Application of liquid glass

Liquid glass

The main areas of application for liquid glass are:

- Manufacturing of various types of concrete and cement, unique in their characteristics;

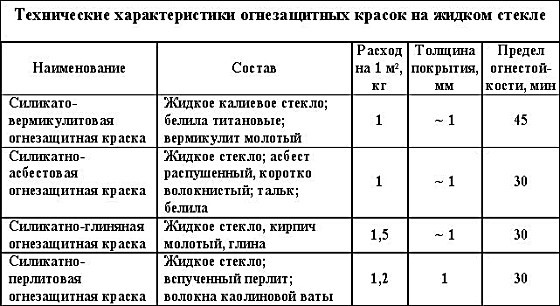

- Manufacturing of fire retardant coatings;

- Soil strengthening;

- Recently - the manufacture of various car polishes;

- Cement waterproofing with liquid glass, which improves the performance of the plaster and concrete layers.

Liquid glass

The use of liquid glass has the following positive effects:

- Leads to an increase in the hardness of the material and its resistance to abrasion;

- Reduces moisture absorption;

- Provides protection of the decorative layer from negative chemical influences.

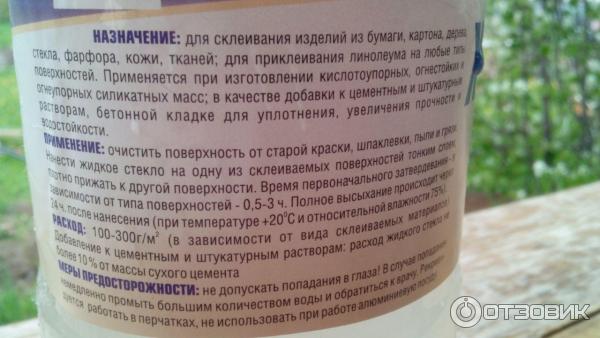

Before use, liquid glass is usually diluted with water (1: 2 ratio). Material consumption is on average 150-300 g / m2.

Impregnation of building structures with liquid glass creates a special protective layer on their surface, restoring weathered areas of the surface of plaster or concrete and creating an antiseptic surface protection.

Let's consider in more detail the main areas of application of liquid glass:

-

There are several types of penetration when liquid glass is processed on a wall surface. Before applying liquid glass to the wall, the surface is carefully leveled and degreased.

For surface impregnation of concrete or plaster layer, use a brush or spray gun, while liquid glass penetrates into the building material to a depth of 1-2 mm. In the case of deep protective impregnation, several layers of liquid glass are applied, which at the same time is capable of penetrating to a depth of up to 20 millimeters.

-

In addition, this material can be used as a material for waterproofing basements and other premises (for example, waterproofing Stekloizol). In this case, it is recommended to add 1 liter of liquid glass to 10 liters of concrete or cement mortar.

Liquid glass can be used both for waterproofing walls and screeds, basements, wells and other building elements and structures.

Also, liquid glass can be used for anti-corrosion treatment of metal. - Liquid glass is also used in the manufacture of fire retardant paints designed to prevent the ignition of various materials. The delivery set of modern fire-retardant paints includes two components that are mixed together immediately before starting work.

Fire retardant paint should be applied to the surface within 6-12 hours from the moment the mixture is received. - Liquid glass is also used to seal the joints of water pipes and to remove old paintwork from any surface.

Liquid glass is also used to create a versatile adhesive that can be used to bond a variety of materials.

Preparation of solutions based on liquid glass

Having decided what glass is in liquid form, you can consider options for preparing the most popular solutions based on it.

Priming solution

From liquid glass, you can prepare a primer mixture for processing bases of various types. For this, the following proportions are observed:

- 2 parts of cement;

- 2 pieces of glass.

The required amount of water is added to the cement, then glass is introduced. The ingredients are mixed with a construction mixer until a viscous mixture is obtained. How long does the finished mixture dry? The curing time is 35 minutes, so the surface treatment starts after the mixture has been prepared. For application, use a soft brush or roller.

Waterproofing agent

To protect the surface from increased moisture, mold and mildew, it is recommended to prepare a waterproofing mixture. For this, an equal amount of ingredients is used:

- 3 pieces of sand;

- 3 parts of Portland cement;

- 3 pieces of glass.

The ingredients must be diluted with water to form a thick mixture. The ready-made solution is suitable for insulating hydraulic structures.

Refractory agent

This solution will protect the surfaces from fire. Prepared in the following proportions:

- 1 part cement;

- 3 pieces of sand;

- 20% glass of the total solution volume;

- water.

First, a cement-sand mixture is mixed on water, then glass is introduced. The ready-made solution is used for fireplace and stove masonry.

Antiseptic solution

Glass based antiseptics prevent bacteria, mildew and mildew from forming on concrete, stone and wood substrates. The solution is prepared as follows:

- 1 piece of glass;

- 1 part water.

A soft roller is used to apply the finished product to the surface.

Impregnating agent

Impregnation for the treatment of wall, ceiling and floor surfaces is prepared as follows:

- 450 g glass;

- 1 liter of water.

How to use the ready-made solution? Surface treatment is carried out in several layers, with each subsequent one applied after the previous one has completely dried.

Types of liquid glass

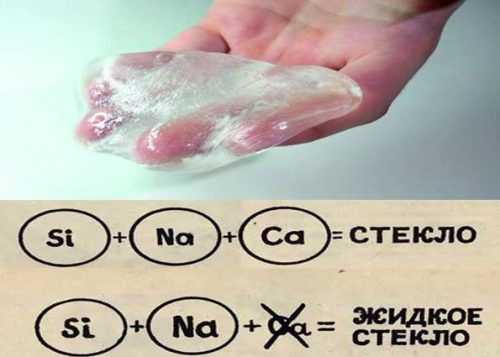

According to the presence of silicate of a certain alkali metal, three types of liquid glass are distinguished.

- Potassium - due to its loose surface, it has increased hygroscopicity. It is more often used in the production of refractory and silicate paints, ensuring their resistance to damaging factors. Good antiseptic properties allow it to be used as an additive against mold and mildew. Contributes to the creation of an anti-reflective surface.

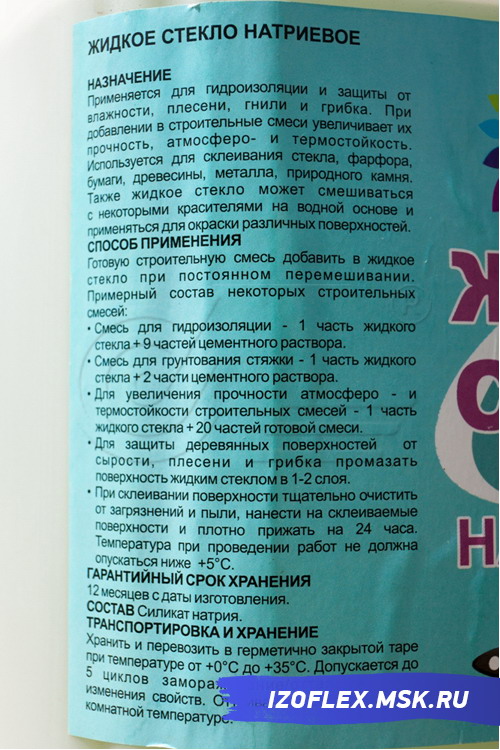

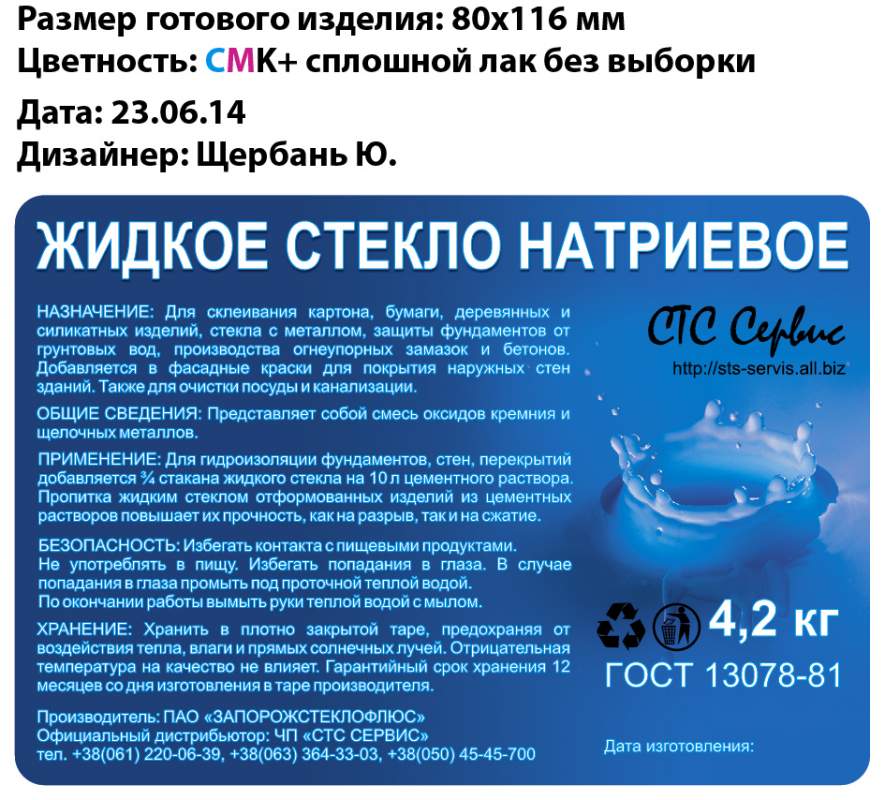

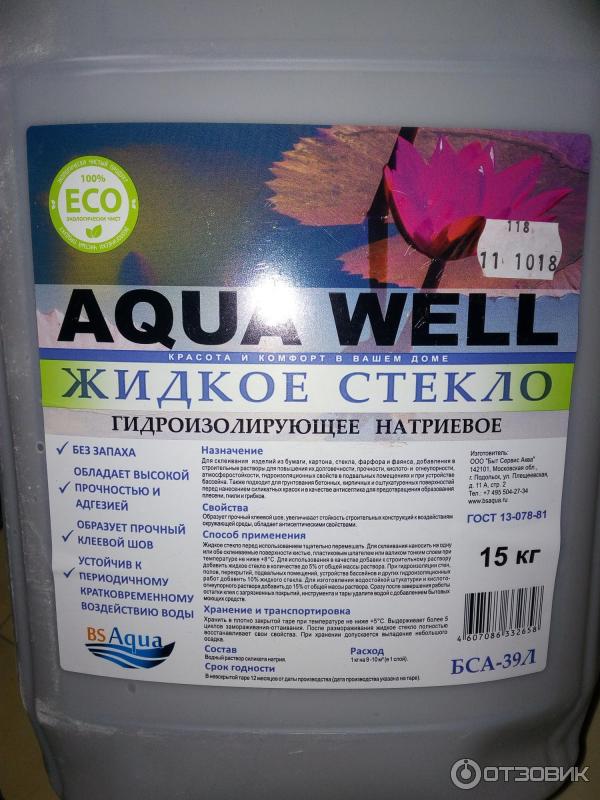

- Sodium - has enhanced strength, high penetrating power, heat-resistant. Priority use as adhesives. The coating created withstands the effects of acids, deforming forces.

- Lithium - based on lithium hydroxide. High adhesive properties, high-quality heat-resistant coating. The scope of application is limited. The surface layers do not form cracks and are excellent weather protection. It is used to create matte surfaces.

Sodium

Known as sodium silicate silicate adhesive. Transparent viscous liquid. When hardened, it forms a layer with high water-repellent properties. It is widely used as waterproofing coatings, the performance of which has been tested for a long time.

Soda water glass is added to adhesive solutions.

Soda water glass is added to adhesive solutions.

It is used in construction, metallurgy, automotive industry, and everyday life. When applied to the surface, it slowly hardens to form a durable protective layer.

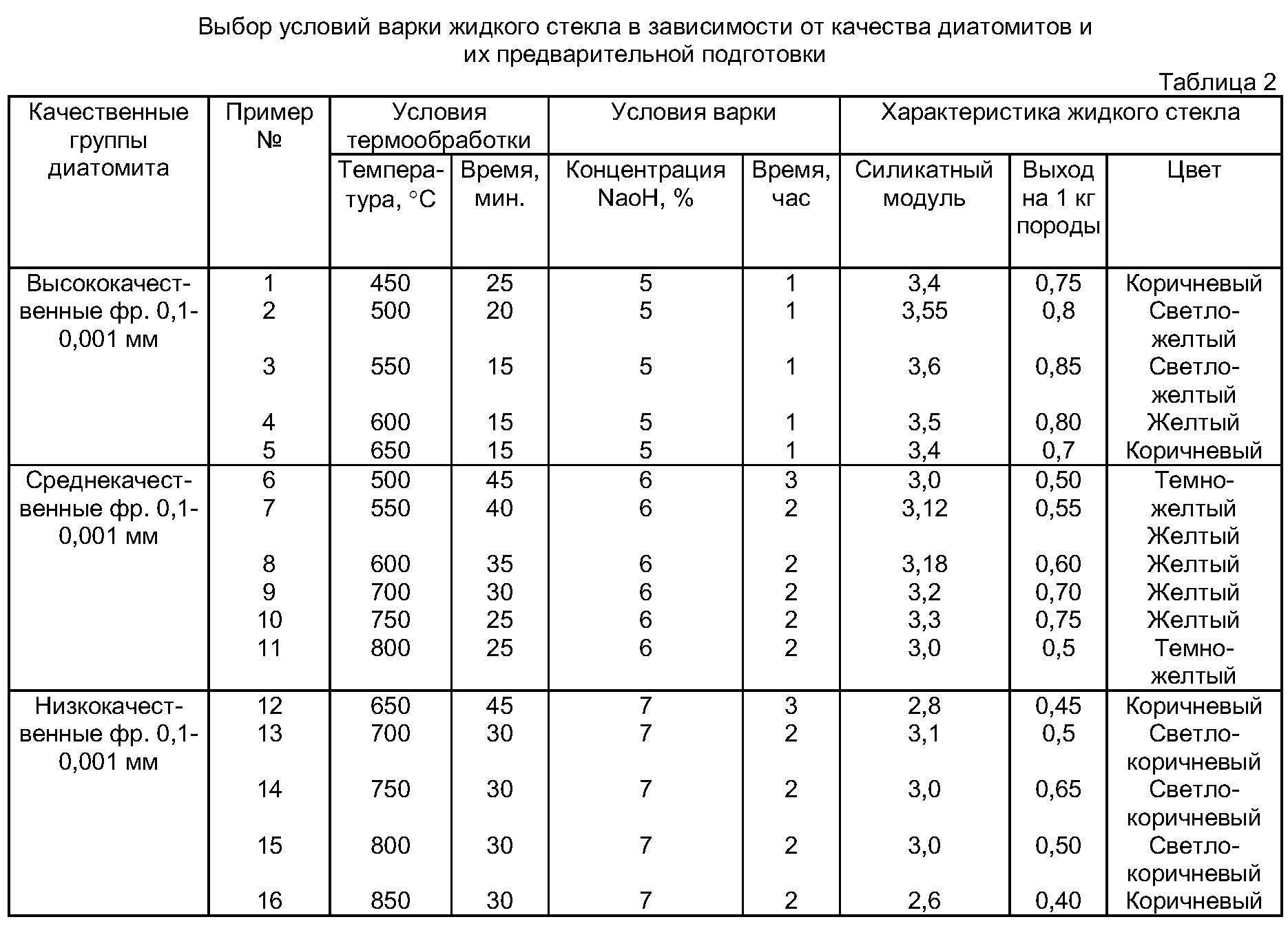

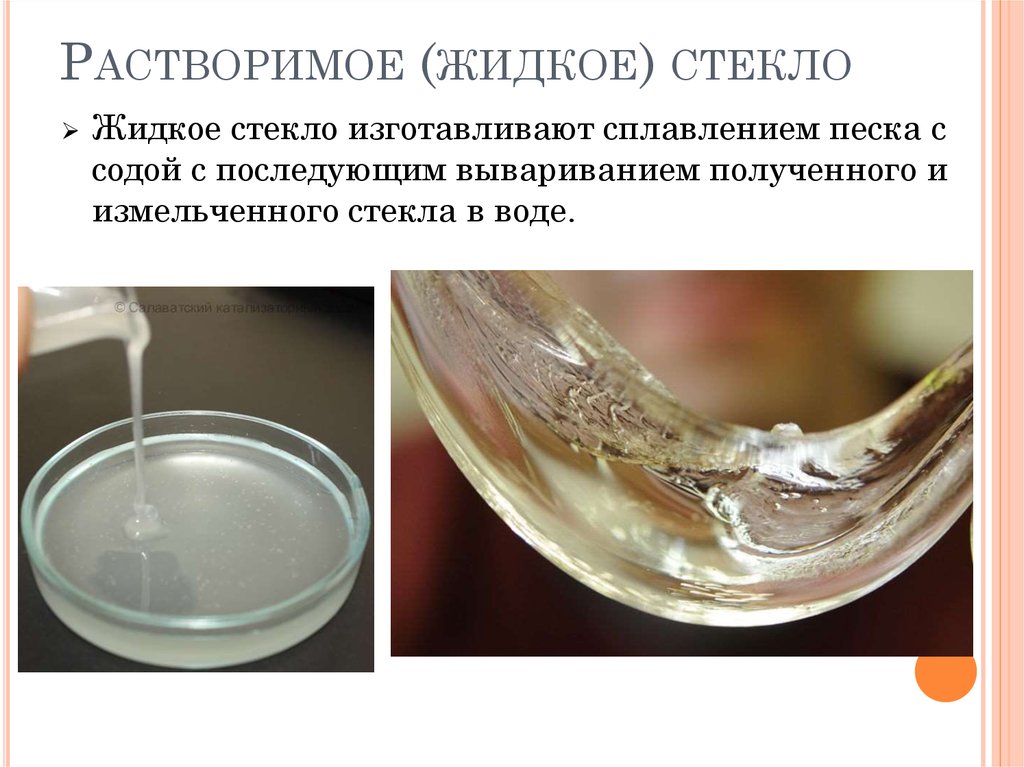

Obtained by melting quartz sand and soda Na2CO3 (sodium sulfate) at a temperature of 1400 degrees. In industrial production, soda glass is first obtained in a solid state in the form of pieces of greenish color. To obtain a liquid solution, silicate lumps are dissolved in water.

The use of sodium glass is much wider, in contrast to other types.

The use of sodium glass is much wider, in contrast to other types.

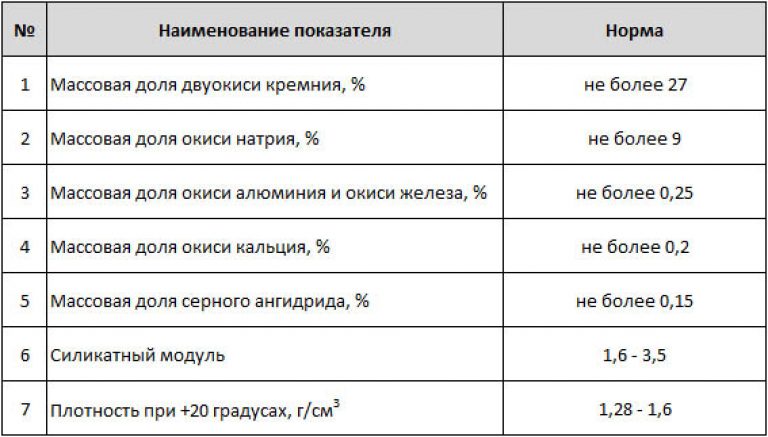

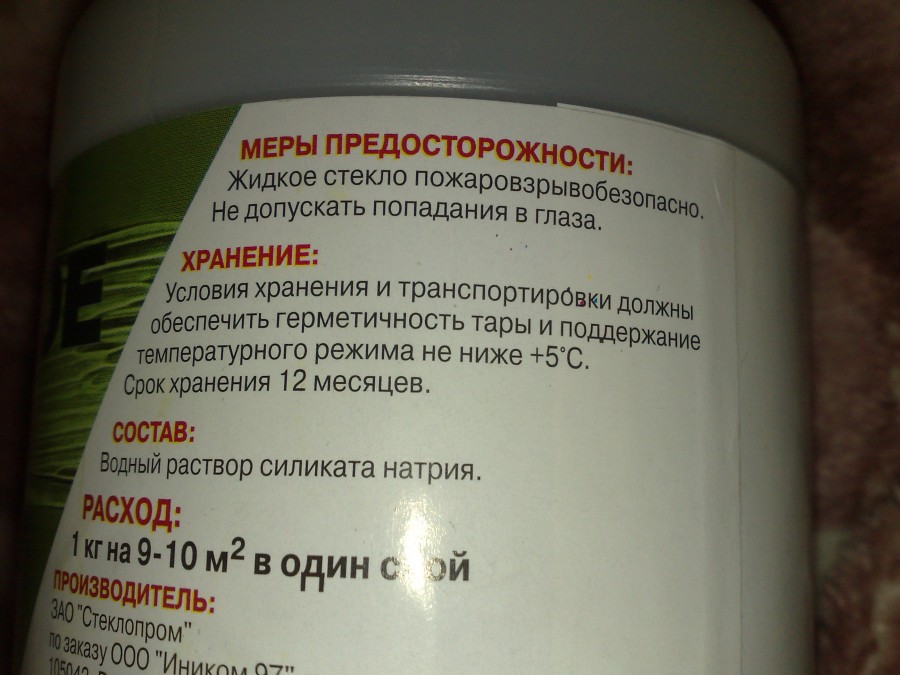

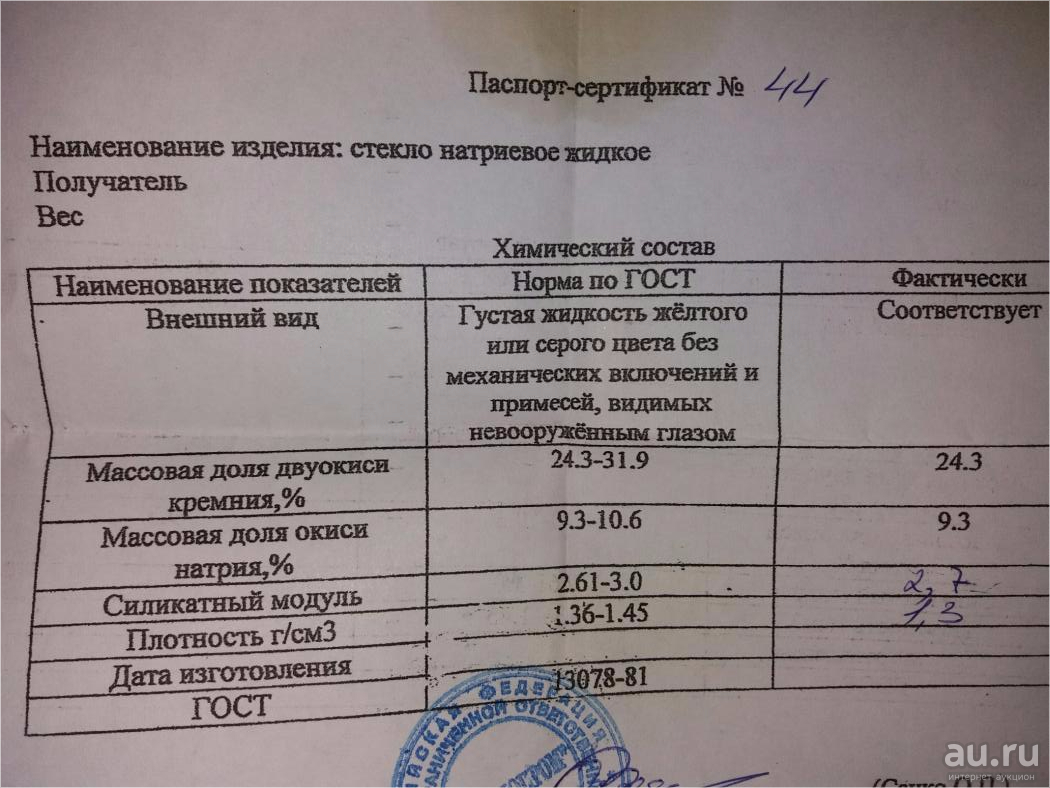

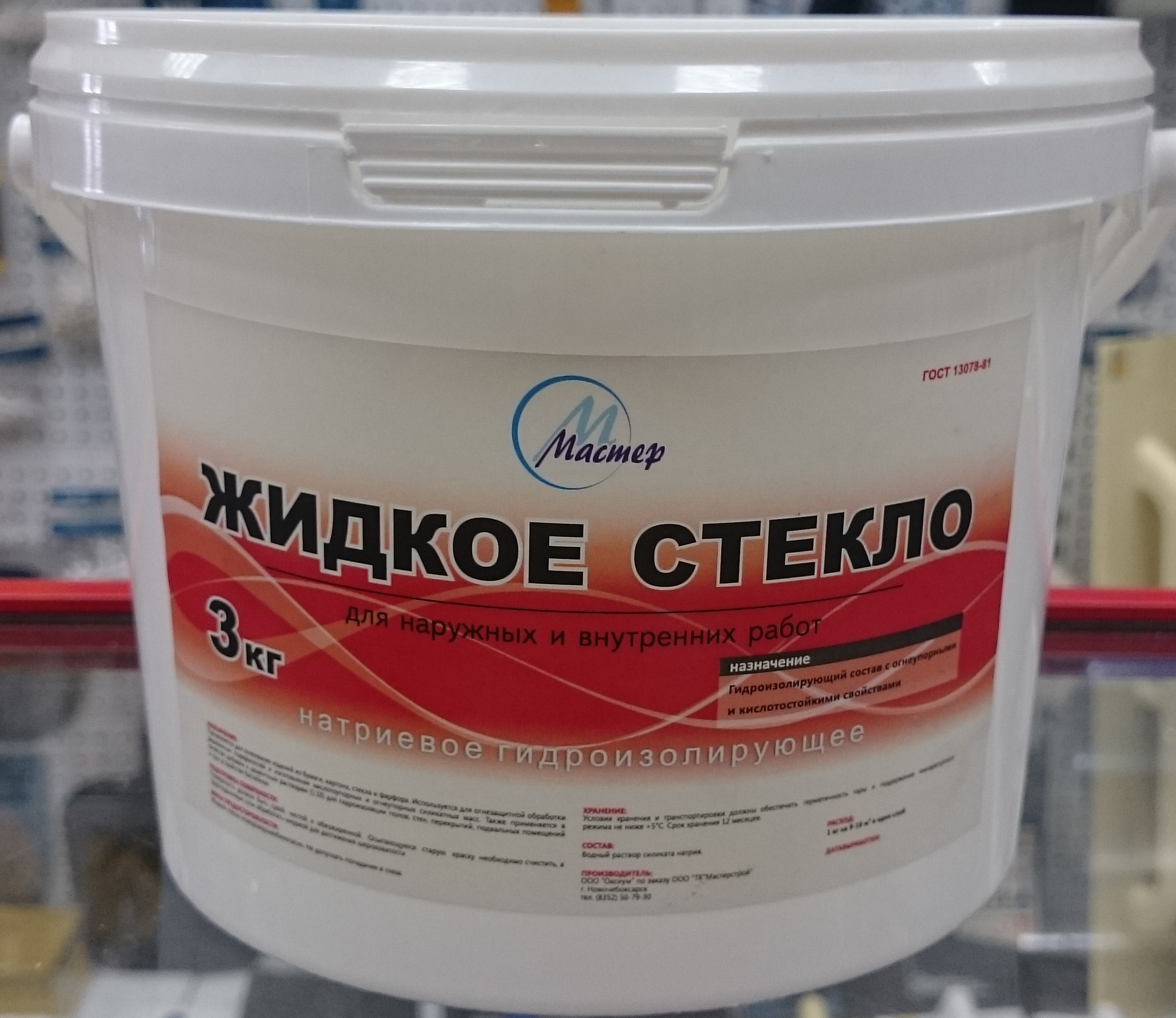

The resulting product must comply with GOST 13078 81 and the following characteristics:

- density - 1.3-1.45 g / cm3

- shelf life - 1 year.

It is produced in containers of various capacities, which allows you not to buy an extra solution.

Protects materials from harmful microorganisms. Relieves static stress. Treated surfaces wear less. Does not react to acids, high temperatures. It is used as a refractory protective compound.

Today, liquid glass is used to protect modern gadgets.

Today, liquid glass is used to protect modern gadgets.

Application in a thin layer ensures economical consumption. It is used for coating concrete and wood surfaces.Due to the porosity of the brick and the threat of its destruction, it is not applied to brick and other similar materials. The waterproofing layer is placed on a pre-primed surface free of dust and debris.

The peculiarity of liquid glass is that it penetrates into the structural elements of the varnish, making the composition durable and protecting it from damage.

The peculiarity of liquid glass is that it penetrates into the structural elements of the varnish, making the composition durable and protecting it from damage.

Potassium

Prepared by a method similar to the preparation of sodium solution. The final product has the same properties as the sodium counterpart. Unlike the latter, it has hygroscopic properties. The hardened layer forms a matte surface. It is part of silicate and refractory paints, significantly enhancing their performance.

Potassium water glass is often included in paints and varnishes.

Potassium water glass is often included in paints and varnishes.

The density is 1.5-1.3 g / cm3. The silicate module for soda glass is 2.0 -3.5, for potash glass it is 3.5-4.5. A higher modulus of glass indicates better quality indicators of a potassium product. Soda glass is cheaper. The common property of potassium and sodium glass is water solubility. The shelf life of potassium silicate solution is 12 months.

Lithium

A transparent solution with a glass modulus of more than 1.5, produced in small batches. Created as a protective thermoregulated material for spacecraft.

Lithium liquid glass has many advantages, the main one being durability.

Lithium liquid glass has many advantages, the main one being durability.

It is obtained by the interaction of an aqueous solution of lithium hydroxide and silicic acid at an elevated temperature. Lithium glass is distinguished by its high adhesion coefficient, long service life, and crack resistance.

How to use?

Instructions for using liquid sodium glass are quite simple. First, everything that flakes off the surface is removed, including old paint. If there are greasy or oil stains on the base, they are also removed, after which dust must be removed, since it prevents any material from fixing to the base. It will simply roll off the surface.

After preliminary cleaning of the base, it is treated with soil, applying it in a uniform layer using a construction roller, and at the joints with a flat brush. After the first coat of primer has dried, another coat can be applied. The application must be uniform. When the second layer dries up, prepare a layer of waterproofing, then spread it over the working base in a thin layer using a spatula.

For more information on the use of sodium liquid glass for a car, see below.

Material application

So, liquid sodium glass is used to solve the following target tasks:

- 1. In the production of building materials, it is used as an additive to impart acid-resistant properties to cement and concrete. The composition has excellent resistance to acidic environments, therefore it is ideal for the intended purpose. Building materials processed with it can be operated without problems in an aggressive environment at chemical plants.

- 2. Also, along with resistance to chemical attack, the substance exhibits excellent characteristics in contact with water. Mortar-treated cement and concrete will not be afraid of moisture, and this applies to both fresh and salty categories. It will be possible to build objects on the banks of rivers and seas, so that part of the structure is under water. This will not affect the strength and stability.

- 3. Another excellent quality is fire resistance. Fabrics soaked in liquid will not burn. Also, on the basis of liquid glass, a special composition is made for processing wood in order to give it resistance to open fire. The substance is also used in the production of refractory paints.

- 4. In agriculture, the composition is used to treat weak soils in order to strengthen them.This procedure significantly reduces the risk of erosion and slows down the process of weathering of the applied fertilizers into the soil composition.

- 5. In the pulp and paper industry, the composition is used as an adhesive.

- 6. Together with quartz sand and other components, it is a raw material for the production of ceramic molds, which are used for casting metal.

- 7. It is used in the manufacture of electrodes to create a protective layer, which will extend the service life of products several times.

- 8. It is added to the composition of polishes for matt surfaces of any type.

- 9. In contact with standard glass, it makes it opaque, and this process is irreversible. So, if you need to darken the windows somewhere, this is a great and cheap way. It is enough just to distribute the liquid evenly over the surface.

What is liquid glass used for in construction

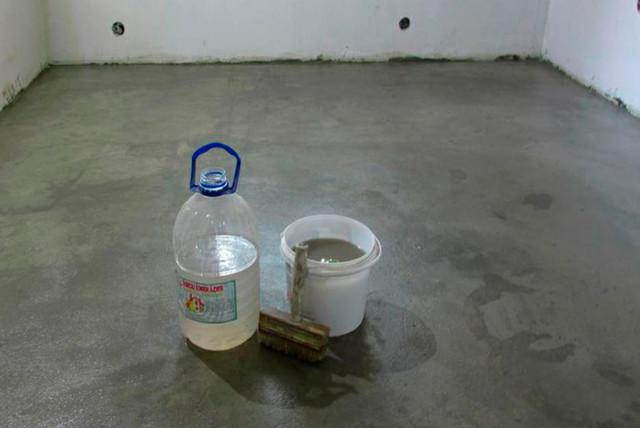

In the construction and repair of residential, warehouse and industrial buildings, liquid glass is most often used as a waterproofing agent. Below is a list of the most common jobs using this composition.

- Applying a waterproofing layer to concrete foundations. The material is diluted in a ratio of 1: 2 and mixed thoroughly. The finished composition is applied to the surface with a roller or brush. The processing technology provides for the application of two layers, the second layer being applied after the first is completely absorbed.

- Hydrophobization of basements and basements... The moisture resistance of the ceiling, walls and floor in a damp basement can be significantly increased by processing the inner surface with a solution of liquid glass prepared in a 1: 2 ratio. Before application, the treated surfaces should be dried using a heat gun or other available method. For greater efficiency, the composition is applied in 2 - 3 layers.

- Modification of concrete mortar. Adding 1 liter of water glass to 100 liters of mortar can significantly increase the moisture resistance of concrete. The composition is thoroughly mixed, which ensures complete mixing of silicate impurities and obtaining a homogeneous working mixture.

- Waterproofing of swimming pools and artificial reservoirs with a concrete bowl. Treatment of the inner surface of the pools with liquid glass allows you to fill the pores and microcracks with a silicate compound, which, after complete polymerization, ensures reliable waterproofing of the bowl. The treatment is carried out in two stages: first, a primer layer is applied, after which the main waterproofing layer is applied. For impregnation, a substance is used diluted with clean water in a 1: 2 ratio. When applying the main layer, the composition is not diluted. For waterproofing 1 m2 of surface, approximately 0.5 l of the substance is required.

- Binding of dust and fine particles. Liquid glass can be used for priming concrete screed. An aqueous solution of the composition penetrates into the concrete structure to a depth of 3 to 5 mm, after which it polymerizes. The hardened silicate composition not only significantly increases the hydrophobicity of the screed, but also binds dust and fine abrasive particles.

- Wood processing. To protect wooden surfaces from moisture, you can use the material diluted with water. Impregnation with a silicate composition will not only reliably protect the wood from the harmful effects of moisture, but also prevent the development of fungi and bacteria.

- Making grout for joints. To seal the joints between ceramic tiles, it is advisable to use a cement-based mixture with the addition of 1/4 of water glass. This grout is not afraid of moisture and has high bactericidal properties, and the addition of various pigments allows you to get the desired shade.

- Preparation of quick-drying adhesive mixtures. When water glass is added to a dry cement-sand mixture, a thick adhesive mass can be obtained, the speed of solidification of which is quite comparable to the speed of solidification of gypsum or alabaster.

- Use as an adhesive. Due to the high adhesion of silicate mixtures, they can be used for gluing pressed cardboard, plywood, chipboard, fiberboard, natural wood and other materials, in particular, porcelain.

-

- Linoleum and carpet flooring. Liquid glass can be used for laying various roll coatings on the subfloor. The main advantages of such mixtures are hydrophobicity and bactericidal properties. The use of silicate glass completely excludes the appearance of mold and other microorganisms under the flooring.

- Antiseptic treatment of trees. During grafting or pruning of branches, through the resulting cut, the tree can be infested with the larvae of harmful insects, and is vulnerable to other adverse effects. To prevent rotting and other undesirable processes, it is enough to treat the cut site with undiluted silicate compound.

- Sealing threaded connections. Undiluted water glass can be used as a sanitary sealant. To do this, you need to apply the composition to the threaded section and assemble the structure. After drying of such a sealant, the connection will have sufficient hydrophobicity, however, even a slight mechanical impact or rotation of the coupling can lead to a depressurization of the connection.

In addition to the above uses, liquid glass has become widespread in the creation of decorative interior items.

Preparation of solutions with liquid glass

It is advisable to purchase ready-made impregnations and mixtures that are designed for specific tasks, but self-mixing of the components will be cheaper, therefore, the necessary solutions are often prepared at the construction site.

Proportions

To prepare a special solution using this substance for various purposes, certain proportions are required. How much to add each substance to a particular solution depends on the scope of the mixture.

Compositions for coloring

The peculiarity of the effect of silicate compositions on pigments limits the number of color options. For the preparation of paints, potassium silicate is used, which, in contrast to sodium silicate, allows a more uniform mixture to be obtained.

Similar compositions are sold ready-made (you only need to mix the two components).

Priming compounds

To obtain a high-quality concrete primer, you need to combine cement and glass in a 1 to 1 ratio, which allows you to significantly strengthen the base. If the surface of the screed is planned to be covered with tiles, the solution is made lighter.

Impregnation of surfaces

To increase the service life of structures and individual products, an aqueous solution of liquid glass is used in a ratio of 1: 5. Impregnation is applied with a brush, roller or spray gun. Individual small elements can be completely immersed in the prepared solution.

Waterproofing compound

To protect concrete surfaces from moisture, a solution is prepared from equal parts of sand, cement and glass. Water is added until a plastic consistency is obtained. This mixture can be used for the treatment of hydraulic structures.

Composition for fire protection

Strengthening the LH of the masonry mortar helps to increase the fire protection effect. The recommended composition of the masonry mortar: cement and sand 1: 3, water is added before the formation of a plastic formation, glass - 20% of the total mass of the mixture. ZhS is added after preparation of the CPR.

Antiseptic composition

To avoid damage to structures by mold, fungi and decay, it is recommended to treat surfaces with an impregnation consisting of equal proportions of water and ZhS.Both reinforced concrete and wooden structures are treated with this impregnation.

Repair composition

To eliminate cracks, seal joints between plates and when pouring a screed, it is necessary to combine the following ingredients: 1 part of ZhS, 1 part of cement and 3 parts of sand. The mixture must be prepared to a sufficiently thick consistency so that it does not flow out of the cracks during work.

Kneading instructions

In order to properly prepare a mixture with the addition of ZhS, you should adhere to the recommendations developed for the compositions used to perform certain types of surface treatment and repair.

Mixing of dry components of the solution is carried out separately, also separately diluted with ZhS with water. Add dry components to the aqueous solution gradually, stirring the layers. If you want to make the mixture more plastic, increase the volume of water.

The subsequent application of liquid glass to the treated areas should be carried out taking into account the finishing technology.

Positive and negative characteristics of the material

The properties of liquid glass, thanks to which this material has become so popular:

- using the material, compositions are created that have the following characteristics: resistant to chemical attack, water resistance, heat resistance, and so on;

- the cost of liquid glass is not high, since the technology of application, production is not complicated;

- the material is safe, has no toxic components;

- the material does not burn, it can be used to create many heat-resistant materials. When heated, it does not emit harmful gases;

- resists ultraviolet rays;

- good antiseptic - resists the appearance of mold and mildew, while killing microbes;

- moisture resistant - the material can be applied at high humidity;

- has a high degree of adhesion to any materials;

- durable, therefore do-it-yourself waterproofing of the foundation with liquid glass is of high quality.

It might be interesting

Like any building material, liquid glass has disadvantages, although there are not many of them:

fast hardening, therefore, when applying the material to large planes, it is necessary to knead often and in small portions;

alkali-based material, therefore, when applying it, you need to protect the skin using protective clothing and gloves

It is especially important to observe this rule when using concentrated solutions.

Preparation of solutions with liquid glass

The stores offer a wide range of ready-made impregnations and mixtures designed for specific jobs. But mixing the components yourself will be much more economical. Therefore, often a solution of the desired consistency is prepared directly at the site and before starting work. In order for the preparation of the solution and its application to meet all the requirements, it is necessary to strictly adhere to the proportions indicated on the package.

Proportions

For the preparation of mixtures of different values, liquid glass is added in the appropriate proportions:

- Priming solution - 2 parts each of Portland cement and water glass

- Waterproofing composition - 3 parts each of sand, cement and glass.

- Refractory - cement and sand 1 to 3, glass 20% of the total volume of the mixture.

- Impregnation for walls, ceilings, floor coverings - for 1 liter of water, 450 g of glass.

- Antiseptic - water and glass in a 1 to 1 ratio.

- For repair work - 1 part of Portland cement and ZhS, 3 parts of sand

Liquid glass for waterproofing: useful tips and safety rules

Specialist advice will be helpful in obtaining good coating properties. And the application will be carried out at the proper level. They advise:

- You cannot use the material for bricks, it will lead to the destruction of its structure, and the answer to the question whether it is possible to apply liquid glass to glass will be no;

- Prepare the solution in small portions, the hardener acts quickly;

- The proportions must be exactly observed.

The master must wear protective gloves and clothing to avoid contact with the skin.

Prepare the solution in small portions, the hardener acts quickly.

Prepare the solution in small portions, the hardener acts quickly.

Liquid glass is the best option for waterproofing different surfaces. Suitable only for concrete and wood, but on them the coating will serve as a reliable layer from water, which serves for a long time. The process must be carried out in compliance with all the rules, otherwise the result will not be of high quality.

Household use

Soda glass is an excellent adhesive composition. It has low consumption and cost. Therefore, you will often find him in any home. It is used for gluing a variety of things: glass, paper or wood.

Cleaning dishes

Many housewives clean their kitchen utensils with a sodium silicate mixture. This method is more effective and affordable than cleaning with commercial products. All carbon deposits disappear if you prepare a solution of water and liquid glass 25/1 and boil your dishes in it.

Removing stains

Liquid glass is an excellent stain remover. Apply a silicate mixture to the stained fabric and leave for 10-15 minutes. The stain should disappear.

Helps in cleaning oil paint and varnish stains from surfaces.

Many water pipe putties are made from soda-lime glass.

Protection for cars

More recently, liquid glass has become in great demand in car care. For this, the car body is treated with special polishes based on sodium silicate. This will reliably protect the surface from water, dirt and scratches.

Tree processing

Experienced gardeners have long used liquid glass to treat cut points near a tree. It disinfects and promotes rapid healing of plants.

Recommendations for use:

- work in gloves and goggles. The product is alkaline and can cause burns on the skin. In case of accidental contact with eyes and unprotected areas of the body, rinse with water.

- good ventilation in places where liquid glass is stored is necessary

- store in a dark place, away from direct sunlight.

- when freezing and thawing, a precipitate appears. At the same time, sodium water glass does not lose its properties.

- upon contact with air, the silicate composition quickly hardens, therefore it is added to the solution before the very beginning of work and is used completely. In some cases, when thickening, it can be diluted with water.

- to increase the service life of surfaces treated with liquid glass, carry out repeated work every 3-5 years.

Korovin Sergey Dmitrievich

Master of Architecture, graduated from the Samara State University of Architecture and Civil Engineering. 11 years of experience in design and construction.

Liquid glass processing of concrete and wood products has been used for a long time. This substance is added to cement, which makes it possible to speed up the process of the mixture rising, it is used for waterproofing basements, for processing swimming pools and other hydraulic structures. Liquid glass in its original state resembles transparent or whitish crystals obtained by melting soda and silicon dioxide in certain proportions under pressure. This material was invented in the 19th century and is still actively used in construction and renovation work due to its unique properties.

To perform construction work, crystals are diluted with water, but most often the material is supplied in industrial packaging. When exposed to open air, ZhS dries instantly, forming a protective film, which allows it to be used for impregnating products and structures in order to provide protection against moisture, fire and decay.

There are several types of liquid glass. They are subdivided according to the basic substance used in the mixture.

Sodium

Formation based on sodium salts is characterized by a viscous structure, high strength and penetrating ability. It perfectly resists open fire, high temperatures, and the composition is also able to maintain its shape even when the base on which it was applied is deformed.

Potassium

This material contains potassium salts. The structure of the mixture is loose, the composition has increased hygroscopicity, forms a matte surface. Potassium formulations are good at resisting excessive heat and deformation.

Lithium

It is used to give the treated surface protection against thermal effects. Produced in small batches. For some works, combined mixtures are used.

Output

Only knowing the features of the use of each composition of liquid glass or solution, you can use the material effectively, for its intended purpose. The sodium and potassium components have 2 advantages that extend the life of the materials - resistance to moisture and deformation. But to achieve the best result, ZhS should be used in combination with other materials. For example, with Portland cement or paintwork materials. With the use of ZhS, the quality characteristics of many materials are increased, the heat and waterproofing characteristics are improved, and additional antiseptic work is not required.

Product description

Liquid sodium glass - thick liquid; the color can range from colorless to yellow or brownish. The color depends on the ratio of silicon and sodium oxides. This ratio is called the silicate modulus and is used in some technological processes that require a specific silicon content in the finished product. From the point of view of chemistry, "liquid glass" is an aqueous alkaline solution of sodium silicate.

Liquid glass is water-soluble, as well as its hardened film; has an alkaline reaction; incompatible with most organic substances; forms hardly soluble silicates with metals.

On an industrial scale, liquid glass is obtained by treating silica-containing raw materials with caustic soda.