How to mix concrete with liquid glass

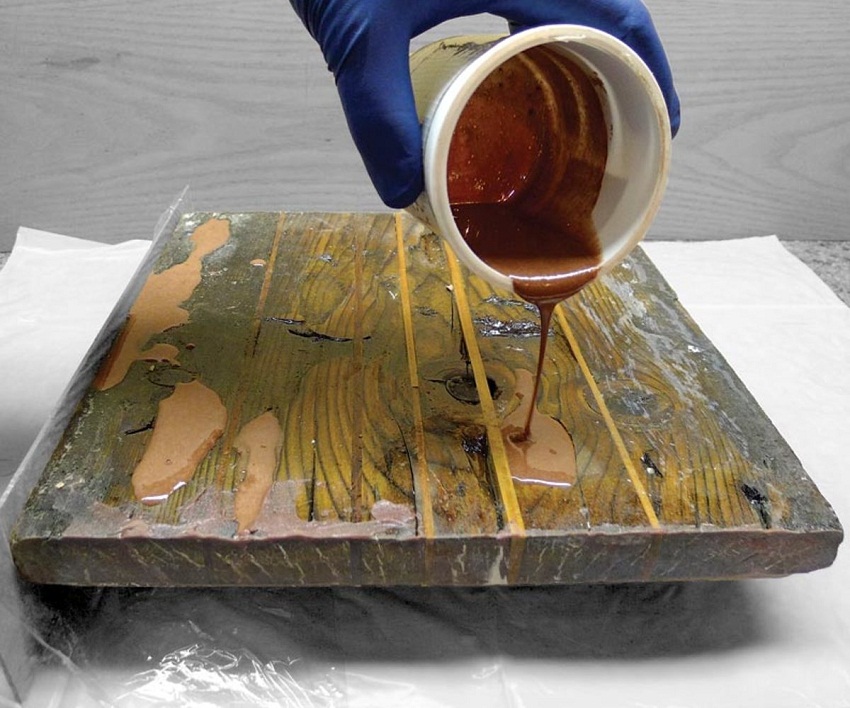

In addition to observing the proportions, in order to obtain high-quality silicate concrete, it is necessary to mix the mortar correctly. The following is the sequence of operations that ensures the plasticity and homogeneity of the working mixture:

- depending on the required amount of solution, choose a container of a suitable volume and fill it with clean cold water in accordance with the recipe;

- the required amount of liquid glass is added to the water and the mixture is intensively stirred. The silicate additive must be completely soluble in water;

- sifted sand and cement are mixed in a separate container. The resulting dry mixture should be homogeneous, and the ratio of ingredients should correspond to the selected recipe;

- a dry sand-cement filler is gradually poured into a liquid glass solution, with continuous stirring, after which the resulting mixture is thoroughly mixed until a homogeneous pasty mass is obtained. For effective mixing, you can use a construction mixer or an electric drill with a special attachment;

- if the consistency of the solution is thicker than required, you can add a small amount of cold water to it and mix thoroughly. If the mixture turns out to be liquid, pure cement is added to it.

Why add liquid glass to concrete

When mixing cement, sand and crushed stone, a fairly strong building material is obtained, however, in some situations, the physical and chemical properties of concrete are not enough. To improve the characteristics of the sand-cement mortar, plasticizing additives, liquid soap, glass, and other additives are added to it.

Liquid glass has the following effect on the solution:

Increases moisture resistance. Therefore, glass is added during the construction of structures in contact with moisture.

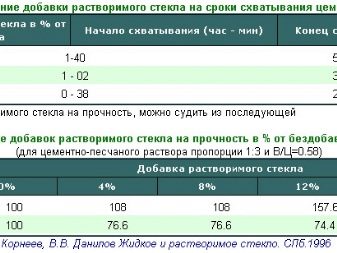

- Accelerates the hardening process. If you prepare a solution from Portland cement M 400, sand and gravel and add an additive to it, then the mixture will harden in a day (provided that the air temperature is at least +20 degrees).

- Gives waterproofing properties to the mortar. Concrete with such an additive is not susceptible to mold and mildew. This is because the liquid glass has antibacterial properties.

- Abrasion resistance is increased.

- The elasticity of the solution increases (some add liquid soap for this, but it is not so effective).

- Heat resistance increases. For comparison, ordinary concrete without any additives is able to withstand heating up to 200 degrees, after which it crumbles. If liquid glass (29-34%) is added to the mixture, then the monolithic structure will withstand up to 1400 degrees. Therefore, in the construction of stoves and fireplaces, just such an additive is most often used.

In addition, silicate glue has an affordable price. A package (15 kg) will cost about 280 rubles.

By and large, soluble glass replaces several expensive plasticizers at once: for waterproofing, plasticity, water resistance and rapid hardening. Neither liquid soap, nor slaked lime or other cheap analogs of plasticizing additives beloved by some builders can "boast" of such properties. Also, silicate glue can be used as a plaster, which is applied with a brush or spray to a cured concrete base.

Depending on the type of building, it is necessary to choose the right proportion of the mixture based on sodium silicate.

What is liquid glass used for?

The most widely used liquid glass is in construction, but it is often used in other areas of production.

Among them, the following areas of application can be distinguished:

- Anti-corrosion agent;

- To fill the voids;

- Priming surfaces to prevent the development of various bacteria and fungi on the surface;

- When producing oil;

- Surface coating to increase fire resistance, hygroscopicity, as well as the strength of materials;

- Metallurgical production;

- Whitening agent;

- Bonding agent in production, as well as during laying;

- Chemical additives to materials and fertilizers;

- Non-stick coatings;

- Stabilization of foam concrete;

- For the production of detergents.

This list cannot be considered final, because soda water glass is also used in the production of textiles, paper, soap, wood products, glass and ceramics. Most often it is used, of course, in construction, because it has unique properties.

If liquid glass is added to putties and paints, then they will be the best solution for painting those rooms in which many people are supposed to be.

Where else can liquid glass be used, the video will tell:

Use in construction

To prevent further cracking of concrete, as well as to improve its quality and properties, a special ironing procedure is performed. It is the use of powdered liquid glass to strengthen the cement screed, increase its strength.

If it is supposed to use liquid glass as an element for ironing, then you need to choose a wet method. The procedure initially consists in applying a cement mortar to the surface.

After that, it is necessary to carefully level the layer and compact it additionally with a trowel. When making a solution, it is imperative to add liquid glass in powder. The proportions in this case will be 1: 1.

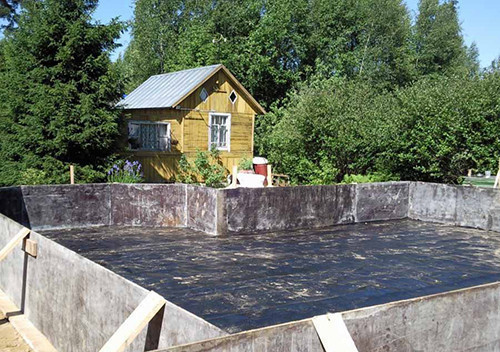

Waterproofing concrete and foundation

Carrying out work on waterproofing various containers and premises requires the observance of certain processes.

Most often, liquid glass is used to improve water repellency and processing:

Sodium silicate has some features, therefore, during waterproofing work related to concrete, as well as the construction of a foundation, judging by the reviews, it is recommended to additionally protect the material. This is due to the fact that, dissolving in water, liquid glass somewhat loses its basic properties and already protects the surface worse.

It should be noted that liquid glass sets very quickly with a cement mortar, therefore, initially only the volume of concrete that is needed must be harvested. If you prepare it "with a reserve", and then stir the setting solution, then it will completely lose all properties.

When building a foundation and its subsequent processing with material, with the addition of liquid glass, it is important to take this into account. Waterproofing with liquid glass:

Waterproofing with liquid glass:

Waterproofing other surfaces

Since this type of material has outstanding qualities, it is also used for protection from water on those surfaces where the use of concrete is undesirable. This method of processing is called coating.

The technology for processing various surfaces is as follows:

- The stage includes a complete cleaning of the surface, as well as the removal of the fat layer using special means;

- Next, you will need to apply first one, and as it dries, another layer;

- Dry the surface, apply roll or pasting waterproofing.

If it is necessary to increase the water-repellent properties, for example, of the materials of a well, then initially it is necessary to prepare the same solution as when ironing concrete. The mass must be plastic. And for better adhesion, you can first treat the surface with water.

What is liquid glass used for in construction

In the construction and repair of residential, warehouse and industrial buildings, liquid glass is most often used as a waterproofing agent.Below is a list of the most common jobs using this composition.

- Applying a waterproofing layer to concrete foundations. The material is diluted in a ratio of 1: 2 and mixed thoroughly. The finished composition is applied to the surface with a roller or brush. The processing technology provides for the application of two layers, the second layer being applied after the first is completely absorbed.

- Hydrophobization of basements and basements... The moisture resistance of the ceiling, walls and floor in a damp basement can be significantly increased by processing the inner surface with a solution of liquid glass prepared in a 1: 2 ratio. Before application, the treated surfaces should be dried using a heat gun or other available method. For greater efficiency, the composition is applied in 2 - 3 layers.

- Modification of concrete mortar. Adding 1 liter of water glass to 100 liters of mortar can significantly increase the moisture resistance of concrete. The composition is thoroughly mixed, which ensures complete mixing of silicate impurities and obtaining a homogeneous working mixture.

- Waterproofing of swimming pools and artificial reservoirs with a concrete bowl. Treatment of the inner surface of the pools with liquid glass allows you to fill the pores and microcracks with a silicate compound, which, after complete polymerization, ensures reliable waterproofing of the bowl. The treatment is carried out in two stages: first, a primer layer is applied, after which the main waterproofing layer is applied. For impregnation, a substance is used diluted with clean water in a 1: 2 ratio. When applying the main layer, the composition is not diluted. For waterproofing 1 m2 of surface, approximately 0.5 l of the substance is required.

- Binding of dust and fine particles. Liquid glass can be used for priming concrete screed. An aqueous solution of the composition penetrates into the concrete structure to a depth of 3 to 5 mm, after which it polymerizes. The hardened silicate composition not only significantly increases the hydrophobicity of the screed, but also binds dust and fine abrasive particles.

- Wood processing. To protect wooden surfaces from moisture, you can use the material diluted with water. Impregnation with a silicate composition will not only reliably protect the wood from the harmful effects of moisture, but also prevent the development of fungi and bacteria.

- Making grout for joints. To seal the joints between ceramic tiles, it is advisable to use a cement-based mixture with the addition of 1/4 of water glass. This grout is not afraid of moisture and has high bactericidal properties, and the addition of various pigments allows you to get the desired shade.

- Preparation of quick-drying adhesive mixtures. When water glass is added to a dry cement-sand mixture, a thick adhesive mass can be obtained, the speed of solidification of which is quite comparable to the speed of solidification of gypsum or alabaster.

- Use as an adhesive. Due to the high adhesion of silicate mixtures, they can be used for gluing pressed cardboard, plywood, chipboard, fiberboard, natural wood and other materials, in particular, porcelain.

-

- Linoleum and carpet flooring. Liquid glass can be used for laying various roll coatings on the subfloor. The main advantages of such mixtures are hydrophobicity and bactericidal properties. The use of silicate glass completely excludes the appearance of mold and other microorganisms under the flooring.

- Antiseptic treatment of trees. During grafting or pruning of branches, through the resulting cut, the tree can be infested with the larvae of harmful insects, and is vulnerable to other adverse effects. To prevent rotting and other undesirable processes, it is enough to treat the cut site with undiluted silicate compound.

- Sealing threaded connections. Undiluted water glass can be used as a sanitary sealant. To do this, you need to apply the composition to the threaded section and assemble the structure. After drying of such a sealant, the connection will have sufficient hydrophobicity, however, even a slight mechanical impact or rotation of the coupling can lead to a depressurization of the connection.

In addition to the above uses, liquid glass has become widespread in the creation of decorative interior items.

Application of liquid glass

Liquid glass has found application in various fields of human activity, therefore, it is impossible to quickly and compactly list all the points of its application. But there are some areas that definitely need to be mentioned:

- Liquid glass is used for waterproofing. Both the walls and the foundation are impregnated with this material - liquid glass turns such surfaces into impervious to moisture and air temperature changes. It is advisable to use this material when insulating the walls of the house from the inside.

- Liquid glass is an excellent antiseptic. On the walls and ceiling of living quarters, and indeed on different surfaces, you can often see fungus and mold - these are the consequences of exposure to moisture. To get rid of this unpleasant and harmful to human health phenomenon, you need to use various means to destroy fungal colonies. If you treat a surface already damaged by mold / fungus with liquid glass, they will simply disappear. For this purpose, liquid glass is used in the preparation of walls for wallpapering.

- Liquid glass has excellent adhesion. This means that it adheres perfectly to any surface. Using this material, you can glue completely different materials - from cardboard to porcelain.

- Liquid glass significantly increases the moisture resistance and fire safety of wood, paper and ceramics - they are specially coated with this agent.

If we consider liquid glass exclusively from the side of construction work, then many mixtures can be made with this material. The material has found application in the following processes:

- Primer with liquid glass. It is used for surface treatment before painting, wallpapering. Naturally, the option under consideration cannot be used in its pure form - it is simply mixed with cement in the following proportion: the same amount of liquid glass is taken for 10 kg of cement. First, you need to mix the cement with water, and then the resulting solution is poured into water glass.

- Mortar for waterproofing works. It is necessary to mix in equal proportions cement, sand and the material in question. The resulting mixture can be used for waterproofing works of any complexity.

- Refractory mortar. First, a cement-sand mixture is prepared - for 1 part of cement, 3 parts of sifted sand are taken. Then a little water glass is added to the resulting mixture (approximately 20% of the total volume of the dry mixture). Use a refractory solution with liquid glass for laying fireplaces and stoves.

- Protective agent against mold and mildew. It is necessary to dilute the material in question in water (proportions 1: 1). The resulting solution is used as an antiseptic for processing wooden, stone, plastered and other surfaces.

- Impregnation for processing materials during preparatory work. It will be necessary to dilute 400 g of liquid glass in a liter of water and lubricate the surface two or three times. But keep in mind: each layer must completely dry and only after that you can start applying the next layer.

Liquid glass: use in needlework and decor

a http-equiv = "Content-Type" content = "text / html; charset = UTF-8 ″> ss =" align-left "> Creative people have noticed for a long time that liquid glass is an excellent tool for making various crafts.

It is used as an adhesive for joining any surfaces - glass, fabric, rubber.Also, liquid glass will help to whiten or dye paper and fabric, make fancy crafts, paintings, or even household items.

Photo: YouTube

Consider what you can do with silicate glue:

Treat figures or sculptures.

If you made a sculpture out of plaster and want to put it in the garden, you need to protect the masterpiece from external natural conditions. To do this, treat the craft with silicate glue and wait until it dries completely - now the sculpture is not afraid of any temperature fluctuations and fungus.

Apply as glue.

How to make a variety of crafts using glass, fabric and other natural materials? You will need a strong glue. For these purposes, liquid glass is perfect.

For example, use silicate glue to make a candlestick. Take a base, apply glass to it and decorate with coffee beans or other decor.

Photo: YouTube

In this way, decorate vases, glasses, lamps and other items.

Also do the painting. Draw a drawing on dense material (it is better if it is plywood). Apply liquid glass, line the pattern with beads, beads or pieces of glass. Finally, coat with a layer of silicate glue to secure.

Decorate the picture or other objects with pieces of broken glass, sea salt, shells, cereals.

Make glass flowers.

Making flowers out of glass takes practice, so don't be discouraged if something doesn't work out the first time.

You will need a special flower petal mold, liquid glass, and acrylic paints.

Mix the paint of the desired color with liquid glass, pour it into the petal forms and wait until it hardens completely. Then carefully remove the petals, wire them into a bud and decorate.

Photo: Maam

Make a table.

If you want to make a small table with your own hands, take a wooden tabletop of the right size and attach a stable leg to it. Then treat the top of the table with liquid glass and leave to dry.

Photo: Mirtesen

Liquid glass is a great helper, a real magic wand for creative people. The possibilities of silicate adhesives are almost endless. Therefore, by connecting imagination, you will find a use for it without difficulty.

16:08

16:53

15:26

14:26

15:09

10:44

15:04

14:29

15:51

16:16

Liquid glass for wood: how to cook

Before covering the lumber with the compound, you must read the label. Manufacturers indicate the proportions in which the ZhS is bred. For wood processing, water glass must have a certain permeability in order to penetrate deeply and not remain on the surface. The consistency of the working solution should resemble liquid jelly. The amount of water is calculated depending on the concentration. On the market you can find 30 and 50% of the mixture.

The consistency of the working solution should resemble liquid jelly.

The consistency of the working solution should resemble liquid jelly.

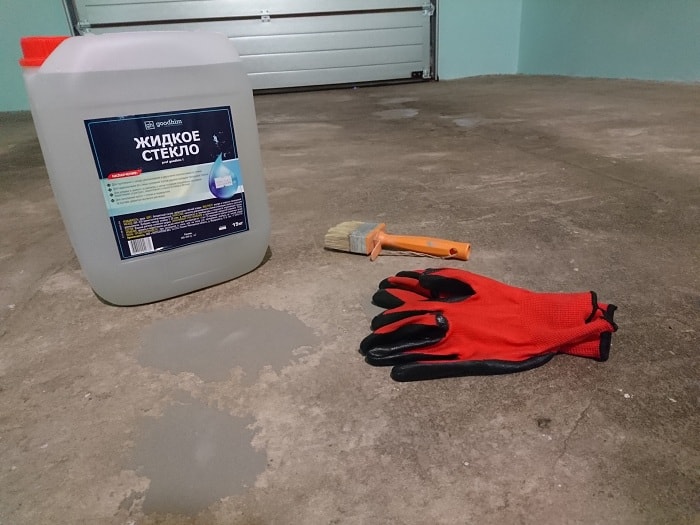

Preparatory work

Wood processing is carried out in protective clothing and gloves. It is first necessary to clean, level the surface to be treated, remove the remnants of shavings, wood powder. Liquid glass is diluted in glass or plastic containers with clean tap water to the desired consistency.

The surface is cleaned from exfoliated fibers, dust, shavings and wood flour are removed. To minimize the consumption of ZhS, increase the strength of structures, it is advisable to fill large gaps with a primer.

First, it is necessary to clean, level the surface to be treated, remove the remnants of shavings, wood powder.

First, it is necessary to clean, level the surface to be treated, remove the remnants of shavings, wood powder.

Pros and cons of using

Based on the numerous reviews, it is possible to draw a conclusion about the disadvantages and positive aspects of the use of liquid glass.

The disadvantages of users include, first of all, the following:

- The need for painstaking work, which includes cleaning from dust and other contaminants;

- Together with the solution, the material hardens very quickly, which means that there is no way to prepare it "with a margin";

- The use of other materials to provide additional protection against mechanical damage, since if they are present, the water-repellent properties of liquid glass are destroyed.

Hello, dear reader of the blog, I am sure that many have heard about liquid glass and is most often used for the installation of waterproofing screeds in the bathroom, toilet. In addition to waterproofing, liquid glass is used to increase the resistance to high temperatures of concrete or to protect metal structures, as well as in primer mixtures for better adhesion.

When you need to solve the issue with waterproofing, liquid glass can serve as an excellent option. But first you need to understand the features of using this material and its strengths.

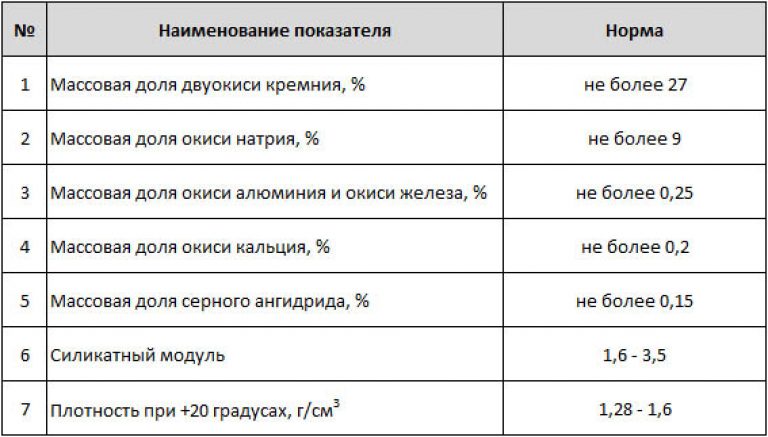

Solutions consisting of sodium or potassium silicates in water are called liquid glass. Therefore, liquid glass is potassium and sodium.

As for potassium glass, it is resistant to atmospheric and acidic influences. Once dry, it does not emit glare. Potassium glass can be added to various paints.

Soda glass has a more sticky texture. Among its main characteristics is easy interaction with various types of minerals. It is soda glass that is more often used when laying waterproofing and in the process of strengthening the foundation. Soda water glass can also be found in fire-resistant impregnations.

In order for the plaster and concrete to become stronger and more stable, the connection of liquid glass with concrete is carried out. Thus, the material will become so hard that the level of performance will increase significantly. In addition, the material will not be afraid of moisture, since it practically cannot be absorbed.

There are several ways to prepare solutions. This is not a very complicated process, the main thing is to observe the proportions and lifetime of the solution.

It is impossible to carry out priming with just liquid glass. Therefore, you will need water, cement and, of course, liquid glass. Cement and liquid glass are taken equally. But first, cement is diluted with water. It must be constantly mixed. Then comes the turn for liquid glass. If the mixture becomes too thick, water is added.

A similar mixture is used when building a fireplace and stove in a bath. The mixture acquires refractory quality when, at the end of mixing the solution, a small amount of liquid glass is added to the concrete. The solution must not be allowed to dry. Therefore, small parties are being prepared.

The glass is diluted, after which it is combined with dry concrete. In this case, you need to take one part of the glue, and ten parts of concrete. The composition hardens very quickly. So you should work with him immediately. Of course, you can add water, but the waterproofing qualities of the mixture will suffer from this. But in general, such a solution also has antiseptic properties, so you can not be afraid of mold.

I did not have to deal with such works as increasing the fire-retardant properties of structures using plasters based on liquid glass, but they often used it for waterproofing in apartment screeds, at a construction site when installing a basement, and made waterproofing screeds in the wells of the drainage system.

I have never seen such soap bubbles

Related articles:

Your thanks for my article is a click on any button below. Thanks!

Liquid glass is one of the commonly available materials that are widely used in various fields of construction. The main feature of this composition is the ability to create a reliable waterproofing layer. In addition, liquid glass can increase the strength of concrete and the level of its moisture resistance, and accelerate the process of its hardening. Such material is also used in the field of decoration.

Liquid glass - use in construction

Unfortunately, many are simply not aware of the potential of this composition. Others may have undeservedly forgotten about it, against the backdrop of a modern variety of materials. Therefore, we will consider a question that may be useful both for some and for others: liquid glass - use in construction.