Varieties and areas of their use

Universal dry mixes differ in composition and purpose, they have their own characteristics and characteristics

You should pay attention to the marking, the number in which indicates the strength of the original product

M100

M100 products are designed for hand plastering and puttying. The mixture lays down in an even thin layer, which leads to material savings. It is easy and pleasant to work with her. The mixture retains its properties for two hours from the moment of dilution. Prices for M100 products are quite affordable.

M150

M150 products are the most popular of the versatile mixes. It is used in virtually all dry mortar construction work. Unlike M300 and M400, it is used for masonry, plaster, screed. Factory packaging is presented in bags of 50 kg, less often they produce products of 25 kg in a package.

The composition of the universal mixture includes Portland cement, sand, mineral powder, plasticizers and other additives. It remains only to dilute the finished composition with cold water in the proportion indicated on the package.

M150 products are endowed with many advantages: they are reliable, frost-resistant, have good adhesion to various surfaces, high moisture resistance and vapor permeability. It is used in any climatic conditions.

The disadvantages of M150 include poor resistance to increased loads (no more than 150 kg per 1 cubic cm), therefore, such a mixture is not used to work with the foundations of multi-storey buildings.

The name "universal" speaks of the variety of application of the composition M150.

- The plaster mix is designed for indoor and outdoor plastering work. Layer thicknesses can be applied up to 50 mm. After mixing, work should be started immediately: the mixture is in a pliable state for 2 hours. The plaster acquires complete dryness and strength in 4 weeks.

- With the help of the M150 mixture for the screed, the floor is leveled in the premises. Checking the level and setting the beacons, the floor is poured with a thickness of 1 to 10 cm. Thanks to the cement base, the floor acquires strong qualities that are resistant to temperature changes.

- The masonry mixture is used for laying gas silicate blocks and bricks of all types. You can work with M150 products inside a building and outdoors in frost and heat, weather conditions do not affect the quality of the masonry. The dry mix has proven itself well in rooms with high humidity.

M200

M200 products are masonry mix. It consists of Portland cement, river sand and special additives. Designed for laying bricks, concreting floor coverings, erecting simple foundations, repairing walls and processing joints in concrete structures.

The M200 can be used for laying garden tiles, as well as for plastering and filling walls. It is produced in 50 kg bags.

M300

Sand concrete M300 not so long ago appeared on the construction market, but has already gained popularity. Unlike the M150, it is designed for heavy loads. The products are durable and reliable, have a long service life, adapt well to weather conditions, are moisture resistant, environmentally friendly, and do not shrink. M300 consists of Portland cement, which includes gypsum, sand and crushed clinker. Products are packaged in bags of 50 kg, less often - 200 kg for an industrial scale.

Due to its special strength, the composition is used in all areas of construction work in any climatic conditions. During installation, they are used to install the foundation, floor screed, leveling walls and other surfaces. The products have proven themselves well as grouting cracks during work on emergency facilities.The composition is used when laying garden paths, stairs, curbs. The mixture is used in the manufacture of expanded clay concrete.

According to their properties, depending on the application, M300 products are divided into several subspecies.

- Coarse grains are incredibly strong and durable. With its help, you can fill the foundation of high-rise buildings.

- Medium-grained is used for screeds, self-leveling floors, curbs and garden paths. It is used wherever a medium-grained fraction of the mixture is required.

- Fine-grained is also reliable and durable, it is used for plastering work.

When choosing a universal dry composition, one should remember: the more famous the brand and the higher the brand of the product, the more expensive the product and the more reliable its technical properties.

For what dry building mixtures are, see the next video.

Specifications

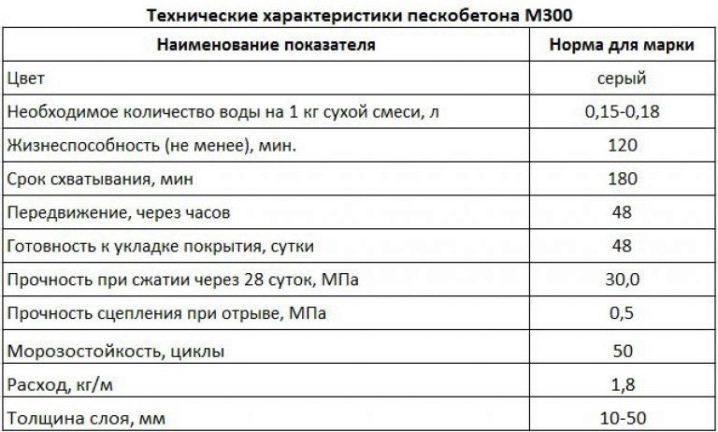

The technical characteristics of sand concrete determine the rules for its operation and resistance to external destructive factors. The composition and technical properties of the M300 mixture make it possible to use it both as a self-leveling mixture (self-leveling mixture) and as a repair compound.

Composition

Any variants of M300 mixes are gray. Its shades can be different depending on the composition. For such materials, Portland cement M500 is used. In addition, the M300 mixture according to GOST has the following proportions of the main components: one third of cement, which is a binding ingredient, and two thirds of sand, which is a filler.

Frost resistance

This indicator indicates the ability of the material to withstand multiple temperature changes, alternating melting and freezing without severe destruction and decrease in strength. Frost resistance allows the use of M300 sand concrete in unheated places (for example, in capital garages).

Frost resistance of mixtures with special additives can be up to 400 cycles. Frost-resistant repair mixes (MBR) are used for mixing building compounds used in the reconstruction and restoration of concrete, reinforced concrete, stone and other joints, filling voids, cracks, anchors and for other purposes.

Compressive strength

This indicator helps to understand the ultimate strength of a material under static or dynamic action on it. Exceeding this indicator has a detrimental effect on the material, leading to its deformation.

Dry mix M300 is able to withstand compressive strength up to 30 MPa. In other words, given that 1 MPa is about 10 kg / cm2, the index of compressive strength of M300 is 300 kg / cm2.

Temperature spread

If the thermal regime is observed at the time of the work, the process technology is not violated. The further preservation of all the performance properties of concrete is also guaranteed.

It is recommended to work with sand concrete M300 at temperatures from +5 to +25? С. However, sometimes builders are forced to violate these guidelines.

Adhesion

This indicator characterizes the ability of layers and materials to interact with each other. Sand concrete M300 is able to form a reliable adhesion with the main layer, which is equal to 4kg / cm2. This is a very good value for dry mixes. To maximize adhesion, manufacturers give appropriate recommendations for preliminary preparatory work.

Bulk density

This indicator means the density of the material in an unconsolidated form, taking into account not only the volume of particles, but also the space that has arisen between them. This value is often used to calculate other parameters. In bags, dry mix M300 is in bulk with a density of 1500 kg / m3.

If we take this value into account, it is possible to draw up an optimal ratio for construction. For example, with a declared density of 1 ton of material, the volume is 0.67 m3

In non-scale construction work, a 10-liter bucket with a volume of 0.01 m3 and containing about 15 kg of dry mix is taken as a meter for the amount of material.

Sand particle size

Plants produce sand concrete M300 using sand of different fractions. These differences determine the peculiarities of the technique of working with a solution.

There are three main sizes of sand used as raw material for dry mixes.

- Small size (up to 2.0 mm) - suitable for street plastering, leveling joints.

- Medium size (0 to 2.2 mm) - used for screeds, tiles and curbs.

- Large size (more than 2.2 mm) - used for pouring foundations and foundations.

Mixture consumption

This indicator characterizes the consumption of material with a layer thickness of 10 mm per 1m2. For sand concrete M300, it usually ranges from 17 to 30 kg per m2. It is worth noting that the lower the consumption, the more economical the work costs will be. In addition, manufacturers often indicate the consumption of sand concrete in m3. In this case, its value will vary from 1.5 to 1.7 t / m3.

Delamination

This indicator characterizes the relationship between the lower and upper parts of the solution. Mix M300 usually has a delamination rate of no more than 5%. This value fully complies with the requirements of the standards.

What sand concrete consists of

The characteristics of sand concrete m300 (composition, proportions 1m³) are standardized by Gost 7473-94.

A high-quality dry mix contains:

- Portland cement PC500 D20 / PC400 D0;

- fractionated dry sand, with a combined composition of fractions (particle size 0.80-4.0 mm);

- other additives (frost-resistant, microsilica, fiberglass) are introduced at the discretion of the manufacturer.

Sand concrete M300 can be used for the construction of wear-resistant high-strength floors as a bearing coating in utility and residential premises, including garages, basements (with a load of 250-300 kg / cm²)

Depending on the sand used, the material of the M300 brand is used for the implementation of certain works:

| Sand, particle size, mm | Characteristic | Application |

| Small - 0.80-1.20 | High wear resistance and strength characteristics | Conducting critical masonry and other outdoor work, light floor screed 50.0 mm, mounting mortars of increased strength |

| Medium - 1.80-2.20 | Increased resistance to operational loads | Implementation of interior works, laying curbs, paving slabs, erection of eurofences, screed up to 100 mm, "warm floor" systems |

| Large - 2.50-4.0 | Moderate moisture absorption | Erection of slab, strip and columnar foundations, plinths, pit floors, without restrictions on thickness using reinforcement |

Composition of sand concrete m200

The composition of sand concrete is determined by GOST 31357 - 2007 "Dry building mixtures on a cement binder". Each manufacturer can make small additions to the composition of the mixture, but there are key components and indicators that are the standard.

Main components:

- Cement m400;

- Sand;

- Crushed stone;

- Water.

When creating, Portland cement M400 is mainly used, it is one of the most common, and its technical characteristics meet all specified standards. Sand is used in two types of fractions - fine-grained and coarse-grained, thoroughly cleaned of impurities.

The composition and proportions of sand concrete m200 per 1m3 according to building standards, the consumption of the mixture is:

- Portland cement - 265 (1 part);

- sand 860 (2 parts);

- crushed stone 1050 (5 parts);

- water 180 (? part).

Tips & Tricks

When planning to prepare a cement-sand mixture, it is necessary to immediately determine in what proportion the different components will be taken, what grade of strength is needed, what properties are basic.

It all depends on the scope of application of the solution - so, if M50 or M75 are suitable for brickwork, then at least a mixture of M150, 200 and higher is prepared for the screed. Any CPF contains cement, sand, water, but the result is different in accordance with the ratio.

A few tips from the masters:

- To prepare a plastic mixture, you can add liquid soap to the solution, previously thoroughly mixed with water.

- You need to know how to properly dilute cement and other components: first, all dry substances are mixed, then water is added in small portions so that it is possible to control the density of the mixture and achieve an ideal consistency.

- When preparing, take into account the brand of the building material from which the walls are being erected. It is desirable that the parameters coincide - then the wall will be of a homogeneous structure, reliable and durable.

- Before making your own cement for plaster, you should take care of buying perlite. If you replace part of the sand with it, it will be possible to achieve better thermal insulation characteristics.

- For work, exclusively fresh cement is used, without lumps, produced by technology and stored under optimal conditions - in this case, it will be possible to achieve the most uniform mixing and high adhesion.

- Detergent or soap is also added to the cement (proportions remain the same, just mix with water for mixing) to increase adhesion.

- The solution is best prepared in a metal, plastic or wood container.

- To thoroughly cleanse the sand from impurities that can reduce the strength, you can soak it in water for a short time.

- The consistency of the finished cement-sand mixture is usually checked with a trowel: the mortar should be distributed evenly over the tool, but not drain in any way (it is worth remembering that this rule works in the preparation of standard mixtures, for some tasks other properties may also be important).

- The finished DSP is used for an hour after mixing, until the solution begins to thicken and harden. Therefore, you need to immediately prepare the required volume - exactly as much as you can work out in an hour.

- It is forbidden to dilute the already frozen solution with water, as it immediately loses its properties and can cause the destruction of the structure / building.

- When mixing a mixture in a volume of more than 2 cubic meters, no drills and nozzles will help - only a concrete mixer or ordering the required volume in a factory.

- The mortar, which is planned to be used where minimal loads and a small mass are noted, can be prepared with a reduced volume of sand. But such an approach is possible only on the condition that before correctly kneading the DSP, the master has precisely defined the features of the application and the rest of the solution will not be used for the implementation of any other tasks.

- Stirring the cement-sand mass should last at least 20 minutes - this way the mortar will turn out to be homogeneous and of high quality.

- The ratio of the proportions of the components is looked at in GOSTs and SNiPs (the opinion of experienced craftsmen is allowed), as well as in the recommendations of the manufacturer of cement, dry mix, etc.

Cement-sand mixture is a versatile material that can be used to perform a whole range of works, obtaining the most durable and strong structures. Subject to the choice of high-quality materials and adherence to the technology for preparing the mixture for the task at hand, everything will be implemented quickly and easily.

Peculiarities

Dry mix M-300 is a ready-made masonry mix, the components of which are selected in the right proportions. Before use, the composition is diluted with water in the amount specified by the manufacturer and mechanically mixed until smooth.

The mixture is sand concrete, since it is based on refined fine concrete and Portland cement. The dimensions of the first do not exceed 3 mm, the used Portland cement has a branded strength of M-400 or M-500). To ensure certain characteristics (frost resistance, moisture resistance, and so on), plasticizers are introduced.

Various reinforcing fibers may be present in formulations operated at subzero temperatures. To improve adhesion, sometimes a special type of clay, coarse sand, granite chips are introduced.

Unlike usual concrete mortars, M-300 sand concrete is distinguished by ease of preparation, plasticity (suitable for laying in a thin layer, which is necessary for certain types of masonry), high strength, and economical consumption. Mix M300 is masonry, that is, it is used to fix bricks or masonry stones. In addition, it can be used as a concrete mixture for casting.

The composition is characterized by non-shrinkage, which allows it to be used as a floor screed. And due to the increased strength and wear resistance, the mixture is used even when organizing high-strength floors. The thixotropy of the composition allows it to be used also for leveling floors, as well as filling gaps in concrete surfaces.

The material is suitable for both private housing construction and for the construction of industrial and administrative facilities, as well as the installation of basements, garages. It is used when pouring the foundation, including in the places of adhesion of concrete and reinforcing sections. The mixture is also used for the device of paths in private suburban areas. By its properties, the material resembles fine-grained concrete, therefore it is used both outside and inside buildings.

General information

A characteristic feature of concrete is its composition, as well as proportions and preparation technology. It consists of cement, fine and coarse fillers, water and various additives. In addition, there are grades of concrete that do not include a large filler. There are different mixtures that are used for specific applications and also have different properties.

Designation and its decoding

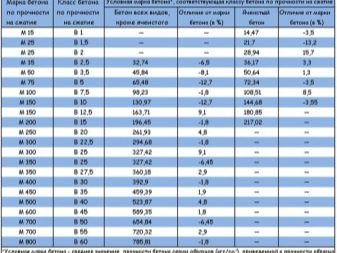

The full strength of concrete structures takes place within 6 months, and in 30 days the concrete gains 70% strength. M300 is used in all structures on which a significant load is applied, therefore, one of the main indicators is its strength. The designation template MXXX does not indicate a specific brand, but is an indicator of the ultimate compression pressure.

In addition, there are other designation patterns, for example, FXXX and WXXX, indicating frost resistance and water resistance, respectively. The class of concretes M300 shows the totality of all grades, the ultimate strength of which is 300 kgf / sq. see Tensile strength is checked in laboratory conditions, when a force is applied to the parallel planes of a product, cast from concrete, in the form of a cube with a side of 150 mm. The strength of the concrete grade is related to its class. These indicators should be chosen for the construction and calculation of the finished structure at the maximum load that it can withstand.

M300 corresponds to class B22.5 with a coefficient of variability (CV), which is 13.5%. It shows the homogeneity of the mixture from which any grade of concrete is made. When this coefficient changes, the concrete grade will also change, that is, if its value is low, the grade increases and vice versa. If the concrete is M300, then with different values of the coefficient its class will change:

- At Kv = 5%, the class is equal to B25.

- With Kv = 13.5% - B22.5.

- At Kv = 18% - B15.

Main characteristics

Concrete is classified into grades, and this distribution is primarily related to the parameters of strength (B), density (D), water resistance (W), frost resistance (F) and mobility (P). One of the best options for most construction work is concrete M300, the characteristics of which are as follows:

- Strength: B22.5 with an indicator of 295 kg / sq. cm.

- Specific gravity of concrete M300: 1800-2500 kg / cu. m.

- Waterproof: W6-W8.

- Frost resistance: F200-F300.

- Mobility: P2-P4.

The strength index is the main characteristic and shows the maximum effect of forces in compression, at which the structure is destroyed. The specific gravity or density of M300 concrete depends on the type of coarse filler included in its composition. When using limestone, the D index is about 1800 kg / m3.m., and when using harder rocks (crushed granite, granodrite, and so on), it can reach a value of 2500 kg / cubic meter. m. Due to its high density, this type is classified as heavy. The density index depends on the presence of violations in the manufacturing technology and air cavities.

Water tightness (WXX) is a value indicating the pressure of water in MPa to pass through 0.15 m of concrete. For concrete grade M300, this indicator is equal to W5-W6, at a pressure of 0.5-0.6 MPa (approximately corresponding to 5-6 atmospheres), it does not allow water to pass at all. With the addition of hydrophobic cement, additives and thorough compaction of the mortar, an increase in the waterproof index is possible.

Frost resistance is indicated as an FXXX template and shows the number of defrost-freeze cycles without loss of strength. This characteristic can be increased in several ways:

- The use of additives that prevent the formation of air bubbles.

- Removing air from the concrete mix with vibrators, as well as using various compactors.

- Decrease in the amount of water (impairs mobility).

- Use of solid aggregates instead of crushed limestone.

Application in construction

Since M300 has good indicators of strength, frost resistance, water resistance and mobility, it is widely used in construction. In addition, its main indicators can be adjusted by changing the components that make up the concrete mixture. It is advisable to use it for the following works:

- Construction of sites, roads and curbs.

- Installation of walls and various supports.

- Construction of stairs, landings and foundation pouring in multi-storey buildings.

- Manufacturing of reinforced concrete products and fences.

- Production of sewer pipes that are constantly exposed to moisture.

- Construction of objects that are affected by constant temperature drops.

How to prepare DSP?

Each ready-made mixture must be accompanied by instructions on the required amount of water, other components are usually not provided. When used in the composition of additional materials (dyes, reinforcing fibers), the proportions must be observed strictly in accordance with the instructions for the additive. Typical mixing to water ratio is 5 to 1 (a bucket of water per bag of mix 50 kg), the proportion of dyes is 0.1%, the proportion of fiber is 1%.

When self-manufacturing, the proportions of water and sand to cement are taken depending on the type of work carried out, strength requirements, as well as the degree of sand moisture:

1. The thickest mortar is required for masonry - the water / cement ratio is not more than 0.8.

2. For screeds and plaster, cream-like compositions with a W / C ratio of 0.8–1.2 are used.

3. When spraying and grouting, the solution is thinned even more, up to W / C - 1.5.

4. Mixtures with W / C less than 0.6 are used when it is necessary to obtain a fast-drying cement-sand mortar of a high grade (M300 and higher), or for concrete.

If a concrete mixer is used for mixing, it is recommended to carry out the work in the following order:

- Pour water into the spinning drum, add additives.

- Pour in 2 buckets of sand.

- Add a bucket of cement, wait until stirring.

- Top up the remaining sand, top up with water if necessary.

With manual mixing, water is poured into the dry mixture. If you do the opposite, water forms a cement film on the surface of small lumps of the mixture, which will slow down the process many times. If the composition is made from its own ingredients, it is advisable to mix them dry before adding water.

After preparation, the mortar must be used before it begins to harden - from 15 minutes to several hours, depending on the use of additives, cement concentration and temperature. A common solution М150-М200 at a temperature of 20 ° C begins to solidify an hour after mixing.

Consumption

In order to plan in advance the mass of the central heating system, it is necessary to approximately calculate the required volume of the solution and multiply by the values of costs per 1 m3 indicated in the description of the mixture. Most often they are indicated in the format "consumption of the mixture per m2", which means a layer with a thickness of 1 cm. To get the cost per 1 m3, it is enough to multiply the indicated value by 100.

Typical values for the consumption of a sand-cement mixture - 1800 kg / m3, for high-quality compositions - up to 2200 kg / m3, for lightweight plasters with lime - 1200-1600 kg / m3.

Calculating the volume of consumption of mortar for plastering and screed is not difficult, but the cost of material for masonry depends on the skill of a particular contractor. If you strictly follow the technology, the mortar consumption will be 25% of the total wall volume, but in practice this value can be up to 35% (thick joints, losses due to splashes), and below 20% (waste masonry, use of low-quality techniques to speed up work ).

Peculiarities

Cement mortars with sand are used when performing a variety of works in the process of construction, decoration, and repair of buildings. It is not difficult to make a mixture with your own hands, but you need to know the exact proportions of cement, sand and water. The easiest way is to use a concrete mixer in the batch, renting it or buying it.

Before making a mortar from cement and sand, it is necessary to determine the scope of application, since the proportions differ significantly. The most popular is DSP for brickwork: cement-sand mortar is used in the creation of load-bearing walls, internal ones with the addition of lime.

The composition of the cement slurry depends to a large extent on the working conditions and operation. If the work is carried out in frost, then special antifreeze additives are introduced into the composition, which do not allow the central heating system to freeze. But they are suitable for work in frost below -20 degrees (it is better to do nothing at all, but wait for warming), since they will not be sufficiently elastic and mobile.

If the cement solution is prepared for use in monolithic hearths with an open-type fire source, in the construction of a furnace or firebox, then heat-resistant fire-resistant mixtures are created: from cement at least M400, with crushed stone from bricks, chamotte fine sand.

For each type of task and working conditions, a solution is prepared from basic materials, but in different proportions and with the addition of additives, plasticizers. As a rule, additives change one parameter - this can be the solidification rate, mobility, frost resistance, etc. Each master defines the priority tasks and performs calculations before preparing the cement slurry.

Specifications

Sand concrete M-300 is a universal composition that is suitable for a wide range of construction work. First of all, this is due to its high strength indicators. The compressive strength is 300 kg / cm2. This means that 1 cm2 is capable of supporting a weight of up to 300 kg.

The repair mixture has an average specific gravity, which indicates such a sand content, due to which the risk of voids formation during pouring is eliminated.

The frost resistance of the composition is at least 50 cycles, that is, it can withstand up to 50 freeze / thaw cycles.

Due to a rather moderate consumption (17-30 kg of the mixture is consumed per 1m2 with a layer thickness of 10 mm), M-300 becomes the best option for a screed, the organization of which is cheaper than using specialized compounds.

The important technical properties include a high solidification rate, as well as moisture resistance (the layer does not allow water to pass through). This allows the composition to be used in emergency situations - when it is necessary to quickly and without preliminary preparation eliminate cracks, cracks, loss of stability.

The grasping of the composition occurs after 12 hours (after this time it is already possible to walk on the sand concrete floor), the final solidification takes place on average after 5 days (after that the construction process can be continued).

At the same time, M-300 sand concrete demonstrates a viability of up to 120 minutes, which allows work to be carried out at an optimal pace (without unnecessary haste) even in the absence of construction skills. The composition has a self-leveling ability, in other words, a self-leveling sand-concrete mixture when pouring does not take much time and effort to level the surface.

Due to its plasticity, the composition can be applied both in a thin (from 10 mm) and thicker (up to 200 mm) layer, which also contributes to the expansion of the scope of its application. For example, masonry requires a thin layer of the mixture, while pouring or leveling the floor may require a thicker layer.

In addition to these characteristics, it should be noted thixotropy (non-shrinkage), high adhesion (4 kg / cm2), the ability to work at temperatures below 5C. The ability to resist corrosion makes the composition suitable for pouring reinforced concrete substrates and similar structures.