Composition and characteristics

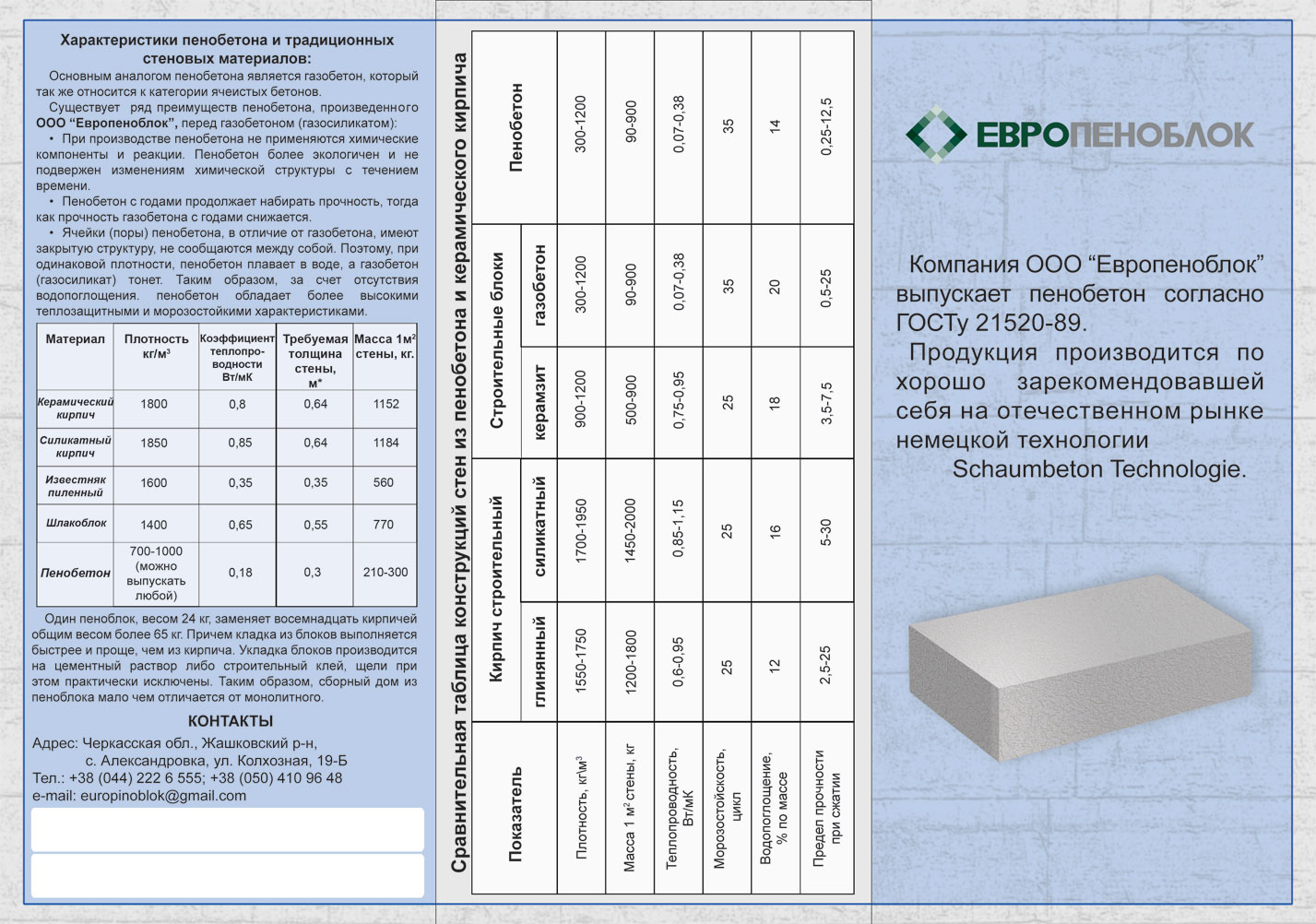

For the first time, the material appeared on the Russian markets in large volumes just a few years ago, although in Europe construction from it has been going on for several decades. Foam concrete belongs to light aerated concrete, it is made by mixing cement mortar and foam. The formation of foam occurs in a foam generator from a synthetic or protein (protein) foam concentrate. It is thanks to the foam that the material has a cellular structure.

Obtaining occurs using two main methods: the classical method and barotechnology. They are also called autoclave and non-autoclave methods. The only difference is in the method of producing the foam. Also, the first one requires a special chamber in which the foam concrete paste hardens at the optimum temperature. Finished products are of higher quality, stronger and less fragile.

In the second case, hardening occurs both in the chamber and in natural conditions. Products are prone to cracking, shrinkage and poor quality. Also, one should not forget about the significant loss of time for its hardening.

Dimensions, weight and density

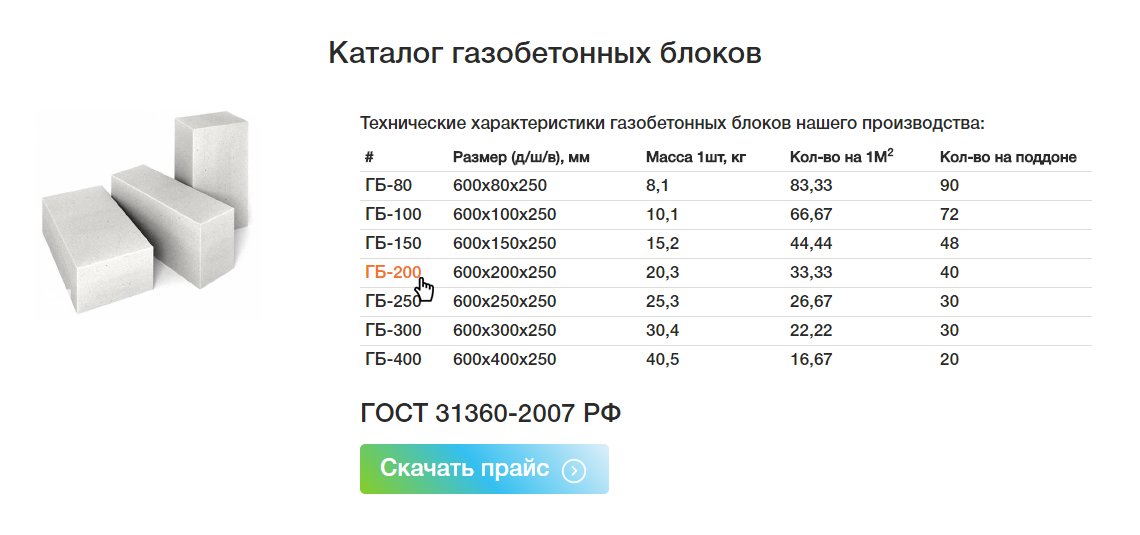

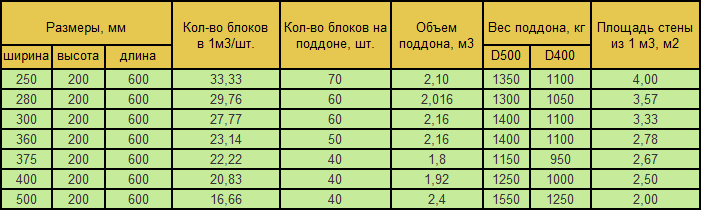

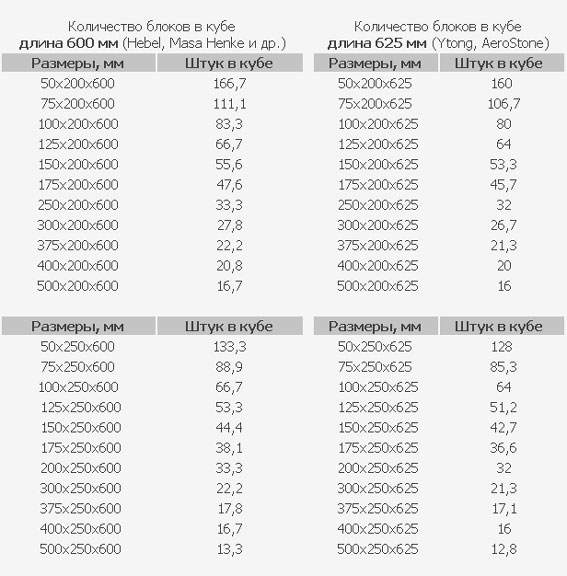

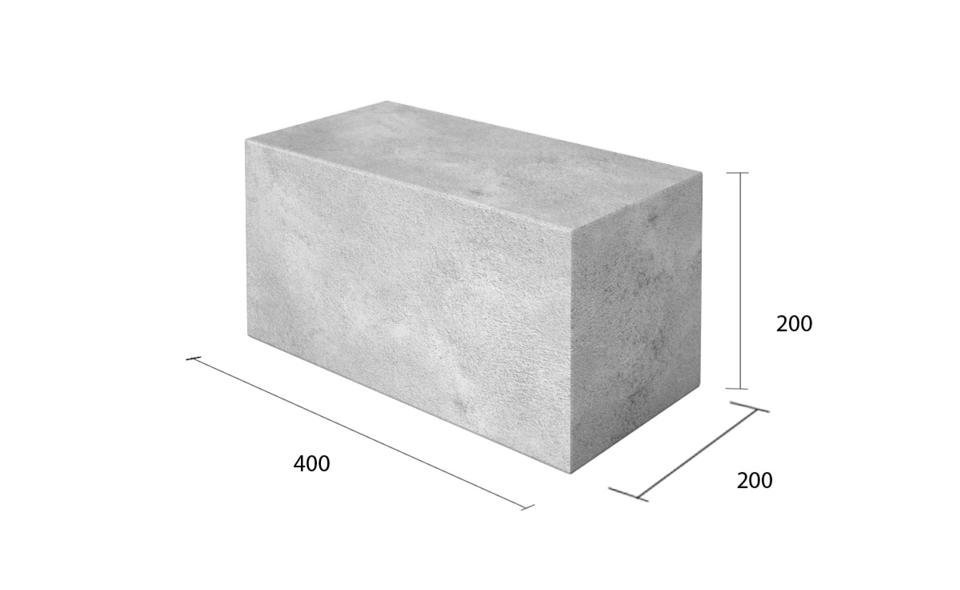

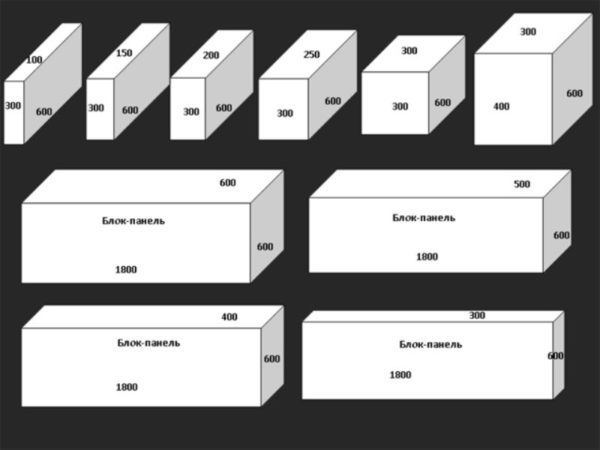

Foam concrete can have several areas of application, based on this, it can have various sizes. The finished mixture is poured into special molds. The dimensions of these forms depend on the purpose of the product. These are mainly low-rise industrial and residential construction. The dimensions of the blocks are either 0.2 x 0.2 x 0.4 m (width x height x length) or 0.2 x 0.3 x 0.6 m, for which the average price is 15–20 rubles per piece. The density and size of the blocks have a significant influence on the price. The higher the density or the larger the dimensions, the higher the price for foam concrete.

To obtain monolithic foam concrete, automated cutting equipment is used. They cut hard material into large slabs, their standards range from 3000x1600x1800mm to 4500x1500x1800mm. These slabs are used for the construction of walls, foundations and floors. Also, using cutting, you can get the following dimensions of blocks and shapes for them:

- The size of the array (monoblock) - 1219x1026x600 mm;

- Form for receiving an array - 1219x1026x600 mm (for the main standard size);

- Typical block dimensions: 198x295x598 mm (96x295x598).

Also, the mixture can be poured directly on the construction site into the formwork, the dimensions of which depend on the technical requirements of the building.

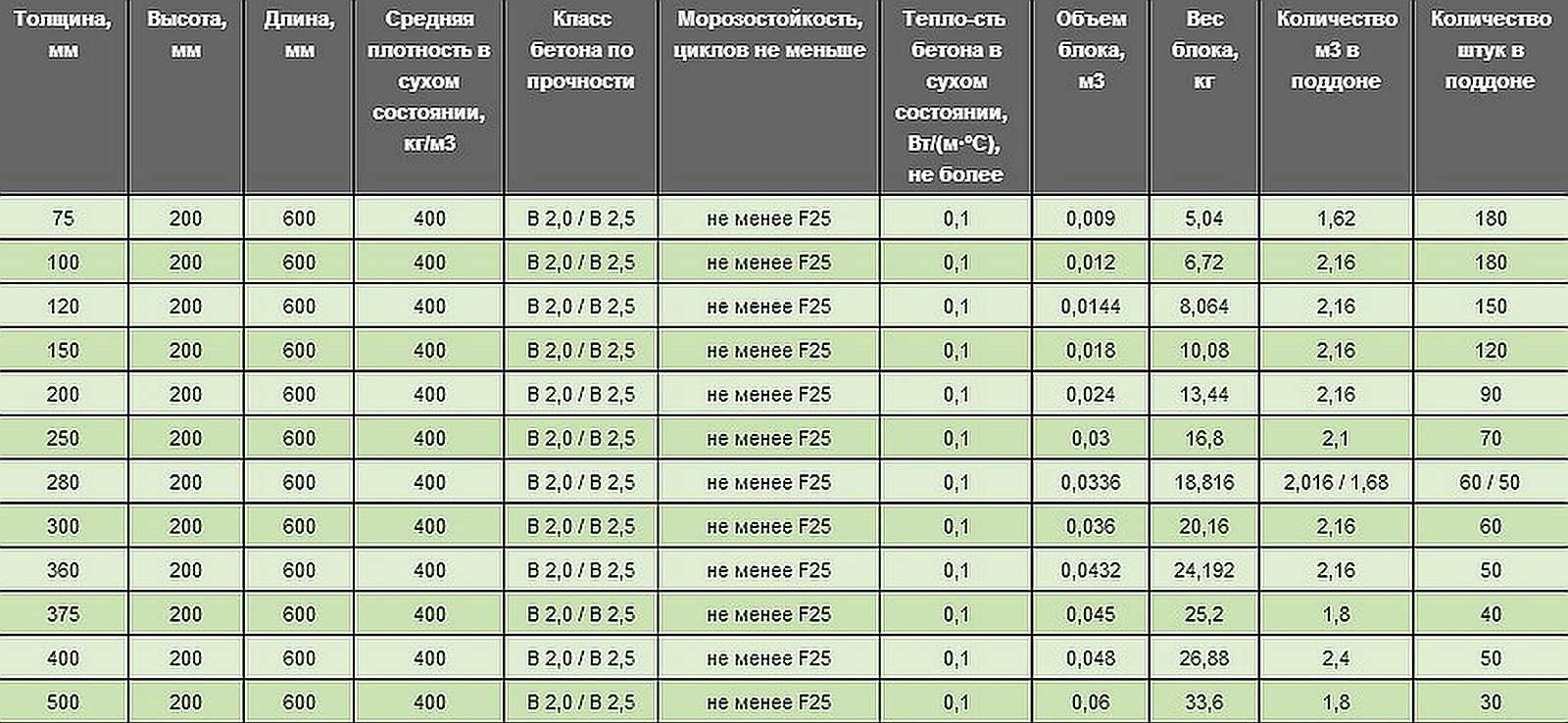

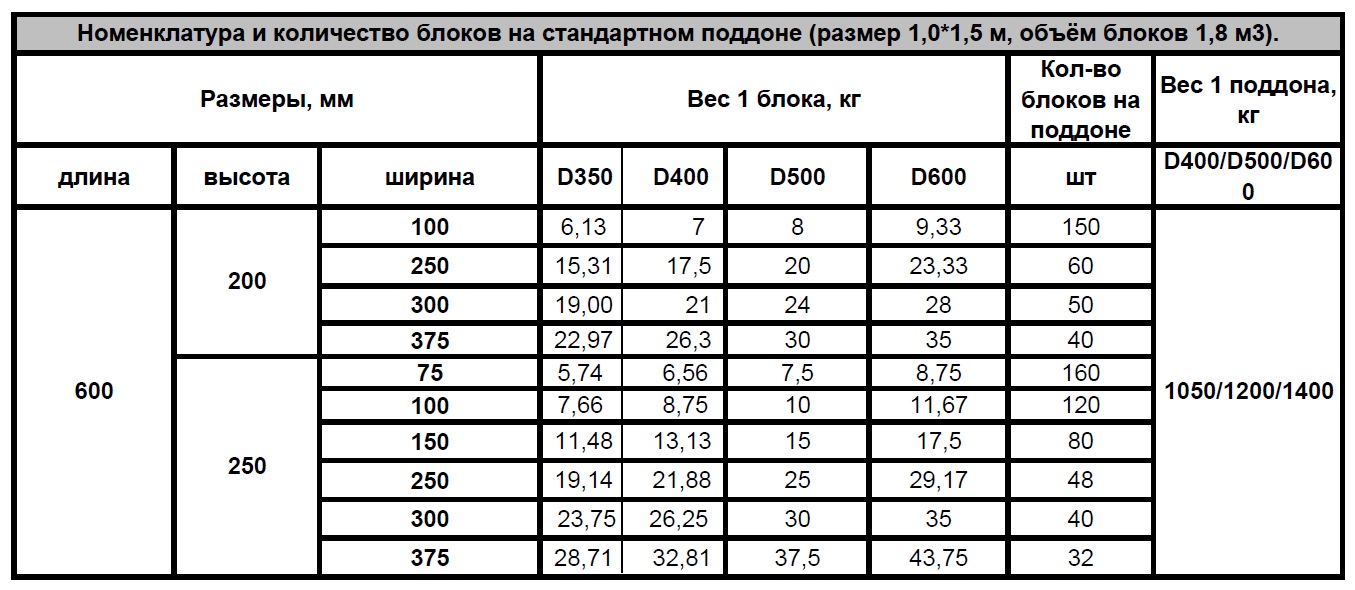

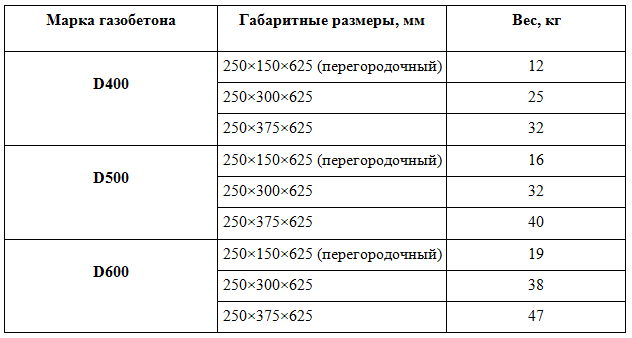

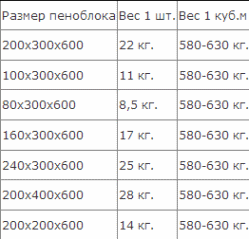

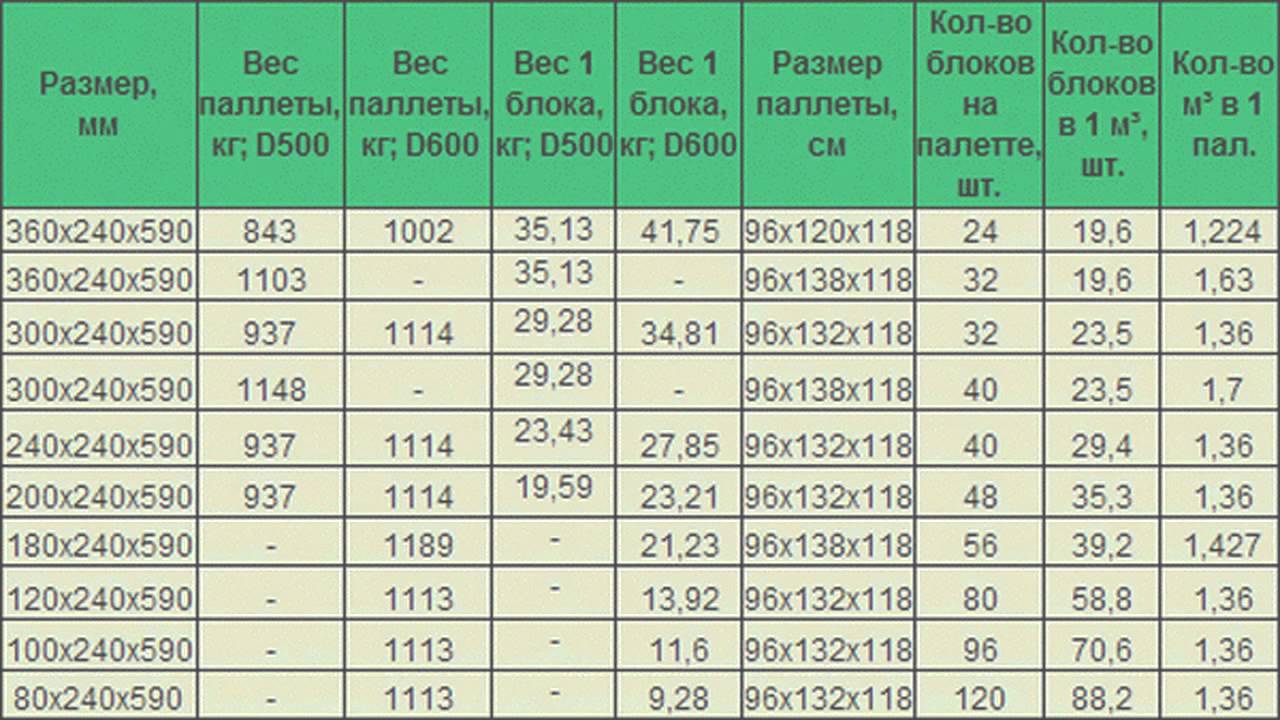

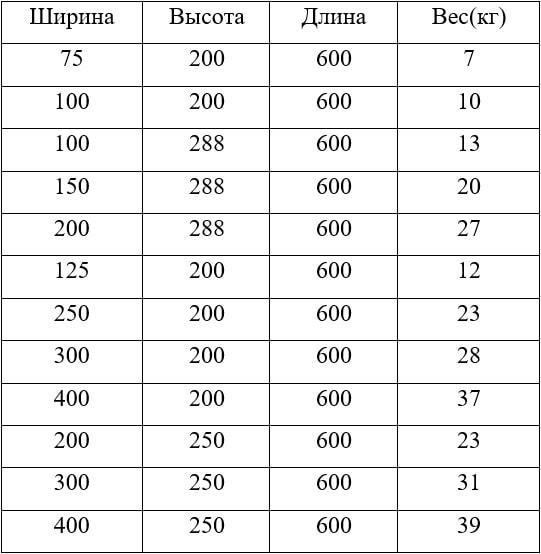

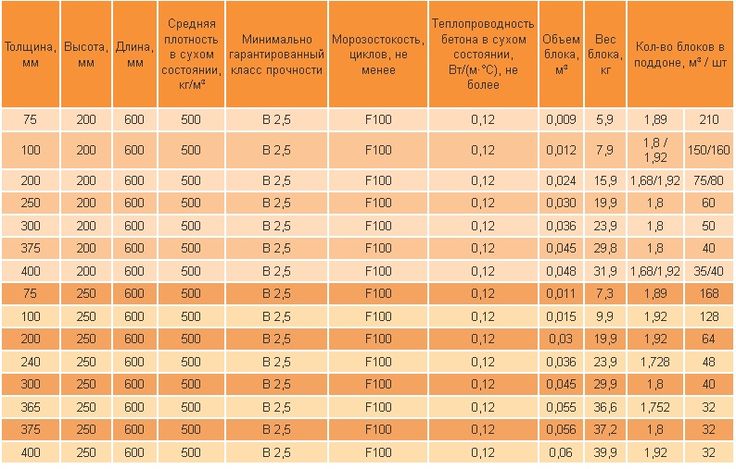

The nominal weight of aerated concrete depends on the size and density of the material. The data on the ratio are presented in the table.

|

Size, mm |

Weight of 1 piece, kg |

Volume weight of 1 cubic meter, kg |

|

200x300x600 |

22 |

580-630 |

|

100x300x600 |

11 |

580-630 |

|

80x300x600 |

8,5 |

580-630 |

|

160x300x600 |

17 |

580-630 |

|

240x300x600 |

25 |

580-630 |

|

200x400x600 |

28 |

580-630 |

|

200x200x600 |

14 |

580-630 |

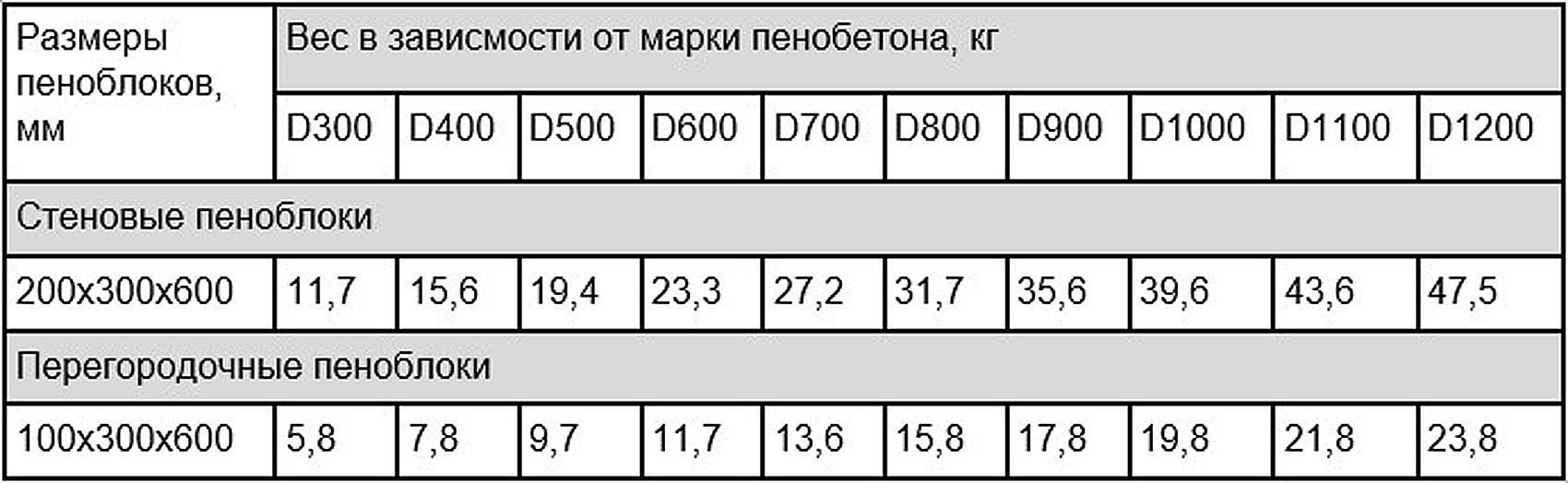

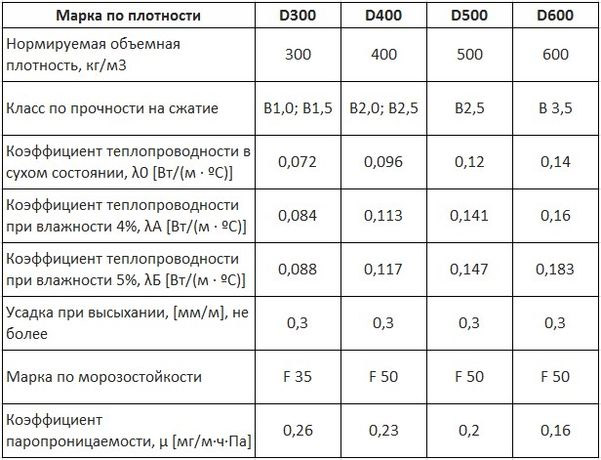

The specific gravity (density) of foam concrete ranges from 300 kg / m3 to 1200 kg / m3. This indicator is reflected in the species categories: heat-insulating, constructional and constructional-heat-insulating.

|

View |

Density grade, kg / m3 |

Strength, kg / m2 |

|

heat insulating |

400 |

9 |

|

500 |

13 |

|

|

Structural and heat-insulating |

600 |

16 |

|

700 |

24 |

|

|

800 |

27 |

|

|

Structural |

900 |

35 |

|

1000 |

50 |

|

|

1100 |

64 |

|

|

1200 |

90 |

The table shows that the density of the product directly affects its strength. The higher the strength of the foam concrete, the lower its heat-conducting qualities. The thermal insulation capacity is several times higher than that of bricks.

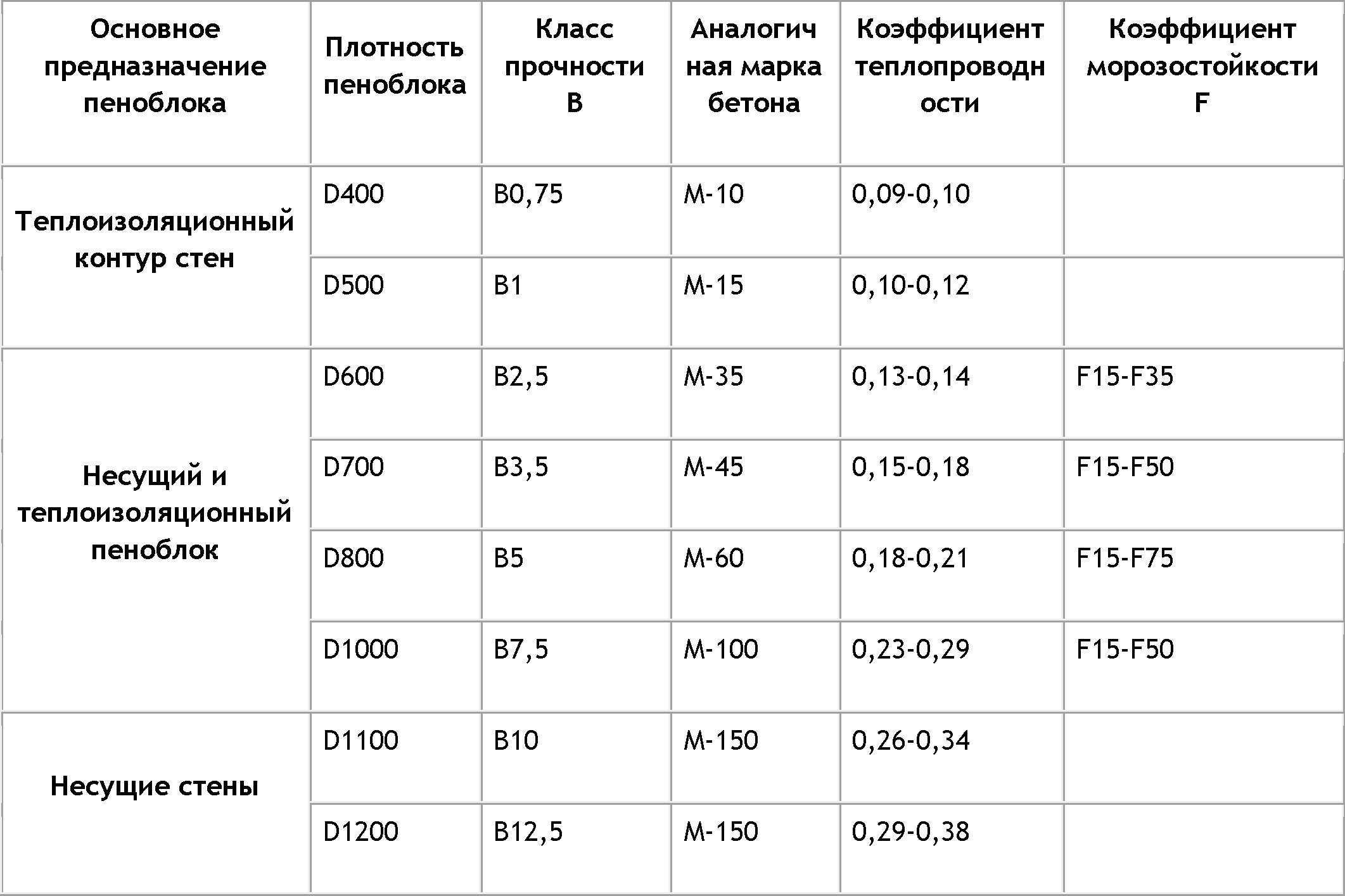

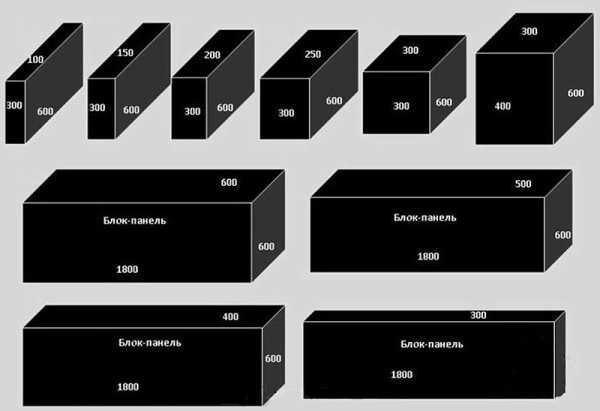

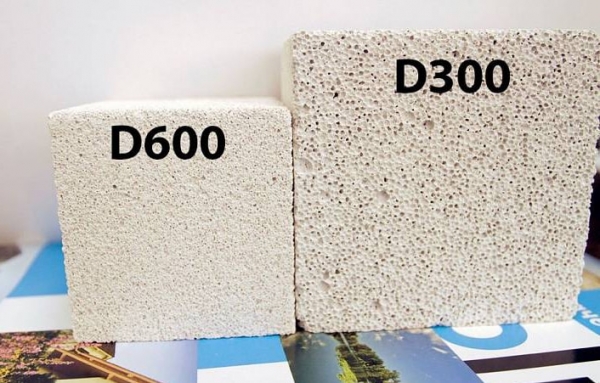

Density

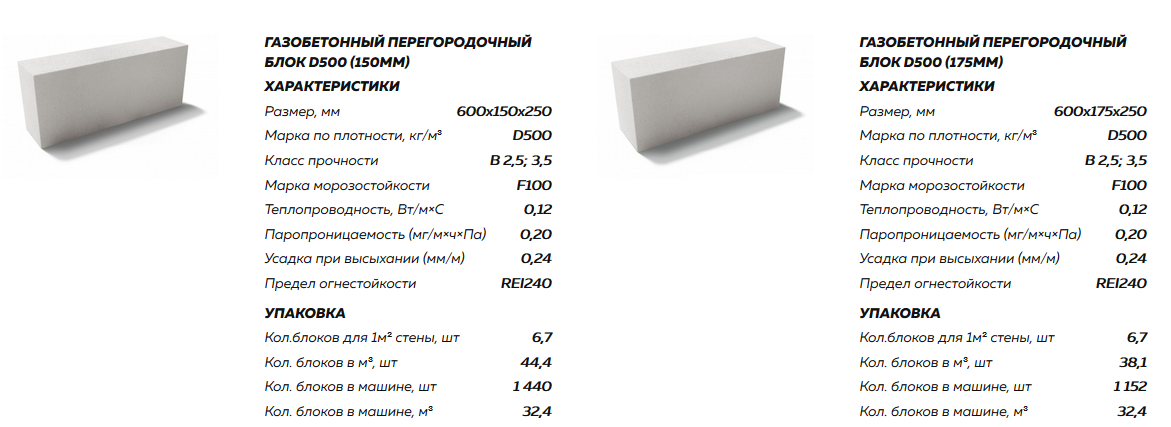

This indicator is proportional to the grade of concrete. Each type of building element is used to lay structures with different loads. In order not to be mistaken when choosing a brand, you should familiarize yourself with their purpose. Aerated concrete D600 is characterized by high strength.

Monoliths are erected from D500 blocks, D 400 - for arranging insulation during the installation of openings. Products made of D350 aerated concrete, which has a high porosity and loose structure, are mainly used for heat insulation.

The material absorbs moisture, so a moisture-insulating soil ball is applied to the walls. The technology for manufacturing blocks provides for mixing the ingredients, which, when interacting, form a porous structure. High density building elements carry more weight.

How much aerated concrete in a cube can be determined by the density of the block. This indicator is designated D, and the numbers after the letter marking indicate the density value. A low index value corresponds to the presence of a large number of air pores, which increase heat conductivity.

The strength index of the D400 gas block is 45% higher than that of the D300, but the thermal conductivity is 30% lower. The price of D400, 200, 300, 600 cm building products in Moscow and other regions is lower than for similar products of higher density.

Pros and cons of the material

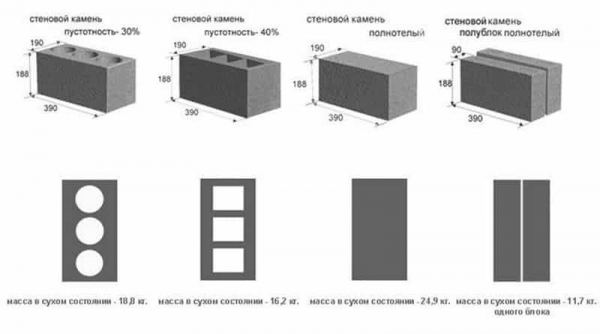

The appearance of cinder blocks is directly related to the natural human desire for waste-free production. In the postwar years, production in the USSR developed at a rapid pace. Metallurgical plants are literally overgrown with mountains of slag. Then the decision came to use this waste to create building materials.

Slag served as a filler for a cement-sand mixture. The resulting mass was molded into large "bricks". The finished blocks were too heavy - they weighed 25-28 kg. To reduce weight, voids were made in them. Hollow specimens were slightly lighter - from 18 to 23 kg with standard dimensions.

The name cinder blocks is still used today, although not only slag, but also other components are used as fillers. In modern blocks, one can find granite screenings or crushed stone, river gravel, broken glass or expanded clay, volcanic mass. Small business is most often engaged in the release of cinder blocks. Small private enterprises produce building blocks on vibrating machines, filling several forms with a cement mixture at once. After molding and tamping, the "bricks" gain strength for at least a month.

Cinder blocks are endowed with certain advantages and disadvantages.

- The advantage of block building material, first of all, is its low cost. That is why the material is in great demand.

- This building material also has other positive characteristics. For example, blocks do not change their size after laying out. The structure will not shrink, which means that the design calculation will not be adjusted during the construction process.

- The strength and hardness of the "big brick" determine its service life. This is no less than 100 years! Durability is not calculated, but time-tested. There are many buildings of the middle of the last century that "stand firmly on their feet." The houses did not lurch or crumble, only the facades require cosmetic repairs.

- Blocks react poorly to ultraviolet light and temperature extremes. The material is not edible for rodents and insects.

- Due to the increased size, construction is proceeding at a rapid pace. Much less masonry mix is used for laying blocks than, for example, for a brick wall of similar dimensions.

- Street noises are not audible behind the cinder block wall, because it is capable of absorbing sounds.

- Finally, if you have simple equipment and desire, the blocks can be made at home, which will further reduce the cost of construction.

The disadvantages of a building material are no less than advantages.

These include the following characteristics.

- Nondescript appearance.

- Problematic of fastening to walls due to voids in the body of the block.

- The need for cladding to make the structure attractive and protect the building material from the effects of external moisture.

- Fragility. If dropped during work, during transportation or loading, the unit may break.

- High thermal conductivity. Without additional insulation, the structure retains heat poorly.

- Wide tolerance limits. Dimensions may differ significantly from the nominal value.

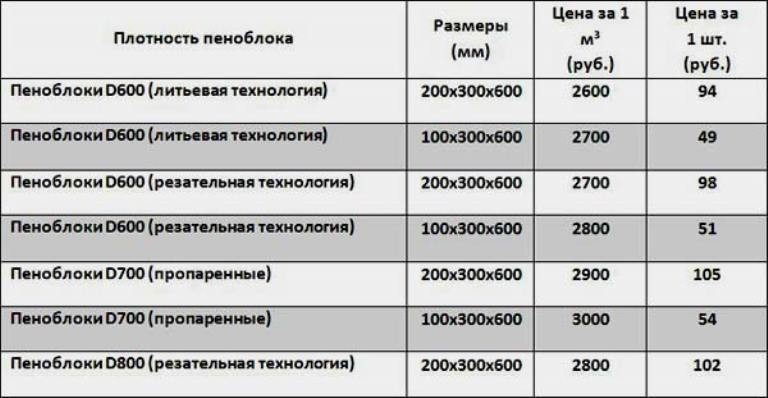

Prices for foam blocks

The cost of foam blocks in Moscow and the regions is different. Pricing is influenced by the quality of the material, its properties, and the dimensions of the products.Structural blocks are more expensive. Their price reaches 4500 rubles. for 1 m³. Structural and thermal insulation material costs in the range of 3200-3800 rubles. for 1 m³. The price of thermal insulation products is much lower. The upper limit of the cost range is 3000 rubles. for 1 m³.

The higher the quality of the blocks, the stronger the difference in price is felt compared to the simpler material. In addition, the price is too low.

Such material can quickly sell out at an affordable price, since it did not gain strength or low-quality cement was used in the production. There is a risk of purchasing such products at a high cost, so you need to ask about the availability of accompanying documentation.

How to make a plan

If it is necessary to calculate the burden of 1 m3 of a foam block, its volume and density must be taken into account. There are standard low-end values adopted for blocks of a certain density and size.

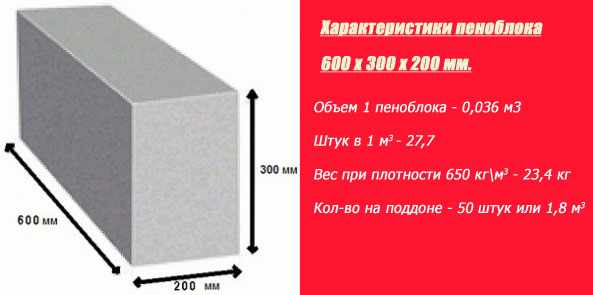

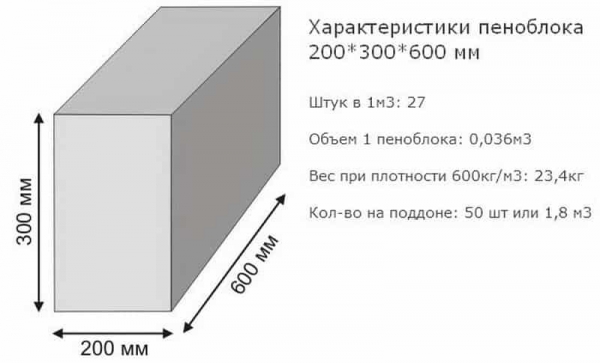

Flat weight of foam blocks measuring 600x300x200 millimeters of popular brands:

D500 - near the porosity of 0%, the weight is 23.4 kilograms, if (soon) the porosity is 20%, then 18.75 kilograms, 50% - 11.7 kilograms.

D600 - near 0% porosity, the weight is 27.72 kilograms, the presence of 20% is 22.18, if the porosity is 50%, because the weight is 13.86 kilograms.

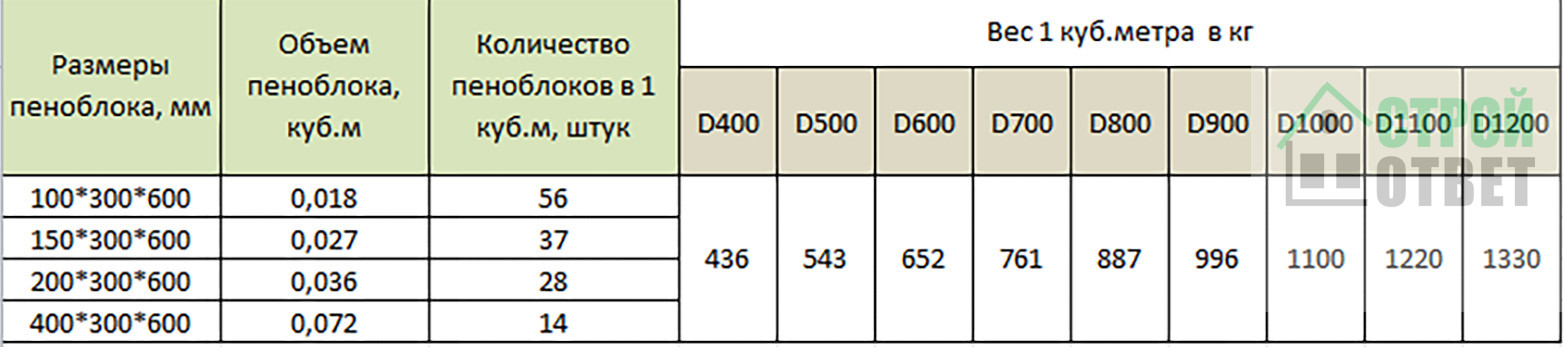

The separate weight according to the standards is determined up to the brand: a cubic meter of D400 material weighs about 436 kilograms, D600 - from 450 to 900 kilograms, D1000, on average, take a cubic meter should mean about 1100 kilograms. These figures are relevant, provided that all established standards are strictly adhered to.

The importance and density of foam concrete are determined by its composition and proportions of sand, cement, water, foaming agent

The titrometric weight of a cubic meter of foam concrete in kilograms can be calculated by density: add volume to density. And in this case, for curiosity, they do not take the humidity indicator, this or that is very important. Indeed, in accordance with the extent to which a certain volume of water is absorbed, a lot of something increases weight, sometimes take a significant indicator. The volume of the block is calculated, multiplying the height and width, take the length.

So, for example, it is unequal to find out the weight of a D600 density block with a size of 600x200x300 millimeters, because the total volume of the structure is 0.036 cubic meters (the value in meters is multiplied 0.6x0.2x0.3). The mark says that a cubic meter of a foam block weighs 600 kilograms. Thus, the significance of one block will be: 0.036 x 600 = 21.6 kilograms.

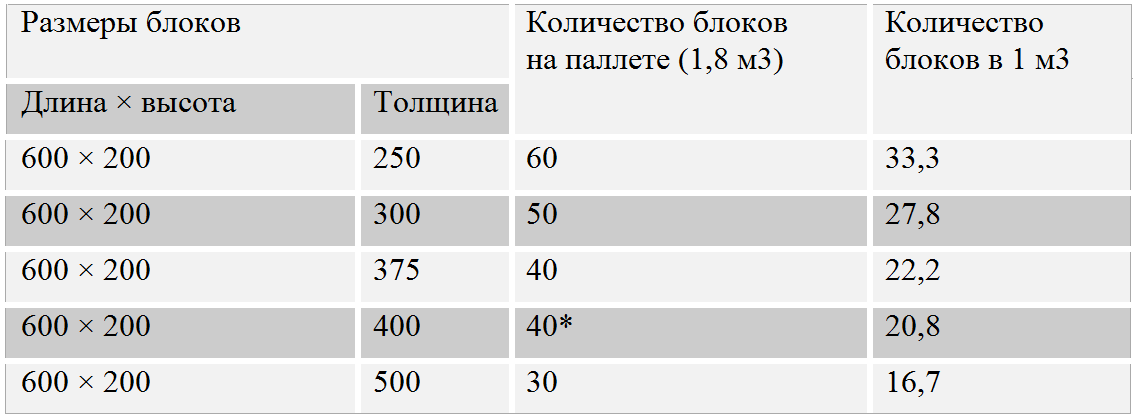

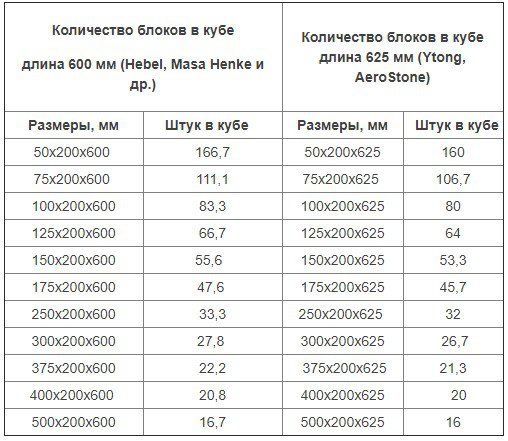

For a cubic meter of volume, there should be 27.8 pieces. foam block measuring 600x200x300 millimeters. As soon as you use blocks 100x300x600, the same volume will only hold more than 55 pieces. Having the subtext of the weight of 1 piece of products, it is allowed to calculate the total weight of one pallet / pallet.

But all these calculations do not take into account the sorption moisture content of the material. Yako, according to GOST 25485-89, the tessitura of the sorption moisture content of foam concrete can show off equal to 8-15% when it is produced on the basis of sand and in addition, the beloved can take up to 22%; ash can be used as a filler

If we take it as a fact how much sorption moisture is at a minimum (8%), because the weight of a product with dimensions of 600x200x300 needs to be increased by another 1.728 kilograms. Thus, the total cloud of the foam block will be equal to the minimum value of 23.328 kilograms. If the sorption humidity is maximum, then the mass of the block will be 26.352 kilograms.

With the intention of avoiding the need to independently make all the calculations, when buying a block, you need to detail all the characteristics from the manufacturer, how much must be confirmed by the appropriate certificates and other documents.

Due to the fact that the foam blocks have a lower density and crowd in comparison with traditional materials, and in turn, due to a decrease in the volume of the solution on the masonry, the total weight of the pressure on the base of the building is significantly reduced

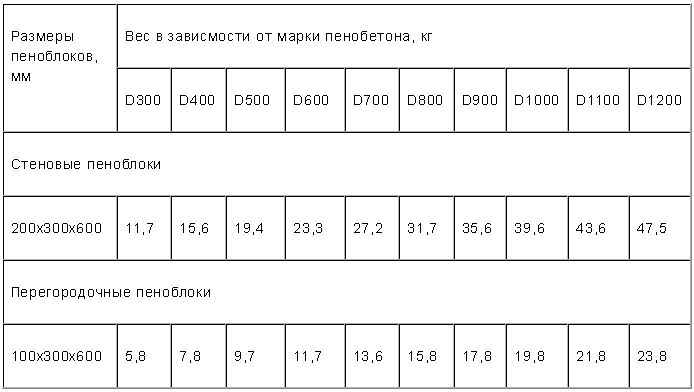

This is important both for a partition wall, for no one knows why, and for a wall block.It is of great importance to influence the characteristics of the field of application of foam blocks: structural grades D600-900 have a value of 23-36 kilograms, insulating D300-500 - 12-19 kilograms

The densest and heaviest blocks measuring 600x300x200 millimeters can play the role of 40-47 kilograms. The average weight of the partition block is 21 kilograms. GOST prohibits the publication of blocks longer than 600 centimeters. For the sake of thermal insulation, wall blocks weigh 11.6-19.5 kilograms, partition wall blocks with dimensions of 100x300x600 millimeters weigh at least only (5.8-9.7 kilograms).

Until now, it is worth mentioning the importance of the correction from above water

It is especially important to look at the value for grades D1000-1200: the weight of the blocks, thin as a chip, is 47 kilograms, although when saturated with moisture, the basics can weigh up to 50 kilograms. For that one block, this is a little bit, but when taking into account a large number of elements in transportation and calculating the load in the foundation, the values are significant

It is important to have the skills to calculate and know how much a foam block weighs, both at the stage of implementation of calculations in the project, for no reason and in the process of building a building. Exclusively taking into account all indicators and preserving the technology will allow you to get a reliable, strong and durable composition

How to correctly calculate the weight of the foam block

When designing a building and structure, it is very important to understand that the foam block is not only convenient and practical, but also very heavy, and is also subject to moisture to a certain extent, which makes the total weight of the building even larger. Calculation of the correct total weight and weight of one foam block under conditions of a certain percentage of humidity in this case is important

Based on the data obtained, not only the foundation of the house will be designed, but also the foundation laid under it. If the weight of the future house is calculated without taking into account weather conditions, the foundation may not withstand and sag, crack, and begin to collapse.

For each type of foam blocks, there are special calculation tables in which the size, density and weight of the foam block are indicated sequentially under normal, ideal conditions and when exposed to moisture. So, the weight of the foam block 600x300x200 varies depending on the density from 11.7 kg to 47.5 kg. These are the basic values, taking into account the total air humidity of 75%. By themselves, foam blocks can weigh from 10.8 to 43.2 kg. This is their mass when loaded and dispatched to the customer.

If the weight of the foam block is unknown, it can be taken into account by simple calculations. So, first we need to get the block volume. It can be obtained by multiplying three quantities: height, width and volume. This volume is then multiplied by the known density (D600, D300, etc.). The resulting number of kilograms is the weight of one "brick".

Now, in order to get its exact weight, taking into account the sorption moisture (moisture content of the foam block), you should find out what the foam concrete is based on.

It is calculated from the product of the "dry" mass of the block and the minimum percentage of moisture. The last step will be the summation of the masses of moisture and the block, which will show the most accurate weight of a given foam block in moisture conditions.

When choosing a suitable material for building a house, the final cost of the materials required for the construction of the building plays an important role. Calculate foam blocks at home calculator presented on ...

So you've decided that you will build your new home from modern materials. Foam concrete blocks have pros and cons in the same way as other materials….

"Aerated concrete" is a common name, which allows you not to break your tongue by pronouncing a long name, but since there are a lot of materials, and in order to avoid deception on the part of sellers, you should know the correct one ...

When planning the construction of houses, extensions to the house, utility blocks and other structures made of foam blocks, it becomes necessary to find out how much does the foam block weigh?

If there are no special measuring instruments, then you can find out the weight of the foam block in the following way.

It is important to know and understand that the weight of the foam block depends primarily on the density, and the density of the foam block, in turn, changes and depends on the amount of cement, the volume of sand and the amount of added water, per cubic meter of foam concrete

Density and mass of foam blocks

Foam concrete can have different densities. It is designated by the Latin letter D, after which there are numbers from 300 to 1200 in increments of 100 units. The higher the density, the greater the mass and strength, but the lower the thermal insulation characteristics. Therefore, according to the area of use, foam blocks are divided into three categories:

-

from D300 to D500 - foam concrete heat-insulating blocks. They are used as insulation (for example, when insulating a balcony or loggia), they are not able to withstand any significant load.

- from D600 to D900 - structural and thermal insulation blocks. They are also often called construction. They can withstand some load, while they have good heat retention properties. These are the ones that are usually used in the construction of private one-two-story houses. The best choices are the D600 and D700. The wall thickness when using blocks of this density is only 35-45 cm (for central Russia), and without the need for additional insulation.

- D1000 to D1200 - building blocks. They are capable of carrying significant loads, but the thermal conductivity is low. Additional insulation is required. Little is used in private construction.

The density of foam blocks affects its mass. In fact, the brand displays the mass of one cubic meter of material. For example, a cubic meter of D400 foam blocks will weigh about 400 kg, a cube of D700 density blocks will weigh about 700 kg.

How much a cube of foam blocks weighs depends on the density of the material

Why "about", because the manufacturing process allows for some error. A little more mass is considered normal - in the range of 10-15%. But at the same time it is necessary to look so that there are no foreign inclusions. Some manufacturers mix in broken brick or crushed stone to reduce costs. Because of this, the mass becomes a little larger, which is generally uncritical. But these additives greatly reduce thermal conductivity, which is not good at all. And this is no longer foam concrete, but incomprehensible building blocks with unknown characteristics and it is not clear how they will behave during operation. So when buying, be sure to be interested in the mass, and if possible, break up a couple and see what is inside.

Advantages and disadvantages

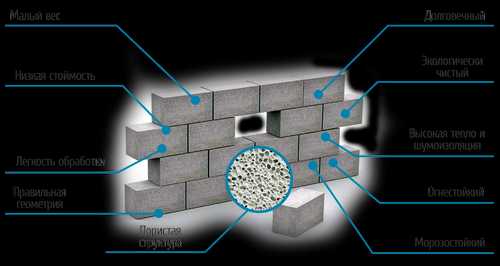

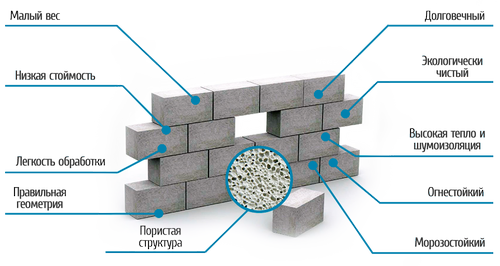

There are 5 main advantages of foam concrete:

There are 5 main advantages of foam concrete:

- Lightness of the material;

- Compressive strength;

- Frost resistance;

- Fire resistance;

- Biostability and environmental safety.

The listed properties are among the advantages, but foam concrete has its pros and cons:

pros

# 1. Reliability

The guaranteed service life of low density foam concrete is 25 years and more. It is ageless and almost timeless material. Low volumetric weight significantly increases the thermal resistance of the wall. Buildings made of it are not susceptible to rotting and the formation of mold and mildew.

No. 2. Heat

Due to its low thermal conductivity, foam concrete structures are able to accumulate heat well; average heating costs can be reduced by 20-30%.

No. 3. Microclimate

It is cool in summer in such a house, and warm enough in winter. It is not afraid of dampness, the microclimate is similar to a wooden house.

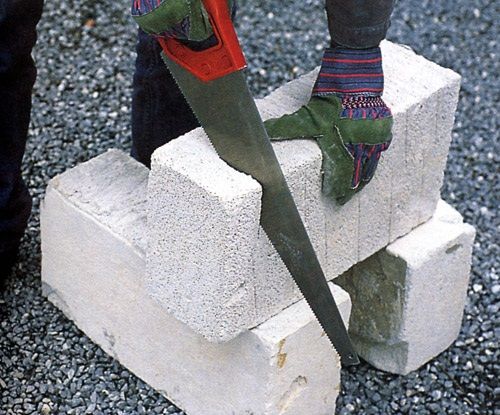

No. 4. Fast installation

Lightness and large dimensions allow to increase the laying speed several times. It is cut and sawn, it is easy to hammer nails and screw in self-tapping screws into it, so the process of additional finishing work is facilitated.

No. 5. Soundproofing

The material has an excellent ability to absorb sounds, it will reliably protect the house from external street noise.

No. 6. Environmental friendliness of foam concrete

It is in second place after wood in terms of its environmental qualities. During operation, it does not emit toxic substances and does not affect the human body.

No. 7. the beauty

The ability to manufacture and create various forms of the premises themselves and their attributes (corners, arches, pyramids).This is an additional beauty and architectural expressiveness of the structures being built.

No. 8. Profitability

Smooth surfaces of foam concrete buildings do not require extra costs for leveling inside and out with plaster. Savings on floors and foundations also help reduce construction costs.

No. 9. Fire safety

Buildings made of foam concrete are able to withstand high temperatures and are fireproof. According to the tests carried out, it has the first degree of fire resistance.

No. 10. Transportation

The ideal ratio of weight and volume, convenient packaging (pallets or pallets) make the material easy to transport. Deliveries are carried out both by road and rail.

No. 11. Width of application

Erection of the foundation, laying of walls, all floors, lintels, partitions, pouring floors indicate the scale of the areas of application of concrete products. The low thermal conductivity of foam concrete additionally influences the choice in its favor as a building material.

Minuses

The main disadvantages include fragility, tendency to form cracks, slight shrinkage of foam concrete. But numerous reviews show that:

- firstly, as one of the types of concrete, it acts as a monolithic material, has strength, is durable, resistant to adverse environmental influences and fire resistant;

- secondly, it has the properties of mineral insulation: low thermal conductivity, excellent sound insulation, light weight and ease of installation;

- thirdly, it is similar to wood, it “breathes”, is environmentally friendly and can be processed by any means.

Therefore, all the listed disadvantages of cellular foam concrete practically do not affect its popularity among other building materials; it can also replace them in construction.

Also, foam concrete, with poor-quality production, reduces its technical characteristics, and, as a result, the erected structure loses its bearing capacity and is not able to withstand heavy loads. Based on this, all parameters of the building material, its strength, quality, method of production and compliance with all instructions and requirements in the process of manufacturing, transportation and operation should be carefully considered.

Price

Blocks can be bought both in cubes and by the piece. Depending on the density (D400, D500, D600, and so on up to D1200), the price per cube starts from 2,500 rubles and grows in proportion to the increase in the value of D. Thus, the price for D1200 is about 5,000 rubles. If we consider the option of purchasing one by one, then you can count on a range from 90 to 200 rubles per block. The indicated prices are shown excluding delivery and pallets, and pallets have a security deposit.

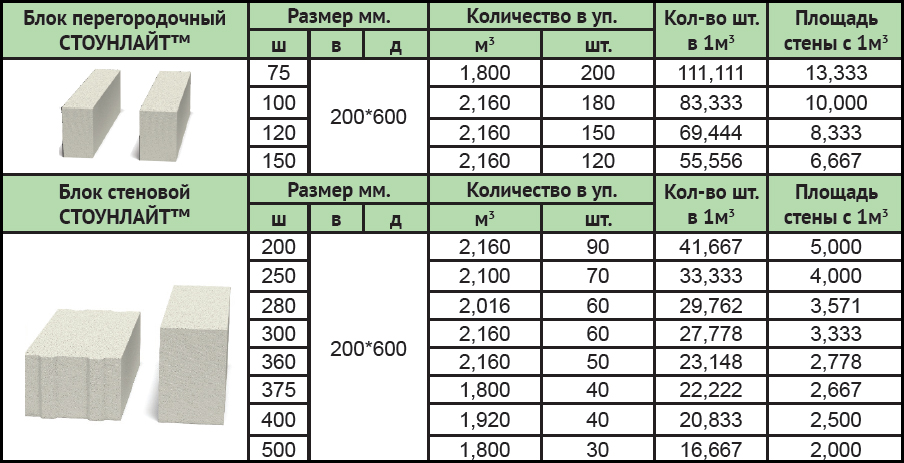

Partition material

These structures do not experience a serious load, they do not impose high requirements on heat resistance, so the dimensions of the foam block can be reduced to 10 x 30 x 60 cm. For what reason are blocks with smaller parameters not used? In this case, the strength of the partitions will be low. It is not recommended to reduce the width in this case, because it is quite difficult to remove a flat partition from a material whose thickness is from 5 cm to 8 cm. And blocks with a thickness of 50 mm (80 mm) may not withstand the weight of the room decor.

> An internal partition thicker than 10 cm will not be economical. A foam block of 100 mm will reduce the interior space of the room, but it will be quite rigid.

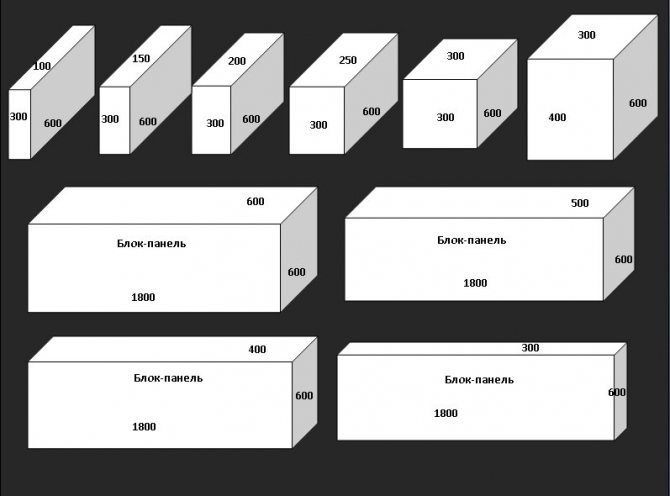

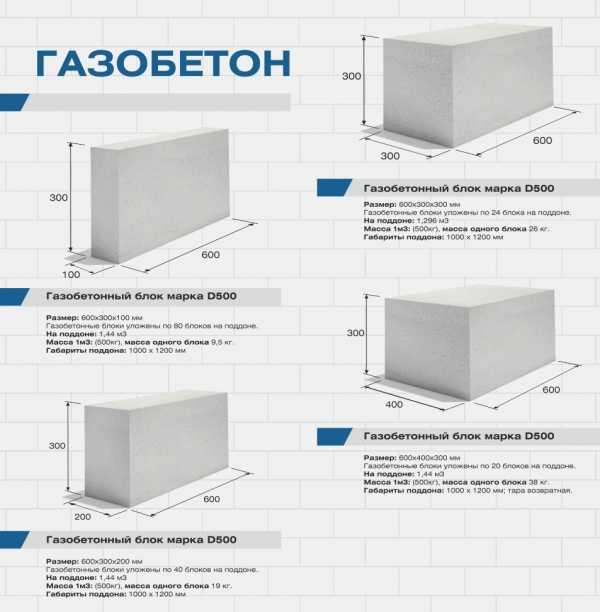

Foam block dimensions

The production of aerated concrete blocks is regulated by GOST 215 20-89. It defines the characteristics and standard dimensions, but there is also a postscript stating that it is allowed to change the parameters at the request of the consumer.

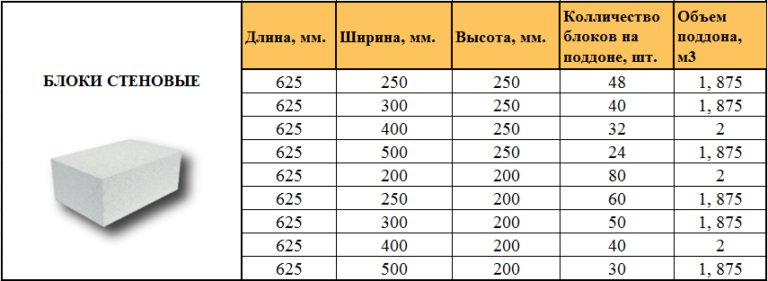

By appointment, foam blocks are wall and partition. Walls are used when laying load-bearing walls. They usually have a size of 600 * 300 * 200mm. Some firms produce blocks with a length of 625 mm. The rest of the parameters remain the same. In that case, the size of the most popular foam block looks like this 625 * 300 * 200 mm.

The dimensions of the foam block can be not only standard

In any case, for a wall 30 cm wide, it is enough to lay one block. Moreover, if you use the D600 or D700 brands, it is quite possible to work alone. One block weighs not so much - from 21 kg to 26 kg (21 kg - less dense, 26 kg - more).

| Foam block dimensions | D 300 | D 400 | D 500 | D 600 | D 700 | D 800 |

|---|---|---|---|---|---|---|

| 600 * 300 * 200mm | 10.8-11.3 kg | 14.0-14.8 kg | 18.0-19.0 kg | 21.5-22.4 kg | 25.0-26.4 kg | 28.6-29.8 kg |

| 600 * 300 * 250mm | 13.5-14.9 kg | 18.0-19.9 kg | 22.5-24.5 kg | 27.0-28.4 kg | 31.5-34.6 kg | 36.0-39.6 kg |

| 600 * 300 * 300mm | 16.2-17.4 kg | 21.6-23.7 kg | 27.0-29.7 kg | 32.4-35.6 kg | 37.8-41.6 kg | 43.2-47.5 kg |

| 600 * 300 * 400mm | 21.6-23.7 kg | 28.8-31.7 kg | 36.0-39.6 kg | 43.2-47.5 kg | 50.4-55.4 kg | 57.6-63.4 kg |

There are wall blocks of different formats. Here are the main dimensions of the foam block, which is used for laying load-bearing walls and partitions:

- 600 * 300 * 200 mm - the most popular size of foam blocks;

- 600 * 300 * 250mm;

- 600 * 300 * 300mm;

- 600 * 300 * 400 mm.

With a density of D600 or D700, it is quite possible to work alone with foam blocks 200 mm, 250 mm wide. Their weight is 20-35 kg. You can do it alone. Even larger ones, 300 mm wide, and even more so 400 mm - this is already a job for two. It is even possible to use a lifting mechanism.

There are large-format block panels. You can work with them only with the use of lifting equipment - at least a winch. But construction is progressing very quickly. The dimensions of the large format foam block are as follows:

- 1000 * 600 * 600mm;

- 1000 * 600 * 500mm;

- 1000 * 600 * 400mm;

- 1000 * 600 * 300 mm.

That is, blocks 300 mm and 400 mm wide when erecting a building in central Russia are stacked in one row. Since their height is 60 cm, there will also be few rows.

The dimensions of the foam block are selected depending on the type of building and wall

There are also small-format blocks. They are usually used for insulation, in some cases for the construction of walls - if a partition is needed of a small thickness, or it is decided to build from small-sized foam concrete blocks. The dimensions of the foam block of small thickness are as follows:

- 600 * 300 * 100mm;

- 600 * 300 * 150 mm.

It is easy to work with them, since they are light and lightweight, especially if they are used as thermal insulation. The density of the foam concrete is then 300 or 400 units, so that the weight of one foam block does not exceed 10 kg.

Classification by use (strength)

Depending on how much the foam block weighs and, accordingly, what density it has, there are various areas of application:

-

Structural - used for the construction of load-bearing structures of a house: walls, basements, light foundations of low-rise buildings. These include products with the brand d1000, 1100, 1200. The strength of such foam blocks is 50, 64 and 90 kg / cm2, respectively. The overwhelming majority of such products have standard dimensions of 600x300x200. Thermal conductivity coefficient 0.29 - 0.38 W / m ° С

- Structural and thermal insulation - used for the construction of load-bearing and enclosing walls and internal partitions. Foam blocks of this type are designated d600, 700, 800, 900, have a strength of 16, 24, 27, 35 kg / cm2, respectively. The thermal conductivity of such a foam block is in the range from 0.15 to 0.29 W / m · ° C.

- Heat-insulating - it is allowed to use it for the construction of an external heat-insulating contour of the walls of the house. Such blocks can only support their own weight with a relatively low load. Depending on the brand (d300, 350, 400, 500), they have strength from 7.5 to 13 kg / cm2. The thermal conductivity coefficient varies in the range of 0.09 - 0.12 W / m · ° С.

What is more profitable: aerated concrete block or foam block

The foam block does not allow air to pass through, since it consists of closed cells. To insulate such a structure, it is permissible to use different types of plates, including polystyrene, which is characterized by the worst properties in comparison with analogues. Gas blocks allow air to pass through, therefore, in this case, it is better to use insulation, which is similar in properties - refers to breathable materials.

If we compare 2 types of blocks in terms of strength, then aerated concrete products surpass the foam block analogue by 3-4 times. In addition, plastering compounds lay on the surface of such a material smoother, which simplifies the work on cladding.

However, gas blocks should not be used for the construction of facilities on an area where there is a high risk of constant contact with moisture: a high level of groundwater occurrence, high air humidity, frequent rains. Such material quickly absorbs liquids.

It is noted that both types of blocks differ in pore size. So, the gas block has the advantage - the cells in the structure of the material are the same.This ensures an even distribution of air in the thickness of the masonry, the thermal conductivity remains unchanged in different parts of the structure.

Another difference is the type of supplements. Aerated concrete is an environmentally friendly material. For comparison, foam concrete is sometimes produced from toxic components (synthetic foaming additives).

Scope of the foam block

As already mentioned, the foam block is used in construction. Depending on the types, it can both form the main part of the load-bearing wall, and act as or be both at the same time.

Much depends on the quality characteristics. More dense blocks are most often used for the construction of large structures, where not only high strength of the walls is required, but also the reliability of the entire structure. Due to their weight, the blocks can both give it massiveness and make it relatively light.

For the construction of private houses, cottages and small outbuildings, blocks with a lower density are used. Depending on the climate of the area, both lightweight options and denser and more massive blocks can be used.

Their additional advantage over them is that one standard block completely replaces about 13-15 standard bricks. Thus, the time spent on the construction of the wall is significantly reduced.

Light weight

The lightest building material for today is a foam block. This quality of the material is of great importance in insulation and construction. The relatively quiet thermal conductivity allows the walls to be thinner than in construction with other materials.

For example, if you compare a foam block with a brick, cinder block, then for 1m2 of a brick wall you will need 190pcs. With the weight of each product in 5 kg, the mass of the wall is 950 kg. For the device of the same wall of the foam block, 21 kg of the foam block will be required. The weight of the wall will be 600kg.

How to determine the weight of a concrete product?

If you need to determine the mass of the foam block, but there is no equipment for measuring nearby, then you can use certain actions. The mass of a concrete product depends directly on the density value. It turns out that we find out the density of the material - we calculate its mass. If you do not take into account the moisture content of foam concrete, then the density of this product will be equal to the mass of its cubic meter. The density of a concrete product depends on its composition: cement, water, sand. All these ingredients are in 1m3 of the foam block. Consider product labeling. For example, in a foam block product marked D300, it is precisely indicated to us that 1m3 weighs 300kg, D500 - 500kg.

To calculate the weight of concrete, you need to multiply its density by its volume. Let's calculate, for example, the weight of a product marked 600x250x100. To begin with, we calculate the volume of one product, for this we translate the dimensions into meters and multiply our values 0.6x 0.25x 0.1. We get the result - 0.015m³. We determine the weight by multiplying 0.015 * 400. The mass of our material is about 6 kg. Such a calculation will be correct if the material is dry, it should be borne in mind that the product can, having absorbed moisture, increase up to 20%. For example, if a D600 brand dry block weighs 22kg, then when wet, the value will increase to 25kg. If we calculate according to this principle the most standard version with marking 600x300x200, then we will get the mass of one block - 22 kg, 600x250x50-4 kg, 600x250x75- 7 kg, 600x400x300 - 28 kg.

This calculation is useful in the case when the product is non-standard. The weight of the standard size models has already been calculated by the manufacturer. For example:

- D400 - the mass of the material is 15 kilograms;

- D700 - weight 27 kilograms;

- D1200 - weight 47 kilograms.

You can determine the mass of the product in another way, simply taking into account the mass of a cubic meter of material and the number of foam blocks included in it. Sometimes it is still easier to ask the seller or manufacturer about the mass of the purchased material, because the production is different, the mass may not coincide, even if everything has been correctly substantiated theoretically.

Different manufacturers have a different mass of blocks, despite the same dimensions.

If we consider the characteristic in terms of density, then the blocks are heat-insulating and structural. Depending on the grade of the material, the weight of the product will also change.

For example, if you find out the characteristics of a foam block with the D300 brand, then in the wall version, the mass of one block of size 600x300x200 will approach 11kg, of a partition wall with a size of 100x300x600 - 5kg.

Technical characteristics allowed foam concrete to take a leading position among other materials in construction. The foam block construction of the wall allows you to make the temperature in any room comfortable. A house made of a modern concrete product retains heat in winter, and in summer it works as an air conditioner, not letting heat into the room.