on ceiling and vertical surfaces.

Selection of the required composition

Application of masonry sand concrete

Working with the M150 requires compliance with certain rules. But they are no different from the procedure for using other building mixtures of this type.

If it is a wall, then it must be completely freed from dust and dirt, plant residues, etc.

Wall cleaning

In the presence of old plaster, it is removed in those places where it does not hold firmly. Only then can a new solution be applied.

Removing old plaster

But for this you need to cook it. For plastering walls, the proportion is as follows: for 10 kg M150 2 liters of water. It is advisable to take clean and cold, but not very much, about 15 C. If necessary, you can add more liquid.

The solution is made like this. The mixture (dry) is gradually added to water and mixed. When the mass becomes homogeneous, let it stand for about 5 minutes. And then it must be quickly mixed again. The batch should be worked out in 2 hours.

Mix preparation

When applying plaster to the surface, it is necessary to cover all cracks and holes with it, if any. And only then level the entire surface. As a rule, the solution itself is applied with a spatula and leveled with a float.

Spatula application

If the work is carried out from the outside, then before that it is necessary to organize the surface reinforcement using a reinforcing mesh for this.

Reinforcement mesh application

М150 is considered a universal brand among similar cement-sand mixtures. She behaves well during various technological operations. This mixture, if necessary, can replace any other. Therefore, it is in demand in the construction market.