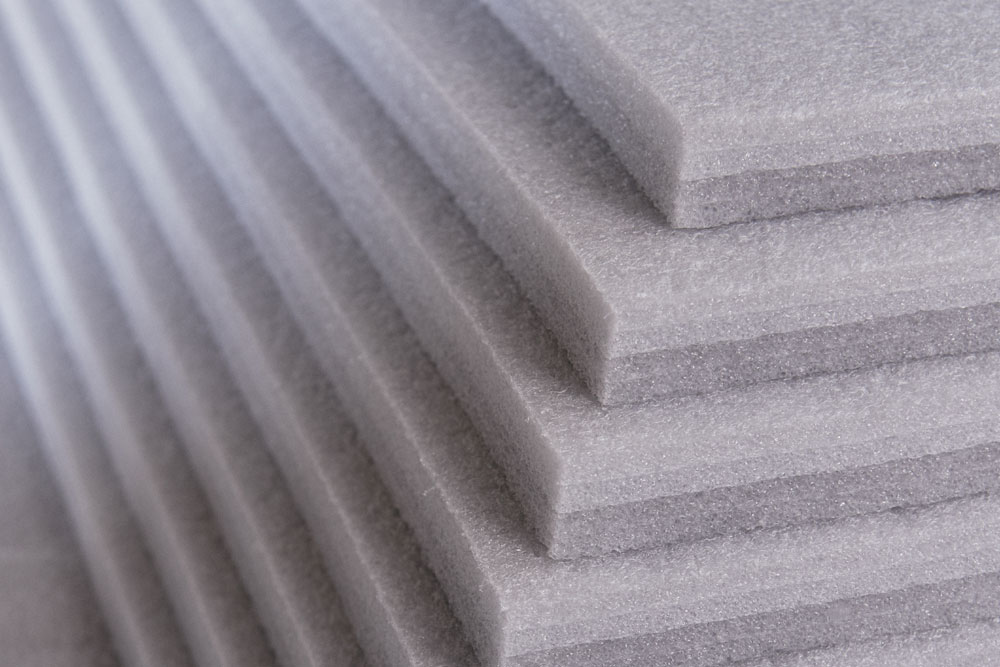

What and how is polyethylene foam sheet made from?

As a raw material for the production of foamed polyethylene, both high, low and medium pressure polyethylene can be used. Dyes, various reagents and additives are also added to the base material.

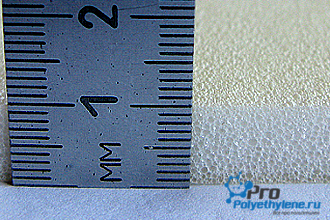

The main method of producing sheet polyethylene foam is extrusion, while at the exit from the die (extrusion head), the polymer almost completely acquires the desired shape (width and thickness).

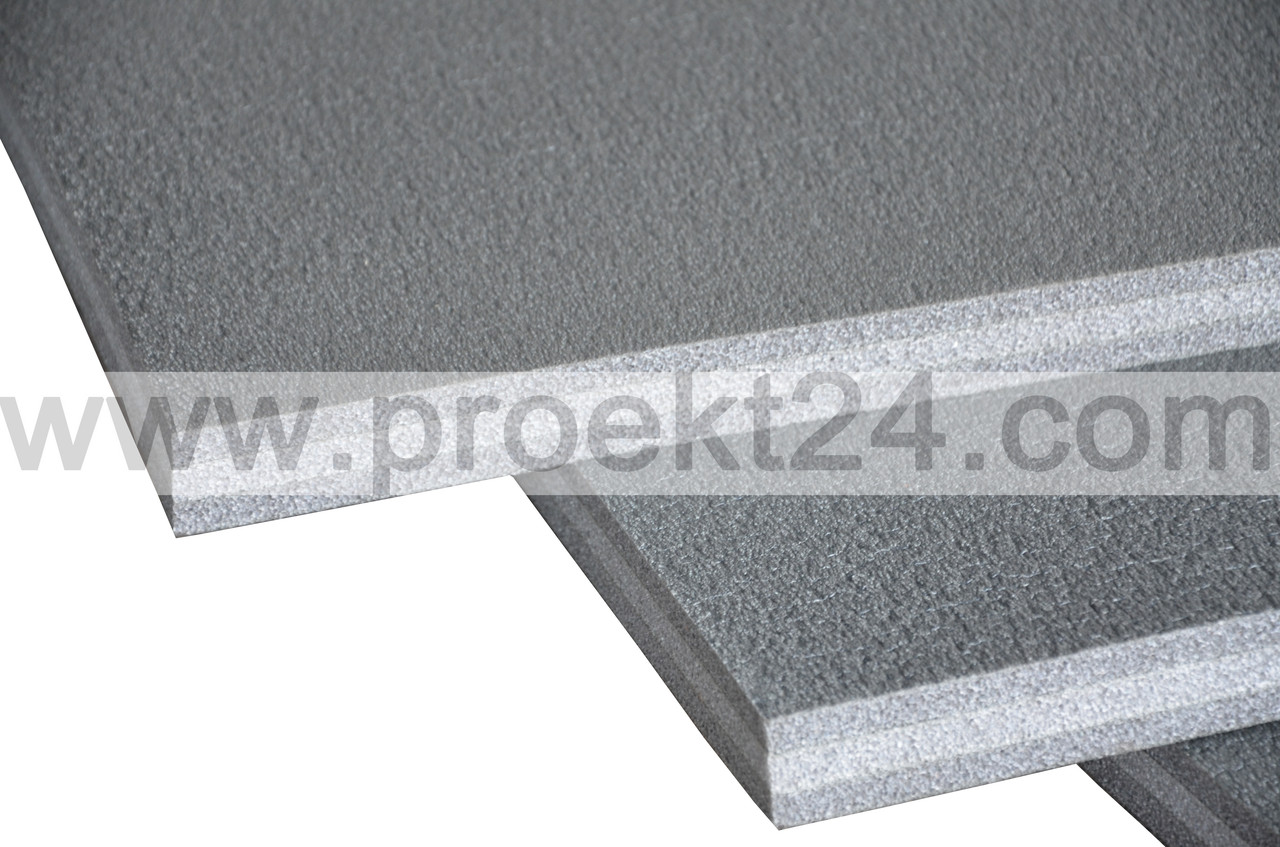

Using various foaming methods, both "crosslinked" and "uncrosslinked" polyethylene foam can be obtained:

- "Crosslinked" is obtained chemically (by adding foaming and crosslinking reagents to the initial polymer) or radiation (by acting on the polymer with an electron beam) methods. As a result, the material acquires a reticulated, cross-linked or spatial molecular structure. Sheets of "cross-linked" expanded polyethylene are characterized by higher operating temperatures (up to 200 ° C) and sufficient strength;

- to obtain "uncrosslinked" foamed polyethylene, isobutane, freon or propane-butane are fed into the chamber of the material cylinder, in which the polymer melts. The structure of molecules after such interaction with gas does not change. However, the foam thus obtained is lighter in weight than its crosslinked counterpart. Its properties are similar to ordinary polyethylene and can also be used at temperatures no higher than 80 ° C.

In order to give the sheets of polyethylene foam any additional properties, a one-sided or two-sided coating is applied to them. For example, with the help of foil, they are endowed with the ability to reflect direct sunlight or heat energy.

It is also possible to apply acrylic glue to the polyethylene foam sheet, which will greatly facilitate its attachment to any surfaces. The final step is cutting the sheets to the desired size.

ABOUT MATERIAL

IZOLON NPE is an environmentally friendly polyethylene foamed according to a special technology with the use of the latest equipment allowing to carry out multi-stage quality control. IZOLON NPE is a sheet elastic closed-cell material with low apparent density based on food-grade high-pressure polyethylene, a blowing agent and technological additives. In addition to the main components, coloring pigments, extinguishing additives, etc. can be included in the composition of isolon of NPE brands. IZOLON NPE-L is produced by heating the sheets of izolon NPE and joining them under pressure. IZOLON NPE is manufactured in the form of a continuous web, wound in a roll or in separate sheets.

|

TECHNICAL CHARACTERISTICS OF ISOLON NPE |

|

|

Apparent density |

26-45 kg / cubic meter |

|

Application temperature |

from -80 ° С to + 80 ° С |

|

Thermal conductivity |

0.040 W / m.K |

|

Specific heat |

1.95 kJ / (kg ° C) |

|

Water absorption by volume |

no more than 0.2% |

|

Vapor permeability |

0.001 mg / (ppm Pa) |

|

Sound absorption |

3% @ 125Hz to 13% @ 4000Hz |

|

Compressive stress (25%) |

Not less than 0.015 MPa |

|

Permanent deformation in compression (25%) |

No more than 20% |

|

Flammability group |

G2 - moderately flammable |

|

Flammability group |

B2 - moderately flammable |

|

Smoke-generating ability group |

D3 - high smoke-generating ability |

|

Combustion products toxicity group |

T3 - highly hazardous |

|

The intensity of the electrostatic field on the surface of the isolon |

15 kV / m |

Produced in accordance with 2244-020-00203476-2004 The quality and complete safety of the ISOLON NPE material is confirmed by all the necessary certificates

|

Fire safety certificate |

|

|

Certificate of Conformity to RF Standards |

|

|

Hygienic certificate, conclusion of the SES of Ukraine |

|

|

Technical certificate of the State Construction Committee of the Russian Federation |

|

|

Type Approval Certificate of the Russian Maritime Register of Shipping |

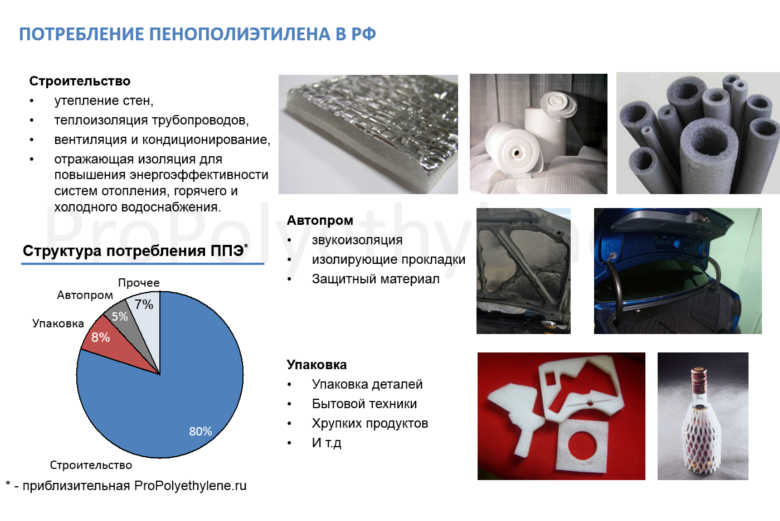

The main brands on the market today

Producers of domestic foamed polyethylene: Tepofol, Vilaterm, Izolon, Energoflex (ROLS ISOMARKET), Thermaflex, Polifom, Penofol, Porileks.

European and American polyethylene foam manufacturers: DOW, Sealed Air, Pactiv, TROCELLEN, EPE Corporation Group, Alveo.

Every year, up to 185 thousand tons of foamed polyethylene foam are produced in the world. This is a lot. Despite the fact that this market is considered relatively young, the pace of production of PES has already outstripped the production of film, the largest segment of LDPE polyethylene. It is expected that the growth in consumption of this heat insulator will continue to grow due to the displacement of more expensive substitutes and the use of polyethylene foam in areas where it has not been previously used - in electrical engineering, camping equipment, etc.

The main advantages of IZOLON NPE

Excellent thermal insulation properties

the material has the lowest thermal conductivity coefficient among insulating materials - 0.040 W / mK with a density of 26 kg / m3. To understand how little heat is carried by IZOLON NPE, you can look at the given comparative table of thermal conductivity of various materials

|

COMPARATIVE INDICATORS OF THERMAL CONDUCTIVITY OF DIFFERENT MATERIALS |

|

|

IZOLON NPE |

0.040 W / (m K) |

|

Steel |

46 W / (m K) |

|

Concrete |

0.84 - 1.3 W / (m K) |

|

Brick |

0.63 - 0.84 W / (m K) |

|

Wood |

0.13 - 0.42 W / (m K) |

|

Air at 20 ° C |

0.024 W / (m K) |

Insulation layer IZOLON NPE of 1 cm replaces 1.4 cm of expanded polystyrene, 16 cm of brickwork, 5 cm of wood!

At the same time, reliable storage of heat energy, as well as cold (the cost of which is much higher), allows you to feel the economic effect of using Izolon already at the very beginning of operation.

Effective protection against moisture and steam

Due to its closed-cell structure, isolon practically does not absorb water and, in addition, is an excellent protection against moisture and water vapor throughout the entire volume of the material. The resistance to diffusion of water vapor is not limited even for an extremely thin outer layer, and does not exceed 0.2%.

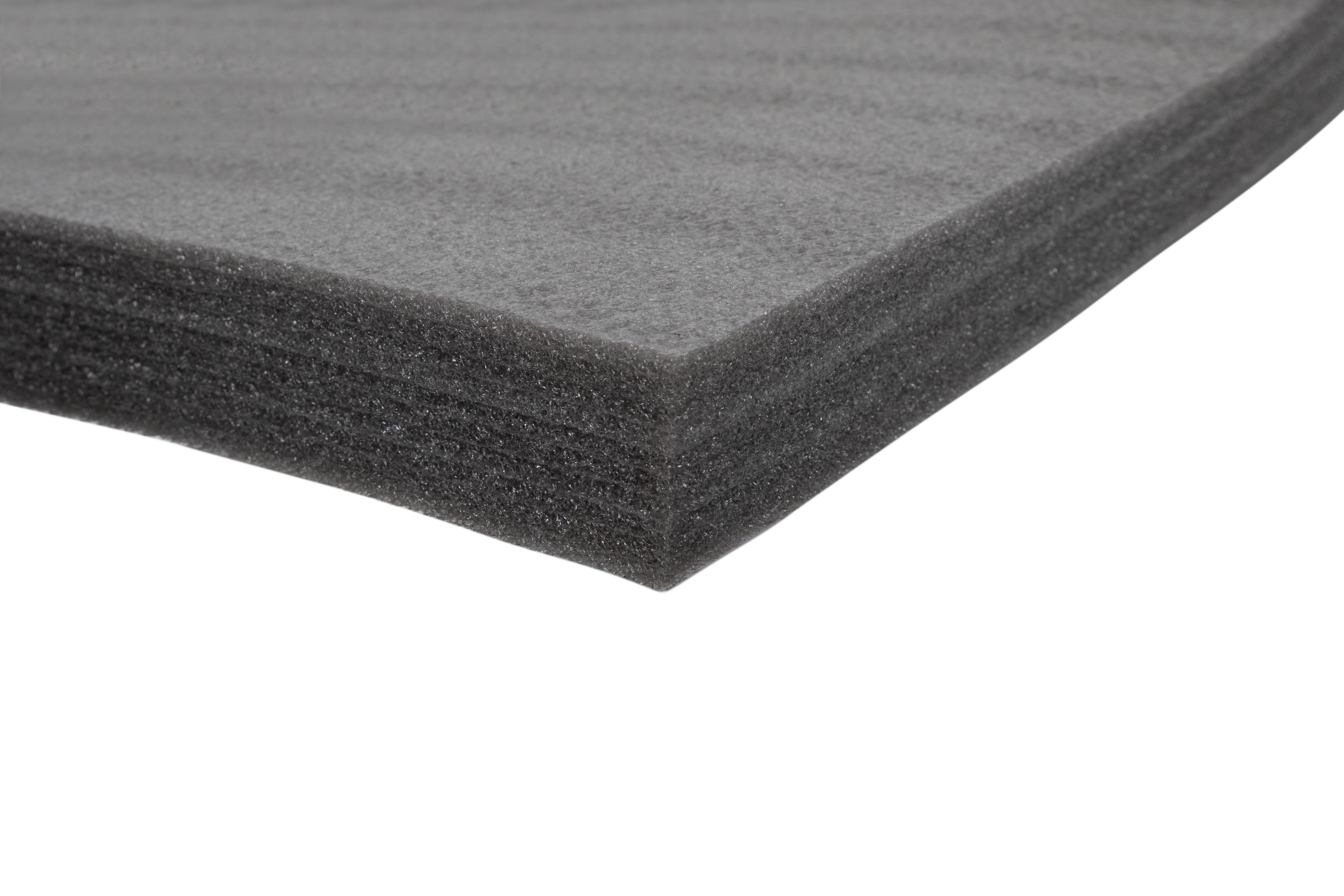

Excellent sound insulation

Sound insulation from knocking and some other noises in combination with low dynamic stiffness and low thickness give IZOLON NPE unique sound insulation properties

Environmental Safety

The material is non-toxic and odorless. In the production of IZOLON NPE, freon is not used, a dangerous gas that destroys the ozone layer in the atmosphere; the material itself is produced on the basis of high-quality food-grade polymer raw materials. Allowed contact with food and human skin.

Chemical stability

Izolon has good oil, oil and petrol resistance, and is also compatible with almost any building materials (for example, concrete, cement, wood, lime, gypsum, etc.)

Durability and retention of performance

The polymers from which IZOLON NPE is produced make the products resistant to decay, in an environment with any microbiological composition, thus, IZOLON NPE does not lose its properties for more than 90 years of operation!

Manufacturability

IZOLON NPE is easy to install. This material, pleasant to the touch, lightweight and elastic, ensures high adaptability to assembly in any conditions. Izolon is easily machined and does not require the use of special devices. Installation requires a knife, stapler, aluminum tape and tape measure.

Appointment

Foamed polyethylene sheet is used for thermal, moisture-proof and noise insulation in various building and instrument-making structures:

- To protect structural elements of buildings - walls, floors, ceilings, etc.,

- In the manufacture of household and industrial refrigeration equipment,

- As a thermal reflective and protective barrier for heating radiators,

- In the form of a backing for wallpaper, warm floors, linoleum and laminate,

- For packaging fragile items with a traumatic surface and expensive devices, as well as cushioning packaging material.

Supplied in standard sizes

|

DESIGNATION |

DESCRIPTION |

STANDARD SIZES |

|

IZOLON NPE |

Foamed polyethylene in rolls |

0.5-1 mm - rolls 1.05 x 200 m 2-10mm - rolls 1.05 x 50 m |

|

IZOLON NPE laminated |

IZOLON NPE laminated with mylar film with a resistant metallized coating (on one or both sides) |

2,3,4,5,8,10 - rolls 1.0 x 25 m rolls 1.2 x 25 m |

|

IZOLON NPE foil |

IZOLON NPE laminated with polished aluminum foil (on one or both sides) |

2,3,4,5,8,10 - rolls 1.0 x 25 m rolls 1.2 x 25 m |

|

IZOLON NPE self-adhesive |

IZOLON NPE with an applied adhesive layer, covered with an anti-adhesive film or paper |

2,3,4,5,8,10 - rolls 1.0 x 25 m rolls 1.2 x 25 m |

|

IZOLON NPE foil-clad self-adhesive |

IZOLON NPE laminated with polished aluminum foil on one side and an adhesive layer on the other |

2,3,4,5,8,10 - rolls 1.0 x 25 m rolls 1.2 x 25 m |

|

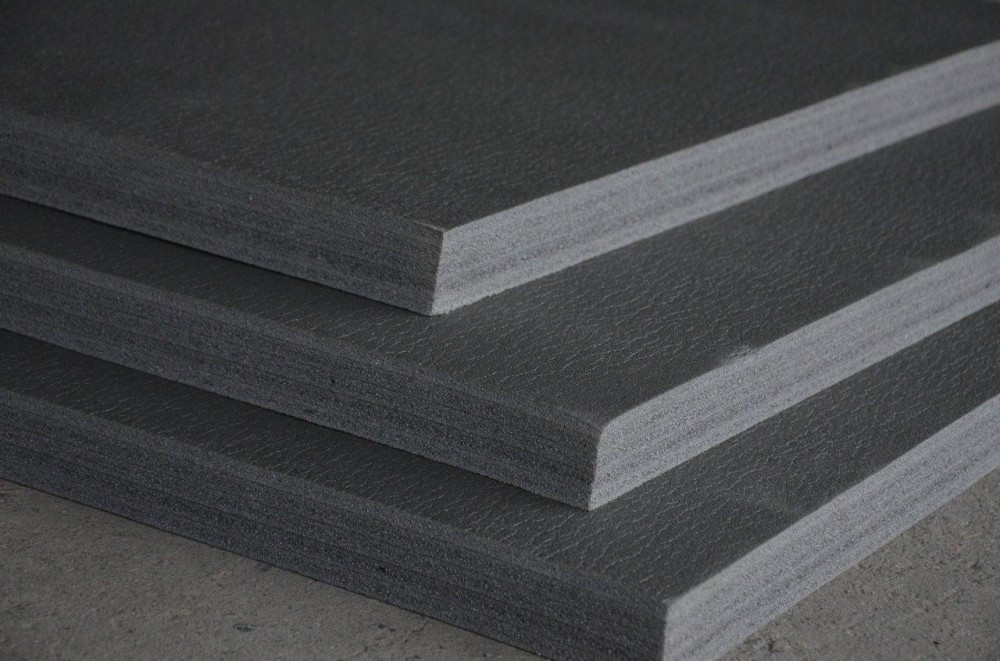

IZOLON NPE-L |

IZOLON NPE duplicated by thermal melting |

20,25,30,35,40,45,50 and more mm. - sheets 1.0 x 2.0 m. |

Specifications

The main properties and characteristics of foamed polyethylene are as follows:

- The density of PPE depends on the method of its production and is: for PPPE and HPPE - from 33 kg / m3 to 300-500 kg / m3. Uncrosslinked PES is much lighter. According to TU, its density should be at least 20 kg / m3, but in fact, material is sold with a density of 12-18 kg / m3.

- Application temperature (from different manufacturers) varies within ± 10 С, but on average, the limits of its operating temperatures range from - 60 С ... + 75С. In the absence of contact with air, FPPE and HPPE can be used for a short time at temperatures up to +150 C (uncrosslinked up to +100 C). If PPE is used at temperatures below -60 C, then the material becomes brittle, and its permanent deformation increases to 35-40%.

- Foamed polyethylene, like all polymers with a closed-cell structure, has a low thermal conductivity coefficient of 0.03-0.38 W / m * K. Insulation made of polyethylene foam is second only to polyurethane foam in terms of its heat-saving characteristics.

- Cross-linked and non-cross-linked PPE have different vapor permeability. For uncrosslinked - this indicator is in the range of 0.003 mg / m * h * Pa, for sewn almost three times less - 0.001 mg / m * h * Pa.

Advantages and disadvantages

On the pros of the material:

- As with all foamed polymers, PPE has a low thermal conductivity coefficient - 0.035 W / (m · deg).

- The material has good shock-absorbing properties. Foamed polyethylene is used to make: packaging (density 25-33 kg / m3), underlay for the floor (density 300 kg / m3), spacers for equipment (300-500 kg / m3).

- Foamed polyethylene has dielectric properties, therefore, self-extinguishing PPE is used to make electrical insulation of high-frequency cables. The dielectric constant of the PES is in the range 1.4 ... 1.5 (water - 81, vacuum - 1).

- PPE is an inert material that does not enter into chemical reactions.

- It is also a lightweight and waterproof material; insects and mice do not eat it. And most importantly, it's inexpensive.

He also has disadvantages:

- Foil-clad PPE will work as thermal insulation only if there is at least 2-3 cm of air gap in front of the foil layer.

- Above 100 C, the material begins to melt and then burn. It can only be used in rooms with a high specific fire load.

Basic properties

The technical characteristics of foamed PE are a synthesis of the properties of polyethylenes, soft elastic materials with a low melting point, and foams with their light weight and low thermal conductivity:

- Like ordinary polyethylene, foamed PE is a combustible material, the maximum operating temperature of which should not exceed + 102 ° C. At higher rates, it will melt.

- At low temperatures, even when lowered to -60 ° C, polyethylene foam will retain all its properties, including strength and elasticity.

- The thermal conductivity of this product is very low, it is 0.038-0.039 W / m * K, which gives products from it a particularly high coefficient of thermal insulation.

- In direct contact with water, foamed PE absorbs it no more than 1-3.5% of its volume per month.

- Foamed polyethylene is very resistant to chemically active media, in particular to oil and petrol products.

- Does not break down in a biologically active environment (does not rot, does not lend itself to the action of bacteria and fungi).

- Perfectly absorbs sounds, so that PPE can be used for noise isolation.

- Absolutely non-toxic, even while burning.

- Easy to transport and install,

- Wear-resistant and durable up to 80 - 100 years of service.

disadvantages

A negative property of foamed PE is its intolerance to ultraviolet rays. Direct exposure to sunlight has a destructive effect on it, therefore, both storage and use of polyethylene foam should take place in a place protected from light. Otherwise, the material itself must contain protection, at least in the form of an opaque film.

Products from polyethylene foam and their area of application

Pipe shells are pipe shells with a well-defined inner diameter. They can be produced with a ready-made technological cut along the entire length (for mounted pipes) or without a cut. Shells for pipes passing in the open air are made in a protective polymer coating. They are used as thermal insulation of engineering systems for hot water supply and air conditioning systems. They are produced with an outer diameter of 6-114 mm, a polyethylene foam thickness of 6-25 mm.

Compensation mats are used as shock-absorbing thermal insulation in the places of turns of hot water pipelines, for heat and sound insulation of walls, partitions, floors. Mats are obtained by gluing foamed polyethylene panels. The process takes place at high temperatures, so the body of the damping mat is an unbreakable structure that is resistant to external damage. Compensation mats made of expanded polyethylene are supplied in sheets, standard size - 1x2 m, thickness from 10 to 100 mm.

Bundles - a cylindrical seal made of foamed polyethylene, products with an outer diameter of Ø 6-120 mm are produced. 1. Bundles Ø 6-12 mm are laid in expansion joints of concrete floors. Ø 12-20 mm seal gaps between the wall and door or window frames. Well, the largest bundles of Ø 20-60 mm in the range fill the joints in the walls of panel houses.

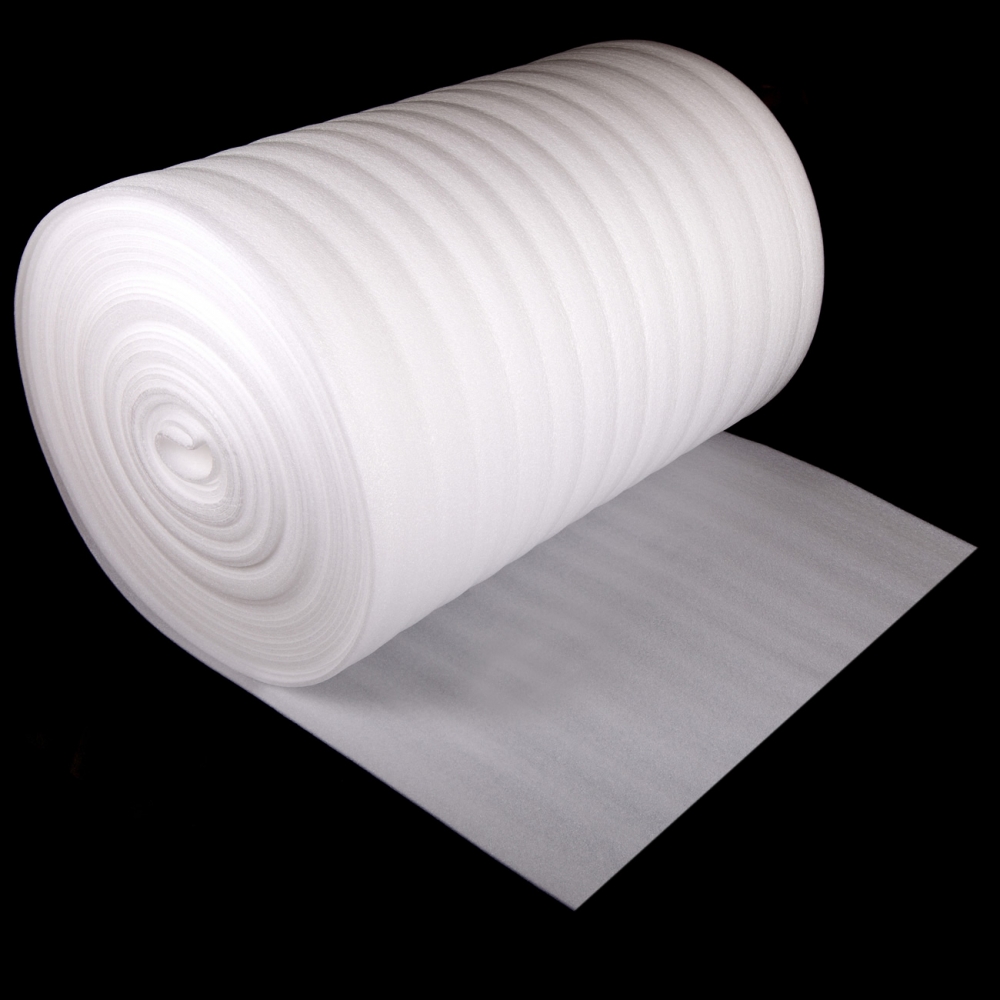

Substrate - made of physically and chemically cross-linked PPE. It is produced in rolls up to 3 meters wide and 2-5 mm thick. A polyethylene foam backing is used as a backing layer between the screed and the laminate.

Packaging polyethylene foam. For packaging, as a rule, uncrosslinked polyethylene foam is used in the form of rolls and bags of various sizes and thicknesses (0.5-20 mm). But there is also a custom-made container - various inserts, protective corners. Foam bags are the most popular type of packaging. They are waterproof, durable, shock absorbent and reduce load vibration during transport. To make the bag more durable and improve its heat-insulating properties, it is covered on top with metallized polypropylene or ordinary film, nylon, kraft paper. Foamed polyethylene packaging material is used for the transportation of electrical equipment, furniture, dishes, shoes.

PACKAGING FOR FURNITURE AND APPLIANCES

- IZOLON NPE-01 and NPE-02 are specially designed for packaging household appliances, furniture and other expensive items subject to careful storage and transportation.They are ideal for preserving the presentation of any product, glass, porcelain, polished surfaces from any materials.

- IZOLON NPE has universal protective properties, protects against impacts and scratches, pollution, including oil products, the destructive effects of low temperatures, any leaks and vapors, direct sunlight, the spread of an unfavorable microbiological environment,

- Due to the complete environmental safety confirmed by the sanitary and epidemiological conclusion, the material can be recommended as packaging for dishes, children's toys, and other products that require increased attention to the safety of materials, including packaging.

- Carefully preserving the presentation of the product, IZOLON NPE itself outwardly favorably differs from most packaging materials, absolutely even and smooth, pleasant to the eye, soft to the touch material with its appearance emphasizes the quality of the packaged product.

Production and features of polyethylene foam

Polyethylene foam is made by processing high-pressure polyethylene (LDPE), to which dyes, refractory reagents and other hydrocarbon compounds are added. For manufacturing, the extrusion method is used, as a result of which foamed polyethylene with a large number of closed pores with air inside is obtained. After that, the material is subjected to heat treatment and foaming at a temperature of 180 °, and, if necessary, further crosslinking of the finished material is carried out.

Polyethylene foam is made by processing high-pressure polyethylene (LDPE), to which dyes, refractory reagents and other hydrocarbon compounds are added. For manufacturing, the extrusion method is used, as a result of which foamed polyethylene with a large number of closed pores with air inside is obtained. After that, the material is subjected to heat treatment and foaming at a temperature of 180 °, and, if necessary, further crosslinking of the finished material is carried out.

Crosslinked polyethylene foam is produced by radiation or chemical means. Polyethylene, reaction catalysts and antioxidants are melted, brought to a thermoplastic state, and then sheets are formed that are stitched together. Uncrosslinked polyethylene foam is formed by foaming conventional polyethylene with a propane-butane mixture or freons.

Material features

Among the main features of polyethylene foam, it is necessary to highlight the following:

- Excellent thermal conductivity, allowing the use of polyethylene foam for thermal insulation. Indicators of thermal conductivity of foamed polyethylene - 0.037 W / m * K

- Reduced hygroscopicity. This property allows the material to be used as a protective barrier against liquids and moisture.

- High quality soundproofing. The physical properties of the material make it possible to use it as sound insulation not only in construction, but also in mechanical engineering.

- The permissible operating temperature range is 240 degrees.

- Strength and wear resistance. The material is not affected by biologically aggressive media, insects and other external factors.

Let's note an interesting fact: 1 cm thick foamed polyethylene easily replaces a 15 cm brickwork or a 5 cm layer of mineral wool.

Application features

The PPE sheet can be completely held in hands and can be easily tried on to the surface it covers. Cutting it is not difficult at all - here you only need a simple pair of scissors. Even an unprepared person can cope with the installation of sheet thermal insulation, subject to several of the following rules:

- Reflective surfaces should always "look" into the room,

- Fastening is done with glue or a construction stapler,

- The joints must be glued with tape, plain or metallized,

- Between the insulation sheet and other surfaces, a gap of at least 2.5-3 mm is required, otherwise the effect of thermal insulation will significantly decrease.

Views

Today, many types of polyethylene foam are manufactured, differing in the following parameters:

Today, many types of polyethylene foam are manufactured, differing in the following parameters:

- The type of base polyethylene:

- High pressure polyethylene (LDPE),

- Made of low-density polyethylene (HDPE), etc.

- Molecular structure:

- Uncrosslinked PE foam, expandable with physical blowing agents.Retains the original molecular structure of polyethylene.

- Stitched chemically or physically. It has a modified structure of molecular bonds, as well as much greater resistance to mechanical and thermal stress, moisture and chemical reagents.

- The structure of the product itself:

- Foamy,

- Pore-like,

- Cellular.

In addition, for ease of use, foamed PE can be produced in different forms: sheet, tile, in the form of a tube, film, etc. and with coatings from various materials (foil, etc.)

Application area

Foamed polyethylene is widely used as an insulating and heat-retaining material, which is explained by the height of the indicators for all its technical characteristics, the variety of forms produced, as well as the comparative cheapness of its production:

- As heat, sound and waterproofing elements of various building structures (foundations, floors, walls and roofs, ventilation systems),

- As an insulating material in automotive and instrument making (for car interiors, ship cabins, soundproofing of military equipment),

- For sealing door elements, insulating glass units, laminate underlays and in combination with other insulating products,

- As a shaping and insulating material in the production of sports equipment, backpacks and protective helmets,

- As a transport packaging for shoes, various equipment, household appliances and much more.