Design

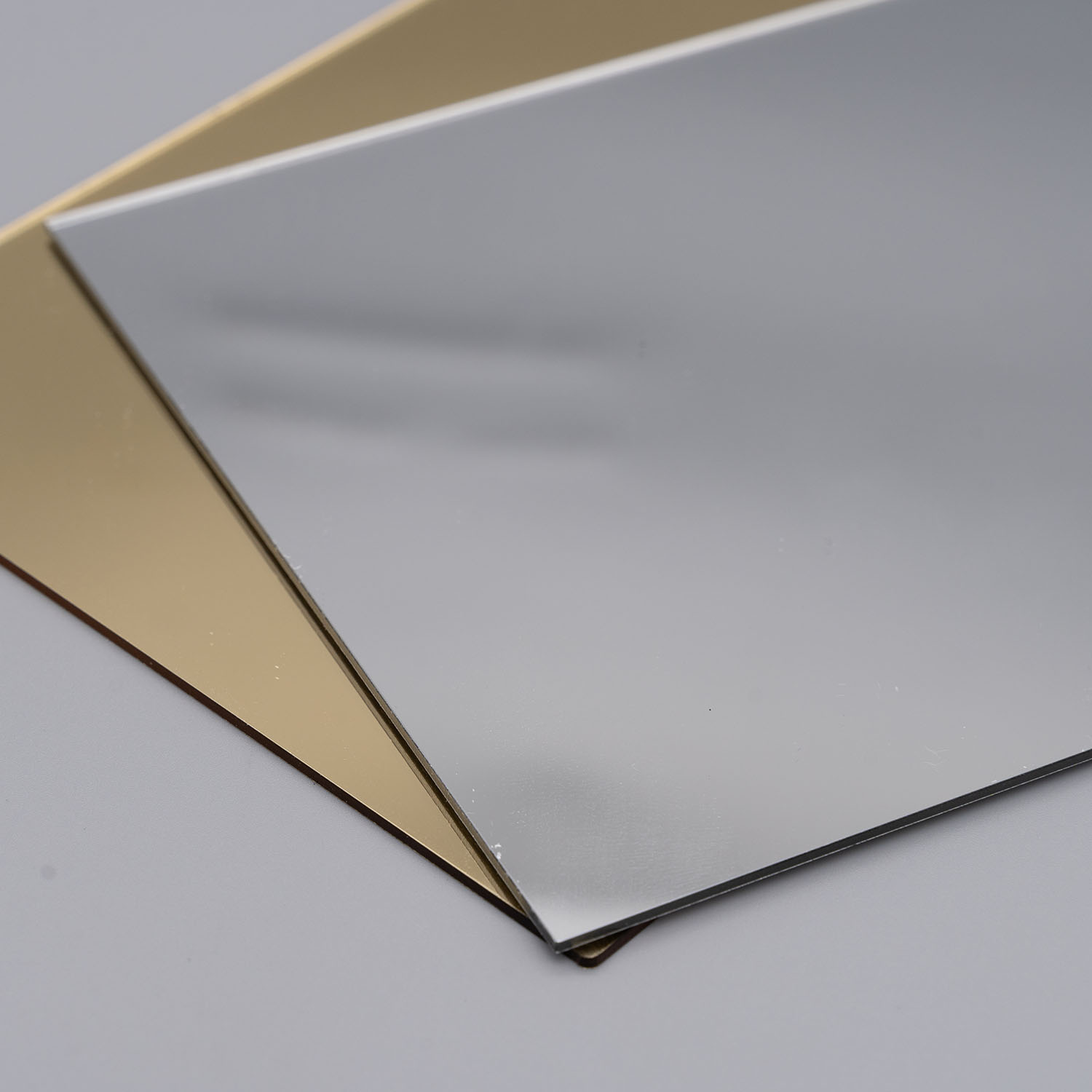

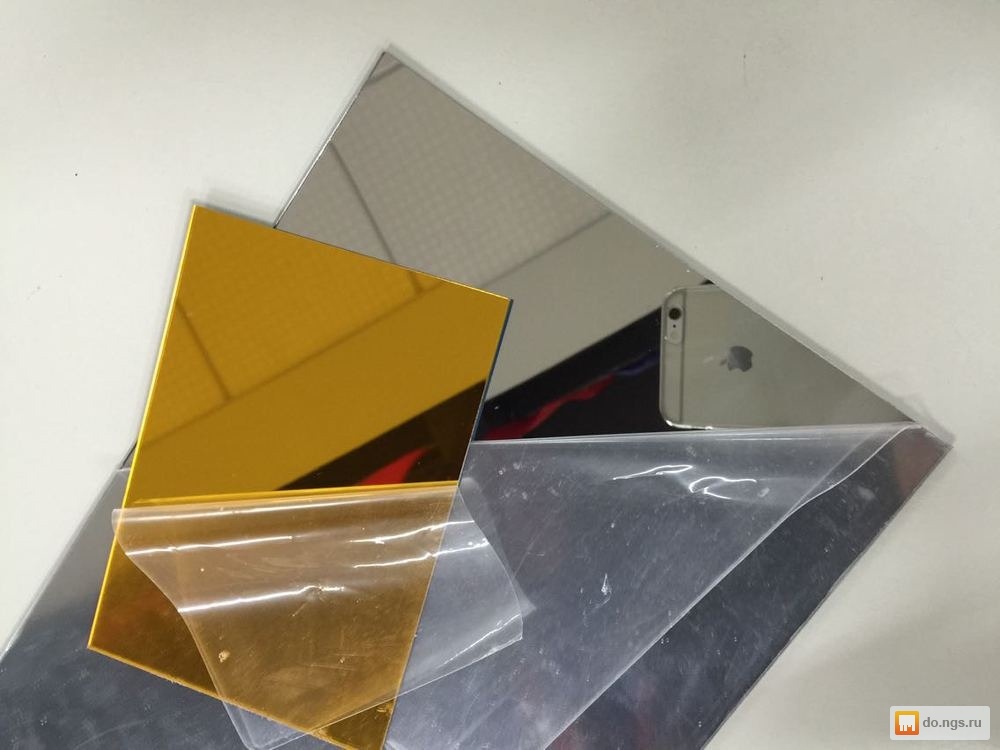

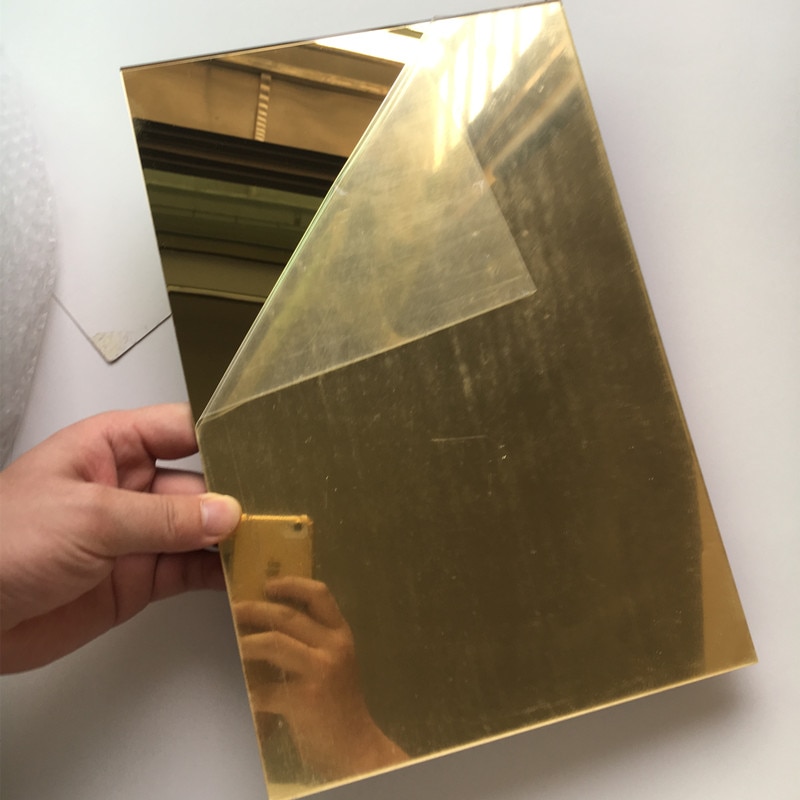

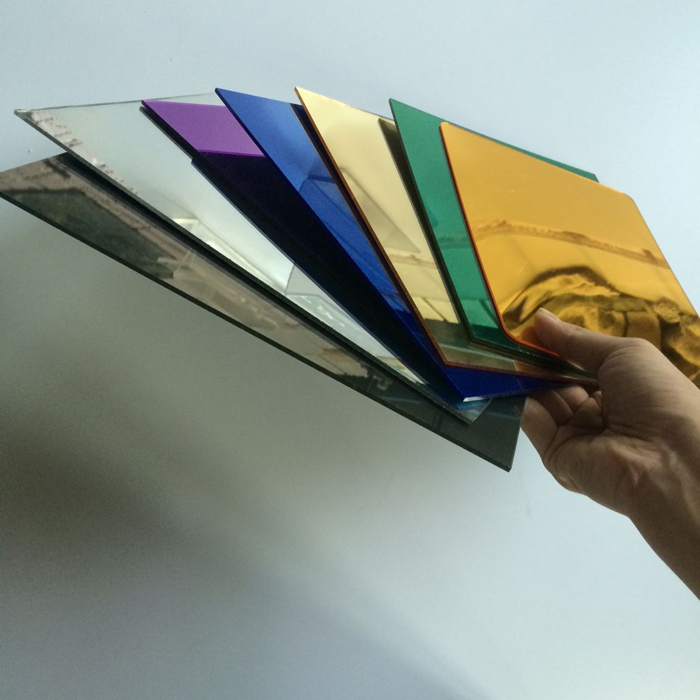

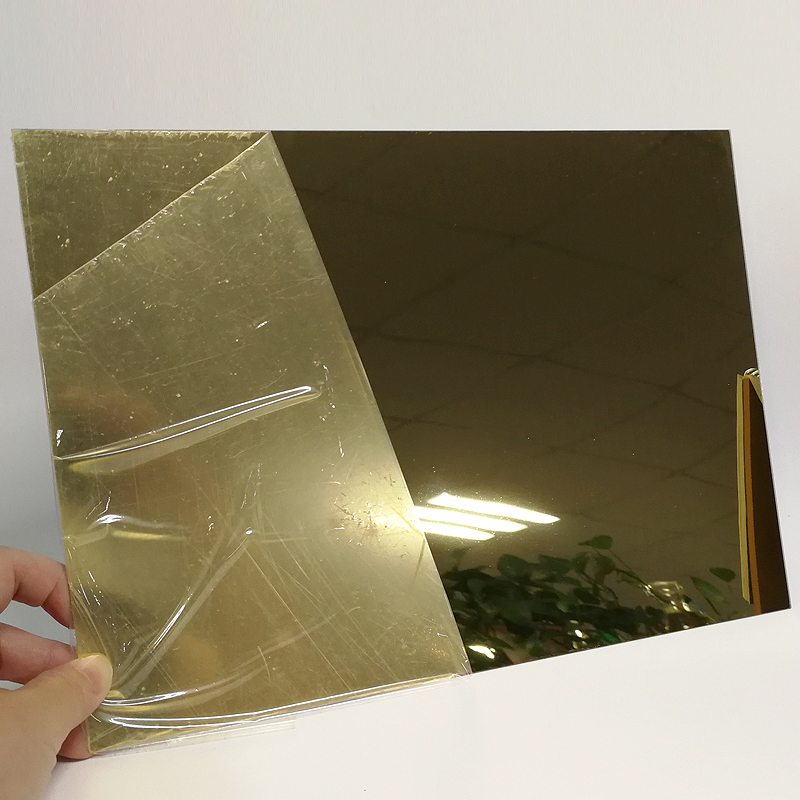

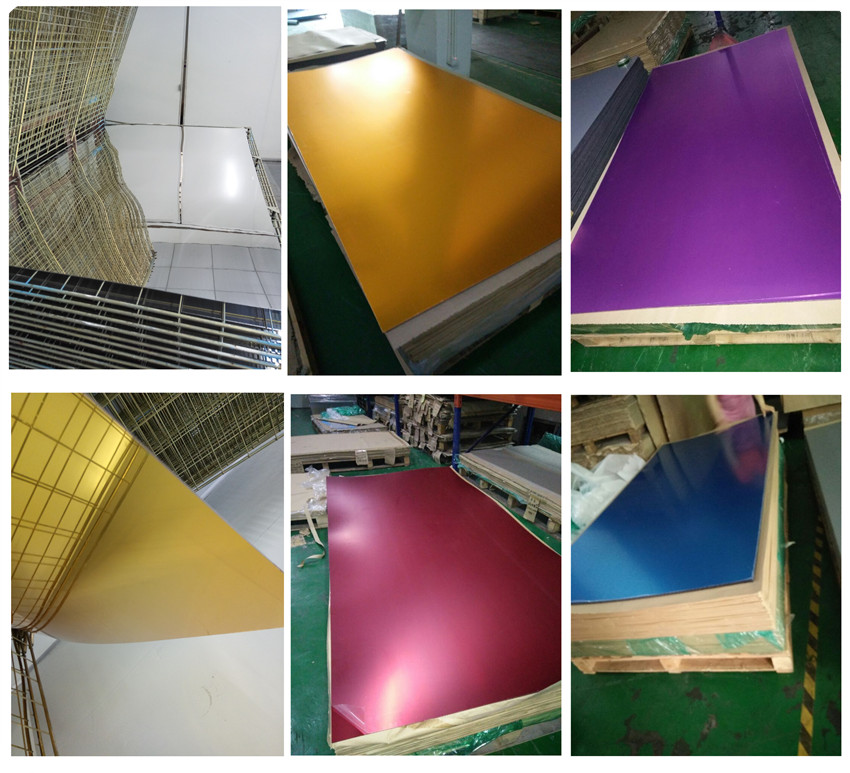

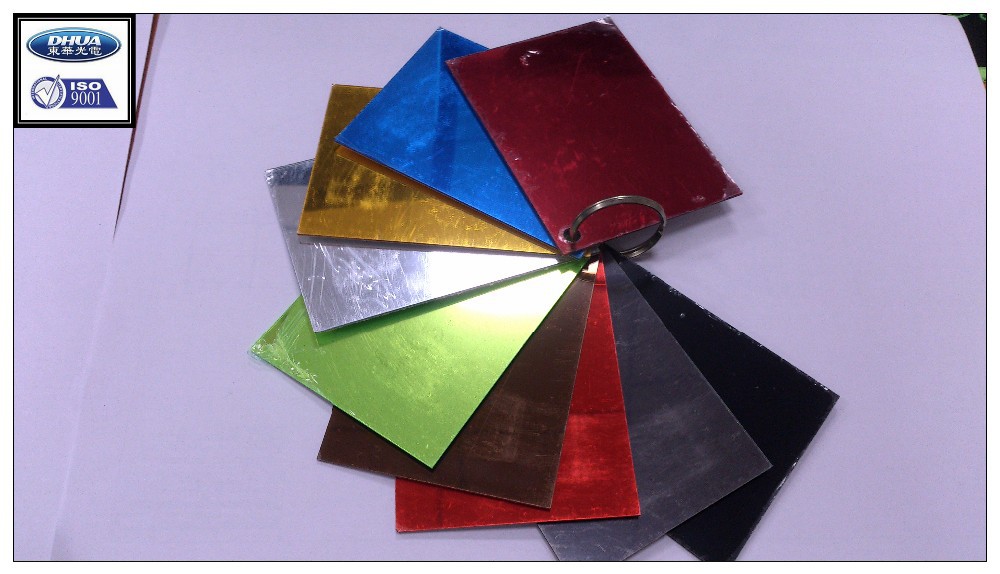

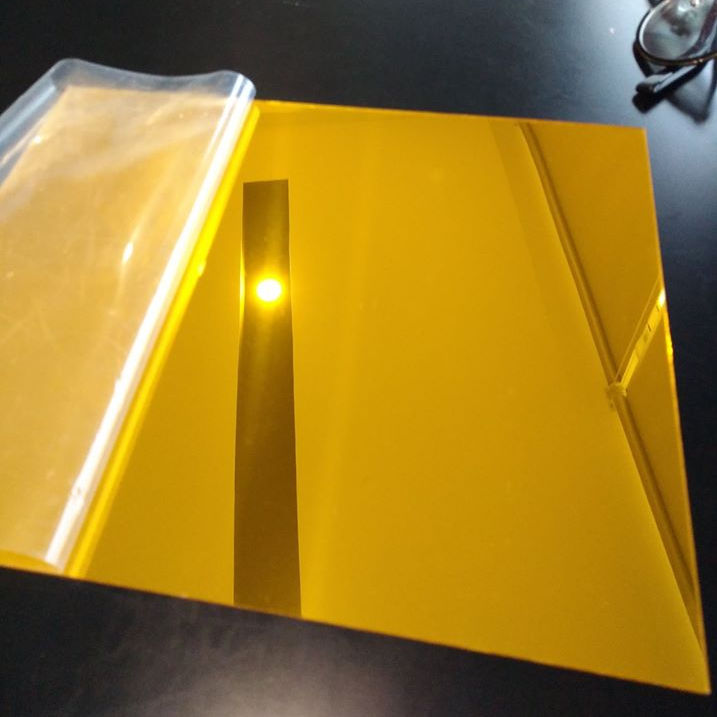

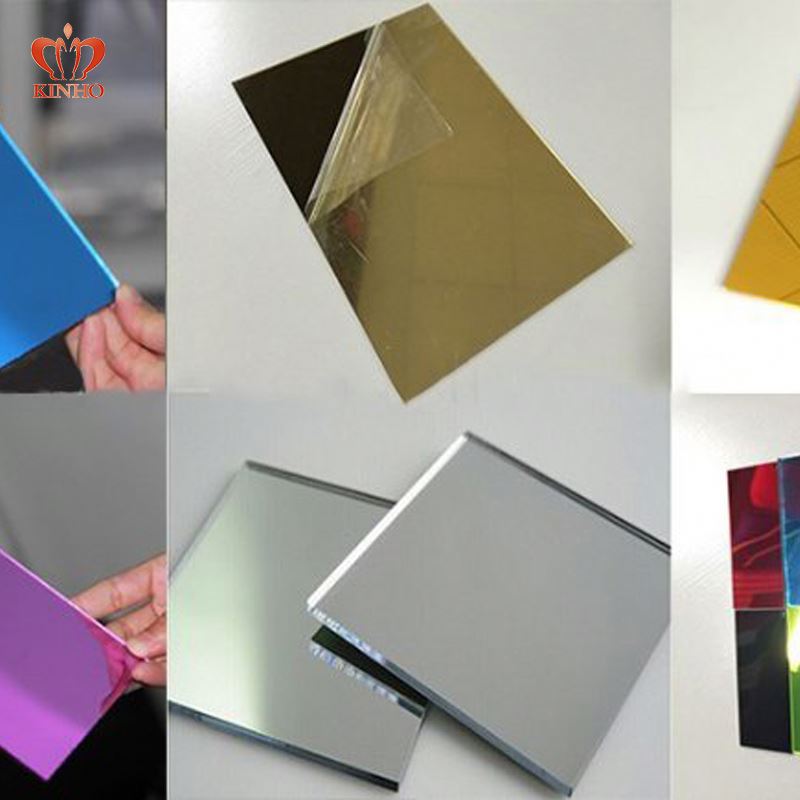

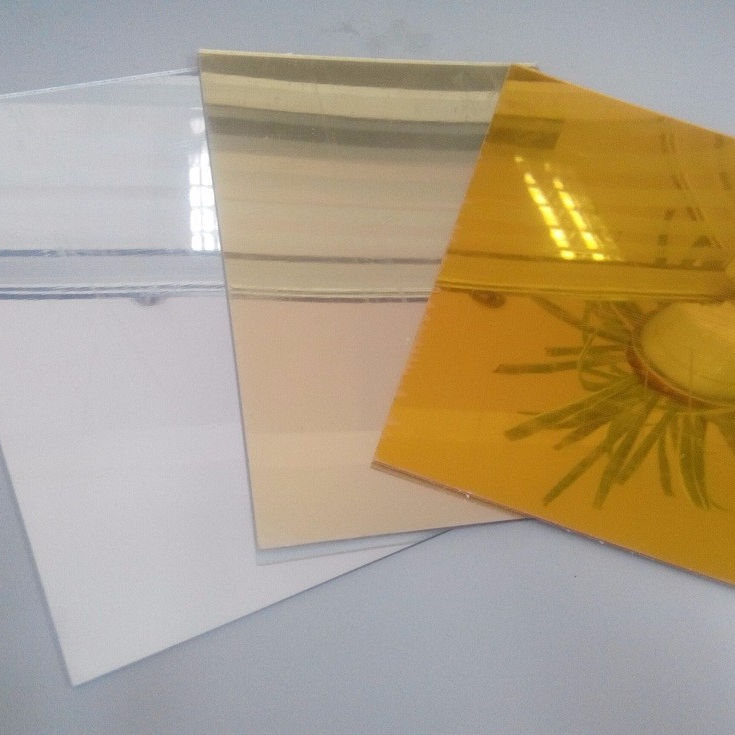

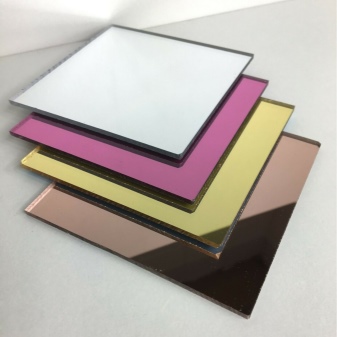

It is wrong to assume that all mirrors are the same - in fact, their reflective coating is made of metal, which gives some reflection. Modern mirrors, including acrylic ones with a transparent layer on top of a reflective one, are made on the basis of aluminum or its analogs, since this metal is white and in fact has no other shade. Such a solution is often called silver, but there is also another “precious” version - gold. In this design, the mirror gives a kind of warmer, slightly yellowish reflection, which can often be seen if letters are made of the material on some office building.

By analogy with "silver" and "gold" mirrors, mirror plastic is now produced in other shades. For the same offices, the black tint has gained immense popularity, when a mirror reflects a picture, but at the same time absorbs most of the light falling on it. Because of this, the reflection can only be seen from a short distance. Only near objects will be in detail, while from afar, the surface will seem just dull shiny.

Applications

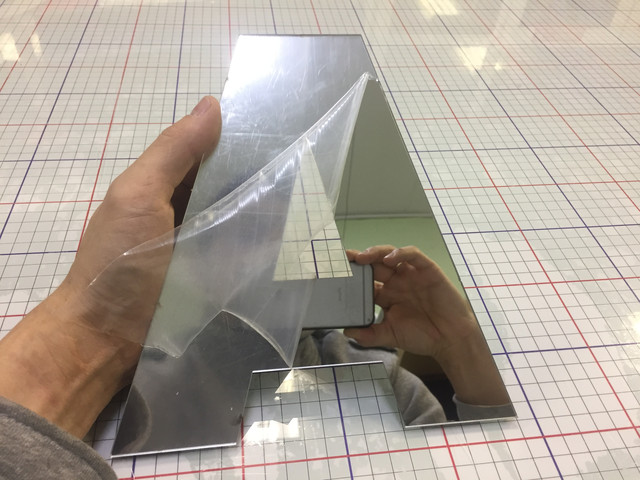

Offices were among the first to use mirror plastic, as well as any other enterprises that have their own showcases and signboards. Bright and effective, and most importantly, the material capable of withstanding the onslaught of the surrounding world quickly became an integral element of the chic of megalopolises - letters and whole figures were cut out of it, they resorted to engraving on top of them, and it turned out so beautifully and attractive that it was simply impossible not to notice such an object.

However, over time, manufacturers and designers realized that mirror plastic would also find a place in the interior of an ordinary apartment. Home solutions, of course, still cannot boast the same chic and in most cases look like an ordinary mirror. However, parents of young children highly appreciate this material for the fact that it generally cracks much less, and even when broken, does not give traumatic fragments.

This fact forced furniture manufacturers to use the material more actively. Today, small table mirrors and large mirror panels are produced from it in the bathroom, such mirrors are also inserted into wardrobes. In the end, this material can be played up in the interior in a different way, finishing the ceiling and walls with it in whole or in fragments.

You can learn how to cut mirror polystyrene from the video below.

Self-adhesive mirror films

Self-adhesive film is a soft and elastic material made of polyvinyl chloride, on the front side it has a metallized coating with a mirror effect, on the back side there is an adhesive layer based on polyacrylate.

Self-adhesive film is a type of mirror plastic

The main purpose of the self-adhesive film is to create a mirror effect at a low cost. The film is unlikely to be suitable as a replacement for a traditional mirror, because even when glued on a flat surface, bubbles, micro-dents may appear, which will result in image distortion.

Decorative self-adhesive film is the material of advertisers. It is cut with ordinary scissors or a stationery knife, although a cutting plotter is used for this in advertising agencies. You can glue it on an uneven surface: wood, metal, plastic, glass. Orafol films are suitable for offset, screen and laser printing. In addition, it is safe and non-toxic.

The disadvantage of vinyl films is that they become brittle and brittle at a temperature of -15C.This limits outdoor adhesion, but does not interfere with the use of self-adhesive films indoors.

In the catalog of materials for advertising from Aluminstroy, buy a metallized ORACAL 352 film with a mirror effect

Pros:

- acceptable price

- can be pasted over any surface

Minuses:

- distortion of reflection,

- on the street will not last very long

Views

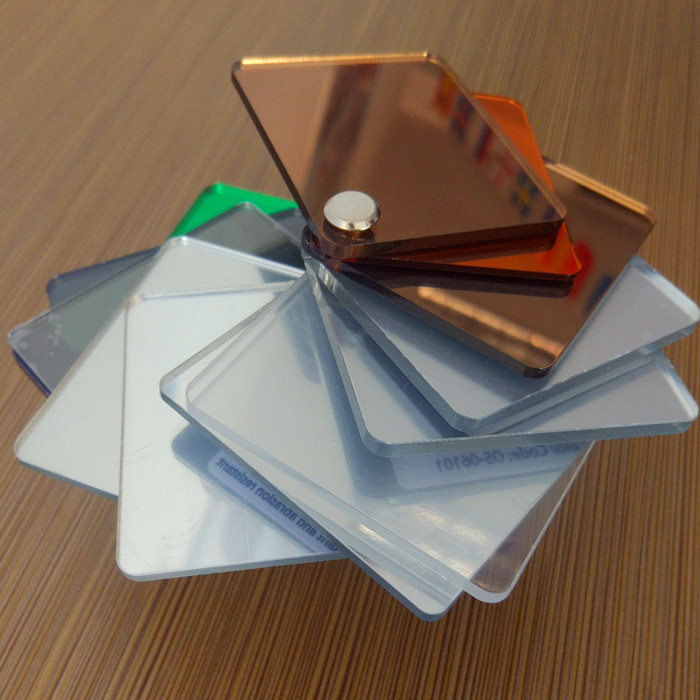

Mirror plastic is not one material, but three different materials at once with different properties. Each of them must be considered separately.

Acrylic

This material is very widespread and has many names - PMMA, polymethyl methacrylate, plexiglass and plexiglass. The above-described advantages and disadvantages of mirror plastic are ideally described by acrylic - all the mentioned pros and cons are presented in approximately equal measure, without distortions.

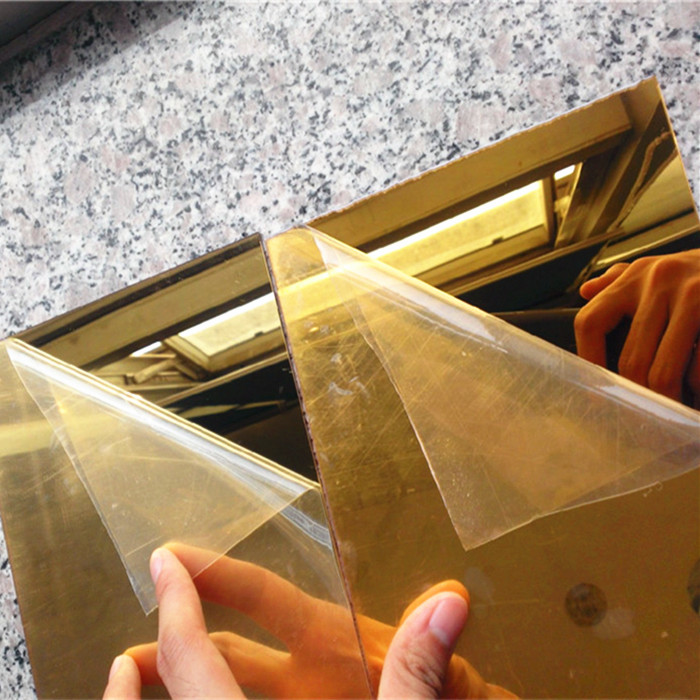

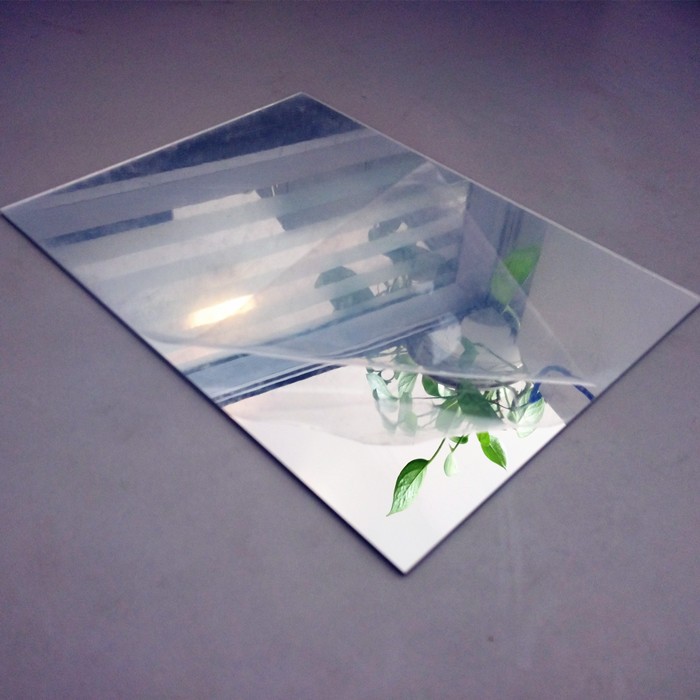

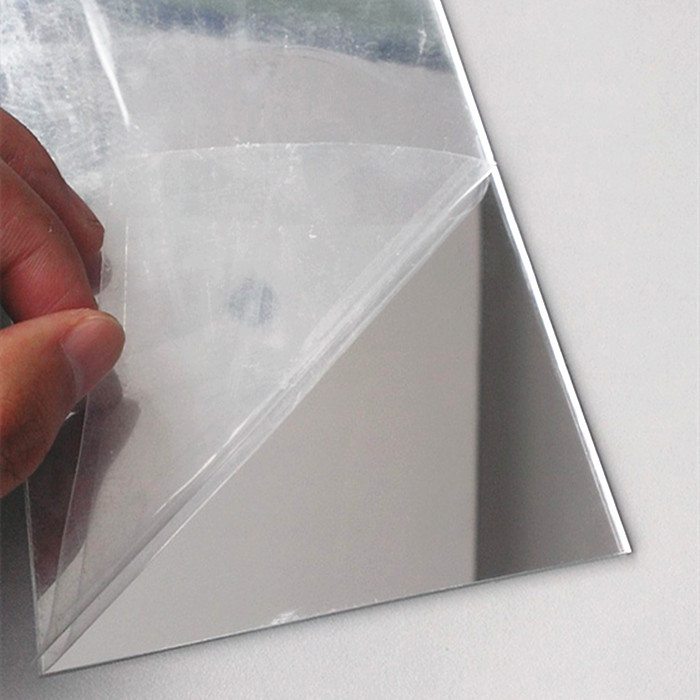

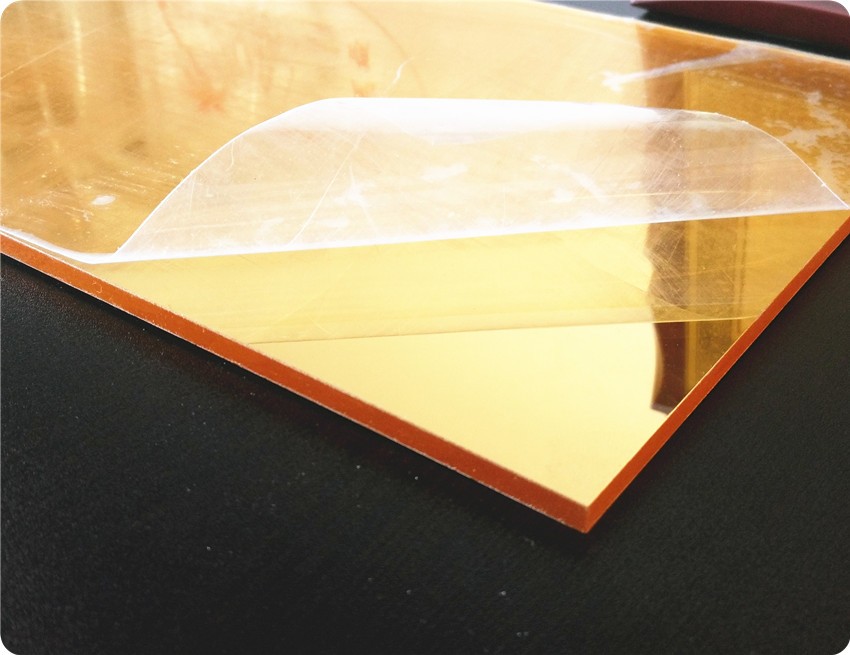

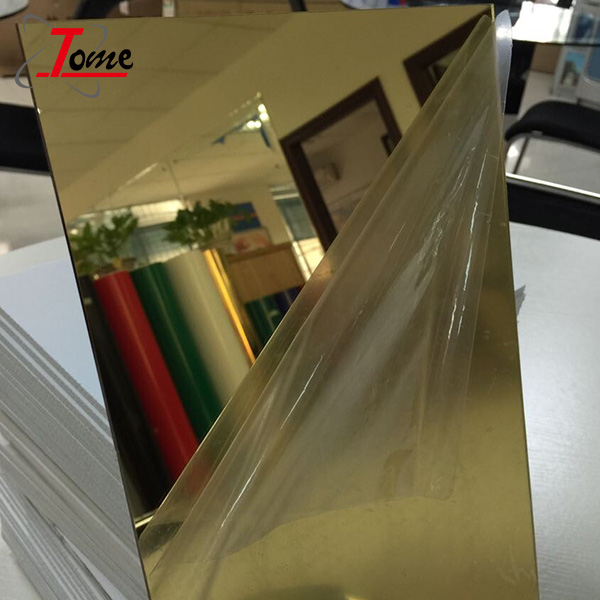

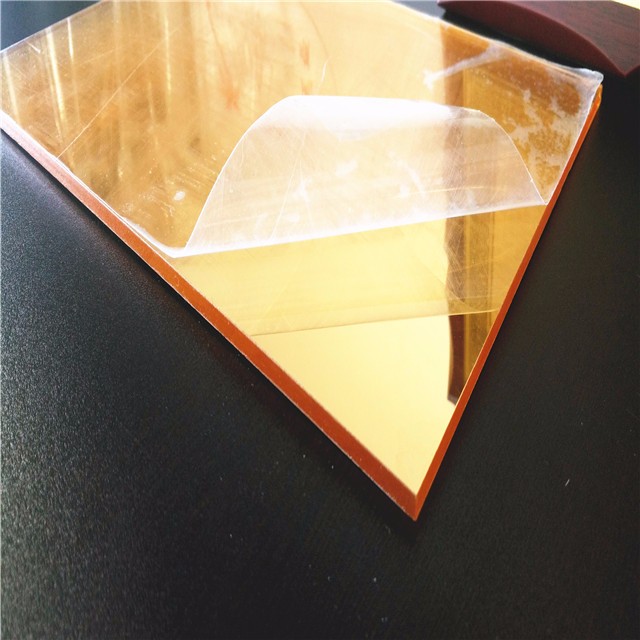

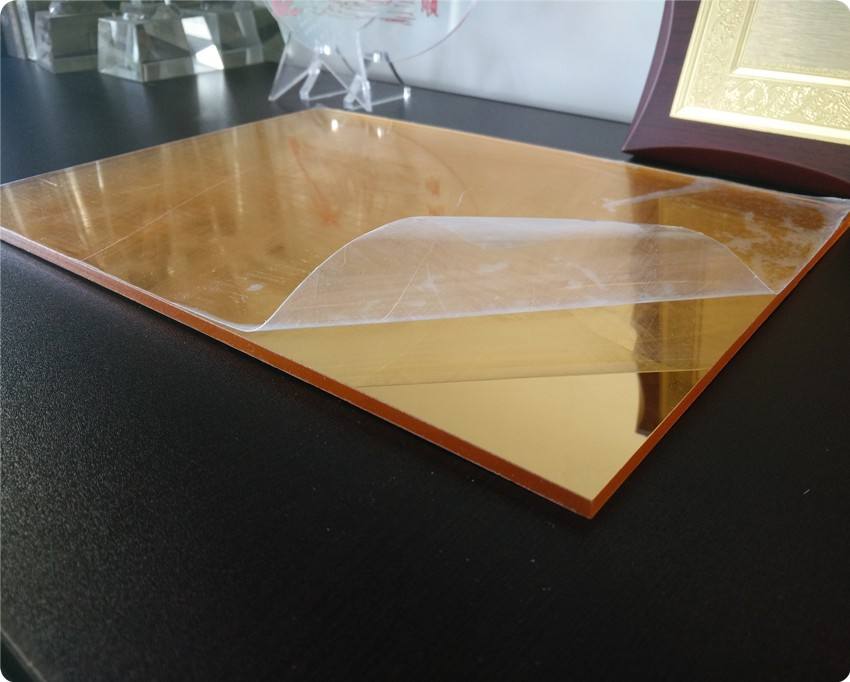

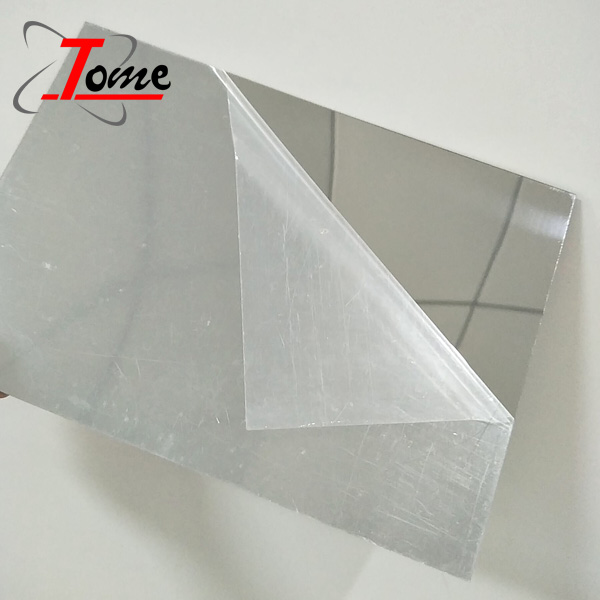

By itself, plexiglass is just an analogue of glass, it does not reflect light. A mirror with his participation is made in the same way as with glass - they take sheet acrylic, and on the reverse side, reflective amalgam is applied to the sheet. After that, the visible surface of the plexiglass is usually additionally covered with a protective film, and the amalgam is painted on the back. Self-adhesive material based on polymethyl methacrylate is also available.

PMMA is quite easy to cut, but the speed of the cutter must be high, otherwise the edge will be uneven. In addition, the cutting site must be cooled in the process, otherwise the edges may melt. The use of acrylic mirrors is quite wide and varied.

Polystyrene

The polystyrene version of mirror plastic is actually a complex polymer of polystyrene and rubber. Thanks to this chemical composition, the material acquires a special shockproof strength - in comparison with it, even plexiglass seems rather soft. Such a mirror is much more reliable in terms of the formation of cracks of any size.

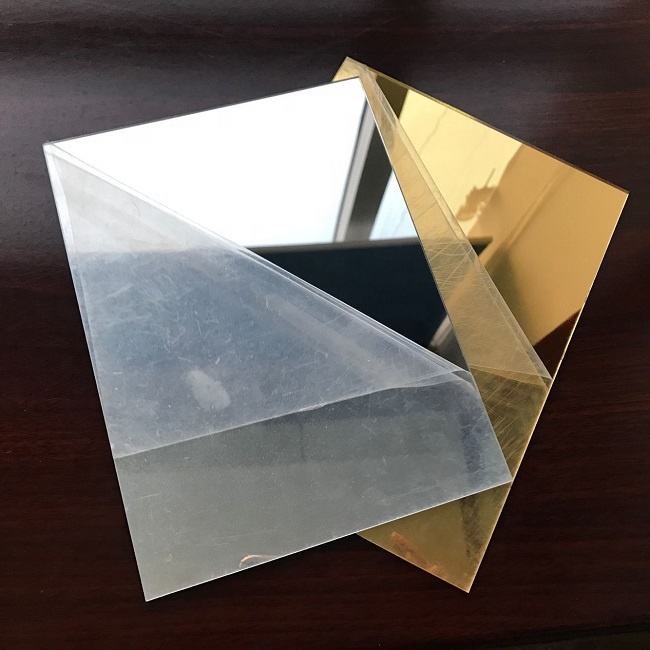

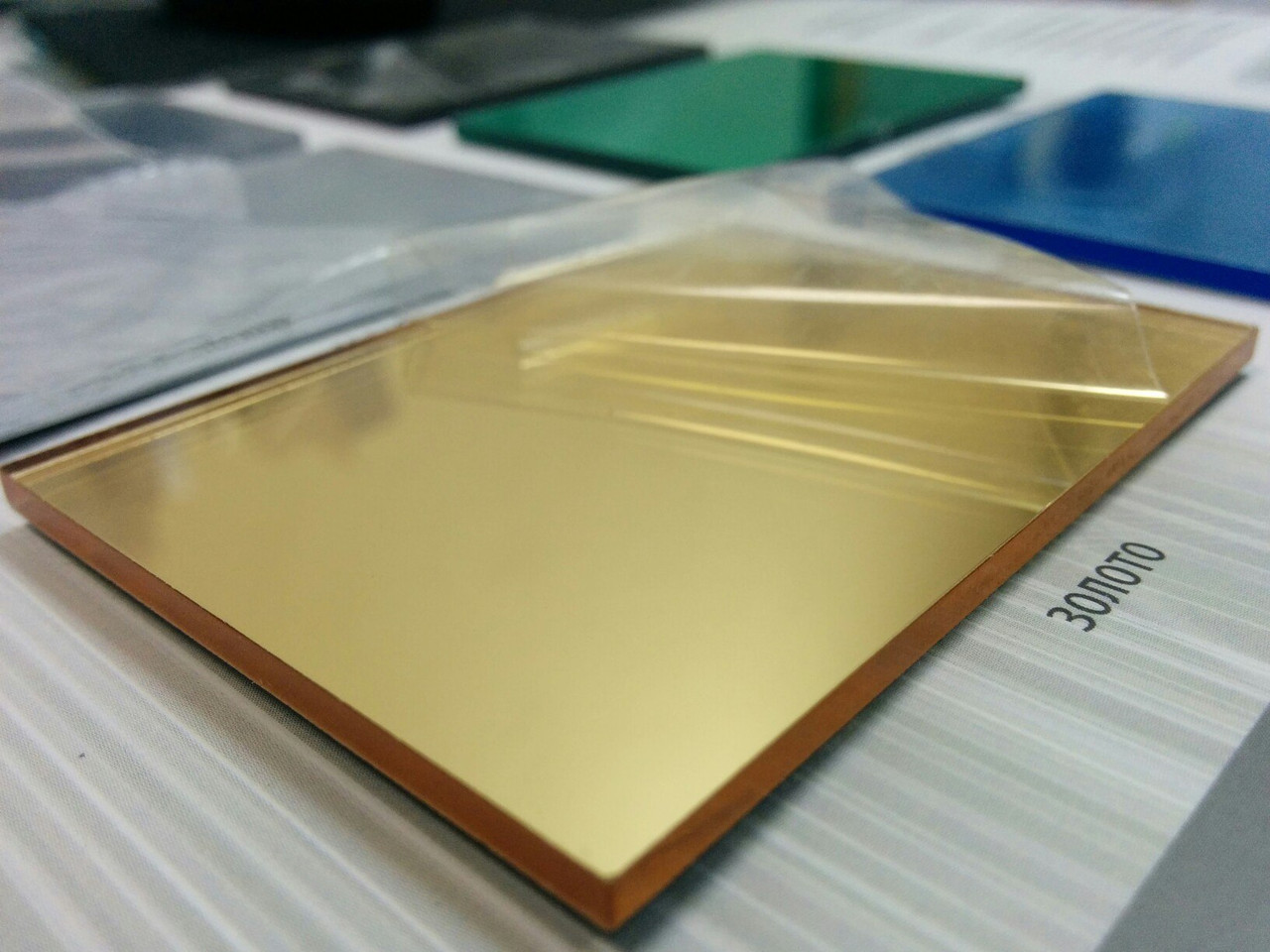

Amalgam is not used in the production of polystyrene-based mirrors - a special polyester film is used to reflect light, on which a thinnest layer of aluminum is applied. In this case, the polystyrene base is generally opaque, and if so, then the reflector is glued precisely from the working side, and not from the back.

Processing of polystyrene mirrors requires great care - otherwise, there is a high risk of peeling off the reflective film from the base. Taking this into account, the film is often specially removed from the cutting line before cutting. At the same time, the material allows printing on its surface with two-component ink. Polystyrene mirrors are good because they have significant flexibility, so they can be used for finishing non-planar surfaces and creating three-dimensional figures.

Polyvinyl chloride

PVC mirrors are made according to the same principle as the polystyrene ones described above: their base is opaque, and therefore hidden from prying eyes, polyvinyl chloride, while the outer side acquires reflective properties due to pasting with a special film, on top of which another one is glued - a protective one.

In addition to the advantages typical for most mirror plastics, PVC mirrors also have the obvious advantage that they do not support combustion. Moreover, it is elastic and flexible, which means that it can be used for finishing surfaces of any complex shape. You can cut such material with any tool without restrictions, while the sheets can not only be glued, but also welded.

It is this material that potentially has every chance of a full-scale conquest of the market, because it is almost impossible to find fault with it. The only reason why it still hasn't won consumer love on a grand scale is that it costs a lot.

Buy mirror plastic

Aluminstroy offers a wide range of advertising materials, including a range of plastics with a reflective mirror surface.You can buy materials for the production of advertising in Moscow or regional offices open in 15 large cities of Russia. We will be glad to see you as regular customers!

Do you have any questions? Ask the manager Aluminstroy. He will call you back at the time specified by you and answer the question, clarify the information and accept the order for advertising materials. "Mirror plastics" can be the subject of a specialist call.

Your message has been sent!

Acrylic mirror

Mirror acrylic, reflective plexiglass, is made by analogy with its prototype - glass, when an amalgam layer is applied to the surface of transparent plastic. However, the resulting material has a number of mechanical and technological advantages and properties in comparison with a classic mirror: the weight is 2-3 times less than that of ordinary glass, and the impact resistance of the acrylic surface is almost 10 times higher

Convenience of mechanical processing of plexiglass, when the material is easily cut with a laser and milled, is an important technological property.

In the photo, the product is made of mirrored acrylic glass

It is difficult to break the acrylic sheet, and the shards have no sharp edges and will not cause harm, so it can be installed in preschool and secondary schools.

However, an acrylic mirror, like any other material, has disadvantages, for example: sensitivity to surface damage and the possible appearance of microcracks. The manufacturer monitors this and usually covers the surface of the canvas with a protective layer. Plexiglas can burn (the ignition temperature is 260 ° C), but it is not dangerous when burning, because does not emit toxic substances.

The main areas of application of this material in advertising: design of expositions, exhibitions, shop windows and points of sale. This material is often used for the manufacture of volumetric mirror letters and logos. Acrylic can be used to make decorations of the most intricate shapes. They can be mounted on thin partitions without worrying about whether the structure can support the weight of a large mirror. Aluminstroy sells Plexiglas XT Mirror acrylic

Pros:

- the most transparent in comparison with other materials,

- not afraid of moisture,

- easy to handle,

- a light weight,

- ease of installation

Minuses:

- vulnerability to superficial damage,

- high price

Advantages and disadvantages

Each type of mirror plastic has its own advantages and disadvantages, but it is not for nothing that different materials are combined into a group with a common name - they have enough in common. If you look at the list of advantages of such materials, it becomes clear why mirror plastic is conquering the market so intensively, because it has the following features:

- does an excellent job with the main task - reflects the light;

- not afraid of ultraviolet radiation or any other external influences, including bad weather and its sudden changes, contact with caustic substances - it does not even turn yellow over time;

- Suitable for use in humid environments, as it is not suitable as a breeding ground for any bacteria;

- weighs less than glass, which allows you to spend less on supporting structures and create stunning "airy" compositions;

- easy to process;

- 100% safe from an environmental point of view, even when burning does not emit toxins;

- is much less afraid of blows than its main competitor.

Nevertheless, ordinary glass mirrors have not disappeared from sale for good, and this is not surprising, because mirror plastic has disadvantages, namely:

easily and rather quickly becomes dirty, and therefore requires regular cleaning;

is flammable, unlike glass, so it should be mounted with caution near electrical appliances and wiring;

it beats with difficulty and does not give sharp fragments, but it is very easily scratched, it can only be cleaned with special non-abrasive agents;

perfectly reflects light, but gives a slightly greater distortion of the "picture" than glass.

Mirror Effect PVC

Mirror polyvinyl chloride (aka PVC or PVC) is another modern polymer material that is highly demanded in the field of construction production and interior decoration.

As in the case of polystyrene, the material consists of a polyvinyl chloride base, a reflective layer that acts as a work surface, and a protective film.

Important technical characteristics of mirror PVC include the following indicators:

- low hygroscopicity. The material does not absorb moisture, does not deform upon prolonged contact with water and can be used in conditions of high humidity;

- resistance to chemically active substances, including acids, alkalis, household and construction chemicals;

- the material does not support combustion;

- polyvinyl chloride has high strength;

- can be processed with any hand and electric tool without restrictions (drills, saws, milling machines, fasteners, and so on);

- the material is very elastic, bends well and takes the shape of the surface on which it is attached;

- the connection of various parts made of mirror plastic can be done both with the help of adhesives and by welding. Mirror PVC plastic on a self-adhesive base is widespread;

- the polymer material complies with modern environmental standards, does not contain heavy metals and does not have a negative effect on the body;

- high density and absence of pores determine good hygienic properties, not susceptibility to fungal attack and the development of microorganisms;

- mirror PVC plastic is very easy to use and not demanding in maintenance. Most chlorine-free chemical detergents can be used to clean the material.

Depending on the thickness, the material can be produced in the form of wall and ceiling panels, self-adhesive tiles, rolls and films. The most famous producing countries of PVC mirror plastic are Italy, Germany, Austria, China and Russia.

Dimensions (edit)

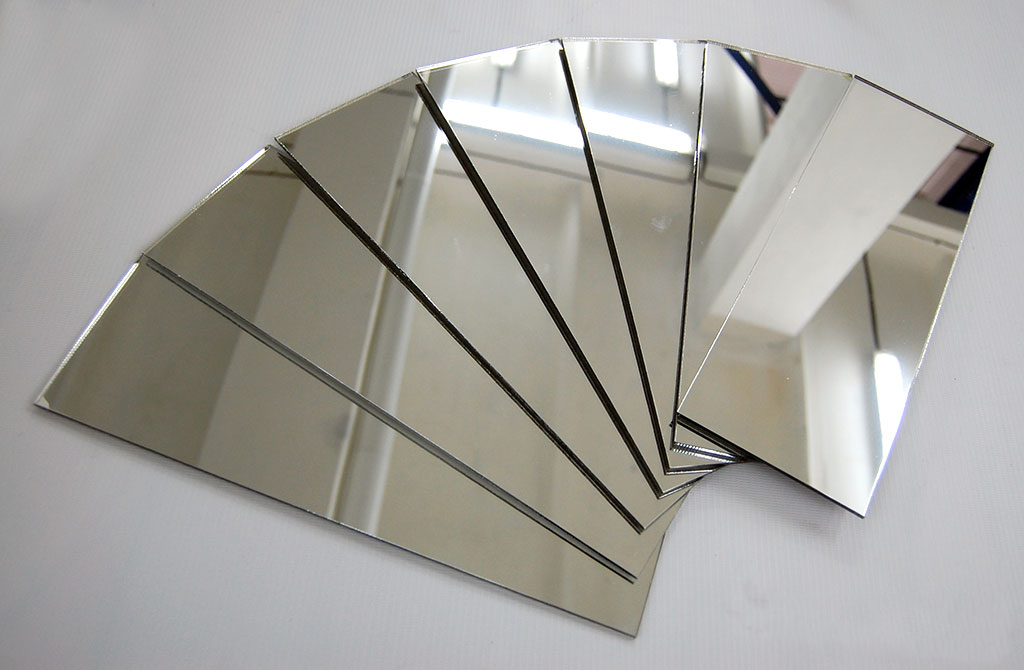

The variety of sizes of mirror plastic is enormous, considering that these are different materials, which are also produced by numerous manufacturers around the globe. For example, polymethyl methacrylate can be found in sheets of various sizes and shapes, but with dimensions of no more than 305 by 205 cm. The thickness is relatively small - only 2-3 mm. The adhesive base may or may not be present.

Mirror polystyrene, despite its flexibility, is also sold not in roll form, but in sheets. At the same time, the fragments are slightly smaller - it is difficult to find a sheet larger than 300 by 122 cm on sale. The thickness of the product ranges from 1 to 3 mm and here you still need to think about the choice: a too large sheet a priori cannot be thin, but an increase in thickness negatively affects flexibility and increases fragility.

PVC sheets of a standard type are characterized by a small thickness - often at the level of 1 mm. At the same time, their sizes are the most modest - up to 100 by 260 cm.

What it is?

The very name of the material (or rather, the group of materials) already fully reveals the essence of what it is. Mirror plastic is a laboratory-created polymer that is so highly reflective that it looks like a mirror from the outside. The logic of using such a material lies on the surface: a plastic product often turns out to be stronger against impacts, in addition, it is safer due to the fact that it does not give sharp fragments when destroyed.

Mirror plastic is also often called plexiglass, although the second concept is broader - it means any materials that resemble glass, but they can also be transparent, while the material we are considering reflects surrounding objects no worse than a real mirror.

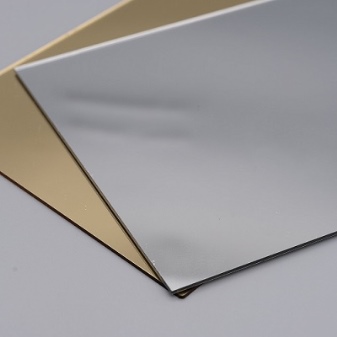

Mirror Coated Aluminum Composite Panel

Aluminum composite panels are used where there are no special requirements for the quality of the reflective surface, but it is required to cover a large area, or flexibility, strength, and rigidity of the structure are required.

Advertising Application of Mirror Aluminum Composite Panel

Mirror panels - for interior design: for wall cladding or ceilings. Composite panels are the main material for outdoor advertising, decoration of exhibition stands, racks, entrance groups. Whole advertising structures can be created from the panels in combination with other mirror plastics, they bend at right angles and keep their shape well. The composite is resistant to high and low temperatures, is often used for outdoor campaign and promotion products.

Aluminum composite panels with a mirror surface can imitate gilding, silver and gloss, or have a matte or "scratched" surface. Such surfaces do not give a deep mirror reflection, but outwardly increase the space, and in addition to an interesting expressive effect, they also give insensitivity to fingerprints and scratches. Mirror composite panels are presented in the catalog of advertising materials Aluminstroy.

Pros:

- durable

- flexible,

- frost and heat resistant,

- easy to machine

Cons: poor mirror surface quality