Vetonite - characteristic features

Putty Vetonit occupies a special place in the market of mixtures for leveling walls and other surfaces. There are several varieties of this material.

LR (LR)

This mixture is intended for applying a finishing layer. Such a putty is not suitable for leveling surfaces, but can act as a decorative finish.

Putty Vetonit LR is designed for work in dry rooms. It is a finishing putty, which is applied before further wallpapering.

The mixture is available in the form of a powder, which must be diluted with a certain amount of liquid, as well as in the form of a ready-made mixture, with which you can work immediately. Here's how to dilute the putty.

Vetonit LR

But in practice, everything can turn out differently, because the method of applying the putty, as well as the thickness of the applied layer, plays a significant role.

For more details about Vetonit LR putty, see the video:

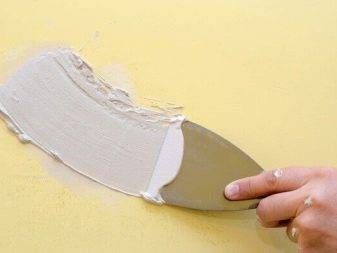

Application of KR putty on walls

This mixture is made on a gypsum base, and it is intended for work in rooms where there is no moisture.

KR

It is also used more for decorative purposes.

How to calculate the consumption of TT putty on a calculator

It is made on a cement basis.

TT

This putty is used to level a wide variety of surfaces - floors, ceilings, walls, etc.

The consumption of Vetonit putty will depend on a variety of circumstances:

- kind of mixture. The consumption of the TT index putty will be higher than the consumption of the gypsum-based putty. And the consumption of Vetonit LR putty will be 1m2 less than the amount of gypsum putty used (KR index);

- the specifics of the works themselves. The thickness of the layer of the ready-made solution for leveling surfaces will be greater than for decorative finishes;

- surface characteristics. If there are a large number of cracks and seams on the walls and ceiling, then this naturally increases the consumption of the mixture;

- the number of layers applied. Experts recommend applying at least two layers.

If we talk about average values, then the consumption of Vetonit putty per 1 m2 is from 1 to 1.3 kg. Also, this indicator is influenced by the method of applying the mixture. If you use an ordinary spatula to putty the walls, then the consumption will be large, but if you resort to using a special sprayer, then the consumption will be reduced.

The use of this device is possible only with a certain type of putty.

Considering that experts advise to apply at least two layers, the consumption of the finished solution applied to the surface will be doubled exactly.

To accurately determine the consumption of Vetonit putty per 1 m2, you can use the calculator, which is located on the official website of the manufacturer.

There are several main advantages that make Vetonit putty one of the most demanded mixtures:

- the finished mixture adheres well to the surface;

- with the exception of plaster putty, Vetonit can be applied to almost any surface;

- resistance to moisture ingress;

- the applied layer dries quickly enough. Here is about how much the putty dries.

Types of self-leveling floor

At the moment, the manufacturer's catalog contains 8 types of self-leveling floors "Vetonit". Separate products for the base layer and topcoat, there is also one 2 in 1. They are compatible with warm floors, simple and automated. Any of them is applicable in rooms with high humidity.

Universal mixtures

Vetonit fast 4000

Create a layer from 5 to 80 mm at a time. The mixture is made using two-in-one technology - screed and finish. It is good to install common floor coverings such as laminate on such a surface.

The tensile strength is 18 MPa, which allows the mixture to be used for the repair of premises with moderate traffic. Compression of the mixture after drying by 0.4 mm / m. Operating time - 30 minutes, sets after 4 hours.

Vetonit 4100

Self-leveling floor with high strength, does not crack under strong impact. Leveling layer - from 2 to 30 mm. Waterproof and non-flammable.

Ideal base for laminate, parquet or tiles. Withstands heating from underfloor heating. Designed for use in apartments, shopping centers, offices and high traffic areas.

Mechanized application is possible. The time of use is 30 minutes, after 40 minutes the floor can withstand walking, the second layer is applied every other day. After a week or more, the final coating can be applied.

Bending resistance - less than 6 MPa, consumption 1.5 kg per m2. Compression is less than 0.5 mm.

Topcoat options

Vetonit 3000

Coating layer - up to 5 mm, creates an absolutely flat surface. A distinctive feature is the filler in the form of finely ground marble. It is used for local repair of cracks up to a depth of 10 mm.

Vetonit finish level

Leveling with a mirror effect, under parquet boards, natural parquet or laminate. They work with it exclusively by hand.

Suitable for various premises. The tensile strength is 18 MPa, the flexural strength is 4 MPa, the coating decreases by about 1 mm / m.

Vetonit 3100

Option for creating a smooth floor without flaws. Suitable for filling cracks up to 20 mm deep.

Dilution and filling can be done manually and with special mechanical tools.

Withstands moderate loads and low permeability in the room. Consumption - 1.6 kg for a layer thickness of 1 mm.

Special mixtures

Vetonit Fast level

The main difference is the fast-hardening composition. The thickness of the poured layer is from 3 to 60 mm. The solution does not harden for about 40 minutes, after 3 hours it hardens to a degree that allows walking on it.

The floor covering can be applied every other day. Application by hand only. Can be used as a base for any flooring.

It can be poured onto a subfloor made of concrete, gypsum or cement-sand composition.

Withstands moderate stress. Withstanding mechanical stress - 15 MPa, bending strength - 3 MPa, floor shrinkage up to 0.4 mm per meter.

Vetonit strong

Reinforced floor, reinforced with fiberglass, which actively protects against cracks. Convenient thanks to good flow and self-leveling formula.

Suitable for a layer of 10-50 mm. The tool makes a screed of any bases, including monolithic and floating ones.

The main purpose is to repair a wooden floor, bitumen base. Further actions to repair the premises should be started no earlier than after 1 week, work with tiles - after 3-7 days.

Vetonit 4350

Suitable for soundproofed floors. It has increased resistance to bending, its strength is less than 4 MPa, resistant to cracking and wear from any external influences due to fiber reinforcement.

Both manual and mechanical application is possible. Layer thickness - from 10 to 50 mm. Types of screeds: on a separating layer, "floating" with heat and sound insulation. Compressive strength - less than 16 MPa, shrinkage - less than 0.3 mm after complete drying.

Vetonite - characteristic features

Putty Vetonit occupies a special place in the market of mixtures for leveling walls and other surfaces. There are several varieties of this material.

LR (LR)

This mixture is intended for applying a finishing layer. Such a putty is not suitable for leveling surfaces, but can act as a decorative finish.

Putty Vetonit LR is designed for work in dry rooms. It is a finishing putty, which is applied before further wallpapering.

The mixture is available in the form of a powder, which must be diluted with a certain amount of liquid, as well as in the form of a ready-made mixture, with which you can work immediately. Here's how to dilute the putty.

Vetonit LR

But in practice, everything can turn out differently, because the method of applying the putty, as well as the thickness of the applied layer, plays a significant role.

For more details about Vetonit LR putty, see the video:

Application of KR putty on walls

This mixture is made on a gypsum base, and it is intended for work in rooms where there is no moisture.

KR

It is also used more for decorative purposes.

How to calculate the consumption of TT putty on a calculator

It is made on a cement basis.

TT

This putty is used to level a wide variety of surfaces - floors, ceilings, walls, etc.

The consumption of Vetonit putty will depend on a variety of circumstances:

- kind of mixture. The consumption of the TT index putty will be higher than the consumption of the gypsum-based putty. And the consumption of Vetonit LR putty will be 1m2 less than the amount of gypsum putty used (KR index);

- the specifics of the works themselves. The thickness of the layer of the ready-made solution for leveling surfaces will be greater than for decorative finishes;

- surface characteristics. If there are a large number of cracks and seams on the walls and ceiling, then this naturally increases the consumption of the mixture;

- the number of layers applied. Experts recommend applying at least two layers.

If we talk about average values, then the consumption of Vetonit putty per 1 m2 is from 1 to 1.3 kg. Also, this indicator is influenced by the method of applying the mixture. If you use an ordinary spatula to putty the walls, then the consumption will be large, but if you resort to using a special sprayer, then the consumption will be reduced.

The use of this device is possible only with a certain type of putty.

Considering that experts advise to apply at least two layers, the consumption of the finished solution applied to the surface will be doubled exactly.

To accurately determine the consumption of Vetonit putty per 1 m2, you can use the calculator, which is located on the official website of the manufacturer.

There are several main advantages that make Vetonit putty one of the most demanded mixtures:

- the finished mixture adheres well to the surface;

- with the exception of plaster putty, Vetonit can be applied to almost any surface;

- resistance to moisture ingress;

- the applied layer dries quickly enough. Here is about how much the putty dries.

Peculiarities

Very often, when choosing a tool for treating and leveling walls in stores, a person is at a loss - on the packages of mineral mixtures based on a binder, there are two different names: putty and putty.

A powdery (or in the form of a paste) mixture, which includes gypsum, mineral fillers, chalk and wood glue, is called a putty. Manufacturers offer types of this building material with different compositions:

- based on latex components;

- oil;

- oil and glue;

- acrylic.

Depending on the composition, the putty is used only for internal or external work. The principle of using the putty is similar, and it should be noted that there is no fundamental difference between these names.

Experts in the construction field consider Weber Vetonit to be one of the best putties. The manufacturer of this building material is rightfully considered world famous - it is a subsidiary of the Saint-Gobain industrial group, formed back in 1900.

Today Weber is the leader in dry mortar production. The company's enterprises are present in all parts of the world, producing a range of products for construction and renovation work.

The undoubted advantages of Weber Vetonit putty:

- the mixture is made from ecological raw materials - it does not emit toxic substances;

- moisture resistance - it is used even in the construction of swimming pools;

- the composition is powdery, so the surface of the wall to be treated becomes perfectly smooth;

- the snowflake painted on the package of the mixture indicates that it can be used at low temperatures to decorate the facade;

- the composition in a diluted form can be stored for 24 hours.

Instructions for use

In order for the leveler to be a good base for the finishing material, the technology is performed according to all the rules. The instruction consists of several step-by-step points.

Preparation

Initially, the base is examined. It is cleaned of debris, dust and dirt. They remove all objects from the room, sweep the floor. To prevent dust from settling on the walls and ceiling material, it is better to use an industrial-type vacuum cleaner.

A few hours before leveling, the surface must be treated with a primer. You can use Vetonit MD16 or Prim Multi primer. You can apply the primer with a brush, although it is more convenient to use a roller.

Preparation

When preparing the working solution, it should be taken into account that the manufacturer's data are approximate. Sometimes, instead of 3.5 liters, 2.8-2.9 liters of water are consumed per bag of dry mix. Water is poured into a clean container and the powder composition is poured into it (not vice versa). The mixture is stirred until a homogeneous mass is formed. For this, a construction mixer is used.

It is worth considering that the more you stir, the shorter its life will be. This rule applies to all plaster and leveling mixtures. If there is a lot of water, this will cause cracks during drying and operation, while the strength of the solution decreases, which will affect the service life. It is undesirable to work with the composition after a certain period of time.

Alignment

Before starting the installation work, close the windows and doors - no drafts should be allowed during the work and when the Vetonit 5000 composition dries up. The prepared solution is spread on the floor surface and immediately stretched. The thickness of the layer depends on the available height difference. In order for the surface to be flawlessly even, it is trimmed with a rule, and, if necessary, sanded with a special float.

Seams

There are times when a quick-drying mixture is used under a tile without additional leveling. In this case, expansion joints are made on the surface after a few hours. This can be done when the surface has hardened and walking on the coating is allowed.

If the seams were originally on the old base, then they can be transferred. If they are absent, it is necessary to cut squares with a side of 6 m along the edges. The seam depth should, on average, be 1/3 of the thickness of the used screed.

Finish coating

If you plan to put tiles or porcelain stoneware on top, the joints must be filled with a special sealant for expansion joints. Waterproofing must be done before flooring. When you plan to lay a thin-layer floor covering, for example, linoleum, you can start work in a day from the moment you apply the leveling agent. The same applies to the self-leveling floor. Ignoring the drying time will lead to shrinkage and deformation of the leveling compound.

Varieties

Depending on the purpose, the putty can be:

- leveling, which is applied to concrete or plaster before subsequent decorative finishing;

- for seams;

- for a surface that has already been painted before.

Each of these types of putty is represented by the Vetonit trademark under its own name and price.

- Finish-LR + and Finish-KR are used for work in dry rooms and are used for finishing walls and ceilings. The average cost of one package of such a mixture is from 650 to 700 rubles.

- Superfinishing “Finish-KR”, “JS Plus” and “LR-Paste” are designed to give perfect smoothness at the last stage of finishing work, and “Siloite gyproc JS” putty is intended exclusively for grouting drywall joints.

- For work in rooms with high humidity, "Finish VH" is perfect at a price of 600-650 rubles per package.

- And for finishing the facades it is worth choosing the "Rend Facade" mixture for 450 rubles.

Depending on the type, plaster is necessary in the following cases:

- full alignment of ceilings and walls;

- alignment of certain areas of the surface for subsequent finishing work;

- applying a decorative plaster layer for further painting inside and outside the room.

The main purpose of self-leveling screeds is:

- creation of a "warm floor" system;

- creation of flooring on unheated balconies and terraces;

- the creation of screeds for the subsequent decorative coating;

- leveling rough surfaces made of concrete or cement.

In addition to the above products, various adhesive mixtures are also presented on the domestic market. The price range for glue from the Vetonit company ranges from 200 to 1000 rubles, depending on the purpose.

- For example, Profi Plus is sold for working with porcelain stoneware, Mramor for working with light tiles and therm S100, which is a versatile material.

- All of them are used for interior work, and in order to glue building materials outdoors, it is worth choosing "Easy fix" or "Ultra fix".

- For finishing the facade, you can purchase an adhesive mixture of the "Ultra fix winter" brand, and for work in rooms with high humidity, dry Optima glue is perfect.

- There are grades of adhesive mixture of rather narrow application, for example, Vetonit MW is used only for joining boards made of mineral wool.

Vetonit also produces mixes for brick and stone masonry, primer and grout and even oven mixes that can withstand high temperatures and are used for the construction of fireplaces and stoves. Colored cementitious grouts are perfect for finishing joints of various sizes, and for rooms with a high temperature drop, it is worth purchasing two-component epoxy compounds. On the shelves you can find all kinds of primers, paints, impregnations and antiseptics. The so-called "dry concrete" is produced for pouring into molds.

Tips & Tricks

In general, work with dry building mixes Vetonit is carried out according to the same algorithm as work with mixes from other manufacturers. The instructions for creating a solution are always indicated on the manufacturer's packaging and is the best option for its preparation.

- Putty of this brand can be applied to the work surface both with the help of special mechanisms and installations, and manually, using a rule and a spatula.

- The surface must be pre-prepared - free from old finishes, dirt and dust. It must be dry, free from oil or grease stains, and sufficiently firm.

- There should be no drafts in the room being finished, so it is better to close windows and doors.

- The mixture does not have harmful vapors or strong odors, so working even in a completely closed room will not cause any deterioration in well-being.

In order to prepare the mixture according to the instructions on the package, it is best to choose a plastic container. The water into which the powder is gradually poured should be at room temperature 20 - 25 degrees. Do not change the sequence and pour water into the powder, as this can lead to the mixture becoming too liquid, and there will be no excess powder left to correct the error.

The resulting solution must be thoroughly mixed with a drill with a special nozzle or mixer for 5 minutes and let it brew for 5-10 minutes. After that, the solution is mixed again and set to work.

Vetonit plaster

- When working with plaster, the surface cleaned of dust, old coating and dirt, if necessary, is additionally reinforced with a special mesh. Grease and oil stains are removed, irregularities are putty. If the surface of the wall or ceiling is concrete, then a primer must be applied to them in front of the plaster in two layers so that the concrete does not draw moisture from the applied solution.

- Dry powder is added to warm (20 - 25 degrees) water and stirred with a drill or mixer. In order to increase the adhesion coefficient of the plaster, 10% of the water in the solution can be replaced with a liquid primer. Stir the plaster until all the lumps disappear. It is not necessary to insist on such a solution, otherwise it will immediately begin to harden.In the process of working with plaster, you should not add water to the solution; stir it without adding liquid.

Self-leveling floor

- The prepared surface is best treated with a primer of the same brand. If the floor is applied in several layers, then each of them is primed after drying. Such processing will avoid the appearance of air bubbles inside the frozen solution and will improve the adhesion of the self-leveling floor to the base. A solution is prepared in a plastic container or a special silicone container. Pour dry powder into warm water and stir the solution with a drill or mixer.

- The prepared solution should not be left "to infuse", you should use it immediately. Filling is done manually or using special installations in separate strips with a width of 30 to 50 centimeters, starting from the corner. The solution poured onto the base is leveled with a metal spatula. To release random air bubbles from the solution, you can roll a needle roller over an uncured surface.

According to the reviews of real buyers, the products of the Vetonit trademark, at a fairly affordable price, are superior in quality to many analogues in the domestic market. Dry mixes allow you to quickly and easily solve repair and construction issues both in small private apartments and in huge warehouse and industrial premises.

The assortment of goods is so wide that you can choose the material to work in any weather conditions, with any bases and decoration. The ease of use of Vetonit mixtures allows not only professionals to work with them, but also those who are undertaking repairs in their own home for the first time.

In the following video, Vetonit presents a complete solution for the perfect wall in a living room or bedroom.

General terms of delivery and pickup:

- At the moment, pickup does not work!

- when paying on the spot, payment for products occurs before unloading the machine (deposit);

- in case of partial or complete refusal of high-quality and paid products at the time of delivery, the funds are returned to the buyer in proportion to the decrease in the cost of the order;

- when ordering goods by individual size or with cutting to individual size (linoleum, gypsum plasterboard, plywood, cable, rolled metal, etc.), 100% prepayment of the order is made, refusal from quality goods sold by the meter, as well as from goods manufactured by individual size is not possible;

- delivery is carried out daily from 9-00 to 18-00;

- the cost of delivery does not include unloading, lifting, as well as cutting and sawing of materials;

- unloading time is limited depending on the weight of the cargo;

- delivery is carried out to the place where the car can go without violating traffic rules and the risk of damage to the vehicle;

- self-pickup is carried out only after prior agreement with the manager of the online store;

- bulky material (insulation, barrels, etc.) is calculated based on the volume of the cargo;

- additional requirements for the car, for example, a low height for entering a parking lot or an open body for vertical unloading is paid additionally: + 25% to the cost of the standard tariff.

| Weight of cargo | up to 100 kg | up to 500 kg | up to 1 t. | up to 1.5 t. | up to 2 tons. | up to 2.5 t. | up to 3 tons. | up to 4 tons. | up to 5 tons. |

up to 7.5 t. with crane - manipulator |

up to 10 tons with a manipulator crane |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Load length | up to 6 m | up to 6 m | up to 6 m | up to 6 m | up to 6 m | up to 6 m | up to 6 m | up to 6 m | up to 6 m | up to 10 m | up to 10 m |

| Moscow within the Moscow Ring Road | 990₽ | 1300₽ | 1600₽ | 2000₽ | 2400₽ | 2800₽ | 3200₽ | 4000₽ | 5000₽ | 6500₽ | 9000₽ |

| Cost of 1 km outside the Moscow Ring Road | 40₽ | 40₽ | 40₽ | 40₽ | 40₽ | 40₽ | 40₽ | 40₽ | 40₽ | 70₽ | 70₽ |

| Unloading time | up to 15 min | up to 15 min | up to 30 min | up to 30 min | up to 45 min | up to 45 min | up to 45 min | up to 1 hour | up to 1 hour | up to 1 hour | up to 1 hour |

| Simple transport when unloading in 1 hour | 200 | 300 | 300 | 400 | 400 | 400 | 500 | 500 | 500 | 1000 | 1000 |

| Delivery cost may vary under non-standard conditions, wishes and places of unloading. |

The cost of loading and unloading and lifting to the floor

| The weight | Unloading (with lift) | Rise without lift (1st floor) |

|---|---|---|

| up to 300 kg | RUB 2 / kg | 2 rub / kg / floor |

| up to 1000 kg | RUB 1.2 / kg | RUB 1.2 / kg / floor |

| up to 3000 kg | RUB 1.1 / kg | RUB 1.1 / kg / floor |

| up to 5000 kg | 1 rub / kg | 1 rub / kg / floor |

| from 5000 kg | individually | |

| Bulky goods | individually | |

| Drywall / Plywood / Sheets | 50 rubles / sheet / floor | |

| Profile / Reiki / Beam | RUB 30 / piece / floor | |

| Insulation | 30 rubles / package / floor | |

| The unloading cost may vary under non-standard conditions, wishes and unloading places. |

Multichannel phone: +7 (495) 968-73-05

Delivery to regions of Russia:

- delivery to the regions of Russia is carried out by means of the transport company CDEK and PEK 2 times a week;

- the goods are shipped to the transport company only after 100% payment for the order;

- the services of the transport company are fully paid by the buyer upon receipt;

- delivery to TC SDEK and PEC 500 rubles.

- return of goods of proper quality through the shopping mall is carried out at the expense of the Buyer.

Opening hours:

Monday-Saturday: 8:00 am to 7:00 pm

Peculiarities

"Vetonit 5000" is a powder-type leveling compound for floors. The product is semi-finished and needs to be diluted before use. To do this, the powdered leveling agent is poured into a separate container and diluted with clean water at room temperature. Then it is kneaded for one minute to the consistency indicated by the manufacturer on the product packaging.

This composition is the basic leveling agent for cement-sand screeds and concrete analogs. It is compatible with the "warm floor" system (including water) and is a good material for local repairs. The leveling device marked 5000 is suitable for leveling a drop of up to 8 cm. It is a high-quality building material, but it can be applied exclusively by hand.

The leveler is a good base for further floor finishing. On top of it, you can perform the installation of a self-leveling coating or laying tiles and porcelain stoneware. It is characterized by the speed of drying. Subject to the manufacturer's conditions after installation, it will be possible to walk on the surface after 3-4 hours.

It is permissible to carry out further finishing of the floor in 3-5 days. It is undesirable to do this after a day, since the material has a slight shrinkage. Until the coating is completely cured, no further finishing can be carried out.