Meaning of other colors

An orange construction helmet is a characteristic feature of ordinary employees and service, support personnel. However, such a headgear is sometimes worn not only by construction workers, but also by surveyors who measure something at the facility. A yellow helmet is a 100% sign that its owner is only following the orders of the management.

Now, in the absence of standards, each company has the right to establish its own procedures even for individual structural divisions and branches. That is why today the color of the helmet does not always allow a stranger to confidently distinguish the difference in positions. But the construction workers themselves can easily recognize other people by the color of their headgear.

This is especially important:

-

over long distances;

-

with a significant difference in height;

-

at night and in bad weather.

Typically, color standards are not just announced by order of the company, but approved in its special standard developed by the industrial safety department. The black helmet is usually the preserve of the locksmith. Blue hats are predominantly worn by plumbers. But if an electrician comes to a construction site, he will most often be given green PPE. The Cherepovets Coke Plant requires ordinary employees to wear orange protective gear.

But if strangers come there, they will be given a yellow helmet. For comparison: at Norilsk Nickel employees with less than 36 months' experience are required to wear red hats. This significantly increases the visibility. When a high-rise crane is working on a construction site, the operator uses a blue guard.

Here are some more facts:

-

yellow and orange are interchangeable;

-

a white helmet can be worn by an environmental protection officer, an employee of a construction or technical supervision;

-

green helmets are often worn by security guards;

-

the electrician installing the wiring for the immediate delivery of the object can be in a yellow or "reddish" helmet;

-

red helmets of non-standard design (without visors) - a common feature of the appearance of high-altitude and industrial climbers;

-

customers and their representatives are given a white helmet;

-

architects often wear a black headdress, but their very appearance is rare.

An overview of the construction helmet "Europe" in the video below.

Materials and technologies

Materials for creating products are applied based on characteristics that are needed to ensure safety in case of accidents.

Polycarbonate is often used, a tough material that reduces impact forces through elastic deformation. If there are no large cracks on the product, then it has retained its properties. Such a headdress cannot always protect a person, for example, in case of a fall.

In the manufacture of helmets, polystyrene foam is used, which deforms upon impact.

The product serves to protect a person from injury due to falls and moving objects. But it will not be able to protect against injury from falling bricks. Once damaged, the product is unusable.

A combination of elastic and deformable elements is often used, or the materials have different properties. This rule is used in sports protective helmets, which can withstand different loads.

Products can be used many times, but it should be borne in mind that the properties of materials are not restored immediately. If there is mechanical damage, then the helmet is changed to a new one. Even slight deformation can lead to injury.

- .

- standartservis.su

- .

The structure of GOST 12.4.307-2016

GOST 12.4.307-2016 has the following structure:

1 area of use.

2. Normative references.

3. Terms and definitions.

4. General requirements.

4.1.Classification.

4.2. Construction (manufacturing).

4.3. Dimensions.

4.4. Appearance and absence of defects.

4.5. Resistance to mechanical, climatic and environmental influences.

4.6. Requirements for electrical properties.

4.7. Physical and mechanical indicators.

4.8. Resistant to low temperatures.

4.9. Resistant to flame spread.

4.10. Requirements for dielectric composite gloves.

4.11. Requirements for gloves with special properties.

4.12. Marking.

4.13. Package.

4.14. User manual.

5. Test methods.

5.1. General requirements.

5.2. Visual inspection.

5.3. Sizing.

5.4. Determination of thickness.

5.5. Durability of marking.

5.6. Physical and mechanical tests.

5.7. Determination of dielectric properties.

5.8. Accelerated aging test.

5.9. Thermal tests.

5.10. Testing of gloves with special properties.

5.11. Testing of composite gloves for mechanical properties.

Now we turn to the second GOST.

Review of GOST ISO 14116-2016. Flame retardant fabrics and flame retardant clothing

The document was put into effect by order of the Ministry of Industry and Trade of the Russian Federation dated December 26, 2016 No. 2075-st as the national standard of the Russian Federation from November 1, 2017.

Translators also sweated over GOST, since the GOST under consideration is identical to ISO 14116: 2008 "Protective clothing - Protection against heat and flame - Limited flame spread materials, material assemblies and clothing, IDT" ...

GOST ISO 14116-2016 establishes the requirements and methods for assessing the properties of materials, packages of materials, special protective clothing (overalls) in terms of limiting the spread of flame.

Overalls made in accordance with GOST ISO 14116-2016 are designed to protect workers from accidental short-term contact with a small flame in the absence of a significant risk from heat of another nature. If, in addition to protection from limited contact with a flame, workers need protection from heat of a different nature, then the clothing must additionally comply with the requirements of ISO 11612, Protective clothing - Clothing to protect against heat and flame (this document seems to have not yet been translated by the translators).

GOST ISO 14116-2016 establishes technical requirements for overalls and materials for its manufacture during design, launching into production and confirmation of conformity.

Design

Safety regulations require the installation in workplaces where there is a risk of injury to the head, the safety sign "Work in a protective helmet". It has a code M02 (ZK-12). The design of this PPE is as follows:

- The carrier tape is positioned on the head so that there is a coverage of the head in the place where the volume is maximum.

- The occipital tape makes additional reinforcement of the helmet on the head, it is located below the carrying tape in the back of the head.

- A shock absorber is a device that covers the head from all sides. The most important design of the helmet, springy when weights fall on the helmet, smoothing the force of the impact.

- The inner padding is designed to increase wearing comfort. The entire inner part is covered with a special material that softly fits the head.

- The cushion bands are similar in their action to the shock absorber of the helmet. They smooth out the force of the blows.

- Protective upholstery is a material that, together with shock absorbers, helps to absorb impact forces.

- Ventilation holes - holes made in the helmet to allow proper air circulation between the helmet and the head.

- Chin Strap - Designed for final attachment to the head. It allows you to perfectly fix the helmet, preventing it from slipping.

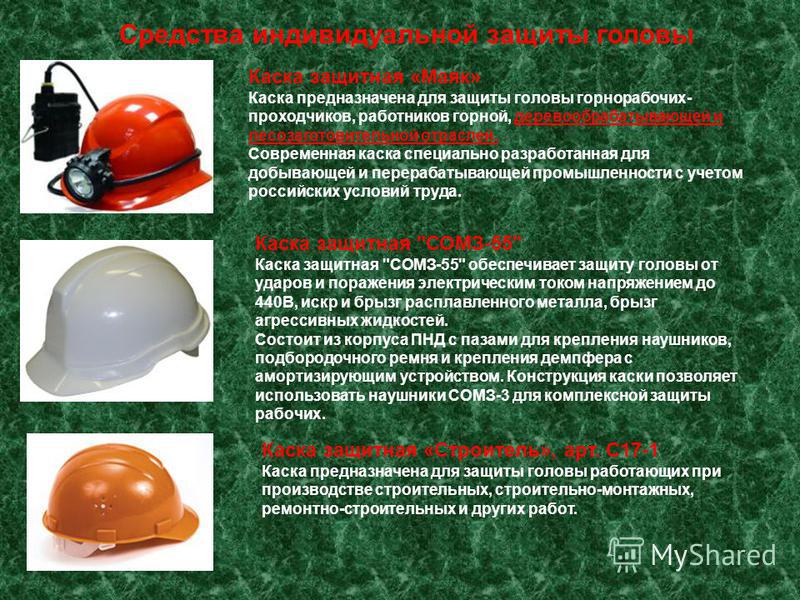

Species overview

By type of use

It is customary to highlight the following options for helmets:

-

winter heat-resistant;

-

universal construction;

-

miners (for underground work);

-

firefighters (with increased fire and electrical resistance);

-

heat-resistant structures;

-

acid and alkali resistant models;

-

intended for other professions.

By color

The color of the safety helmet can vary greatly. And professionals have long come to the conclusion that such color coding allows for increased safety.In addition, it will facilitate the identification of personnel at long distances and in low visibility. The state standard for the coloring of protective headgear, approved in 1987, has long been canceled. The following normative documents say nothing about specific colors.

And yet for convenience, and partly for reasons of tradition, builders and others adhere to established color schemes. White helmets are usually worn by the management of organizations and their structural units, as well as labor protection inspectors. Recently, they have also become an attribute of security services (guards, watchmen, watchmen). And some construction organizations practice white helmets in the outfit of engineering personnel.

The red headdress is worn by foremen, engineering and technical personnel of industrial enterprises. In the industrial sphere, they are also used by chief mechanics and chief power engineers. Yellow and orange helmets can be used by ordinary and auxiliary personnel at various sites. However, there is another approach according to which the color of protective headgear is distributed as follows:

-

orange - surveyors;

-

red - beginners and visitors;

-

yellow - ordinary staff (but not trainees);

-

green - for electricians and electricians;

-

black - locksmiths;

-

blue - plumber service specialists;

-

brown - miners;

-

blue - crane operator;

-

white or red - fire departments.

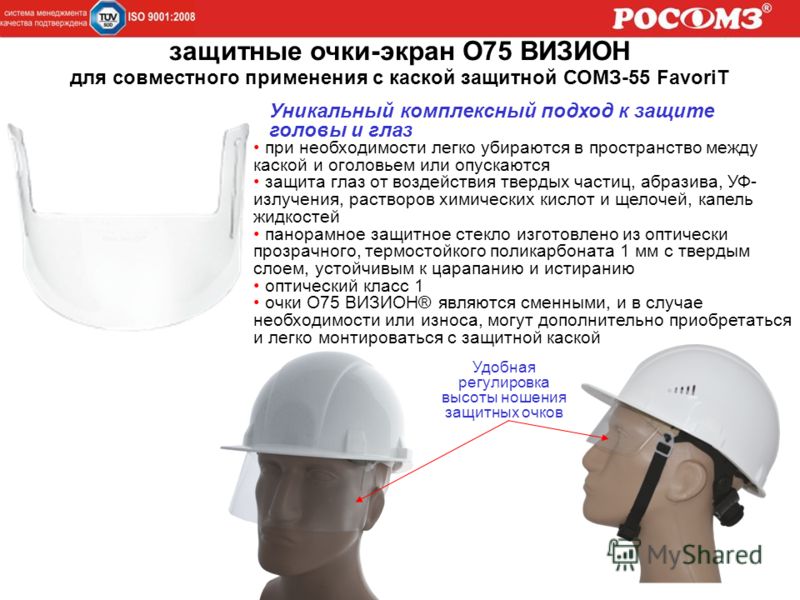

By type of additional equipment

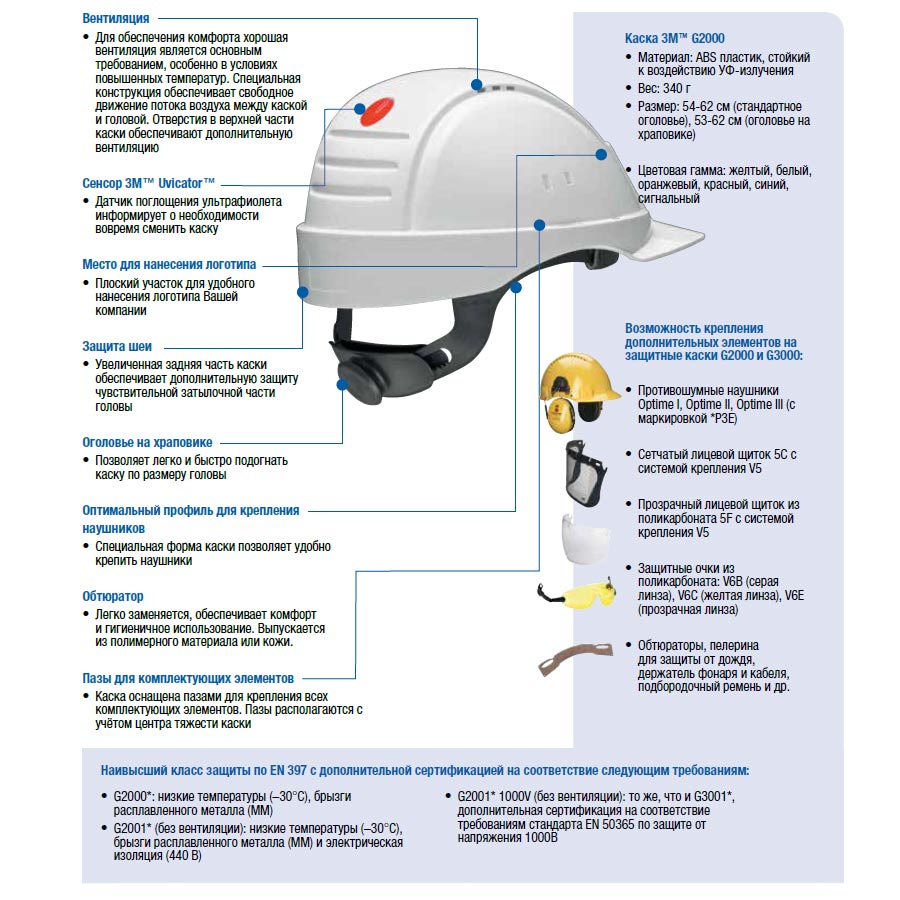

Some professions strongly require the use of a special headgear with face protection. Helmets with a screen or a shield made of transparent materials provide reliable protection against splashing metal, drops of corrosive liquid, flying chips, fragments and dust. A special part is used to attach such an element. There are also shockproof shields that can be made of transparent materials. Some models can protect against high temperatures.

Some of the helmets are equipped with a visor that maximizes the safety of the face in general and the eyes in particular. Such designs are useful for the logging, construction and installation industries. In many industries, helmets with headphones are actively used. Such an addition allows both to escape from incessant loud sounds and to organize constant communication between employees.

Communication headphones for helmets:

-

equipped with built-in electronics that suppress impulse noise;

-

suitable for work in an explosive environment;

-

can transmit signals via Bluetooth;

-

are calculated to contain sounds of different loudness, different frequencies.

Separate helmets are supplied with (or used in conjunction with) goggles. When the work requiring the use of glasses is finished, they can be returned under the helmet in one motion. Pulling back this protective device is no more difficult.

Any helmet is equipped with a chin strap, without which it cannot be properly held on the head. The width of the strap cannot be less than 1 cm, its attachment can be located on the body of the headgear or on the strap.

Helmets with a comforter, characterized by increased heat resistance, are quite common. It compensates for the danger of increased temperature and heat radiation. Such equipment is used most often by welders and metallurgists. There are also helmets with comforters:

-

for machine builders;

-

builders;

-

miners;

-

oil producers;

-

oil refiners;

-

electricians.

In appearance

Brims and canopies significantly increase light protection. Also holders for flashlights are additionally used. It is worth considering the following options:

-

equipping with a removable cape;

-

adding a warm liner to protect against hypothermia;

-

made from a combination of glass with textolite and plastic.

TECHNICAL REQUIREMENTS

2.1.The helmet must be manufactured in accordance with the requirements of this standard and comply with the reference standards approved in the prescribed manner.

2.2. The helmet should consist of a shell, inner harness and a chin strap.

At the request of the consumer, the helmet can be equipped with devices for attaching shields, ear muffs and other personal protective equipment.

2.3. Helmet shells should be produced in four colors:

white - for the leadership of organizations and enterprises, heads of sections and workshops, public inspectors for labor protection, employees of the safety service;

red - for foremen, foremen, engineers and technicians, chief mechanics and chief power engineers;

yellow and orange - for workers and junior maintenance personnel.

2.4. For the manufacture of helmets, materials permitted by the USSR Ministry of Health must be used. The body and internal equipment of the helmet must be made of non-toxic materials, and the parts in direct contact with the scalp and face must not cause pathological changes in the skin. Materials must be resistant to the action of petroleum products, acid-base electrolyte, hot water (80 ° C), disinfectants.

2.5. The materials used for the manufacture of helmets must correspond to those indicated in table. 3.

Table 3

|

Name of helmet elements |

Material name |

Normative and technical documentation |

|

Helmet body and chinstrap clip |

High density polyethylene |

GOST 16338-85 |

|

Carrying tape, suspension |

Same, low density |

GOST 16338-85 |

|

Drape, carrier tape covering |

Current regulatory and technical documentation |

Note. It is allowed to use other materials with physical and chemical properties not lower than those indicated in table. 3 and ensuring that helmets meet all the requirements of this standard.

2.6. Interior fittings must be made of durable and resilient materials. The carrier tape (except for its back of the head) must be covered with natural or perforated artificial leather or other porous material that protects the skin from chafing.

2.7. The internal equipment of the helmet must provide the ability to adjust its size, if necessary, use a comforter, and must not allow the helmet to move when turning the head and performing work in an inclined position.

The design of the carrying strap and shock absorber should provide for the adjustment of the depth of the helmet on the head.

2.8. The inner harness and chin strap must be removable and have means for attaching to the helmet shell. The chin strap must be adjustable in length, and the attachment method must ensure that it can be quickly detached.

2.9. The outer surface of the helmet shell must be smooth, free of cracks and bubbles. On the surface of the helmet body, inclusions of a different color are allowed in the amount allowed by the standards for materials.

2.10. The inner surface of the helmet shell, as well as the outer and inner surfaces of the rig must be smooth, and the edges and edges are blunt.

2.11. The quality of the seams on the inner fittings must meet GOST 29122-91.

2.12. The side surfaces of the helmet body must have ventilation openings with a total area of at least 200 mm2, hermetically sealed by rotating shields.

2.13. Mechanical strength, shock absorption, the strength of the connection of the internal equipment with the helmet body, flammability, electrical protection properties of the helmet must comply with GOST 12.4.128-83.

2.14. When tested for perforation by impacts with an energy of at least 30 J, the helmet body must exclude the possibility of penetration of the tip of the cone to the surface of the head mock-up.

2.15. Helmets must retain their protective properties during the entire period of operation at an ambient temperature from minus 50 to plus 40 ° C.

Sh 4

1 - bed; 2 - racks; 3 - guide tube; 4 - drummer; 5 - trigger device; 6, 7 - nodes of the time counter; 8 — test shield; 9 - a model of a human head in accordance with GOST 12.4.128; 10 - device for securing the flap

Heck. 2

Stand for testing the mechanical strength of shields

The mass of the striker required for testing in accordance with Appendix 2 is provided by filling its cavity with shot (GOST 7837 or GOST 11964). Checking the weight is carried out by weighing on a scale.

The stand is calibrated in accordance with Appendix 3.

The drop height of the striker is checked with a ruler.

Ensure the horizontal position of the shield on the head model so that the impact points of the striker are inside a circle with a radius of 15 mm drawn from the center of the glass.

For a transparent colorless body, the impact points must correspond to the projection area of the eyes on the body of the shield, ie, be at a distance S from the edge of the head mount (Fig. 2). Place stand 1 under the free end of the housing (Fig. 4).

3.10.3. Testing

Impact hammer for testing mechanical strength Device for securing the shield during testing

shields (side view)

1 and 2 - shells; 3 - shank; 4, 5 - strikers

Heck. 3

Shields are tested using a striker freely falling from a height of (1.3 + 0.005) m with a removable striker made of steel with a hardness of at least 350 HB in the form of a hemisphere with a radius of (11 + 0.1) mm.

Note. When carrying out perforation tests, a striker is used with a cone-shaped striker with a sharpening angle (60 ± 1) ° and a radius of curvature of the tip (0.5 ± 0.1) mm (Fig. 3).

A striker with a striker in the form of a hemisphere is installed in the stand holder, after which it is given a free fall onto the surface of the shield.

At a given value of the striker's energy W, three strikes with the same energy are made on the body of the shield or on the glass. The shield is considered suitable if, after three blows, no cracks or chips are found on the body of the shield or the sight glass, and the body or glass itself remains securely fixed.

Prices

Consider if there is a difference between expensive and cheap helmets. In specialized stores, there is a sufficient number of goods with the name "protective helmet", the price of which ranges between 60 and 2000 rubles per piece. What is the difference between them? Can an expensive helmet save you from a brick that has fallen on your head?

Most of the construction companies do not torment themselves with unnecessary questions, buying cheap helmets for their employees. Is this the correct solution? Partly yes. However, it is necessary that the main requirement is fulfilled - ensuring the safety of the employee. Each batch is subjected to laboratory tests before reaching the retail outlets. Only helmets that meet GOST standards are allowed on store shelves. Thus, regardless of the price, each certified helmet can provide protection for the builder.

It is important that the labeling allows the purpose to be determined. Unmarked helmets cannot guarantee safety

Many people wonder: why are expensive helmets produced? The price of expensive products often includes a fee for the brand. In addition, the buyer may need additional features: stylish design, visor or glasses, adjustable ventilation.

History

The oldest helmets are considered to be Sumerian protective helmets, which appeared in the middle of the 3rd millennium BC. They had the shape of low domes, not differing significantly from modern helmets.

One of the first personal protective equipment for the head was a hat - a fur headdress with volume and protection from cold weather and in battle. In the course of the development of civilization, people came to the manufacture of protective helmets from metal and leather.

The helmet was originally used during military operations and served to protect against various shell and bomb fragments and small penetrating bullets.

The helmets entered the Russian army in the 16th century.By the beginning of the 19th century, they were used as headdresses for combat arms that fought with melee weapons. These are dragoons and cuirassiers. The helmet allowed, to some extent, not to allow the head to be chopped off with a blow from above. It served as a milestone on the road to the invention of the protective helmet. Its name comes from the Latin word for a metal helmet.

Now the production of protective helmets has been launched, using the highest technologies and protecting against various classes of hazards, such as hot metal, heavy objects falling on the head.

Helmet materials:

When buying a helmet, it is necessary to take into account the sphere in which it will be applied, based on this, it is worth paying attention to the material of production

At the moment, the manufacturer offers us 3 types of materials.

- The first is polycarbonate (a very strong material), has elastic deformation and is designed to reduce the force of impact. This type of helmet is heavy (up to 1.5 kg), but reliable and until noticeable cracks appear, you can be sure of its protective properties.

- The second is expanded polystyrene (soft material), which is necessarily deformed upon impact. This type of helmet is more suitable for cyclists, and completely useless if a brick falls on your head.

- The third is polypropylene or butyl nitrate, a combination type of material. But it is more focused on athletes and is unlikely to be useful at construction sites.

If even the slightest crack is found, it is imperative to change the helmet to a new one.

Popular models

The products of the Czech company JSP are in demand. These helmets have a one-touch system and fit exactly to your head. The range includes models for universal and industrial use. Helmets from this company are painted in bright, rich colors.

It is very difficult to find products from Sweden, but you can pay attention to the goods of Delta Plus (France). This company has been operating for over 40 years.

It is represented all over the world. Today Delta Plus products are shipped to 140 countries. A good example is the BASEBALL DIAMOND V. This helmet comes in 7 different colors. ABS plastic is used for its manufacture; normal operation is guaranteed at temperatures down to -30 degrees

This company has been operating for over 40 years. It is represented all over the world. Today Delta Plus products are shipped to 140 countries. A good example is the BASEBALL DIAMOND V. This helmet comes in 7 different colors. ABS plastic is used for its manufacture; normal operation is guaranteed at temperatures down to -30 degrees.

Granite Wind Model:

-

also made of ABS;

-

has two seating positions - 53 and 63 cm;

-

has 3 fixation points;

-

designed for work at height.

The Airving B-WR model from Uvex is also popular in our country. For its imposing appearance, she was nicknamed the "chief's helmet". The main structural material is HDPE. Operation is guaranteed for at least 60 consecutive months. A long visor and an elongated occipital block are used.

Choosing a light helmet, you should pay attention to the modification of the "Pheos B-WR" of the same manufacturer. This product is made in a classic sports spirit.

The release began in 2012. Thanks to the ratchet mechanism, the headband can be adjusted from 52 to 61 cm. Thanks to proprietary adapters, you can use both shields, headphones, and headlights.

Very good results also show:

-

polypropylene helmets RFI-3 BIOT;

-

SOMZ-55 VISION;

-

Peltor G3000;

-

MSA V-Gard.

CLASSIFICATION

1.1. Protective face shields, depending on the design, are divided into the types indicated in table. 1.

Shields of other designs are allowed.

The housings of the shields indicated in table. 1 versions, can have forced ventilation and a movable glass holder.

Table 1

|

Type of |

Flap housing design |

Designation |

|

Head-mounted guards |

Colorless transparent shockproof |

NBT |

|

Colorless transparent chemically resistant |

NBH |

|

|

Light filtering |

NF |

|

|

Reticulate |

NS |

|

|

Opaque |

NN |

|

|

Helmet-mounted guards |

Colorless transparent shockproof |

KBT |

|

Colorless transparent chemically resistant |

KBH |

|

|

Light filtering |

CF |

|

|

Reticulate |

KS |

|

|

Opaque |

book |

|

|

Guards with handle |

Opaque |

PH |

|

Light filtering |

RF |

|

|

Universal shields |

Opaque |

UN |

Official edition

Reprinting prohibited

In this case, the words "with forced ventilation" or "with a movable glass holder" are added to the name of the type of shield and the letter "B" or "P" is added to the designation, respectively.

Examples of the type designation of a flap with a handle, an opaque body and a movable glass holder:

RNP

The same, with a helmet mount, light filter housing with forced ventilation:

KFV

1.2. Protective face shields, depending on the purpose, are divided into groups and subgroups indicated in table. 2.

table 2

|

Group |

Subgroup |

Type of |

Flap housing design |

Sight glass type |

|

Impact guards against solid particles |

— |

Shin guards with head mount (or helmet mount) |

Colorless transparent shockproof |

— |

|

Shields for protection |

Shields for protection |

Any |

Light filter |

Light filter or |

|

you are from radiation |

you are from infrared radiation |

opaque, opaque or reticulate |

its combination with transparent colorless glass |

|

|

UV protection shields |

Any |

Light filtering or opaque |

Light filter or its combination with transparent colorless glass |

|

|

Glare shields |

Any |

Light filtering or opaque |

Light filter or its combination with transparent colorless glass |

|

|

Shields for protection against microwave radio waves |

Shields with head mount (or helmet mount) |

|||

|

Shields for protection against splashes, dilute acids, alkalis, salt solutions |

Shields with head mount (or helmet mount) |

Colorless transparent chemically resistant |

||

|

Spark and molten metal splash guards |

Any |

Light filtering, opaque or mesh |

Light filter or its combination with transparent colorless glass |

|

|

Shields to protect against a combination of the above factors |

Views

The division of construction helmets is based on two criteria.

- Colour. According to this parameter, hats are allocated for workers, representatives of the management of the facility, and visitors to the enterprise.

- Purpose. Depending on this parameter, the product can have a different shape, size, equipment. Also, helmets can be divided into winter and summer options.

American headwear is made primarily of plastic, polyethylene, and polyester. Also, in the manufacturing process, polycarbonate with additional reinforcement can be used. The listed materials are characterized by shock resistance and improved performance characteristics.

Helmets can counter the following factors.

- Mechanical. Head hats soften impacts, preventing serious injury. They are made of durable materials.

- Temperature. For the manufacture of helmets, materials are used that are resistant to high temperatures. They do not catch fire and reliably protect the head from burns.

- Chemical. For the manufacture of some helmets, special materials are used that are not afraid of the effects of chemically active substances. They also do not deform under hot metals.

- Weather. The products allow you to organize uninterrupted operation at the facility even on a sultry day, even in rain, slush or snow.

CONSTRUCTION CONSTRUCTION HELMETS

TECHNICAL CONDITIONS

Official edition

IPK PUBLISHING STANDARDS Moscow

INTERSTATE STANDARD

Occupational safety standards system CONSTRUCTION CONSTRUCTION HELMETS

GOST

12.4.087-84

Technical conditions

Occupational safety standards system. Building. Building helmets. Specifications

MKC 13.340.20

Instead of

GOST 12.4.087-80

By the decree of the State Committee of the USSR for Construction Affairs dated May 10, 1984 No. 73, the date of introduction was established 01.01.85

This standard applies to plastic helmets designed to protect the head of workers from mechanical damage, water and electric current during construction, construction and repair work.

1. BASIC PARAMETERS AND DIMENSIONS

1.1. Helmets should be made in two sizes with steps for adjusting the length of the carrying tape no more than 10 mm:

I — from 54 to 58 cm;

II - from 58 to 62 cm.

At the request of the consumer, it is allowed to make large helmets from 62 to 64 cm.

1.2. The main dimensions of the helmets must correspond to those indicated in the drawing and in table. 1.

Schematic representation of the construction of a helmet

1 2 3

a - body height; b - the depth of the internal equipment; в - the width of the visor; r - the width of the fields; d - annular gap; e - vertical safety gap; 1 - case; 2 - stiffener; 3 - shock absorber; 4 - suspension; 5 - carrier

ribbon

Official edition

Reprinting prohibited

Reissue. December 2003

Standards Publishing House, 1984 IPK Standards Publishing House, 2004

Table 1 mm

|

Size name |

Standard size for helmets |

|

|

I |

II |

|

|

Body height a, no more |

160 |

165 |

|

Depth of internal equipment b, not less |

80 |

85 |

|

Width of fields g, no more |

15 |

|

|

Visor width in, not more |

60 |

|

|

Vertical safety clearance e |

25 to 50 |

|

|

The annular gap between the helmet body and |

||

|

carrier tape d |

5 to 20 |

Note. When making helmets from 62 to 64 cm in size, the main dimensions must correspond to size II.

1.3. Differentiated indicators of helmets by quality category are shown in table. 2.

table 2

|

Quality indicator name |

Quality index value for helmets |

|

|

first quality category |

the highest quality category |

|

|

Helmet weight (without capes and comforters), t, no more, for size: I |

400 |

390 |

|

II |

430 |

410 |

|

Maximum transmitted force, at |

||

|

rated impact energy 50 J, kN, no more |

5 |

4,0-4,5 |

|

Availability of other types of fastening devices |

||

|

personal protective equipment |

— |

Must have |

|

Material Intensity Ratio |

0,81 |

0,80 |

1.4. Helmets, depending on the operating conditions, have the following types of completeness:

set A - for those working in the premises: helmet;

set B - for those working outdoors in a hot climatic zone: helmet and cap;

set B - for those working outdoors in a temperate climatic zone: helmet, drape and padded comforter;

set G - for those working outdoors in a cold climatic zone: helmet, drape, woolen comforter;

set D - for those working in a special climatic zone: helmet, drape, comforter on wadding, woolen comforter.

Each helmet must be accompanied by instructions for installation and operation, indicating the service life.

An example of a symbol for a helmet set A, size I, white:

A-16

The same, set D, size II, red:

G-Pk