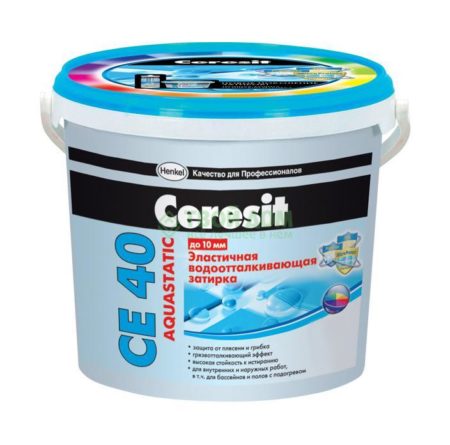

Ceresit grout

The Ceresit brand has many positive reviews and has a solid position in the construction market. Ceresit grout is sold dry. To mix the grout, see the table on the package. It has a rich color gamut and many uses: for the street, for rooms with high humidity, for rooms with sudden temperature changes, for direct sunlight. Grout palette Ceresit Grout properties:

Grout palette Ceresit Grout properties:

- Grout sets in the shortest possible time.

- Does not paint the edges of gypsum tiles like brick or stone.

- The composition includes components that prevent the occurrence of fungus.

- Safe for humans and animals.

The price of grouting for joints is 450 rubles. To apply the grout, it is necessary that the joints are dry and the glue dry. The gypsum tile should fit snugly against the substrate.

The grout should be poured in the required amount with cold water and mixed until smooth. The solution should stand for 3 minutes, mix it thoroughly again. Do not pour a large amount of water into the dry mixture, this will deteriorate the characteristics of the mixture. Ceresit grouting mixture It should be slightly pressed inward so that the air trapped in it escapes. If the grout gets on the gypsum tiles, it should be removed immediately with a wet sponge or rag. The grout will harden quickly and the face of the tile will be damaged.

Ceresit grouting mixture It should be slightly pressed inward so that the air trapped in it escapes. If the grout gets on the gypsum tiles, it should be removed immediately with a wet sponge or rag. The grout will harden quickly and the face of the tile will be damaged.

All grouting work should be carried out at temperatures up to +30 degrees in a dry room. When using a cement-based grout, a test should be done first as it contains alkali.

Preparatory activities

The jointing can be carried out immediately after the brick has been laid or after the walls have been erected. In the first case, the bricklayer brings the masonry back into proper form after several rows have been passed and the mortar begins to set.

In the second case, when laying, the master leaves the outer part of the seam empty for subsequent filling with a jointing mixture, and they begin to refine the walls after a certain time, necessary for the complete shrinkage of the masonry.

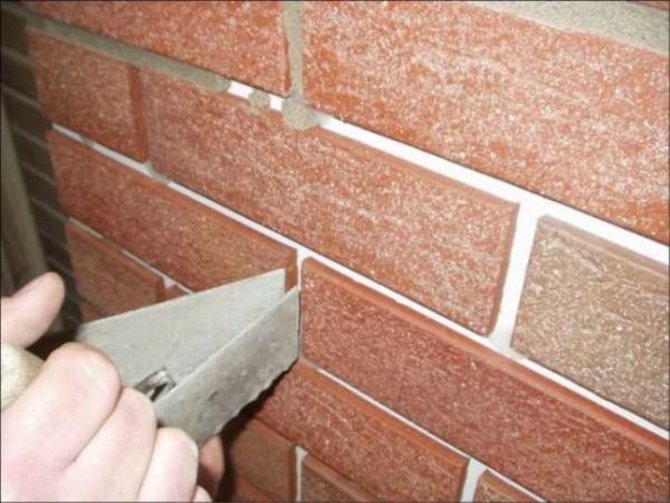

Before restoring old masonry, it is necessary to remove the mortar from the joints to a depth of 15 mm and clean the wall from dust and dirt

The preparation of the masonry is performed in the following sequence:

- If it is necessary to renew the cladding of the old wall, parts of the old jointing are removed from the seams to a depth of 10 - 15 mm. To avoid damaging the bricks, it is best to use a narrow wooden wedge and hammer. If it is not possible to knock down parts of the frozen solution, use a chisel;

- Use improvised means to remove dust and dirt from the walls of the building;

- The seams are cleaned with a stiff brush or high-pressure washer. This work should be carried out very carefully, since dirt and dust particles interfere with the adhesion of the joint mortar;

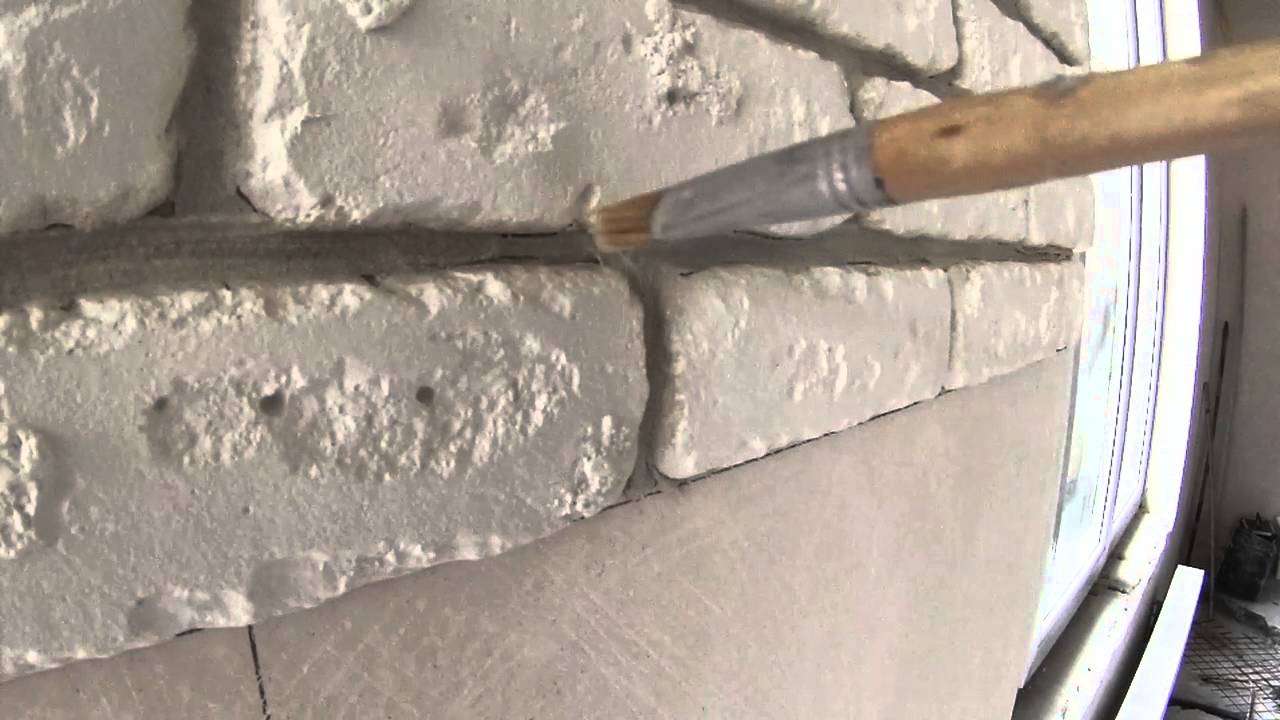

- After cleaning, the seams are moistened, for which a roller or soft brush and a bucket of water are used.

The preparation of the cement-sand mixture is started only after complete preparation of the surface for the next stage, at which the joint mortar is prepared.

You can make your own jointing mix or use a ready-made factory-made mix that is sold as dry. and wet. Since the solution is used for decorative purposes, it is allowed to introduce dyes for concrete into it.

The concrete mixer will speed up the preparation of the joint mixture

If you prefer to do everything yourself, then to prepare the optimal mixture, take lime, sand and cement in a ratio of 1: 10: 1 and stir with water until you get a very thick sour cream consistency.Remember that the composition remains mobile for up to 1.5-2 hours, so mix only as much as you can use during this time.

If the mixture you received is too liquid, you can remove excess moisture from it by placing a dry red brick in a container with a solution for 1 - 2 minutes.

With large volumes of work and the presence of assistants, a concrete mixer will help speed up the process.

Mashing compounds

In hardware stores and markets, you can purchase the most suitable grout for gypsum tiles for brick, which differ in composition. Depending on the main component, they are:

- cement mixtures;

- based on epoxy resin.

The most popular mixtures for grouting decorative bricks are cement-based mixtures. The main advantages of grout for decorative gypsum bricks are high resistance to temperature extremes and other aggressive environmental influences and ease of application and preparation of the mixture.

Experienced craftsmen recommend, when purchasing a cement grout for gypsum bricks, adding a small amount of latex to it. This improves its elasticity.

Compositions based on epoxy resin are distinguished by an increased level of viscosity. This property of the material assumes a quick and high-quality application of the solution, therefore it is recommended to work with it only by professional craftsmen.

Ceresit

The most demanded materials of the Ceresit company for work on surfaces faced with decorative bricks are:

- ce 40 aquastatic. It is used for sealing joints, the width of which does not exceed 1 cm. Suitable for use on surfaces faced with stone, ceramics, glass, and decorative bricks. They are characterized by a high level of water repellency and resistance to dirt. The surface of the seams is velvety. The material acquires maximum hydrophobicity 5 days after the completion of work;

- ce-33 Super. Masonry grout is used for joints that are no more than 5 mm wide. It is characterized by moisture resistance, frost resistance, represented by 50 different colors. Grouting for bricks is carried out at a temperature regime of plus 5 degrees and above;

- ce 43 Super Strong. Brick grout is intended for outdoor use and is used for joints up to 2 cm wide. It is characterized by a high level of moisture resistance, frost resistance, and has increased strength. The disinfecting effect is characteristic, it is not deformed.

Kiilto

They use materials of the Kiilto brand for work both inside and outside the premises. White brick grout is made on the basis of cement with the inclusion of a certain amount of lime and various polymers. It is characterized by high elasticity, easy to apply. After completion of the work, it can be easily removed from the surface of decorative bricks or tiles.

During the preparation of the solution, strict adherence to the proportion is required, you cannot add more water than indicated in the instructions, otherwise the composition may be washed out within 5 days after application.

Mapei

The materials from Mapei are characterized as follows:

- the composition of the mixture is represented by hydraulic binder, fractionated aggregate and modified additives, due to which increased resistance to efflorescence and fading is provided;

- the material line is presented in 5 colors;

- preparing a solution for work is simple, as well as applying;

- after the material has finally hardened, no shrinkage is observed;

- characterized by a high level of adhesion and a long service life;

- due to its high density, the material does not form stains either on the surface of the seam itself or on the facing material;

- characterized by sufficient vapor permeability, high level of frost resistance, resistant to atmospheric precipitation and adverse environmental conditions;

- facing brick grout can be used at temperatures plus 5 degrees and above;

- work should be done only in dry weather.

Using Mapei materials, after the completion of the work, insulation of the treated surface is required for a period of seven days, limiting the effect of possible adverse weather conditions.

How to erase them?

For high-quality processing of the seam, it is necessary to study the instructions on the packaging of the grouting material, and also prepare for work. You will need tools and materials:

- mixer;

- spatula / gun;

- kneading drill;

- sponge;

- rags or rags;

- gloves;

- mixing container.

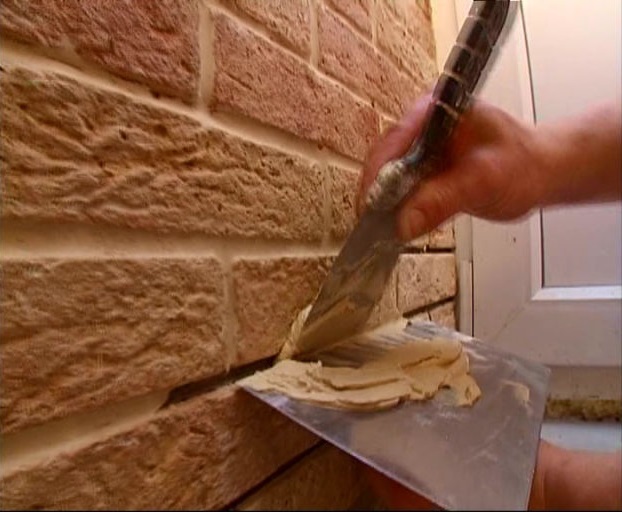

Regardless of the purpose of the grout, it is applied with a gun or trowel / spatula.

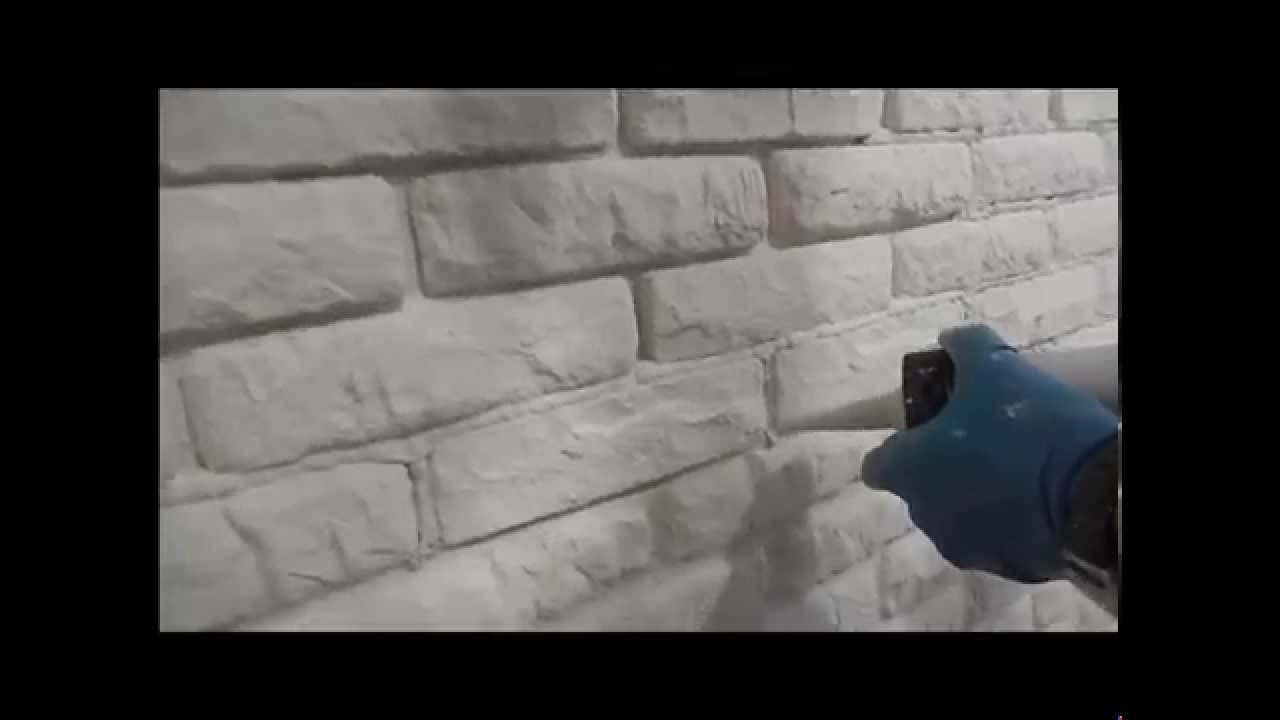

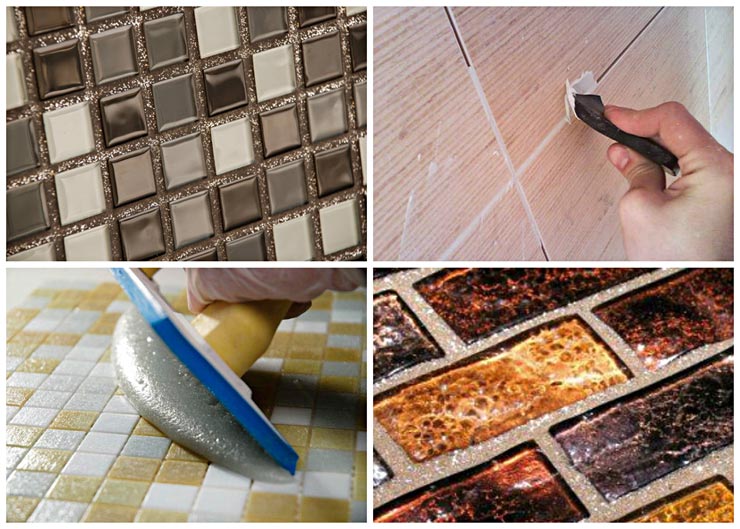

Let's consider how to properly fill and grind the joint joints when laying stone cladding. Work progress when sealing seams:

- Surface preparation - clean the cladding, allow to dry.

- Knead a small amount of grout to prevent the excess from hardening.

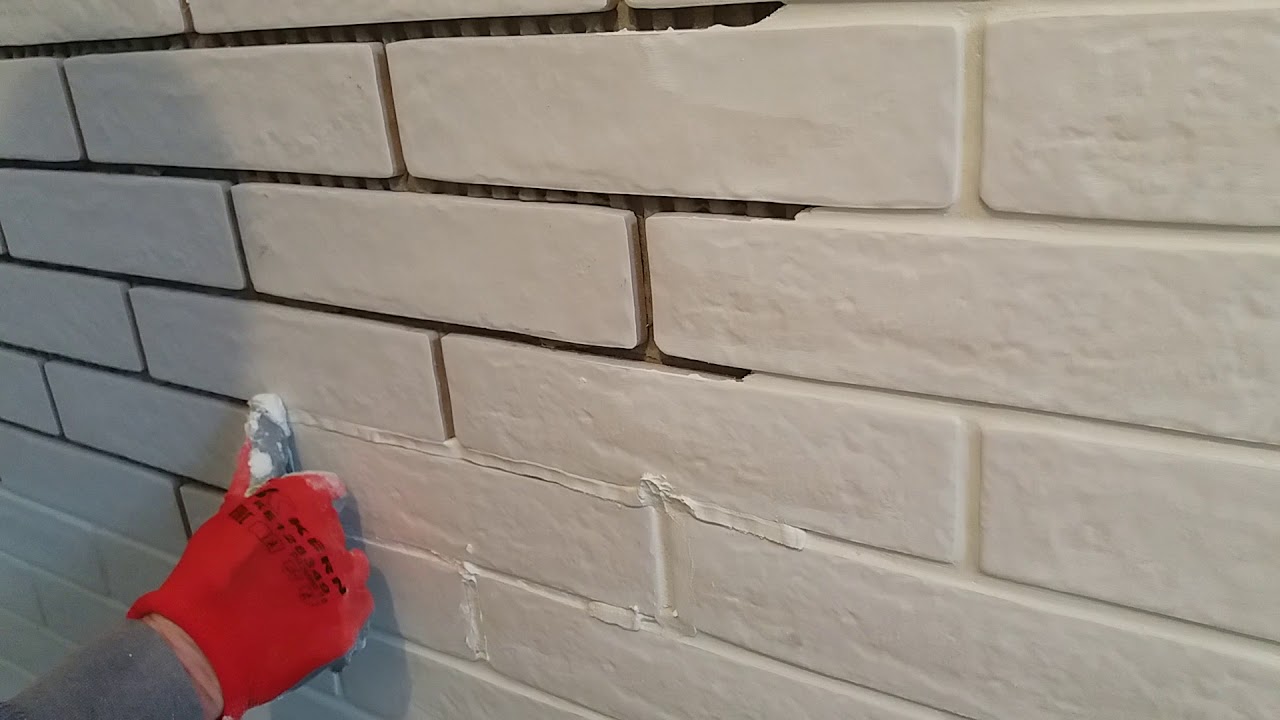

- Treat the seams in one of the ways - from a pistol or a spatula, apply the mixture, tamp into the suture gap. The excess must be wiped off immediately.

- Let the solution set.

- Treat it with a fixative.

Important

Each mixture has its own instructions for use. On average, dry formulations are prepared in proportions of 1 kg per 200 ml of water

The mass is stirred until homogeneous, the grout has the best characteristics in the first three hours, then it begins to thicken and loses its elasticity. It is recommended not to use a stale mortar, as this will lead to a loss of waterproofing and if the seam is repaired with such a tool, microcracks may appear.

We recommend watching a video on how to grind the seams on decorative brick:

Jointing

Jointing of seams is the final stage of surface facing. It is necessary for fixing the facing elements, completing the composition, additional processing of the gaps between the elements from various influences (temperature, dirt, moisture).

Jointing of seams is the final stage of surface facing. It is necessary for fixing the facing elements, completing the composition, additional processing of the gaps between the elements from various influences (temperature, dirt, moisture).

For planing, the following materials and tools must be prepared:

- grout for joints;

- foam sponge;

- several containers: for water and fugue breeding;

- trowel spatula;

- masking tape;

- rubber gloves.

For jointing, you need to purchase a special grouting gun or rubber trowel. The latter is a small plate with a handle. Tools made from different materials are selected depending on the process in which it is used. To apply and press grout into the gap between decorative stones, spatulas with a springy rubber surface with a narrow blade are used.

Advice

Rubbing with a spatula is faster than using a pistol, but this requires skill in execution.

Before work, the stone can be covered with masking tape so as not to get dirty and not wipe it off again. For the final cleaning of surfaces from contamination with a grout and its residues, special synthetic-cellulose or foam sponges are used. But a soft cloth moistened with warm water may also work if it does not spoil the stone (it is better to check beforehand).

After work, it is better not to store the remnants of the diluted fugue: after use, it dries up, loses its elasticity.

You can familiarize yourself with the options and principles of finishing the corridor, hall, bedroom, area near the TV, balcony, doorways, arches and columns with decorative stone.

Recommendations from the masters

To avoid simple errors, you need to know useful tips from professionals:

- In order for the grouting of gypsum bricks to be of the desired consistency, the sand must be sieved.

- When the batch is created according to the instructions, let it stand for 15 minutes, after which it is stirred again and work begins.

- When creating a seam, do not go on the bricks themselves.

- If the solution is excessive, it is immediately removed.

- When a mistake is made, it must be corrected immediately, otherwise the solution will harden and nothing will work out.

Grouting is a completely feasible process, and it does not matter what kind of base material we are talking about.

What needs to be prepared?

What is needed to start working on seams in brickwork with your own hands? Not a lot of materials are needed. The first thing you need is a grout solution, the creation of which is a little below.

The second thing you need to get started are the tools that will be used for joining and additional actions. You may need:

- spatula / trowel;

- construction mixer, or perforator attachment;

- a sieve to sift the sand;

- mixing utensils;

- metal fixture - jointing.

The jointing must match the size of the seam. If the horizontal and vertical lines are different sizes, you need to purchase two tools that match each. The list contains only the main tools that are supposed to be used. All adaptations may not be useful in all cases. For example, if you do not plan to create a curly seam, then the excess solution can be immediately eliminated with a trowel.

Next, you need to prepare how to seal the seams between the brickwork. To do this, you need to mix a special mixture. The color is chosen after the completion of the brickwork. But you can preliminarily decide on the colors, even when selecting materials for construction. It is better to acquire materials that are in harmony with each other as much as possible, combined in color. It so happens that an experiment with colors can look quite interesting; in the case of a design approach, a contrasting grout is obtained. But this option needs to be chosen more carefully. In the event that a color scheme of a suitable color could not be found, the jointing can be done with a conventional mixture of cement and sand. This is a win-win option, since the color of such a solution is in harmony with any others.

To prepare the solution for which the work will be performed, the following materials are needed:

- quality cement - 4 parts;

- fine sand, cleaned - 2 parts;

- grout mixture;

- water.

The number of materials is approximate. Based on these proportions, you can calculate the costs. To prepare the mixture, you must first sift the sand with fine force. This is done in order to remove debris or large pieces that will spoil the finished mixture, respectively, and the appearance of dried grout. One part of the sand must be combined with two parts of cement in a dry form, after which you can add a little water. With a special mixer for construction, you need to mix the resulting mixture until a homogeneous mass is formed. After that, the trowel mixture and the remaining water are added. All components must be mixed well together and allowed to stand. After the solution is infused and the liquid is absorbed a little, the mixture must be mixed again.

Mashing compounds

Varieties of grout.

Before you go to choose a mixture, you should study the requirements and know what to consider when choosing the composition of a particular manufacturer:

Composition - first of all, it is worth paying attention to what material the mixture was made on.

Where the decorative material and the composition itself will be used: inside or outside the room.

Colors - you can choose a dye to mash the desired color for almost any color of brick, tile or stone.

According to professionals, it is best to choose cement-based formulations. With their high strength and resistance to weather conditions, such materials are good for working with finishing materials on the outside of the house.

Cement is not the only possible base, it all depends on where and for what materials it will be used, for example, a resin-based grout is also used for decorative tiles.

To grind the seams of decorative bricks, a variety of mixtures can be used, made on the basis of materials such as:

- cement;

- epoxy resins.

As noted earlier, cement-based decorative brick grouting is more popular. Some experts advise adding latex to the cement mixture to improve its properties.

Grouting tools.

The advantages of cement mixtures are their wide availability, resistance to temperature changes and other environmental influences, ease of dilution and work.

Grouting of decorative bricks can also be done with epoxy-based mixtures. Such mixtures are somewhat different from cement ones, they have an increased viscosity. For this reason, working with epoxy grout mixes requires quick and focused work. If a decision is made to use this particular type of grout, you should entrust the work to a specialist.

If it is decided to use a gypsum brick or slab as a decorative material, then you need to know that to work with it, you need to purchase a special glue for attaching to a wall or other surface, which must first be prepared for finishing. Seams, in case plaster decor, should also be rubbed. For this, all the same special mixtures are used for grouting decorative bricks.

What kind of connections to make?

The most important parameters for determining which seam is required are as follows:

- By color - the grout should be in harmony with the overall composition and color scheme.

- In width - the calculation is done even when laying the decorative stone, then the gap itself is filled. This is necessary to calculate the amount of consumable material.

It will be possible to wipe the seams aesthetically and reliably only where the building and finishing standards were initially respected:

- evenness of masonry with the same distance between stones;

- tiles do not stick out over adjacent ones.

In this case, filling the joints is easy. Building standards indicate the size of the seam - up to 1 cm, but no more. This will help determine the quantity of the consumable, for example:

- for a depth and width of 10 mm, you will need from 6 to 8 kg of trowel per 1 sq. m;

- for a standard brick stone measuring 240 by 71 mm, 2.5-3 kg will be needed to process the seams.

When laying, special attention should be paid to the main characteristics of the facing material, since the manufacturers themselves indicate which gap should be left. Attention

Most mixes are sold in standard 25 kg bags, which is enough for a mash of 8-9 sq.

m.

Attention

Most mixes are sold in standard 25 kg bags - enough for a mash of 8-9 square meters. m.

Retainer

The seam lock is a special solution for working with natural and artificial stone. When cladding, it ensures the preservation of the gaps of the required size between the masonry elements.

The seam lock is a special solution for working with natural and artificial stone. When cladding, it ensures the preservation of the gaps of the required size between the masonry elements.

Each manufacturer has guidelines for maintaining gap size and fixing mortar. For example:

- for clinker - 10–12 mm;

- for a large stone - 15 mm;

- for a stone of irregular shape - 15–20 mm.

Based on these dimensions of the gap, manufacturers calculate the consumption rates of stone, grout and fixative.

Retainers are made mainly of extruded polystyrene foam - an elastic solid material. This is a very useful property when laying artificial stone with straight edges.

Trowel technique

To carry out the last stage of laying the cladding elements, it is necessary to prepare tools and materials:

- putty knife;

- bag;

- gun;

- mixture;

- gloves;

- container with water.

Important

Not every job can be done with a syringe, so an ordinary, narrow spatula and a bag that is filled with grout may be required.

Additional tool:

- mixer;

- trowel;

- level;

- container for the solution (if it was in the bag).

- First you need to prepare the surface. It is cleaned of excess glue and dust solution. They wait for it to dry (10–20 minutes), prepare for grouting.

- The composition is laid neatly into the seams, compacted. Excess when applied is removed immediately, while not hardened.

It is important to choose the right mix for the cladding. Dilute it according to the instructions that manufacturers have on the packaging

If the composition is purchased dry, a small amount must be diluted. It will be convenient to work this way, and a large volume may begin to dry out. And stale (if you cook a lot and leave the next day) will lose its properties, worsen the waterproofing of the seams and crack.

When all the factors of the grouting process are taken into account, and the composition is selected in accordance with the lining, then you can rub it in the following ways:

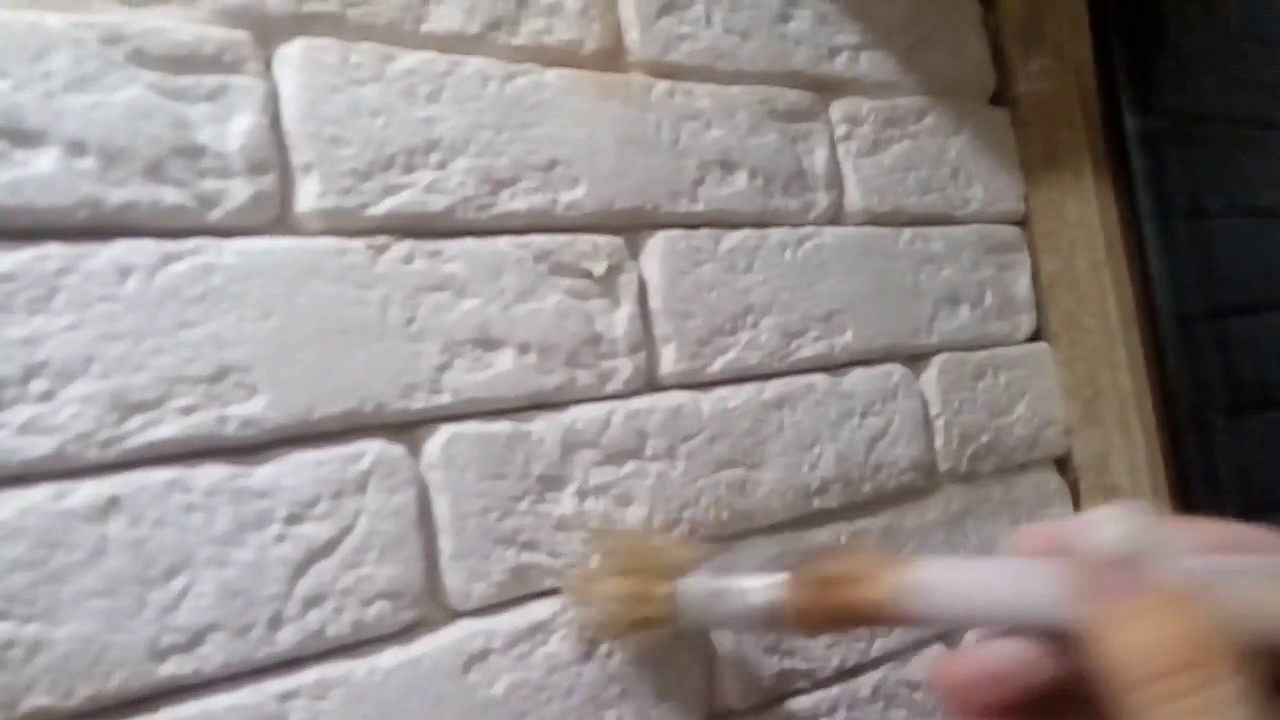

- Inside - the solution is tamped under the stone, without leaving it outside, if necessary, additional indentations are made. The seam becomes concave and the stone appears to protrude outward.

- Flush - performed with a semi-dry mixture, you can rub it in with your hands (but with gloves). After rubbing, wipe the surface with a rag or hard cloth to get rid of excess.

- Convex - the composition is rubbed with a special spatula, which is carried along the seam, then, on the contrary, it protrudes outward. It is worth practicing for this method, as it requires certain skills.

- Beveling is a method that does not require skill. It is necessary to move the trowel along the seam, and then immediately remove part of the mortar, making indentations up to 4 mm at an angle.

- The triangular method is a complex and beautiful grouting method used more indoors. For mashing, you will need to remove a certain amount of mortar between the bricks, the remaining composition is placed in a triangle. This requires skill and skill from the master.

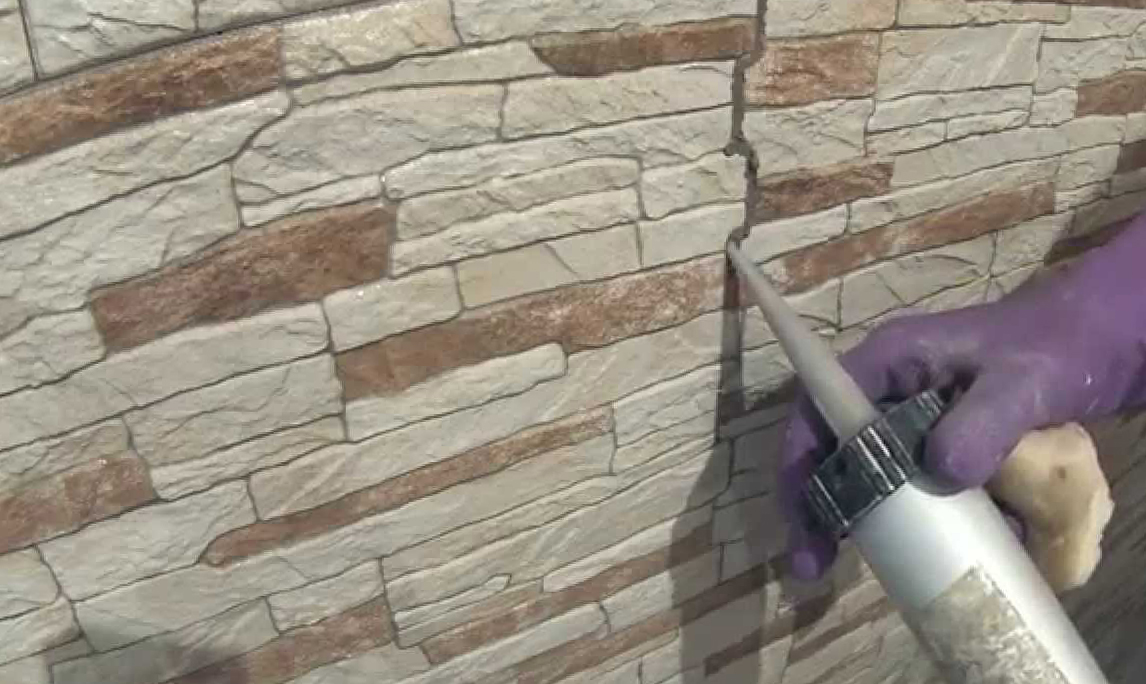

With a syringe gun

The method is used in the following cases:

The method is used in the following cases:

- outdoor cladding;

- a large amount of work;

- when processing a porous or sandy surface.

Grouting with a gun allows you to apply an exact strip of the seam along the entire length of the decorative elements, while eliminating the occurrence of voids, interruptions, bubbles.

The tile or stone remains clean after work, material loss is minimized and the grouting speed is high.

- The finished composition is put into the gun with a trowel or spatula.

- Then, by neat straight extrusion from the tool, vertical seams are filled from top to bottom, and horizontal seams - from left to right.

If there is no special gun, then you can buy a disposable grout. It looks like a syringe tube, it has a seal, and the solution inside does not need to be prepared and diluted.

Spatula

Attention

The rubber spatula is the most common tool in the job. A thin strip of grouting material is collected on it, and then laid between stones or tiles at the desired angle

The solution must be put with effort into the gap, then walk along the seam, removing the excess.

The force must be sufficient to rub the tool plate with the plate so that it fills the entire seam cavity and ensures that the tile lining is tight. Cement and epoxy grouts can be applied with a trowel.

From individual publications of experts on our website, you can find out what types of decorative stone exist and are used for wall decoration, as well as read how to beautifully and correctly decorate with such materials Khrushchev, balconies, arches, kitchens and hallways, as well as doorways in various apartments ...

Types of plaster mixes suitable for such a finish

Brick plaster in interior work can be implemented using the following compositions:

- Mortar based on sand and cement.

- Mixtures of lime and sand.

- Clay based mortar.

- Gypsum plaster.

Brick plaster in interior work can be implemented using several compounds.

But, regardless of the main composition, as additional elements can be introduced:

Coloring pigments - thanks to this, it is possible to achieve the most diverse in shade and saturation surfaces;

Additives - they increase the resistance of the coating to various aggressive environments and water;

Plasticizers allow you to give the material itself more flexibility

Their addition is quite important, since in this case the surface does not crack, shrink or deform for a long period of time. Thanks to coloring pigments, it is possible to achieve a variety of surfaces in shade and saturation.

Thanks to coloring pigments, it is possible to achieve the most varied in shade and saturation surfaces.

Thanks to coloring pigments, it is possible to achieve the most varied in shade and saturation surfaces.

Top 3 best manufacturers

For grouting, you can use ready-made production mixtures:

- Ceresit;

- Kiilto;

- Mapei.

Ceresit

The Ceresit brand has many positive reviews from customers. It is sold dry, and the packaging contains a mixing table. There is no need to add color to the mixture, as you can choose any color. Grout is intended:

- for internal;

- outdoor work.

Properties:

- sets quickly;

- does not paint the edges of the decorated stone;

- gives an antibacterial layer;

- environmentally friendly, safe.

Kiilto

The grout is produced by a foreign company in Finns. The mixture is available in a wide range of colors. She, like the first, meets quality standards and has the following properties:

- put in a thin layer, unlike others, it can be spread with a layer of up to 8 mm;

- resistant to temperature extremes;

- requires additional impregnation with antifungal solutions;

- waterproof (water-repellent).

The manufacturer additionally offers to process the cladding with protective means of its own production. This will help to fix them, protect them from outside influences and improve the quality of the glue. These solutions are added directly to the trowel mixture.

Mapei

The company produces a grout that fits perfectly into the seam. Has a wide range of colors, including a translucent mixture, which is not in the first two brands. Fugue properties:

- elastic;

- repels dust, small particles, does not allow to gain a foothold on itself;

- lasts a long time;

- does not deform with a sharp change in humidity and temperature;

- does not fade;

- moisture resistant, water repellent.

The main advantage of Mapei is the quick setting of the mortar. The mixture already includes antifungal ingredients. Suitable for troweling plaster stone cladding both outdoors and indoors.

Overview of grout for stone

The market offers many types of grout, so choosing can be difficult. When choosing, you need to focus not only on the scope, but also on the reputation of the manufacturer.

Grout RSS

The material is suitable for working with internal and external surfaces faced with artificial stone. The basis of the solution is mineral. A positive characteristic of the mixture is its resistance to temperature extremes and high humidity.

The grout is sold in paper bags of 25 kg. The material is easy to use. It is characterized by high resistance to mechanical damage and cracking. The solution does not flow during mixing.

Ceresit Super

The mixture is used for grouting narrow and wide joints. The product line of this manufacturer is extensive, so here you can find a suitable option. Kohler is not required when working with these compositions, since it is fashionable to choose a product of the desired color. The substance does not leave stains on the cladding, it hardens quickly. The solution contains antibacterial components and is environmentally friendly.

Kiilto saumalaasti

The grout color of this manufacturer is different. The basis of the material is cement. The composition also contains polymer additives that give the material the necessary technical characteristics. Its use is not difficult, since it has good elasticity.

After completion of the work, the solution is quickly washed from the cladding. The maximum joint width is 6 mm and the thickness is 8 mm. The product repels moisture well, does not collapse under the influence of temperature extremes. An additional component in the composition is lime.

Perel

The products are represented by a wide range of products, among which there are brands for use in the winter. The material is resistant to cracking and moisture. Grouting is simple, but the prepared solution must be used within 3 hours.

As soon as the mixture solidifies, it must be thoroughly mixed. There is no need to add water. The advantage of the material is its immunity to temperature and humidity changes. This composition is universal, as it is suitable for interior and exterior surfaces. It can be applied with a syringe gun.

Fm quick mix

The products are available in 16 different shades. After hardening, the material creates a strong seam. It does not contain toxins, so it is not harmful to health. A small amount of liquid is required to obtain a workable solution. The mixture is sold dry.